Académique Documents

Professionnel Documents

Culture Documents

Table 1-1. Availability of Shapes, Plates, and Bars According To ASTM Structural Steel Specifications

Transféré par

Awi YakumoshiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Table 1-1. Availability of Shapes, Plates, and Bars According To ASTM Structural Steel Specifications

Transféré par

Awi YakumoshiDroits d'auteur :

Formats disponibles

1 - 15

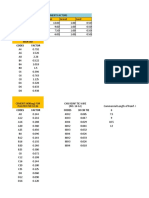

Table 1-1.

Availability of Shapes, Plates, and Bars According to

ASTM Structural Steel Specifications

Fy Shapes Plates and Bars

Mini- Group per Over Over Over Over Over Over Over Over Over

mum Fu ASTM A6 1⁄ ″ 3⁄ ″ 11⁄4″ 11⁄2″ 2″ 21⁄2″ 4″ 5″ 6″

2 4

ASTM Yield Tensile To to to to to to to to to to

a 1⁄ ″ 3 ⁄ ″ 11 ⁄ ″

Steel Desig- Stress Stress 2 4 4 11⁄2″ 2″ 21⁄2″ 4″ 5″ 6″ 8″ Over

b

Type nation (ksi) (ksi) 1 2 3 4 5 incl. incl. incl. incl. incl. incl. incl. incl. incl. incl. 8″

Carbon A36 32 58–80

36 58–80c

42 42 60–85

A529f Grade

50 50 70–100 d

High- 42 42 60

A572 Grade

Strength 50 50 65

Low-alloy

60 60 75

65 65 80

Corrosion A242 42 63

Resistant 46 67

High-

strength 50 70

Low-alloy A588 42 63

46 67

50 70

Quenched A852e 70 90–110

&

Tempered

Alloy

Quenched A514e 90 100–130

&

Tempered A514e 100 110–130

Low-Alloy

aMinimum unless a range is shown.

bIncludes bar-size shapes

cFor shapes over 426 lb / ft minimum of 58 ksi only applies.

dPlates to 1 in. thick, 12 in. width; bars to 11⁄ in.

2

ePlates only.

fTo improve the weldability of A529 steel, the specification of a maximum carbon equivalent

(per ASTM Supplementary Requirement S78) is recommended.

Available

Not Available

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 32 DIMENSIONS AND PROPERTIES

tf Y k1 k

W SHAPES

Dimensions

d X X T

tw

Y k

bf

Web Flange Distance

Area Depth Thickness tw Width Thickness

Desig-

A d tw 2 bf tf T k k1

2

nation in. in. in. in. in. in. in. in. in.

W21×201 59.2 23.03 23 0.910 15⁄

16

1⁄

2 12.575 125⁄8 1.630 15⁄8 181⁄4 23⁄8 1

W40×182 53.6 22.72 223⁄4 0.830 13⁄

16

7⁄

16 12.500 121⁄2 1.480 11⁄2 181⁄4 21⁄4 1

W40×166 48.8 22.48 221⁄2 0.750 3⁄

4

3⁄

8 12.420 123⁄8 1.360 13⁄8 181⁄4 21⁄8 15⁄

16

W40×147 43.2 22.06 22 0.720 3⁄ 3⁄ 12.510 121⁄2 1.150 11⁄8 181⁄4 17⁄8 11⁄16

4 8

W40×132 38.8 21.83 217⁄8 0.650 5⁄

8

5⁄

16 12.440 121⁄2 1.035 11⁄16 181⁄4 113⁄16 1

W40×122 35.9 21.68 215⁄8 0.600 5⁄

8

5⁄

16 12.390 123⁄8 0.960 15⁄

16 181⁄4 111⁄16 1

W40×111 32.7 21.51 211⁄2 0.550 9⁄

16

5⁄

16 12.340 123⁄8 0.875 7⁄

8 181⁄4 15⁄8 15⁄

16

W40×101 29.8 21.36 213⁄8 0.500 1⁄

2

1⁄

4 12.290 121⁄4 0.800 13⁄

16 181⁄4 19⁄16 15⁄

16

W21×93 27.3 21.62 215⁄8 0.580 9⁄

16

5⁄

16 8.420 83⁄8 0.930 15⁄

16 181⁄4 111⁄16 1

W40×83 24.3 21.43 213⁄8 0.515 1⁄

2

1⁄

4 8.355 83⁄8 0.835 13⁄

16 181⁄4 19⁄16 15⁄

16

W40×73 21.5 21.24 211⁄4 0.455 7⁄

16

1⁄

4 8.295 81⁄4 0.740 3⁄

4 181⁄4 11⁄2 15⁄

16

W40×68 20.0 21.13 211⁄8 0.430 7⁄

16

1⁄

4 8.270 81⁄4 0.685 11⁄

16 181⁄4 17⁄16 7⁄

8

W40×62 18.3 20.99 21 0.400 3⁄ 3⁄ 8.240 81⁄4 0.615 5⁄ 181⁄4 13⁄8 7⁄

8 16 8 8

W21×57 16.7 21.06 21 0.405 3⁄ 3⁄ 6.555 61⁄2 0.650 5⁄ 181⁄4 13⁄8 7⁄

8 16 8 8

W40×50 14.7 20.83 207⁄8 0.380 3⁄

8

3⁄

16 6.530 61⁄2 0.535 9⁄

16 181⁄4 15⁄16 7⁄

8

W40×44 13.0 20.66 205⁄8 0.350 3⁄

8

3⁄

16 6.500 61⁄2 0.450 7⁄

16 181⁄4 13⁄16 7⁄

8

W18×311* 91.5 22.32 223⁄8 1.520 11⁄2 3⁄

4 12.005 12 2.740 23⁄4 151⁄2 37⁄16 13⁄16

W40×283* 83.2 21.85 217⁄8 1.400 13⁄8 11⁄

16 11.890 117⁄8 2.500 21⁄2 151⁄2 33⁄16 13⁄16

W40×258* 75.9 21.46 211⁄2 1.280 11⁄4 5⁄

8 11.770 113⁄4 2.300 25⁄16 151⁄2 3 11⁄8

W40×234* 68.8 21.06 21 1.160 13⁄16 5⁄

8 11.650 115⁄8 2.110 21⁄8 151⁄2 23⁄4 1

W40×211* 62.1 20.67 205⁄8 1.060 11⁄16 9⁄

16 11.555 111⁄2 1.910 115⁄16 151⁄2 2 ⁄16

9 1

W40×192 56.4 20.35 203⁄8 0.960 1 1⁄

2 11.455 111⁄2 1.750 13⁄4 151⁄2 27⁄16 15⁄

16

W40×175 51.3 20.04 20 0.890 7⁄ 7⁄ 11.375 113⁄8 1.590 19⁄16 151⁄2 21⁄4 7⁄

8 16 8

W40×158 46.3 19.72 193⁄4 0.810 13⁄

16

7⁄

16 11.300 111⁄4 1.440 17⁄16 151⁄2 21⁄8 7⁄

8

W40×143 42.1 19.49 191⁄2 0.730 3⁄

4

3⁄

8 11.220 111⁄4 1.320 15⁄16 151⁄2 2 13⁄

16

W40×130 38.2 19.25 191⁄4 0.670 11⁄

16

3⁄

8 11.160 111⁄8 1.200 13⁄16 151⁄2 17⁄8 13⁄

16

W18×119 35.1 18.97 19 0.655 5⁄ 5⁄ 11.265 111⁄4 1.060 11⁄16 151⁄2 13⁄4 15⁄

8 16 16

W40×106 31.1 18.73 183⁄4 0.590 9⁄

16

5⁄

16 11.200 111⁄4 0.940 15⁄

16 151⁄2 15⁄8 15⁄

16

W40×97 28.5 18.59 185⁄8 0.535 9⁄

16

5⁄

16 11.145 111⁄8 0.870 7⁄

8 151⁄2 19⁄16 7⁄

8

W40×86 25.3 18.39 183⁄8 0.480 1⁄

2

1⁄

4 11.090 111⁄8 0.770 3⁄

4 151⁄2 17⁄16 7⁄

8

W40×76 22.3 18.21 181⁄4 0.425 7⁄

16

1⁄

4 11.035 11 0.680 11⁄

16 151⁄2 13⁄8 13⁄

16

W18×71 20.8 18.47 181⁄2 0.495 1⁄

2

1⁄

4 7.635 75⁄8 0.810 13⁄

16 151⁄2 11⁄2 7⁄

8

W40×65 19.1 18.35 183⁄8 0.450 7⁄

16

1⁄

4 7.590 75⁄8 0.750 3⁄

4 151⁄2 17⁄16 7⁄

8

W40×60 17.6 18.24 181⁄4 0.415 7⁄

16

1⁄

4 7.555 71⁄2 0.695 11⁄

16 151⁄2 13⁄8 13⁄

16

W40×55 16.2 18.11 181⁄8 0.390 3⁄

8

3⁄

16 7.530 71⁄2 0.630 5⁄

8 151⁄2 15⁄16 13⁄

16

W40×50 14.7 17.99 18 0.355 3⁄ 3⁄ 7.495 71⁄2 0.570 9⁄ 151⁄2 11⁄4 13⁄

8 16 16 16

W18×46 13.5 18.06 18 0.360 3⁄ 3⁄ 6.060 6 0.605 5⁄ 151⁄2 11⁄4 13⁄

8 16 8 16

W40×40 11.8 17.90 177⁄8 0.315 5⁄

16

3⁄

16 6.015 6 0.525 1⁄

2 151⁄2 13⁄16 13⁄

16

W40×35 10.3 17.70 173⁄4 0.300 5⁄

16

3⁄

16 6.000 6 0.425 7⁄

16 151⁄2 11⁄8 3⁄

4

*Group 4 or Group 5 shape. See Notes in Table 1-2.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

