Académique Documents

Professionnel Documents

Culture Documents

Next-Generation Power Electronics: Tatsuo Oomori

Transféré par

Pankaj RupaniTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Next-Generation Power Electronics: Tatsuo Oomori

Transféré par

Pankaj RupaniDroits d'auteur :

Formats disponibles

Next-Generation Power Electronics

Power Electronics Devices Everywhere, for an Energy-Efficient

Society and more Affluent Lifestyles

Power electronics address power issues in the super smart

society of the future

Anyone could wish a future society that balances the environment with lifestyle conveniences. And power electronics is a

key technology to realize such the future. Already, improvements in power electronics development have resulted in energy

savings for everything from home appliances to trains. The global market of power electronics is poised for significant

future growth, and Japan has the opportunity to develop world-leading next-generation power electronics technologies that

will provide both competitive industry advantage and an energy-efficient society enjoying more affluent lifestyles.

Program Director

Profile

Tatsuo Tatsuo Oomori graduated from the University of Tokyo with an MS

degree in Electronic Engineering in 1980, after which he joined Mitsubishi

Electric Corporation Central Research Laboratory. He was promoted to

Oomori manager of the company's Advanced Device Technology Department,

Advanced Technology R&D Center in 2003. Named SiC Device

Development Group Manager in 2005, Oomori was next promoted to

Power Device Works Deputy General Manager in 2010. He was appointed

Mitsubishi Electric Corporation Corporate Research and Development Group Fellow in 2013, and then

Chief Technical Adviser, Corporate to Chief Technical Adviser of the Corporate Research and Development

Research and Development Group Group in 2016.

Research and Development Topics

Ⅰ. Create a center for common basic technology development related to SiC

To promote the development of basic technologies underlying SiC (silicon carbide) power electronics devices, we will set up a R&D

center that brings together the public, private and academic sectors to design the next generation of SiC wafers, devices and modules.

These advancements will produce more compact, more reliable technologies capable of handling higher voltages with minimal losses.

The new center will also provide researcher training programs.

Ⅱ. Create a center for common basic technology development related to GaN

To bolster basic technologies for gallium nitride (GaN) power electronics, the program will construct a research center as a home for a

network of industry-academy-government experts. The center will focus on developing reliable production systems for next-generation

GaN wafers for power devices with minimal defect rates as well as vertical GaN power devices.

Ⅲ. Conduct basic research and development for next-generation power module application

To promote the use of next-generation power

modules and broaden the scope of potential

•R&D Conceptual Diagram: Next-Generation Power Electronics

applications, the program will develop

implementation technologies for more efficient SIP

high-performance power converter systems and

Applications for next-generation power modules

more efficient motor drive systems that offer high • Implementation technologies for next-generation power module circuits

Devices and

power density. In addition, the program will use Circuits

and systems

• Product prototypes and operational testing

simulation technologies to enable the efficient Ultra-high-voltage multi-level DC power converters, 6.6 kV

interconnected transformerless

integration of these systems into power modules power converters, fully integrated EV motor drive inverters New

Circuits/Software

and to aid in the design of product prototypes. Next-Generation SiC Modules • Power processing

Ⅳ. Conduct basic research and development

• Ultra-compact, high-current density technology

Modules

module technologies

(Implementation

• Development of high-temperature, high-current

to support future power electronics

technologies and

high-temperature, density, high-voltage material components New Material

high voltage passive • Module design and reliability technologies Technologies

To produce high-performance power devices that components) • Heat-resistant modules for automotive applications

• Ga 2O 3 (gallium

oxide) power

Next-Generation SiC Devices

surpass SiC and GaN, the program will conduct • Insulated gate bipolar transistors (IGBT)

Next-Generation devices

GaN Devices • Diamond power

Devices

research for innovative performance improvements. • PiN junction diodes

• Super-Junction field-effect

• Vertical power devices devices

This will include pioneering Ga2O3 (gallium oxide), transistors

Next-Generation

diamond, and other new materials, as well as Wafer and

Next-Generation SiC Wafers GaN Wafers

• High-voltage devices • High-quality

developing new structures and circuits supporting Epitaxial Low-stress multi-layer wafers with

Materials thick film wafers low defect

foundational technologies beyond traditional power • Conductivity control technology density

electronics. The goal of this work is to achieve Basic

Technologies Silicon carbide (SiC) Gallium nitride (GaN) Future Technologies

commercialization within the next 10 to 15 years.

12 Cross-ministerial Strategic Innovation Promotion Program (SIP)

Exit Strategies

Consider and formulate strategy

Consider and formulate a strategy for activities toward creating an ideal society, as well as for finding new applications and

implementation of power electronics technologies geared towards the world of 2030. Create new industries and markets based on power

electronics, and pursue intellectual property and standardization strategies. Utilize NEDO studies to pursue new market opportunities

by envisaging the future world of 2030, designing the applications needed to achieve this vision. Work backwards (backcasting) from

performance specifications in applications to produce a roadmap for a seamlessly integrated technology hierarchy that encompasses all

stages from input materials through final products.

Prove required performance levels through prototyping

Prove performance, quality, and manufacturability using prototypes to demonstrate successful development of technologies that meet

performance and specification requirements identified via backcasting from the applications. Promote the development of product

commercialization in industry.

Engage in activities to promote adoption of results

Conduct standardization and other activities to promote the adoption of program results. Research the best standardized test methods

for assessing the performance of component parts to promote standardization. Promote research of a performance certification system

for each component and material. Set up a research consortium to develop related technologies and promote the wider adoption of

research outcomes.

Implementation Structure Cabinet Office PD (Tatsuo Oomori)

Sub-PD Promoting Committee

Establish a Promoting Committee consisting of (Professor Hori, University of Tokyo) (open to public)

representatives of government ministries and experts

guided by the Program Director (PD) and the Information Sharing and Tie-Ups

NEDO Public Symposia

Cabinet Office. Utilize the resources of NEDO and

leverage the NEDO relationship with JST to help in

selecting research project leaders and assist the PD Intellectual Property Committee Leadership Council Workshop

and Promoting Committee.

Set up an Intellectual Property Committee, a

Leadership Council, and workshops at the underlying Waseda

Tokyo Shibaura

Institute of Institute of Universities and

levels. With the exception of public symposiums, these AIST, etc. University,

etc.

Kyoto University, etc.

Technology, Technology, Research Institutes

etc. etc.

organizations will be run under a closed structure,

SiC SiC SiC Modules for GaN GaN GaN Power Electrome- Foundation New

while inside cross-pollination, frank discussion, Wafers Devices Modules Automotive Wafers Devices Basic Electronics chanically for New Circuits/

and horizontal partnerships are encouraged. These Applications Technologies Device Integrated Materials Software

Integrated Inverter

organizations will coordinate materials assessment System

in conjunction with AIST and universities, separate Research and Research and Research and Research and

from the SIP. This will enable discussion and debate Development Items Ⅰ Development Items Ⅱ Development Items Ⅲ Development Items Ⅳ

throughout the organization as a whole.

Progress to Date

Prototypes already completed for some technologies

Several SiC (silicon carbide) power electronics device designs are •A power module with embedded passive elements

already at the product development stage. However, there is still

room for further improvement in SiC performance characteristics. 1,200 V 100 A

Based on optimized device designs, we have built prototypes for two-in-one module

next-generation compact high-speed SiC modules that are three Current and voltage

Approx.

times smaller than conventional modules. We accomplished this by 約17㎜

17mm waveform stabilized

embedding next-generation SiC devices designed for high voltages and through design

Approx. optimization

high-speed operations, together with passive elements optimized to 約36㎜

36mm

the performance characteristics of SiC materials. We are on track to

complete testing technology for a 6.6 kV interconnected transformerless

power converter that is four times smaller than a standard factory

30mm

power converter. The GaN (gallium nitride) development program is (Example) Current typical module

ahead of schedule, with successes in wafer quality as well as exciting without

6 0m

new developments in power device basic technology.

passive elements

m

10 0mm

Cross-ministerial Strategic Innovation Promotion Program (SIP) 13

Program Director Tatsuo Oomori Interview

Developing technologies for

new materials beyond silicon

Power electronics represents a key technology for electronic device energy savings in everything from home

appliances to trains. SIP has had a number of successes in the development of technologies for new materials

beyond Si (silicon), to strengthen this area where Japanese research has already been well advanced.

miniaturization. The next stage involves planning reliability

SiC devices on the path to commercialization testing with a view to commercialization by the year 2020

Next-generation power electronics represents a key or so. We have produced a scaled-down prototype of 6.6 kV

technology for the energy-conscious world of the future. interconnected transformerless high-voltage power converter

Program Director Tatsuo Oomori reflected on the designed for industrial applications. We plan to use this for

achievements over the last two years. testing and system validation.