STRUCTURAL SHAPES 1 - 33

W SHAPES tf Y k1 k

Properties

d X X T

tw

Y k

bf

Nom- Compact Plastic

inal Section Elastic Properties Modulus

Wt. Criteria Axis X-X Axis Y-Y

per

ft bf h Fy′′′ X1 X2 × 106 I S r I S r Zx Zy

lb 2tf tw ksi ksi 2

(1/ksi) in. 4

in. 3

in. in. 4

in. 3

in. in.3

in.3

201 3.9 20.6 — 4290 453 5310 461 9.47 542 86.1 3.02 530 133

182 4.2 22.6 — 3910 649 4730 417 9.40 483 77.2 3.00 476 119

166 4.6 24.9 — 3590 904 4280 380 9.36 435 70.1 2.98 432 108

147 5.4 26.1 — 3140 1590 3630 329 9.17 376 60.1 2.95 373 92.6

132 6.0 28.9 — 2840 2350 3220 295 9.12 333 53.5 2.93 333 82.3

122 6.5 31.3 — 2630 3160 2960 273 9.09 305 49.2 2.92 307 75.6

111 7.1 34.1 55 2400 4510 2670 249 9.05 274 44.5 2.90 279 68.2

101 7.7 37.5 45 2200 6400 2420 227 9.02 248 40.3 2.89 253 61.7

93 4.5 32.3 61 2680 3460 2070 192 8.70 92.9 22.1 1.84 221 34.7

83 5.0 36.4 48 2400 5250 1830 171 8.67 81.4 19.5 1.83 196 30.5

73 5.6 41.2 38 2140 8380 1600 151 8.64 70.6 17.0 1.81 172 26.6

68 6.0 43.6 34 2000 10900 1480 140 8.60 64.7 15.7 1.80 160 24.4

62 6.7 46.9 29 1820 15900 1330 127 8.54 57.5 13.9 1.77 144 21.7

57 5.0 46.3 30 1960 13100 1170 111 8.36 30.6 9.35 1.35 129 14.8

50 6.1 49.4 26 1730 22600 984 94.5 8.18 24.9 7.64 1.30 110 12.2

44 7.2 53.6 22 1550 36600 843 81.6 8.06 20.7 6.36 1.26 95.4 10.2

311 2.2 10.6 — 8160 38 6960 624 8.72 795 132 2.95 753 207

283 2.4 11.5 — 7520 52 6160 564 8.61 704 118 2.91 676 185

258 2.6 12.5 — 6920 71 5510 514 8.53 628 107 2.88 611 166

234 2.8 13.8 — 6360 97 4900 466 8.44 558 95.8 2.85 549 149

211 3.0 15.1 — 5800 140 4330 419 8.35 493 85.3 2.82 490 132

192 3.3 16.7 — 5320 194 3870 380 8.28 440 76.8 2.79 442 119

175 3.6 18.0 — 4870 274 3450 344 8.20 391 68.8 2.76 398 106

158 3.9 19.8 — 4430 396 3060 310 8.12 347 61.4 2.74 356 94.8

143 4.2 21.9 — 4060 557 2750 282 8.09 311 55.5 2.72 322 85.4

130 4.6 23.9 — 3710 789 2460 256 8.03 278 49.9 2.70 291 76.7

119 5.3 24.5 — 3340 1210 2190 231 7.90 253 44.9 2.69 261 69.1

106 6.0 27.2 — 2990 1880 1910 204 7.84 220 39.4 2.66 230 60.5

97 6.4 30.0 — 2750 2580 1750 188 7.82 201 36.1 2.65 211 55.3

86 7.2 33.4 57 2460 4060 1530 166 7.77 175 31.6 2.63 186 48.4

76 8.1 37.8 45 2180 6520 1330 146 7.73 152 27.6 2.61 163 42.2

71 4.7 32.4 61 2680 3310 1170 127 7.50 60.3 15.8 1.70 145 24.7

65 5.1 35.7 50 2470 4540 1070 117 7.49 54.8 14.4 1.69 133 22.5

60 5.4 38.7 43 2290 6080 984 108 7.47 50.1 13.3 1.69 123 20.6

55 6.0 41.2 38 2110 8540 890 98.3 7.41 44.9 11.9 1.67 112 18.5

50 6.6 45.2 31 1920 12400 800 88.9 7.38 40.1 10.7 1.65 101 16.6

46 5.0 44.6 32 2060 10100 712 78.8 7.25 22.5 7.43 1.29 90.7 11.7

40 5.7 51.0 25 1810 17200 612 68.4 7.21 19.1 6.35 1.27 78.4 9.95

35 7.1 53.5 22 1590 30300 510 57.6 7.04 15.3 5.12 1.22 66.5 8.06

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 38 DIMENSIONS AND PROPERTIES

tf Y k1 k

W SHAPES

Dimensions

d X X T

tw

Y k

bf

Web Flange Distance

Area Depth Thickness tw Width Thickness

Desig-

A d tw 2 bf tf T k k1

2

nation in. in. in. in. in. in. in. in. in.

W12×336* 98.8 16.82 167⁄8 1.775 13⁄4 7⁄

8 13.385 133⁄8 2.955 215⁄16 91⁄2 311⁄16 11⁄2

W16×305* 89.6 16.32 163⁄8 1.625 15⁄8 13⁄

16 13.235 131⁄4 2.705 211⁄16 91⁄2 37⁄16 17⁄16

W16×279* 81.9 15.85 157⁄8 1.530 11⁄2 3⁄

4 13.140 131⁄8 2.470 21⁄2 91⁄2 33⁄16 13⁄8

W16×252* 74.1 15.41 153⁄8 1.395 13⁄8 11⁄

16 13.005 13 2.250 21⁄4 91⁄2 215⁄16 15⁄16

W16×230* 67.7 15.05 15 1.285 15⁄16 11⁄

16 12.895 127⁄8 2.070 21⁄16 91⁄2 23⁄4 11⁄4

W16×210* 61.8 14.71 143⁄4 1.180 13⁄16 5⁄

8 12.790 123⁄4 1.900 17⁄8 91⁄2 25⁄8 11⁄4

W16×190 55.8 14.38 143⁄8 1.060 11⁄16 9⁄

16 12.670 125⁄8 1.735 13⁄4 91⁄2 27⁄16 13⁄16

W16×170 50.0 14.03 14 0.960 15⁄ 1⁄ 12.570 125⁄8 1.560 19⁄16 91⁄2 21⁄4 11⁄8

16 2

W16×152 44.7 13.71 133⁄4 0.870 7⁄

8

7⁄

16 12.480 121⁄2 1.400 13⁄8 91⁄2 21⁄8 11⁄16

W16×136 39.9 13.41 133⁄8 0.790 13⁄

16

7⁄

16 12.400 123⁄8 1.250 11⁄4 91⁄2 115⁄16 1

W16×120 35.3 13.12 131⁄8 0.710 11⁄

16

3⁄

8 12.320 123⁄8 1.105 11⁄8 91⁄2 113⁄16 1

W16×106 31.2 12.89 127⁄8 0.610 5⁄

8

5⁄

16 12.220 121⁄4 0.990 1 91⁄2 111⁄16 15⁄

16

W16×96 28.2 12.71 123⁄4 0.550 9⁄

16

5⁄

16 12.160 121⁄8 0.900 7⁄

8 91⁄2 15⁄8 7⁄

8

W16×87 25.6 12.53 121⁄2 0.515 1⁄

2

1⁄

4 12.125 121⁄8 0.810 13⁄16 91⁄2 11⁄2 7⁄

8

W16×79 23.2 12.38 123⁄8 0.470 1⁄

2

1⁄

4 12.080 121⁄8 0.735 3 ⁄4 91⁄2 17⁄16 7⁄

8

W16×72 21.1 12.25 121⁄4 0.430 7⁄

16

1⁄

4 12.040 12 0.670 11⁄16 91⁄2 13⁄8 7⁄

8

W16×65 19.1 12.12 121⁄8 0.390 3⁄

8

3⁄

16 12.000 12 0.605 5⁄

8 91⁄2 15⁄16 13⁄

16

W12×58 17.0 12.19 121⁄4 0.360 3⁄

8

3⁄

16 10.010 10 0.640 5⁄

8 91⁄2 13⁄8 13⁄

16

W16×53 15.6 12.06 12 0.345 3⁄ 3⁄ 9.995 10 0.575 9⁄ 91⁄2 11⁄4 13⁄

8 16 16 16

W12×50 14.7 12.19 121⁄4 0.370 3⁄

8

3⁄

16 8.080 81⁄8 0.640 5⁄

8 91⁄2 13⁄8 13⁄

16

W16×45 13.2 12.06 12 0.335 5⁄ 3⁄ 8.045 8 0.575 9⁄ 91⁄2 11⁄4 13⁄

16 16 16 16

W16×40 11.8 11.94 12 0.295 5⁄ 3⁄ 8.005 8 0.515 1⁄ 91⁄2 11⁄4 3⁄

16 16 2 4

W12×35 10.3 12.50 121⁄2 0.300 5⁄

16

3⁄

16 6.560 61⁄2 0.520 1⁄

2 101⁄2 1 9⁄

16

W16×30 8.79 12.34 123⁄8 0.260 1⁄

4

1⁄

8 6.520 61⁄2 0.440 7⁄

16 101⁄2 15⁄

16

1⁄

2

W16×26 7.65 12.22 121⁄4 0.230 1⁄

4

1⁄

8 6.490 61⁄2 0.380 3⁄

8 101⁄2 7⁄

8

1⁄

2

W12×22 6.48 12.31 121⁄4 0.260 1⁄

4

1⁄

8 4.030 4 0.425 7⁄

16 101⁄2 7⁄

8

1⁄

2

W16×19 5.57 12.16 121⁄8 0.235 1⁄

4

1⁄

8 4.005 4 0.350 3⁄

8 101⁄2 13⁄

16

1⁄

2

W16×16 4.71 11.99 12 0.220 1⁄ 1⁄ 3.990 4 0.265 1⁄ 101⁄2 3⁄ 1⁄

4 8 4 4 2

W16×14 4.16 11.91 117⁄8 0.200 3⁄

16

1⁄

8 3.970 4 0.225 1⁄

4 101⁄2 11⁄

16

1⁄

2

*Group 4 or Group 5 shape. See Notes in Table 1-2.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