“This was the first real attempt at a genuine collaboration

Next-generation GaN materials now at the validation

between government, private enterprise and the academic sector

testing stage

in Japan. There were some difficulties at the initial stage, not

the least of which was a sort of language barrier between the GaN (gallium oxide) is an exciting next-generation material

universities and the private-sector companies. But once we that holds the key to vertical device development. Researchers

started talking properly together, we were able to coordinate are working to enhance quality standards for GaN wafers

our ideas and begin pulling in the same direction. Asking the as the core technology in power devices. GaN wafer quality

universities to produce concrete results actually made it easier standards are steadily improving with respect to operational

for them to come up with concepts and drive the R&D work.” stability and efficiency.

Let’s take a look at some of the achievements in each domain “There are still many technical hurdles to overcome and

thus far, early in the third year of the program. it will take several years before large GaN wafers can be

A number of compact high-performance power electronics made to the required quality standards. We hope to achieve

products featuring the next-generation SiC (silicon carbide) commercialization by around 2025, and perhaps even get there

materials are already at the product development stage. a bit earlier than that,” says Oomori.

Even so, there is still room for further improvement We are working on futuristic power devices designed

in SiC performance characteristics. SiC high-speed to operate at very high voltages with minimal losses.

modules developed using high-voltage SiC devices also At this stage, we are identifying the main challenges

feature embedded passive elements that allow significant to commercialization of power electronics featuring

new materials such as Ga2O3

•Conceptual diagram for SiC base common core technology development research structure

(gallium trioxide) and diamond.

Evaluation and Verification Meanwhile, research designed to

Basic Research Identify Issues Module Development

Industry-Academy-Government yield revolutionary performance

Research of Phenomena Implementation

Cooperative Structure improvements, such as new

Research of Mechanisms Propose Verifications Technology

of Principles structures and circuits that constitute

Device Supply,

the core future technologies that

Test Products go beyond conventional power

Evaluation and Verification electronics. These advancements will

Basic Research Identify Issues lead to power processing systems

Industry-Academy-Government Establish

Research of Phenomena Device Development Cooperative Structure capable of computing electrical

Research of Mechanisms Propose Verifications Network

power based on finite power sources.

of Principles

This, in turn, will drive a significant

Wafer Test

increase in potential applications

Item/Test

for power electronics. We expect

Evaluation and Verification

Basic Research Identify Issues commercialization in this field by the

Industry-Academy-Government year 2030 or thereabout.

Research of Phenomena Wafer Development Cooperative Structure

Research of Mechanisms Propose Verifications

of Principles

14 Cross-ministerial Strategic Innovation Promotion Program (SIP)

Next-Generation Power Electronics

Power Electronics Devices Everywhere, for an Energy-Efficient Society and more Affluent Lifestyles

Energy-saving technology ideas for the super smart experience in building and operating power electronics devices.

society of the future Power electronics is expected to make an important

contribution to the upcoming Society 5.0.

At the beginning of the third year of this program, we conducted Says Oomori, "We are seeing the advent of a super smart

a review of program content, systems, etc. Our focus was on society built on Big Data. But there is always the issue of power

identifying key areas of research deemed feasible within the in operating devices once the information has been processed.

remaining three years of the program related to core future The potential applications of power electronics are not limited

technologies in new circuits and materials. We also identified the to data centers. Next-generation power processing can be used

key challenges on the path toward achieving concrete results. to minimize power losses even further.”

We continue to raise targets to drive development in other While Japan is making steady advancements in energy-saving

areas as well. In terms of operating structures, we provide home appliances, there is still much room to contribute to

a variety of forums for demonstration, assessment, and power electronics across the world. By broadening the scope of

discussion. These include closed workshops within SIP, venues applications of low-cost high-performance power electronics

for discussion among researchers from various fields, and a devices, our nation could establish a dominant market position

consortium-style body that encompasses universities and AIST. through SiC devices and modules alone. This market is

As far as human resources training, we are conducting potentially worth hundreds of billions of yen. At the same time

practical sessions and university classes in conjunction we can make a significant contribution to addressing global

with NEDO to provide younger researchers with hands-on energy issues.

Future Plans

As we head towards the last year of the program, we are conducting validation tests of SiC modules for fully integrated

in-wheel motors used in cars, looking to develop products ultimately. We are making advancements in larger GaN

wafers that offer optimum quality standards, as well as in technologies for new materials, structures, and circuits.