STRUCTURAL SHAPES 1 - 39

W SHAPES tf Y k1 k

Properties

d X X T

tw

Y k

bf

Nom- Compact Plastic

inal Section Elastic Properties Modulus

Wt. Criteria Axis X-X Axis Y-Y

per

ft bf h Fy′′′ X1 X2 × 106 I S r I S r Zx Zy

lb 2tf tw ksi ksi (1/ksi) 2

in. 4

in. 3

in. in. 4

in. 3

in. in.3

in.3

336 2.3 5.5 — 12800 6.05 4060 483 6.41 1190 177 3.47 603 274

305 2.4 6.0 — 11800 8.17 3550 435 6.29 1050 159 3.42 537 244

279 2.7 6.3 — 11000 10.8 3110 393 6.16 937 143 3.38 481 220

252 2.9 7.0 — 10100 14.7 2720 353 6.06 828 127 3.34 428 196

230 3.1 7.6 — 9390 19.7 2420 321 5.97 742 115 3.31 386 177

210 3.4 8.2 — 8670 26.6 2140 292 5.89 664 104 3.28 348 159

190 3.7 9.2 — 7940 37.0 1890 263 5.82 589 93.0 3.25 311 143

170 4.0 10.1 — 7190 54.0 1650 235 5.74 517 82.3 3.22 275 126

152 4.5 11.2 — 6510 79.3 1430 209 5.66 454 72.8 3.19 243 111

136 5.0 12.3 — 5850 119 1240 186 5.58 398 64.2 3.16 214 98.0

120 5.6 13.7 — 5240 184 1070 163 5.51 345 56.0 3.13 186 85.4

106 6.2 15.9 — 4660 285 933 145 5.47 301 49.3 3.11 164 75.1

96 6.8 17.7 — 4250 405 833 131 5.44 270 44.4 3.09 147 67.5

87 7.5 18.9 — 3880 586 740 118 5.38 241 39.7 3.07 132 60.4

79 8.2 20.7 — 3530 839 662 107 5.34 216 35.8 3.05 119 54.3

72 9.0 22.6 — 3230 1180 597 97.4 5.31 195 32.4 3.04 108 49.2

65 9.9 24.9 — 2940 1720 533 87.9 5.28 174 29.1 3.02 96.8 44.1

58 7.8 27.0 — 3070 1470 475 78.0 5.28 107 21.4 2.51 86.4 32.5

53 8.7 28.1 — 2820 2100 425 70.6 5.23 95.8 19.2 2.48 77.9 29.1

50 6.3 26.2 — 3170 1410 394 64.7 5.18 56.3 13.9 1.96 72.4 21.4

45 7.0 29.0 — 2870 2070 350 58.1 5.15 50.0 12.4 1.94 64.7 19.0

40 7.8 32.9 59 2580 3110 310 51.9 5.13 44.1 11.0 1.93 57.5 16.8

35 6.3 36.2 49 2420 4340 285 45.6 5.25 24.5 7.47 1.54 51.2 11.5

30 7.4 41.8 37 2090 7950 238 38.6 5.21 20.3 6.24 1.52 43.1 9.56

26 8.5 47.2 29 1820 13900 204 33.4 5.17 17.3 5.34 1.51 37.2 8.17

22 4.7 41.8 37 2160 8640 156 25.4 4.91 4.66 2.31 0.847 29.3 3.66

19 5.7 46.2 30 1880 15600 130 21.3 4.82 3.76 1.88 0.822 24.7 2.98

16 7.5 49.4 26 1610 32000 103 17.1 4.67 2.82 1.41 0.773 20.1 2.26

14 8.8 54.3 22 1450 49300 88.6 14.9 4.62 2.36 1.19 0.753 17.4 1.90

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 40 DIMENSIONS AND PROPERTIES

tf Y k1 k

W SHAPES

Dimensions

d X X T

tw

Y k

bf

Web Flange Distance

Area Depth Thickness tw Width Thickness

Desig-

A d tw 2 bf tf T k k1

2

nation in. in. in. in. in. in. in. in. in.

W10×112 32.9 11.36 113⁄8 0.755 3⁄

4

3⁄

8 10.415 103⁄8 1.250 11⁄4 75⁄8 17⁄8 15⁄

16

W10×100 29.4 11.10 111⁄8 0.680 11⁄

16

3⁄

8 10.340 103⁄8 1.120 11⁄8 75⁄8 13⁄4 7⁄

8

W10×88 25.9 10.84 107⁄8 0.605 5⁄

8

5⁄

16 10.265 101⁄4 0.990 1 75⁄8 15⁄8 13⁄

16

W10×77 22.6 10.60 105⁄8 0.530 1⁄

2

1⁄

4 10.190 101⁄4 0.870 7⁄

8 75⁄8 11⁄2 13⁄

16

W10×68 20.0 10.40 103⁄8 0.470 1⁄

2

1⁄

4 10.130 101⁄8 0.770 3⁄

4 75⁄8 13⁄8 3⁄

4

W10×60 17.6 10.22 101⁄4 0.420 7⁄

16

1⁄

4 10.080 101⁄8 0.680 11⁄

16 75⁄8 15⁄16 3⁄

4

W10×54 15.8 10.09 101⁄8 0.370 3⁄

8

3⁄

16 10.030 10 0.615 5⁄

8 75⁄8 11⁄4 11⁄

16

W10×49 14.4 9.98 10 0.340 5⁄ 3⁄ 10.000 10 0.560 9⁄ 75⁄8 13⁄16 11⁄

16 16 16 16

W10×45 13.3 10.10 101⁄8 0.350 3⁄

8

3⁄

16 8.020 8 0.620 5⁄

8 75⁄8 11⁄4 11⁄

16

W10×39 11.5 9.92 97⁄8 0.315 5⁄

16

3⁄

16 7.985 8 0.530 1⁄

2 75⁄8 11⁄8 11⁄

16

W10×33 9.71 9.73 93⁄4 0.290 5⁄

16

3⁄

16 7.960 8 0.435 7⁄

16 75⁄8 11⁄16 11⁄

16

W10×30 8.84 10.47 101⁄2 0.300 5⁄

16

3⁄

16 5.810 53⁄4 0.510 1⁄

2 85⁄8 15⁄

16

1⁄

2

W10×26 7.61 10.33 103⁄8 0.260 1⁄

4

1⁄

8 5.770 53⁄4 0.440 7⁄

16 85⁄8 7⁄

8

1⁄

2

W10×22 6.49 10.17 101⁄8 0.240 1⁄

4

1⁄

8 5.750 53⁄4 0.360 3⁄

8 85⁄8 3⁄

4

1⁄

2

W10×19 5.62 10.24 101⁄4 0.250 1⁄

4

1⁄

8 4.020 4 0.395 3⁄

8 85⁄8 13⁄

16

1⁄

2

W10×17 4.99 10.11 101⁄8 0.240 1⁄

4

1⁄

8 4.010 4 0.330 5⁄

16 85⁄8 3⁄

4

1⁄

2

W10×15 4.41 9.99 10 0.230 1⁄ 1⁄ 4.000 4 0.270 1⁄ 85⁄8 11⁄ 7⁄

4 8 4 16 16

W10×12 3.54 9.87 97⁄8 0.190 3⁄

16

1⁄

8 3.960 4 0.210 3⁄

16 85⁄8 5⁄

8

7⁄

16

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

STRUCTURAL SHAPES 1 - 41

W SHAPES tf Y k1 k

Properties

d X X T

tw

Y k

bf

Nom- Compact Plastic

inal Section Elastic Properties Modulus

Wt. Criteria Axis X-X Axis Y-Y

per

ft bf h Fy′′′ X1 X2 × 106 I S r I S r Zx Zy

lb 2tf tw ksi ksi (1/ksi) 2

in. 4

in. 3

in. in. 4

in. 3

in. in.3

in.3

112 4.2 10.4 — 7080 56.7 716 126 4.66 236 45.3 2.68 147 69.2

100 4.6 11.6 — 6400 83.8 623 112 4.60 207 40.0 2.65 130 61.0

88 5.2 13.0 — 5680 132 534 98.5 4.54 179 34.8 2.63 113 53.1

77 5.9 14.8 — 5010 213 455 85.9 4.49 154 30.1 2.60 97.6 45.9

68 6.6 16.7 — 4460 334 394 75.7 4.44 134 26.4 2.59 85.3 40.1

60 7.4 18.7 — 3970 525 341 66.7 4.39 116 23.0 2.57 74.6 35.0

54 8.2 21.2 — 3580 778 303 60.0 4.37 103 20.6 2.56 66.6 31.3

49 8.9 23.1 — 3280 1090 272 54.6 4.35 93.4 18.7 2.54 60.4 28.3

45 6.5 22.5 — 3650 758 248 49.1 4.32 53.4 13.3 2.01 54.9 20.3

39 7.5 25.0 — 3190 1300 209 42.1 4.27 45.0 11.3 1.98 46.8 17.2

33 9.1 27.1 — 2710 2510 170 35.0 4.19 36.6 9.20 1.94 38.8 14.0

30 5.7 29.5 — 2890 2160 170 32.4 4.38 16.7 5.75 1.37 36.6 8.84

26 6.6 34.0 55 2500 3790 144 27.9 4.35 14.1 4.89 1.36 31.3 7.50

22 8.0 36.9 47 2150 7170 118 23.2 4.27 11.4 3.97 1.33 26.0 6.10

19 5.1 35.4 51 2420 5160 96.3 18.8 4.14 4.29 2.14 0.874 21.6 3.35

17 6.1 36.9 47 2210 7820 81.9 16.2 4.05 3.56 1.78 0.844 18.7 2.80

15 7.4 38.5 43 1930 14300 68.9 13.8 3.95 2.89 1.45 0.810 16.0 2.30

12 9.4 46.6 30 1550 35400 53.8 10.9 3.90 2.18 1.10 0.785 12.6 1.74

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 50 DIMENSIONS AND PROPERTIES

k x Y xp tf

CHANNELS

AMERICAN STANDARD

T X X d Dimensions

tw

k Y grip

eo bf

Web Flange Distance Max.

Flge.

Area Depth Thickness tw Width Thickness Fas-

A d tw 2 bf tf T k Grip tener

Desig-

nation in.2 in. in. in. in. in. in. in. in. in.

C15×50 14.7 15.00 0.716 11⁄ 3⁄ 3.716 33⁄4 0.650 5⁄ 121⁄8 17⁄16 5⁄ 1

16 8 8 8

C15×40 11.8 15.00 0.520 1⁄ 1⁄ 3.520 31⁄2 0.650 5⁄ 121⁄8 17⁄16 5⁄ 1

2 4 8 8

C15×33.9 9.96 15.00 0.400 3⁄ 3⁄ 3.400 33⁄8 0.650 5⁄ 121⁄8 17⁄16 5⁄ 1

8 16 8 8

C12×30 8.82 12.00 0.510 1⁄ 1⁄ 3.170 31⁄8 0.501 1⁄ 93⁄4 11⁄8 1⁄ 7⁄

2 4 2 2 8

C15×25 7.35 12.00 0.387 3⁄ 3⁄ 3.047 3 0.501 1⁄ 93⁄4 11⁄8 1⁄ 7⁄

8 16 2 2 8

C15×20.7 6.09 12.00 0.282 5⁄ 1⁄ 2.942 3 0.501 1⁄ 93⁄4 11⁄8 1⁄ 7⁄

16 8 2 2 8

C10×30 8.82 10.00 0.673 11⁄ 5⁄ 3.033 3 0.436 7⁄ 8 1 7⁄ 3⁄

16 16 16 16 4

C15×25 7.35 10.00 0.526 1⁄ 1⁄ 2.886 27⁄8 0.436 7⁄ 8 1 7⁄ 3⁄

2 4 16 16 4

C15×20 5.88 10.00 0.379 3⁄ 3⁄ 2.739 23⁄4 0.436 7⁄ 8 1 7⁄ 3⁄

8 16 16 16 4

C15×15.3 4.49 10.00 0.240 1⁄ 1⁄ 2.600 25⁄8 0.436 7⁄ 8 1 7⁄ 3⁄

4 8 16 16 4

C9×20 5.88 9.00 0.448 7⁄ 1⁄ 2.648 25⁄8 0.413 7⁄ 71⁄8 15⁄ 7⁄ 3⁄

16 4 16 16 16 4

C5×15 4.41 9.00 0.285 5⁄ 1⁄ 2.485 21⁄2 0.413 7⁄ 71⁄8 15⁄ 7⁄ 3⁄

16 8 16 16 16 4

C5×13.4 3.94 9.00 0.233 1⁄ 1⁄ 2.433 23⁄8 0.413 7⁄ 71⁄8 15⁄ 7⁄ 3⁄

4 8 16 16 16 4

C8×18.75 5.51 8.00 0.487 1⁄ 1⁄ 2.527 21⁄2 0.390 3⁄ 61⁄8 15⁄ 3⁄ 3⁄

2 4 8 16 8 4

C8×13.75 4.04 8.00 0.303 5⁄ 1⁄ 2.343 23⁄8 0.390 3⁄ 61⁄8 15⁄ 3⁄ 3⁄

16 8 8 16 8 4

C8×11.5 3.38 8.00 0.220 1⁄ 1⁄ 2.260 21⁄4 0.390 3⁄ 61⁄8 15⁄ 3⁄ 3⁄

4 8 8 16 8 4

C7×12.25 3.60 7.00 0.314 5⁄ 3⁄ 2.194 21⁄4 0.366 3⁄ 51⁄4 7⁄ 3⁄ 5⁄

16 16 8 8 8 8

C8×9.8 2.87 7.00 0.210 3⁄ 1⁄ 2.090 21⁄8 0.366 3⁄ 51⁄4 7⁄ 3⁄ 5⁄

16 8 8 8 8 8

C6×13 3.83 6.00 0.437 7⁄ 3⁄ 2.157 21⁄8 0.343 5⁄ 43⁄8 13⁄ 5⁄ 5⁄

16 16 16 16 16 8

C8×10.5 3.09 6.00 0.314 5⁄ 3⁄ 2.034 2 0.343 5⁄ 43⁄8 13⁄ 3⁄ 5⁄

16 16 16 16 8 8

C8×8.2 2.40 6.00 0.200 3⁄ 1⁄ 1.920 17⁄8 0.343 5⁄ 43⁄8 13⁄ 5⁄ 5⁄

16 8 16 16 16 8

C5×9 2.64 5.00 0.325 5⁄ 3⁄ 1.885 17⁄8 0.320 5⁄ 31⁄2 3⁄ 5⁄ 5⁄

16 16 16 4 16 8

C8×6.7 1.97 5.00 0.190 3⁄ 1⁄ 1.750 13⁄4 0.320 5⁄ 31⁄2 3⁄ — —

16 8 16 4

C4×7.25 2.13 4.00 0.321 5⁄ 3⁄ 1.721 13⁄4 0.296 5⁄ 25⁄8 11⁄ 5⁄ 5⁄

16 16 16 16 16 8

C8×5.4 1.59 4.00 0.184 3⁄ 1⁄ 1.584 15⁄8 0.296 5⁄ 25⁄8 11⁄ — —

16 16 16 16

C3×6 1.76 3.00 0.356 3⁄ 3⁄ 1.596 15⁄8 0.273 1⁄ 15⁄8 11⁄ — —

8 16 4 16

C8×5 1.47 3.00 0.258 1⁄ 1⁄ 1.498 11⁄2 0.273 1⁄ 15⁄8 11⁄ — —

4 8 4 16

C8×4.1 1.21 3.00 0.170 3⁄ 1⁄ 1.410 13⁄8 0.273 1⁄ 15⁄8 11⁄ — —

16 16 4 16

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

STRUCTURAL SHAPES 1 - 51

CHANNELS k x Y xp tf

AMERICAN STANDARD

Properties T X X d

tw

k Y grip

eo bf

Nom- Shear Axis X-X Axis Y-Y

inal Center PNA

Wt. Loca- Loca-

per _ tion tion

ft x eo xp I Z S r I Z S r

4 3 3 4 3 3

lb in. in. in. in. in. in. in. in. in. in. in.

50 0.798 0.583 0.488 404 68.2 53.8 5.24 11.0 8.17 3.78 0.867

40 0.777 0.767 0.390 349 57.2 46.5 5.44 9.23 6.87 3.37 0.886

33.9 0.787 0.896 0.330 315 50.4 42.0 5.62 8.13 6.23 3.11 0.904

30 0.674 0.618 0.366 162 33.6 27.0 4.29 5.14 4.33 2.06 0.763

25 0.674 0.746 0.305 144 29.2 24.1 4.43 4.47 3.84 1.88 0.780

20.7 0.698 0.870 0.252 129 25.4 21.5 4.61 3.88 3.49 1.73 0.799

30 0.649 0.369 0.439 103 26.6 20.7 3.42 3.94 3.78 1.65 0.669

25 0.617 0.494 0.366 91.2 23.0 18.2 3.52 3.36 3.19 1.48 0.676

20 0.606 0.637 0.292 78.9 19.3 15.8 3.66 2.81 2.71 1.32 0.692

15.3 0.634 0.796 0.223 67.4 15.8 13.5 3.87 2.28 2.35 1.16 0.713

20 0.583 0.515 0.325 60.9 16.8 13.5 3.22 2.42 2.47 1.17 0.642

15 0.586 0.682 0.243 51.0 13.5 11.3 3.40 1.93 2.05 1.01 0.661

13.4 0.601 0.743 0.217 47.9 12.5 10.6 3.48 1.76 1.95 0.962 0.669

18.75 0.565 0.431 0.343 44.0 13.8 11.0 2.82 1.98 2.17 1.01 0.599

13.75 0.553 0.604 0.251 36.1 10.9 9.03 2.99 1.53 1.73 0.854 0.615

11.5 0.571 0.697 0.209 32.6 9.55 8.14 3.11 1.32 1.58 0.781 0.625

12.25 0.525 0.538 0.255 24.2 8.40 6.93 2.60 1.17 1.43 0.703 0.571

9.8 0.540 0.647 0.203 21.3 7.12 6.08 2.72 0.968 1.26 0.625 0.581

13 0.514 0.380 0.317 17.4 7.26 5.80 2.13 1.05 1.36 0.642 0.525

10.5 0.499 0.486 0.255 15.2 6.15 5.06 2.22 0.866 1.15 0.564 0.529

8.2 0.511 0.599 0.198 13.1 5.13 4.38 2.34 0.693 0.993 0.492 0.537

9 0.478 0.427 0.262 8.90 4.36 3.56 1.83 0.632 0.918 0.450 0.489

6.7 0.484 0.552 0.217 7.49 3.51 3.00 1.95 0.479 0.763 0.378 0.493

7.25 0.459 0.386 0.264 4.59 2.81 2.29 1.47 0.433 0.697 0.343 0.450

5.4 0.457 0.502 0.241 3.85 2.26 1.93 1.56 0.319 0.569 0.283 0.449

6 0.455 0.322 0.291 2.07 1.72 1.38 1.08 0.305 0.544 0.268 0.416

5 0.438 0.392 0.242 1.85 1.50 1.24 1.12 0.247 0.466 0.233 0.410

4.1 0.436 0.461 0.284 1.66 1.30 1.10 1.17 0.197 0.401 0.202 0.404

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 52 DIMENSIONS AND PROPERTIES

k x Y xp tf

CHANNELS

MISCELLANEOUS

T X X d Dimensions

tw

k Y grip

eo bf

Web Flange Distance Max.

Flge.

Area Depth Thickness tw Width Thickness Fas-

A d tw 2 bf tf T k Grip tener

Desig-

nation in.2 in. in. in. in. in. in. in. in. in.

MC18×58 17.1 18.00 0.700 11⁄ 3⁄ 4.200 41⁄ 0.625 5⁄ 151⁄4 13⁄8 5⁄ 1

16 8 4 8 8

MC18×51.9 15.3 18.00 0.600 5⁄ 5⁄ 4.100 41⁄8 0.625 5⁄ 151⁄4 13⁄8 5⁄ 1

8 16 8 8

MC18×45.8 13.5 18.00 0.500 1⁄ 1⁄ 4.000 4 0.625 5⁄ 151⁄4 13⁄8 5⁄ 1

2 4 8 8

MC18×42.7 12.6 18.00 0.450 7⁄ 1⁄ 3.950 4 0.625 5⁄ 151⁄4 13⁄8 5⁄ 1

16 4 8 8

MC13×50 14.7 13.00 0.787 3⁄ 3⁄ 4.412 43⁄8 0.610 5⁄ 101⁄4 13⁄8 5⁄ 1

16 8 8 8

MC18×40 11.8 13.00 0.560 9⁄ 1⁄ 4.185 41⁄8 0.610 5⁄ 101⁄4 13⁄8 9⁄ 1

16 4 8 16

MC18×35 10.3 13.00 0.447 7⁄ 1⁄ 4.072 41⁄8 0.610 5⁄ 101⁄4 13⁄8 9⁄ 1

16 4 8 16

MC18×31.8 9.35 13.00 0.375 3⁄ 3⁄ 4.000 4 0.610 5⁄ 101⁄4 13⁄8 9⁄ 1

8 16 8 16

MC12×50 14.7 12.00 0.835 13⁄ 7⁄ 4.135 41⁄ 0.700 11⁄ 93⁄8 15⁄16 11⁄ 1

16 16 8 16 16

MC18×45 13.2 12.00 0.712 11⁄ 3⁄ 4.012 4 0.700 11⁄ 93⁄8 15⁄16 11⁄ 1

16 8 16 16

MC18×40 11.8 12.00 0.590 9⁄ 5⁄ 3.890 37⁄8 0.700 11⁄ 93⁄8 15⁄16 11⁄ 1

16 16 16 16

MC18×35 10.3 12.00 0.467 7⁄ 1⁄ 3.767 33⁄4 0.700 11⁄ 93⁄8 15⁄16 11⁄ 1

16 4 16 16

MC18×31 9.12 12.00 0.370 3⁄ 3⁄ 3.670 35⁄8 0.700 11⁄ 93⁄8 15⁄16 11⁄ 1

8 16 16 16

MC12×10.6 3.10 12.00 0.190 3⁄ 1⁄ 1.500 11⁄2 0.309 5⁄ 105⁄8 11⁄ — —

16 8 16 16

MC10×41.1 12.1 10.00 0.796 13⁄ 3⁄ 4.321 43⁄ 0.575 9⁄ 71⁄2 11⁄4 9⁄ 7⁄

16 8 8 16 16 8

MC18×33.6 9.87 10.00 0.575 9⁄ 5⁄ 4.100 41⁄8 0.575 9⁄ 71⁄2 11⁄4 9⁄ 7⁄

16 16 16 16 8

MC18×28.5 8.37 10.00 0.425 7⁄ 3⁄ 3.950 4 0.575 9⁄ 71⁄2 11⁄4 9⁄ 7⁄

16 16 16 16 8

MC10×25 7.35 10.00 0.380 3⁄ 3⁄ 3.405 33⁄8 0.575 9⁄ 71⁄2 11⁄4 9⁄ 7⁄

8 16 16 16 8

MC18×22 6.45 10.00 0.290 5⁄ 1⁄ 3.315 33⁄8 0.575 9⁄ 71⁄2 11⁄4 9⁄ 7⁄

16 8 16 16 8

MC10×8.4 2.46 10.00 0.170 3⁄ 1⁄ 1.500 11⁄2 0.280 1⁄ 85⁄8 11⁄ — —

16 16 4 16

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

STRUCTURAL SHAPES 1 - 53

CHANNELS k x Y xp tf

MISCELLANEOUS

Properties T X X d

tw

k Y grip

eo bf

Nom- Shear Axis X-X Axis Y-Y

inal Center PNA

Wt. Loca- Loca-

per _ tion tion

ft x eo xp I Z S r I Z S r

4 3 3 4 3 3

lb in. in. in. in. in. in. in. in. in. in. in.