FY 2014 2015 2016 2017 2018

Ⅰ. Create a center for

Verification

Prototype

Interconnection among

common basic Component Technology Applied Technology

Element Technology

technology development Development Development

Developments

related to SiC

Ⅱ. Create a center for Research and

Verification

Prototype

common basic Development Application Technology

Application Technology Development

technology development Facilities and Development

related to GaN Structure

Ⅲ. Conduct basic research Research and

Verification

Prototype

and development for Development Applied Technology

Component Technology Development

next-generation power Facilities and Development

module application Structure

Ⅳ. Conduct basic research Set up a technology

Stage-Gate

Technology verification and

and development to verification develop technology

necessary component and

support future power structure, verification systems

technology development

electronics define key issues

Develop compact high-performance power

electronics devices to establish a competitive

edge in global markets and contribute to

solutions for energy issues.

Cross-ministerial Strategic Innovation Promotion Program (SIP) 15

Vous aimerez peut-être aussi

- MembinamatlamatkerjayaDocument15 pagesMembinamatlamatkerjayaMuhd Nur SalamPas encore d'évaluation

- Apresentação APROT BR - ENDocument31 pagesApresentação APROT BR - ENAndré SuzukiPas encore d'évaluation

- CST Studio Suite: Electromagnetic Field Simulation SoftwareDocument8 pagesCST Studio Suite: Electromagnetic Field Simulation SoftwareSOLIDWORKS Indonesia - PT Arisma Data SetiaPas encore d'évaluation

- Hitachi Development in Traction For Dump TruckDocument10 pagesHitachi Development in Traction For Dump Truckamir sadighiPas encore d'évaluation

- A Modular Simulink-Based Controlled Three-Phase Switch Mode InverterDocument7 pagesA Modular Simulink-Based Controlled Three-Phase Switch Mode InverterLee EzzitouniPas encore d'évaluation

- Pavan Singh Tomar, PHD: ObjectiveDocument3 pagesPavan Singh Tomar, PHD: ObjectivePAVAN SINGH TOMARPas encore d'évaluation

- IoT Home Automation ProposalDocument9 pagesIoT Home Automation ProposalLiaqat Hussain BhattiPas encore d'évaluation

- Report On Study of Electrical Equipments in Power SystemDocument92 pagesReport On Study of Electrical Equipments in Power Systemvanya gupta100% (2)

- GaN TransistorsDocument4 pagesGaN TransistorsDheeraj SharmaPas encore d'évaluation

- Digital Substation Dream or NightmareDocument10 pagesDigital Substation Dream or NightmarejulioPas encore d'évaluation

- Master of Engineering (Electrical Engineering) : Program SnapshotDocument4 pagesMaster of Engineering (Electrical Engineering) : Program SnapshotHans DegayPas encore d'évaluation

- Leistelek enDocument8 pagesLeistelek enBalramPas encore d'évaluation

- EV Charging Using Wireless Power TransmissionDocument8 pagesEV Charging Using Wireless Power Transmissionதளபதி PraveenPas encore d'évaluation

- Joint Professional Training Course 2024Document5 pagesJoint Professional Training Course 2024acforofficeusePas encore d'évaluation

- It ReportDocument13 pagesIt ReportNiño BangcalePas encore d'évaluation

- Project Phase 2Document13 pagesProject Phase 2Lalit SinghalPas encore d'évaluation

- ABB HVAC Webinars Managing Your Specification For HVACR Projects 29072020Document22 pagesABB HVAC Webinars Managing Your Specification For HVACR Projects 29072020dave chaudhuryPas encore d'évaluation

- Ijres-V18p103 5Document10 pagesIjres-V18p103 5Usha ParmarPas encore d'évaluation

- Siemens PLM Adding Intelligence To Your Electrical System EbookDocument8 pagesSiemens PLM Adding Intelligence To Your Electrical System EbookSARAPas encore d'évaluation

- Optical BrochureDocument6 pagesOptical BrochureMujeeb AhmedPas encore d'évaluation

- WIESL Company ProfileDocument9 pagesWIESL Company Profilesamadmuse444Pas encore d'évaluation

- Technical and System Requirements For Advanced Distribution Automation PDFDocument5 pagesTechnical and System Requirements For Advanced Distribution Automation PDFNmg KumarPas encore d'évaluation

- Power Flow Analysis in Smart Grid Network For EV InfrastructureDocument12 pagesPower Flow Analysis in Smart Grid Network For EV InfrastructureMichael MufambaPas encore d'évaluation

- BROCHURE-Smart Grid MarketsDocument2 pagesBROCHURE-Smart Grid Marketssubbanna chPas encore d'évaluation