58 0.862 0.695 0.472 676 94.6 75.1 6.29 17.8 9.94 5.32 1.02

51.9 0.858 0.797 0.422 627 86.5 69.7 6.41 16.4 9.13 5.07 1.04

45.8 0.866 0.909 0.372 578 78.4 64.3 6.56 15.1 8.42 4.82 1.06

42.7 0.877 0.969 0.347 554 74.4 61.6 6.64 14.4 8.10 4.69 1.07

50 0.974 0.815 0.564 314 60.5 48.4 4.62 16.5 10.1 4.79 1.06

40 0.963 1.03 0.450 273 50.9 42.0 4.82 13.7 8.57 4.26 1.08

35 0.980 1.16 0.394 252 46.2 38.8 4.95 12.3 7.95 3.99 1.10

31.8 1.00 1.24 0.358 239 43.1 36.8 5.06 11.4 7.60 3.81 1.11

50 1.05 0.741 0.610 269 56.1 44.9 4.28 17.4 10.2 5.65 1.09

45 1.04 0.844 0.549 252 51.7 42.0 4.36 15.8 9.35 5.33 1.09

40 1.04 0.952 0.488 234 47.3 39.0 4.46 14.3 8.59 5.00 1.10

35 1.05 1.07 0.426 216 42.8 36.1 4.59 12.7 7.91 4.67 1.11

31 1.08 1.18 0.416 203 39.3 33.8 4.71 11.3 7.44 4.39 1.12

10.6 0.269 0.284 0.129 55.4 11.6 9.23 4.22 0.382 0.639 0.310 0.351

41.1 1.09 0.864 0.601 158 38.9 31.5 3.61 15.8 8.71 4.88 1.14

33.6 1.08 1.06 0.490 139 33.4 27.8 3.75 13.2 7.51 4.38 1.16

28.5 1.12 1.21 0.415 127 29.6 25.3 3.89 11.4 6.83 4.02 1.17

25 0.953 1.03 0.364 110 25.8 22.0 3.87 7.35 5.21 3.00 1.00

22 0.990 1.13 0.468 103 23.6 20.5 3.99 6.50 4.86 2.80 1.00

8.4 0.284 0.332 0.122 32.0 7.86 6.40 3.61 0.328 0.552 0.270 0.365

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 56 DIMENSIONS AND PROPERTIES

Y

x

xp

ANGLES

Z

Equal legs and unequal legs

Properties for designing

X X

y, yp

k

α

Y Z

Size Weight Axis X-X

and per

Thickness k ft Area I S r y Z yp

2 4 3 3

in. in. lb in. in. in. in. in. in. in.

L8×8×11⁄8 13⁄4 56.9 16.7 98.0 17.5 2.42 2.41 31.6 1.05

L8×8×1 15⁄8 51.0 15.0 89.0 15.8 2.44 2.37 28.5 0.938

L8×8×17⁄8 11⁄2 45.0 13.2 79.6 14.0 2.45 2.33 25.3 0.827

L8×8×13⁄4 13⁄8 38.9 11.4 69.7 12.2 2.47 2.28 22.0 0.715

L8×8×15⁄8 11⁄4 32.7 9.61 59.4 10.3 2.49 2.23 18.6 0.601

L8×8×19⁄16 13⁄16 29.6 8.68 54.1 9.34 2.50 2.21 16.8 0.543

L8×8×11⁄2 11⁄8 26.4 7.75 48.6 8.36 2.50 2.19 15.1 0.484

L8×6×1 11⁄2 44.2 13.0 80.8 15.1 2.49 2.65 27.3 1.50

L8×8×17⁄8 13⁄8 39.1 11.5 72.3 13.4 2.51 2.61 24.2 1.44

L8×8×13⁄4 11⁄4 33.8 9.94 63.4 11.7 2.53 2.56 21.1 1.38

L8×8×15⁄8 11⁄8 28.5 8.36 54.1 9.87 2.54 2.52 17.9 1.31

L8×8×19⁄16 11⁄16 25.7 7.56 49.3 8.95 2.55 2.50 16.2 1.28

L8×8×11⁄2 1 23.0 6.75 44.3 8.02 2.56 2.47 14.5 1.25

L8×8×17⁄16 15⁄

16 20.2 5.93 39.2 7.07 2.57 2.45 12.8 1.22

L8×4×1 11⁄2 37.4 11.0 69.6 14.1 2.52 3.05 24.3 2.50

L8×8×17⁄8 13⁄8 33.1 9.73 62.5 12.5 2.53 3.00 21.6 2.44

L8×8×13⁄4 11⁄4 28.7 8.44 54.9 10.9 2.55 2.95 18.9 2.38

L8×4×15⁄8 11⁄8 24.2 7.11 46.9 9.21 2.57 2.91 16.0 2.31

L8×8×19⁄16 11⁄16 21.9 6.43 42.8 8.35 2.58 2.88 14.5 2.28

L8×8×11⁄2 1 19.6 5.75 38.5 7.49 2.59 2.86 13.0 2.25

L8×4×17⁄16 15⁄

16 17.2 5.06 34.1 6.60 2.60 2.83 11.5 2.22

L7×4×3⁄4 11⁄4 26.2 7.69 37.8 8.42 2.22 2.51 14.8 1.88

L7×4×5⁄8 11⁄8 22.1 6.48 32.4 7.14 2.24 2.46 12.6 1.81

L7×4×1⁄2 1 17.9 5.25 26.7 5.81 2.25 2.42 10.3 1.75

L7×4×7⁄16 15⁄

16 15.7 4.62 23.7 5.13 2.26 2.39 9.09 1.72

L7×4×3⁄8 7⁄

8 13.6 3.98 20.6 4.44 2.27 2.37 7.87 1.69

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

STRUCTURAL SHAPES 1 - 57

Y

ANGLES x

xp

Equal legs and unequal legs Z

Properties for designing

X X

y, yp

k

α

Y Z

Size Axis Y-Y Axis Z-Z

and

Thickness I S r x Z xp r Tan

in. in. 4

in. 3

in. in. in. 3

in. in. α

L8×8×11⁄8 98.0 17.5 2.42 2.41 31.6 1.05 1.56 1.000

L8×8×1 89.0 15.8 2.44 2.37 28.5 0.938 1.56 1.000

L8×8×17⁄8 79.6 14.0 2.45 2.33 25.3 0.827 1.57 1.000

L8×8×13⁄4 69.7 12.2 2.47 2.28 22.0 0.715 1.58 1.000

L8×8×15⁄8 59.4 10.3 2.49 2.23 18.6 0.601 1.58 1.000

L8×8×19⁄16 54.1 9.34 2.50 2.21 16.8 0.543 1.59 1.000

L8×8×11⁄2 48.6 8.36 2.50 2.19 15.1 0.484 1.59 1.000

L8×6×1 38.8 8.92 1.73 1.65 16.2 0.813 1.28 0.543

L8×8×17⁄8 34.9 7.94 1.74 1.61 14.4 0.718 1.28 0.547

L8×8×13⁄4 30.7 6.92 1.76 1.56 12.5 0.621 1.29 0.551

L8×8×15⁄8 26.3 5.88 1.77 1.52 10.5 0.522 1.29 0.554

L8×8×19⁄16 24.0 5.34 1.78 1.50 9.52 0.472 1.30 0.556

L8×8×11⁄2 21.7 4.79 1.79 1.47 8.51 0.422 1.30 0.558

L8×8×17⁄16 19.3 4.23 1.80 1.45 7.50 0.371 1.31 0.560

L8×4×1 11.6 3.94 1.03 1.05 7.72 0.688 0.846 0.247

L8×4×17⁄8 10.5 3.51 1.04 0.999 6.77 0.608 0.848 0.253

L8×8×13⁄4 9.36 3.07 1.05 0.953 5.81 0.527 0.852 0.258

L8×4×15⁄8 8.10 2.62 1.07 0.905 4.86 0.444 0.857 0.262

L8×8×19⁄16 7.43 2.38 1.07 0.882 4.38 0.402 0.861 0.265

L8×8×11⁄2 6.74 2.15 1.08 0.859 3.90 0.359 0.865 0.267

L8×4×17⁄16 6.02 1.90 1.09 0.835 3.42 0.316 0.869 0.269

L7×4×3⁄4 9.05 3.03 1.09 1.01 5.65 0.549 0.860 0.324

L7×4×5⁄8 7.84 2.58 1.10 0.963 4.74 0.463 0.865 0.329

L7×4×1⁄2 6.53 2.12 1.11 0.917 3.83 0.375 0.872 0.335

L7×4×7⁄16 5.83 1.88 1.12 0.893 3.37 0.330 0.875 0.337

L7×4×3⁄8 5.10 1.63 1.13 0.870 2.90 0.285 0.880 0.340

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 58 DIMENSIONS AND PROPERTIES

Y

x

xp

ANGLES

Z

Equal legs and unequal legs

Properties for designing

X X

y, yp

k

α

Y Z

Size Weight Axis X-X

and per

Thickness k ft Area I S r y Z yp

2 4 3 3

in. in. lb in. in. in. in. in. in. in.

L6×6×1 11⁄2 37.4 11.0 35.5 8.57 1.80 1.86 15.5 0.917

L6×6×17⁄8 13⁄8 33.1 9.73 31.9 7.63 1.81 1.82 13.8 0.811

L6×6×13⁄4 11⁄4 28.7 8.44 28.2 6.66 1.83 1.78 12.0 0.703

L6×6×15⁄8 11⁄8 24.2 7.11 24.2 5.66 1.84 1.73 10.2 0.592

L6×6×19⁄16 11⁄16 21.9 6.43 22.1 5.14 1.85 1.71 9.26 0.536

L6×6×11⁄2 1 19.6 5.75 19.9 4.61 1.86 1.68 8.31 0.479

L6×6×17⁄16 15⁄

16 17.2 5.06 17.7 4.08 1.87 1.66 7.34 0.422

L6×6×13⁄8 7⁄

8 14.9 4.36 15.4 3.53 1.88 1.64 6.35 0.363

L6×6×15⁄16 13⁄

16 12.4 3.65 13.0 2.97 1.89 1.62 5.35 0.304

L6×4×7⁄8 13⁄8 27.2 7.98 27.7 7.15 1.86 2.12 12.7 1.44

L6×4×3⁄4 11⁄4 23.6 6.94 24.5 6.25 1.88 2.08 11.2 1.38

L6×4×5⁄8 11⁄8 20.0 5.86 21.1 5.31 1.90 2.03 9.51 1.31

L6×4×9⁄16 11⁄16 18.1 5.31 19.3 4.83 1.90 2.01 8.66 1.28

L6×4×1⁄2 1 16.2 4.75 17.4 4.33 1.91 1.99 7.78 1.25

L6×4×7⁄16 15⁄

16 14.3 4.18 15.5 3.83 1.92 1.96 6.88 1.22

L6×4×3⁄8 7⁄

8 12.3 3.61 13.5 3.32 1.93 1.94 5.97 1.19

L6×4×5⁄16 13⁄

16 10.3 3.03 11.4 2.79 1.94 1.92 5.03 1.16

L6×31⁄2×1⁄2 1 15.3 4.50 16.6 4.24 1.92 2.08 7.50 1.50

L6×31⁄2×3⁄8 7⁄

8 11.7 3.42 12.9 3.24 1.94 2.04 5.76 1.44

L6×31⁄2×5⁄16 13⁄

16 9.80 2.87 10.9 2.73 1.95 2.01 4.85 1.41

L5×5×7⁄8 13⁄8 27.2 7.98 17.8 5.17 1.49 1.57 9.33 0.798

L5×5×3⁄4 11⁄4 23.6 6.94 15.7 4.53 1.51 1.52 8.16 0.694

L5×5×5⁄8 11⁄8 20.0 5.86 13.6 3.86 1.52 1.48 6.95 0.586

L5×5×1⁄2 1 16.2 4.75 11.3 3.16 1.54 1.43 5.68 0.475

L5×5×7⁄16 15⁄

16 14.3 4.18 10.0 2.79 1.55 1.41 5.03 0.418

L5×5×3⁄8 7⁄

8 12.3 3.61 8.74 2.42 1.56 1.39 4.36 0.361

L5×5×5⁄16 13⁄

16 10.3 3.03 7.42 2.04 1.57 1.37 3.68 0.303

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

STRUCTURAL SHAPES 1 - 59

Y

ANGLES x

xp

Equal legs and unequal legs Z

Properties for designing

X X

y, yp

k

α

Y Z

Size Axis Y-Y Axis Z-Z

and

Thickness I S r x Z xp r Tan

in. in. 4

in. 3

in. in. in. 3

in. in. α

L6×6×1 35.5 8.57 1.80 1.86 15.5 0.917 1.17 1.000

L6×6×17⁄8 31.9 7.63 1.81 1.82 13.8 0.811 1.17 1.000

L6×6×13⁄4 28.2 6.66 1.83 1.78 12.0 0.703 1.17 1.000

L6×6×15⁄8 24.2 5.66 1.84 1.73 10.2 0.592 1.18 1.000

L6×6×19⁄16 22.1 5.14 1.85 1.71 9.26 0.536 1.18 1.000

L6×6×11⁄2 19.9 4.61 1.86 1.68 8.31 0.479 1.18 1.000

L6×6×17⁄16 17.7 4.08 1.87 1.66 7.34 0.422 1.19 1.000

L6×6×13⁄8 15.4 3.53 1.88 1.64 6.35 0.363 1.19 1.000

L6×6×15⁄16 13.0 2.97 1.89 1.62 5.35 0.304 1.20 1.000

L6×4×7⁄8 9.75 3.39 1.11 1.12 6.31 0.665 0.857 0.421

L6×4×3⁄4 8.68 2.97 1.12 1.08 5.47 0.578 0.860 0.428

L6×4×5⁄8 7.52 2.54 1.13 1.03 4.62 0.488 0.864 0.435

L6×4×9⁄16 6.91 2.31 1.14 1.01 4.19 0.442 0.866 0.438

L6×4×1⁄2 6.27 2.08 1.15 0.987 3.75 0.396 0.870 0.440

L6×4×7⁄16 5.60 1.85 1.16 0.964 3.30 0.349 0.873 0.443

L6×4×3⁄8 4.90 1.60 1.17 0.941 2.85 0.301 0.877 0.446

L6×4×5⁄16 4.18 1.35 1.17 0.918 2.40 0.252 0.882 0.448

L6×31⁄2×1⁄2 4.25 1.59 0.972 0.833 2.91 0.375 0.759 0.344

L6×31⁄2×3⁄8 3.34 1.23 0.988 0.787 2.20 0.285 0.767 0.350

L6×31⁄2×5⁄16 2.85 1.04 0.996 0.763 1.85 0.239 0.772 0.352

L5×5×7⁄8 17.8 5.17 1.49 1.57 9.33 0.798 0.973 1.000

L5×5×3⁄4 15.7 4.53 1.51 1.52 8.16 0.694 0.975 1.000

L5×5×5⁄8 13.6 3.86 1.52 1.48 6.95 0.586 0.978 1.000

L5×5×1⁄2 11.3 3.16 1.54 1.43 5.68 0.475 0.983 1.000

L5×5×7⁄16 10.0 2.79 1.55 1.41 5.03 0.418 0.986 1.000

L5×5×3⁄8 8.74 2.42 1.56 1.39 4.36 0.361 0.990 1.000

L5×5×5⁄16 7.42 2.04 1.57 1.37 3.68 0.303 0.994 1.000

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 74 DIMENSIONS AND PROPERTIES

bf

tf k

STRUCTURAL TEES

Y

Cut from W shapes

yp , y

X X Dimensions

d

tw

Stem Area Flange

Depth of of Dis-

Tee Thickness tw Stem Width Thickness tance

Area d tw 2 bf tf k

Designation in.2 in. in. in. in.2 in. in. in.

WT10.5×100.5 29.6 11.515 111⁄2 0.910 15⁄

16

1⁄

2 10.5 12.575 125⁄8 1.630 15⁄8 23⁄8

WT10.5×91 26.8 11.360 113⁄8 0.830 13⁄

16

7⁄

16 9.43 12.500 121⁄2 1.480 11⁄2 21⁄4

WT10.5×83 24.4 11.240 111⁄4 0.750 3⁄

4

3⁄

8 8.43 12.420 123⁄8 1.360 13⁄8 21⁄8

WT10.5×73.5 21.6 11.030 11 0.720 3⁄ 3⁄ 7.94 12.510 121⁄2 1.150 11⁄8 17⁄8

4 8

WT10.5×66 19.4 10.915 107⁄8 0.650 5⁄

8

5⁄

16 7.09 12.440 121⁄2 1.035 11⁄16 113⁄16

WT10.5×61 17.9 10.840 107⁄8 0.600 5⁄

8

5⁄

16 6.50 12.390 123⁄8 0.960 15⁄

16 111⁄16

WT10.5×55.5 16.3 10.755 103⁄4 0.550 9⁄

16

5⁄

16 5.92 12.340 123⁄8 0.875 7⁄

8 15⁄8

WT10.5×50.5 14.9 10.680 105⁄8 0.500 1⁄

2

1⁄

4 5.34 12.290 121⁄4 0.800 13⁄

16 19⁄16

WT10.5×46.5 13.7 10.810 103⁄4 0.580 9⁄

16

5⁄

16 6.27 8.420 83⁄8 0.930 15⁄

16 111⁄16

WT10.5×41.5 12.2 10.715 103⁄4 0.515 1⁄

2

1⁄

4 5.52 8.355 83⁄8 0.835 13⁄

16 19⁄16

WT10.5×36.5 10.7 10.620 105⁄8 0.455 7⁄

16

1⁄

4 4.83 8.295 81⁄4 0.740 3⁄

4 11⁄2

WT10.5×34 10.0 10.565 105⁄8 0.430 7⁄

16

1⁄

4 4.54 8.270 81⁄4 0.685 11⁄

16 17⁄16

WT10.5×31 9.13 10.495 101⁄2 0.400 3⁄

8

3⁄

16 4.20 8.240 81⁄4 0.615 5⁄

8 13⁄8

WT10.5×28.5 8.37 10.530 101⁄2 0.405 3⁄

8

3⁄

16 4.26 6.555 61⁄2 0.650 5⁄

8 13⁄8

WT10.5×25 7.36 10.415 103⁄8 0.380 3⁄

8

3⁄

16 3.96 6.530 61⁄2 0.535 9⁄

16 15⁄16

WT10.5×22 6.49 10.330 103⁄8 0.350 3⁄

8

3⁄

16 3.62 6.500 61⁄2 0.450 7⁄

16 13⁄16

WT9×155.5 45.8 11.160 113⁄16 1.520 11⁄2 3⁄

4 17.0 12.005 12 2.740 23⁄4 37⁄16

WT9×141.5 41.6 10.925 1015⁄16 1.400 13⁄8 11⁄

16 15.3 11.890 117⁄8 2.500 21⁄2 33⁄16

WT9×129 38.0 10.730 103⁄4 1.280 11⁄4 5⁄

8 13.7 11.770 113⁄4 2.300 25⁄16 3

WT9×117 34.4 10.530 101⁄2 1.160 13⁄16 5⁄

8 12.2 11.650 115⁄8 2.110 21⁄8 23⁄4

WT9×105.5 31.1 10.335 105⁄16 1.060 11⁄16 9⁄

16 11.0 11.555 111⁄2 1.910 115⁄16 2 ⁄16

9

WT9×96 28.2 10.175 103⁄16 0.960 1 1⁄

2 9.77 11.455 111⁄2 1.750 13⁄4 27⁄16

WT9×87.5 25.7 10.020 10 0.890 7⁄ 7⁄ 8.92 11.375 113⁄8 1.590 19⁄16 21⁄4

8 16

WT9×79 23.2 9.860 97⁄8 0.810 13⁄

16

7⁄

16 7.99 11.300 111⁄4 1.440 17⁄16 21⁄8

WT9×71.5 21.0 9.745 93⁄4 0.730 3⁄

4

3⁄

8 7.11 11.220 111⁄4 1.320 15⁄16 2

WT9×65 19.1 9.625 95⁄8 0.670 11⁄

16

3⁄

8 6.45 11.160 111⁄8 1.200 13⁄16 17⁄8

WT9×59.5 17.5 9.485 91⁄2 0.655 5⁄

8

5⁄

16 6.21 11.265 111⁄4 1.060 11⁄16 13⁄4

WT9×53 15.6 9.365 93⁄8 0.590 9⁄

16

5⁄

16 5.53 11.200 111⁄4 0.940 15⁄

16 15⁄8

WT9×48.5 14.3 9.295 91⁄4 0.535 9⁄

16

5⁄

16 4.97 11.145 111⁄8 0.870 7⁄

8 19⁄16

WT9×43 12.7 9.195 91⁄4 0.480 1⁄

2

1⁄

4 4.41 11.090 111⁄8 0.770 3⁄

4 17⁄16

WT9×38 11.2 9.105 91⁄8 0.425 7⁄

16

1⁄

4 3.87 11.035 11 0.680 11⁄

16 13⁄8

WT9×35.5 10.4 9.235 91⁄4 0.495 1⁄

2

1⁄

4 4.57 7.635 75⁄8 0.810 13⁄

16 11⁄2

WT9×32.5 9.55 9.175 91⁄8 0.450 7⁄

16

1⁄

4 4.13 7.590 75⁄8 0.750 3⁄

4 17⁄16

WT9×30 8.82 9.120 91⁄8 0.415 7⁄

16

1⁄

4 3.78 7.555 71⁄2 0.695 11⁄

16 13⁄8

WT9×27.5 8.10 9.055 9 0.390 3⁄ 3⁄ 3.53 7.530 71⁄2 0.630 5⁄ 15⁄16

8 16 8

WT9×25 7.33 8.995 9 0.355 3⁄ 3⁄ 3.19 7.495 71⁄2 0.570 9⁄ 11⁄4

8 16 16

WT9×23 6.77 9.030 9 0.360 3⁄ 3⁄ 3.25 6.060 6 0.605 5⁄ 11⁄4

8 16 8

WT9×20 5.88 8.950 9 0.315 5⁄ 3⁄ 2.82 6.015 6 0.525 1⁄ 13⁄16

16 16 2

WT9×17.5 5.15 8.850 87⁄8 0.300 5⁄

16

3⁄

16 2.66 6.000 6 0.425 7⁄

16 11⁄8

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

STRUCTURAL TEES (WT, MT, ST) 1 - 75

bf

STRUCTURAL TEES tf k

Y

Cut from W shapes

yp , y

Properties X X

d

tw

Nom- Axis X-X Axis Y-Y Qs*

inal

Wt.

per

ft h I S r y Z yp I S r Z Fy, ksi

tw

lb in.4 in.3 in. in. in.3 in. in.4 in.3 in. in.3 36 50

100.5 10.3 285 31.9 3.10 2.57 58.6 1.18 271 43.1 3.02 66.6 — —

91 11.2 253 28.5 3.07 2.48 52.1 1.07 241 38.6 3.00 59.6 — —

83 12.4 226 25.5 3.04 2.39 46.3 0.984 217 35.0 2.98 53.9 — —

73.5 13.0 204 23.7 3.08 2.39 42.4 0.864 188 30.0 2.95 46.3 — —

66 14.4 181 21.1 3.06 2.33 37.6 0.780 166 26.7 2.93 41.1 — —

61 15.6 166 19.3 3.04 2.28 34.3 0.724 152 24.6 2.92 37.8 — 0.993

55.5 17.1 150 17.5 3.03 2.23 31.0 0.662 137 22.2 2.90 34.1 — 0.917

50.5 18.8 135 15.8 3.01 2.18 27.9 0.605 124 20.2 2.89 30.9 0.990 0.826

46.5 16.2 144 17.9 3.25 2.74 31.8 0.812 46.4 11.0 1.84 17.4 — 0.968

41.5 18.2 127 15.7 3.22 2.66 28.0 0.728 40.7 9.75 1.83 15.3 — 0.856

36.5 20.6 110 13.8 3.21 2.60 24.4 0.647 35.3 8.51 1.81 13.3 0.908 0.730

34 21.8 103 12.9 3.20 2.59 22.9 0.606 32.4 7.83 1.80 12.2 0.853 0.664

31 23.5 93.8 11.9 3.21 2.58 21.1 0.554 28.7 6.97 1.77 10.9 0.784 0.583

28.5 23.2 90.4 11.8 3.29 2.85 21.2 0.638 15.3 4.67 1.35 7.42 0.793 0.592

25 24.7 80.3 10.7 3.30 2.93 20.8 0.771 12.5 3.82 1.30 6.09 0.733 0.533

22 26.8 71.1 9.68 3.31 2.98 17.6 1.06 10.3 3.18 1.26 5.09 0.638 0.460

155.5 5.3 383 46.5 2.89 2.93 90.6 1.91 398 66.2 2.95 104 — —

141.5 5.7 337 41.5 2.85 2.80 80.1 1.75 352 59.2 2.91 92.5 — —

129 6.3 298 37.0 2.80 2.68 71.0 1.61 314 53.4 2.88 83.2 — —

117 6.9 260 32.6 2.75 2.55 62.4 1.48 279 47.9 2.85 74.5 — —

105.5 7.5 229 29.0 2.72 2.44 55.0 1.34 246 42.7 2.82 66.2 — —

96 8.3 202 25.8 2.68 2.34 48.5 1.23 220 38.4 2.79 59.4 — —

87.5 9.0 181 23.4 2.66 2.26 43.6 1.13 196 34.4 2.76 53.1 — —

79 9.9 160 20.8 2.63 2.18 38.5 1.02 174 30.7 2.74 47.4 — —

71.5 11.0 142 18.5 2.60 2.09 34.0 0.938 156 27.7 2.72 42.7 — —

65 11.9 127 16.7 2.58 2.02 30.5 0.856 139 24.9 2.70 38.3 — —

59.5 12.3 119 15.9 2.60 2.03 28.7 0.778 126 22.5 2.69 34.6 — —

53 13.6 104 14.1 2.59 1.97 25.2 0.695 110 19.7 2.66 30.2 — —

48.5 15.0 93.8 12.7 2.56 1.91 22.6 0.640 100 18.0 2.65 27.6 — —

43 16.7 82.4 11.2 2.55 1.86 19.9 0.570 87.6 15.8 2.63 24.2 — 0.937

38 18.9 71.8 9.83 2.54 1.80 17.3 0.505 76.2 13.8 2.61 21.1 0.990 0.826

35.5 16.2 78.2 11.2 2.74 2.26 20.0 0.683 30.1 7.89 1.70 12.3 — 0.963

32.5 17.8 70.7 10.1 2.72 2.20 18.0 0.629 27.4 7.22 1.69 11.2 — 0.877

30 19.3 64.7 9.29 2.71 2.16 16.5 0.583 25.0 6.63 1.69 10.3 0.964 0.796

27.5 20.6 59.5 8.63 2.71 2.16 15.3 0.538 22.5 5.97 1.67 9.27 0.913 0.735

25 22.6 53.5 7.79 2.70 2.12 13.8 0.489 20.0 5.35 1.65 8.29 0.823 0.625

23 22.3 52.1 7.77 2.77 2.33 13.9 0.558 11.3 3.72 1.29 5.85 0.831 0.635

20 25.5 44.8 6.73 2.76 2.29 12.0 0.489 9.55 3.17 1.27 4.97 0.690 0.496

17.5 26.8 40.1 6.21 2.79 2.39 12.0 0.450 7.67 2.56 1.22 4.03 0.638 0.460

*Where no value of Qs is shown, the Tee complies with LRFD Specification Section E2.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

Vous aimerez peut-être aussi

- 6L45 6L90 Zip in PDFDocument12 pages6L45 6L90 Zip in PDFAnonymous WzR5h9g8V100% (3)

- Surge Analysis Alabama FacilityDocument73 pagesSurge Analysis Alabama FacilityCONNOR MENSAH100% (1)

- 307Document140 pages307Mihail Barna100% (3)

- Modeling and Control of Wind Power System PDFDocument212 pagesModeling and Control of Wind Power System PDFAdel Klk50% (2)

- Sheet Metal Screws Through Gypsum Board Wall Sheathing: RecentlyDocument4 pagesSheet Metal Screws Through Gypsum Board Wall Sheathing: Recentlytigani brigdarPas encore d'évaluation

- Siemens Pipeline Compressor PDFDocument19 pagesSiemens Pipeline Compressor PDFMilos BajicPas encore d'évaluation

- Compressive Strength For Cast-In-Place Concrete: Table 1.7Document25 pagesCompressive Strength For Cast-In-Place Concrete: Table 1.7Ayban Dela CruzPas encore d'évaluation

- Sfa-5 7Document10 pagesSfa-5 7Armando Lujan VelazquezPas encore d'évaluation

- Bahan Dan Struktur Jalan RayaDocument59 pagesBahan Dan Struktur Jalan RayaHizbulmalik ZiyanPas encore d'évaluation

- Bahan Dan Struktur Jalan RayaDocument59 pagesBahan Dan Struktur Jalan RayaHizbulmalik ZiyanPas encore d'évaluation

- Aseptic FillingDocument5 pagesAseptic FillingMIKEPas encore d'évaluation

- Installation With Mortar - Umlauf 2015Document18 pagesInstallation With Mortar - Umlauf 2015Moud SaklyPas encore d'évaluation

- Moeller DF5 Manual PDFDocument140 pagesMoeller DF5 Manual PDFspiritos1234567890% (1)

- 5010 Dismatling Joints Edition3 En0607Document3 pages5010 Dismatling Joints Edition3 En0607AhmedRamadan100% (1)

- Table 1-1. Availability of Shapes, Plates, and Bars According To ASTM Structural Steel SpecificationsDocument17 pagesTable 1-1. Availability of Shapes, Plates, and Bars According To ASTM Structural Steel SpecificationsAwi YakumoshiPas encore d'évaluation

- Stell Construction - Perfiles AISC - LRFDDocument112 pagesStell Construction - Perfiles AISC - LRFDelpijuPas encore d'évaluation

- Wire Welded Fabric Mesh PDFDocument2 pagesWire Welded Fabric Mesh PDFHarish RajaramPas encore d'évaluation

- Minimum Bolt Tension Per AISC 360-16, Table J3.1: Bolt Diameter, In. A325 Bolts A490 BoltsDocument2 pagesMinimum Bolt Tension Per AISC 360-16, Table J3.1: Bolt Diameter, In. A325 Bolts A490 Boltsrob westoverPas encore d'évaluation

- Snap AnvilDocument2 pagesSnap AnvilhanselltechfirePas encore d'évaluation

- Vemis Steel Firm CatalogDocument18 pagesVemis Steel Firm CatalogSaddam BousbataPas encore d'évaluation

- S&T - Design 2013 - 2 PDFDocument40 pagesS&T - Design 2013 - 2 PDFSalmanPas encore d'évaluation

- MarinersDocument1 454 pagesMarinersJulian SanchezPas encore d'évaluation

- Mechanical-T Bolted Branch Outlet: Victaulic Firelock Style 927Document15 pagesMechanical-T Bolted Branch Outlet: Victaulic Firelock Style 927Kenix TehPas encore d'évaluation

- Threaded Mechanical Branch TeeDocument2 pagesThreaded Mechanical Branch TeeJulian RiverosPas encore d'évaluation

- Hot Rolled Sheets: LARSSEN (U) SectionsDocument1 pageHot Rolled Sheets: LARSSEN (U) SectionsdikhwanaPas encore d'évaluation

- Basalt Catalogue-CDocument4 pagesBasalt Catalogue-Cdanny buiPas encore d'évaluation

- AssyDocument1 pageAssyArief FibonacciPas encore d'évaluation

- Victaulic Firelock Low-Profile Sprinkler-Tee Style 912: 1.0 Product DescriptionDocument3 pagesVictaulic Firelock Low-Profile Sprinkler-Tee Style 912: 1.0 Product DescriptionRemus PacurarPas encore d'évaluation

- MarinoWARE Cold Formed Steel Framing Suggested ConnectionsDocument1 pageMarinoWARE Cold Formed Steel Framing Suggested ConnectionsJon CatalanPas encore d'évaluation

- Salcedo Housing Project Estimated MaterialsDocument2 pagesSalcedo Housing Project Estimated MaterialsJayson DaiganPas encore d'évaluation

- Turnbuckle AssembliesDocument4 pagesTurnbuckle AssembliesarbiPas encore d'évaluation

- Victaulic AGS Rigid Coupling Style W07: 1.0 Product DescriptionDocument6 pagesVictaulic AGS Rigid Coupling Style W07: 1.0 Product DescriptionFrancisco VillaPas encore d'évaluation

- For K 0.156, Compression Steel Required.: Structures & Tall Buildings (CON4338) Data Page 1Document12 pagesFor K 0.156, Compression Steel Required.: Structures & Tall Buildings (CON4338) Data Page 1Ho JamesPas encore d'évaluation

- Conical StrainerDocument2 pagesConical StrainernguyennhatbaoPas encore d'évaluation

- REGULAR TYPE Creep Hoist With Motor-Driven TrolleyDocument21 pagesREGULAR TYPE Creep Hoist With Motor-Driven TrolleyDo BuiPas encore d'évaluation

- SpecificationDocument2 pagesSpecificationToxic ToucanPas encore d'évaluation

- Filtro de Gas - MUELLERDocument2 pagesFiltro de Gas - MUELLERCarlos BaezaPas encore d'évaluation

- Zinc Alloys - Properties, Processing and Applications - MatmatchDocument9 pagesZinc Alloys - Properties, Processing and Applications - Matmatchshahin azPas encore d'évaluation

- Quantity EstimateDocument59 pagesQuantity EstimateJohn Christopher JusayanPas encore d'évaluation

- Perfiles WDocument18 pagesPerfiles Wlizzy MartinezPas encore d'évaluation

- Cone Fender SPC1100Document14 pagesCone Fender SPC1100tabah sentosaPas encore d'évaluation

- Acoplamentos Sitex PDFDocument4 pagesAcoplamentos Sitex PDF3DLAB CAD/CAMPas encore d'évaluation

- Tank List PLTU Palu: S.G Water 1000 Volume S.F 1.1 SF Weight 1.2Document1 pageTank List PLTU Palu: S.G Water 1000 Volume S.F 1.1 SF Weight 1.2Anonymous lQiANQusxiPas encore d'évaluation

- 5 STOREY GDS SCBF Connection DesignDocument1 page5 STOREY GDS SCBF Connection DesigndantevariasPas encore d'évaluation

- Catalogo WsDocument18 pagesCatalogo WsGABRIEL BRUNO CALLEJAS PARRAGAPas encore d'évaluation

- Quantity EstimateDocument64 pagesQuantity Estimatefrancis sebastian lagamayoPas encore d'évaluation

- Weight of G.I.Strip Flat KG MT.: X X X X X X X X XDocument2 pagesWeight of G.I.Strip Flat KG MT.: X X X X X X X X XHiral SolankiPas encore d'évaluation

- Bolt Data: Non-Preloaded Ordinary Bolts Grade 4.6 Bolts in S275 DmeterDocument1 pageBolt Data: Non-Preloaded Ordinary Bolts Grade 4.6 Bolts in S275 DmeterAlphyl BalasabasPas encore d'évaluation

- Hyundai Steel Products GuideDocument40 pagesHyundai Steel Products GuidecarloPas encore d'évaluation

- SDL J (Pedestal)Document4 pagesSDL J (Pedestal)SURAJ SINHAPas encore d'évaluation

- Com. BLDGDocument12 pagesCom. BLDGLenon RugayanPas encore d'évaluation

- Features: Water WaterDocument1 pageFeatures: Water WaterajsdlkasjdklPas encore d'évaluation

- EVRO - PROFIL-Steel Profile CatalogDocument12 pagesEVRO - PROFIL-Steel Profile CatalogOleksandrMISPas encore d'évaluation

- 1000 WOG, Economical Type 2-PC Body, Full Port Thread Ends Ball ValveDocument4 pages1000 WOG, Economical Type 2-PC Body, Full Port Thread Ends Ball ValveabrahamPas encore d'évaluation

- 0007335-Course - Segmented and Perforated Shear WallsDocument15 pages0007335-Course - Segmented and Perforated Shear Wallsmeda012Pas encore d'évaluation

- Substation Design DataDocument23 pagesSubstation Design DataHugh cab100% (1)

- Core Design Sheet 2000 KVA, 11 / 0.415 KVDocument5 pagesCore Design Sheet 2000 KVA, 11 / 0.415 KVwecanbdPas encore d'évaluation

- Victaulic Carbon Steel Couplings and Grooved FittingsDocument16 pagesVictaulic Carbon Steel Couplings and Grooved FittingsAnonymous 7I5qQ0eAxgPas encore d'évaluation

- DatasheetDocument16 pagesDatasheetErick MauricioPas encore d'évaluation

- Multilayer Chip Capacitors X7R/B Characteristic: FeaturesDocument17 pagesMultilayer Chip Capacitors X7R/B Characteristic: FeaturesLupita Motta TobíasPas encore d'évaluation

- Technical Data K-Ball VibratorDocument1 pageTechnical Data K-Ball VibratorautomatizacionPas encore d'évaluation

- Sealed Self-Aligning Roller Bearings - WA Type: CorporationDocument7 pagesSealed Self-Aligning Roller Bearings - WA Type: CorporationWin LaboraPas encore d'évaluation

- Safety GratingDocument21 pagesSafety GratingAhmed IrakyPas encore d'évaluation

- TDG 19 CLT DiaphragmsDocument6 pagesTDG 19 CLT DiaphragmsCarsonBakerPas encore d'évaluation

- Brida Flexible VitaulicDocument3 pagesBrida Flexible VitaulicG Abigail MorenoPas encore d'évaluation

- NR20 Pipe Riser Clamp Spec SheetDocument1 pageNR20 Pipe Riser Clamp Spec SheetFrancisPas encore d'évaluation

- Threadbars (Imperial Units) : Dywidag - Technical DataDocument1 pageThreadbars (Imperial Units) : Dywidag - Technical Dataradi_ashrafPas encore d'évaluation

- Nyumba Ya Akiba-Cement Plant 3000 TPD Songololo Lime Crusher -111 Bar Bending ScheduleDocument17 pagesNyumba Ya Akiba-Cement Plant 3000 TPD Songololo Lime Crusher -111 Bar Bending ScheduleSmart KhanPas encore d'évaluation

- Flat Oval Spiral Pipe & Fittings: Sheet Metal Connectors, Inc. (SMC)Document4 pagesFlat Oval Spiral Pipe & Fittings: Sheet Metal Connectors, Inc. (SMC)Shaun SullivanPas encore d'évaluation

- Laga-An Health Center ExtensionDocument4 pagesLaga-An Health Center ExtensionJan DavesonPas encore d'évaluation

- Syaiful Syam: Format Nama Zoom No UrutDocument1 pageSyaiful Syam: Format Nama Zoom No UrutAwi YakumoshiPas encore d'évaluation

- Hydration of Portland Cement: December 2001Document30 pagesHydration of Portland Cement: December 2001Awi YakumoshiPas encore d'évaluation

- Tata Pipa B OkDocument31 pagesTata Pipa B OkAwi YakumoshiPas encore d'évaluation

- Tubes New OnoDocument132 pagesTubes New OnoAwi YakumoshiPas encore d'évaluation

- Venturi Meter OkDocument10 pagesVenturi Meter OkAwi YakumoshiPas encore d'évaluation

- Tata Pipa A OkDocument33 pagesTata Pipa A OkAwi YakumoshiPas encore d'évaluation

- Venturi Meter OkDocument10 pagesVenturi Meter OkAwi YakumoshiPas encore d'évaluation

- Optimizing Air Instrument KPIsDocument31 pagesOptimizing Air Instrument KPIsMindiRahayuPas encore d'évaluation

- G02 FinalReport PDFDocument78 pagesG02 FinalReport PDFLuciferPas encore d'évaluation

- Basic SWOT MatrixDocument1 pageBasic SWOT MatrixTarenjeet SinghPas encore d'évaluation

- Battery Free CellphoneDocument13 pagesBattery Free CellphoneANAYAT .H.WANI78% (27)

- L P GDocument11 pagesL P GPhi MacPas encore d'évaluation

- Lathan Esei 5png TermoplastikDocument2 pagesLathan Esei 5png TermoplastikMell Honey MardenPas encore d'évaluation

- Gen 3 Partners - Triz Companies DatabaseDocument10 pagesGen 3 Partners - Triz Companies DatabaseTRIZtease100% (2)

- QCM E190Document18 pagesQCM E190Adil KhPas encore d'évaluation

- Workstation Assembly Instructions PDFDocument1 pageWorkstation Assembly Instructions PDFChris EfstathiouPas encore d'évaluation

- Assignment IDocument2 pagesAssignment IShivpreet SharmaPas encore d'évaluation

- Bill of Quantities & Price Schedule - Lobby InteriorsDocument14 pagesBill of Quantities & Price Schedule - Lobby InteriorsAnonymous P7VckOJZUgPas encore d'évaluation

- Yea Kaeps800000042k SGDV Ac APDocument24 pagesYea Kaeps800000042k SGDV Ac APthanh_cdt01Pas encore d'évaluation

- Maxon DC MotorDocument16 pagesMaxon DC MotorteguhPas encore d'évaluation

- Test Results: Supreeth Raghuprakash, Hai Le Dang, Steven Engelen, Bert MonnaDocument1 pageTest Results: Supreeth Raghuprakash, Hai Le Dang, Steven Engelen, Bert MonnafidoruckPas encore d'évaluation

- Quickly Overcome Obstacles: LukasDocument2 pagesQuickly Overcome Obstacles: LukasArrum FirdaPas encore d'évaluation

- Catalogue FTHC Daikin CAT 700-5 LR Horz-Cncld Fan Coil CatalogDocument12 pagesCatalogue FTHC Daikin CAT 700-5 LR Horz-Cncld Fan Coil CatalogElvin SolisPas encore d'évaluation

- Fire Paint Area - QuantityDocument19 pagesFire Paint Area - QuantityBurning TrainPas encore d'évaluation

- Demontare V158Document3 pagesDemontare V158Oferta AnuntPas encore d'évaluation

- Attached Growth SystemDocument42 pagesAttached Growth SystemRiyad ArafatPas encore d'évaluation

- IDirect Spec Sheet Ku PLL LNB 0515Document3 pagesIDirect Spec Sheet Ku PLL LNB 0515Promise KumaloPas encore d'évaluation

- MultiFlow SeningDocument51 pagesMultiFlow SeningOlgaPas encore d'évaluation