- Abdul Khaliq Mohammed: ContactDocument4 pagesAbdul Khaliq Mohammed: ContactAchrefPas encore d'évaluation

- Smart Energy Meter With Power Usage Monitoring and Controlling Using IotDocument5 pagesSmart Energy Meter With Power Usage Monitoring and Controlling Using IotSsanta SanthosshPas encore d'évaluation

- TNSCST-Student Project Scheme2Document6 pagesTNSCST-Student Project Scheme2Maha LakshmiPas encore d'évaluation

- Modern Electrical Machine Design Optimization Techniques, Trends and Best PracticesDocument13 pagesModern Electrical Machine Design Optimization Techniques, Trends and Best PracticesZxytm Xyt MPas encore d'évaluation

- Design and Operation of Smart Energy Meter For Effective Energy Utilization in Smart CitiesDocument5 pagesDesign and Operation of Smart Energy Meter For Effective Energy Utilization in Smart CitiesKelly joyPas encore d'évaluation

- ASV Ieee Micro03 2Document12 pagesASV Ieee Micro03 2vidya gubbalaPas encore d'évaluation

- Overview of The DOE VTO Electric Drive Technologies R&D ProgramDocument23 pagesOverview of The DOE VTO Electric Drive Technologies R&D ProgramilyasoftPas encore d'évaluation

- High Speed Electrical Machines - Technologies, Trends and DevelopmentsDocument15 pagesHigh Speed Electrical Machines - Technologies, Trends and Developments劉振邦Pas encore d'évaluation

- SERVODocument7 pagesSERVONicole RodriguezPas encore d'évaluation

- Resume of Chandan Das GuptaDocument2 pagesResume of Chandan Das GuptaSS EntertainmentPas encore d'évaluation

- Siwes Report On NetworkingDocument22 pagesSiwes Report On Networkingali purityPas encore d'évaluation

- Lvped216026en WebDocument235 pagesLvped216026en WebUsman IsmailPas encore d'évaluation

- MasterPact MTZDocument234 pagesMasterPact MTZfirasalthiyabyPas encore d'évaluation

- 2015 Model Predictive Control MPC's Role in The Evolution of Power ElectronicsDocument15 pages2015 Model Predictive Control MPC's Role in The Evolution of Power Electronicsdaiduongxanh14113Pas encore d'évaluation

- Relay Software Models For Use With: Electromagnetic Transient Analysis ProgramsDocument3 pagesRelay Software Models For Use With: Electromagnetic Transient Analysis ProgramsPabloPas encore d'évaluation

- Relay Software Models For Use With: Electromagnetic Transient Analysis ProgramsDocument3 pagesRelay Software Models For Use With: Electromagnetic Transient Analysis ProgramsPabloPas encore d'évaluation

- WIFI-Based Smart Grid for Renewable Energy Monitoring and ControlDocument6 pagesWIFI-Based Smart Grid for Renewable Energy Monitoring and ControlAnonymous ytZsBOVPas encore d'évaluation

- EMTP-RV Newsletter 2009 MayDocument28 pagesEMTP-RV Newsletter 2009 MayLong LeoPas encore d'évaluation

- AC Motors For Application in A Commercial Electric Vehicle: Designing AspectsDocument5 pagesAC Motors For Application in A Commercial Electric Vehicle: Designing Aspectsabde samadPas encore d'évaluation

- Development of A Smart LED Lighting System: Rapid Prototyping ScenarioDocument6 pagesDevelopment of A Smart LED Lighting System: Rapid Prototyping ScenariocarlosPas encore d'évaluation

- Iqbal Uzair 0625210 EResumeDocument4 pagesIqbal Uzair 0625210 EResumeuzair274Pas encore d'évaluation

- 1st PartialDocument8 pages1st PartialMariam ramirezPas encore d'évaluation

- Advance in MechatronicsDocument6 pagesAdvance in Mechatronicsj rPas encore d'évaluation

- Roland Berger Computer On WheelsDocument24 pagesRoland Berger Computer On WheelsTime to Relax100% (1)

- Studentsprojectsguide in Electrical Projects PDFDocument4 pagesStudentsprojectsguide in Electrical Projects PDFShyamPas encore d'évaluation

- Control & Instrumentation Engineer ResumeDocument3 pagesControl & Instrumentation Engineer ResumeLincolyn MoyoPas encore d'évaluation

- Nabeel Arif (Electrical Engineer) ResumeDocument4 pagesNabeel Arif (Electrical Engineer) ResumeEngineer Nabeel ArifPas encore d'évaluation

- Lectric Mobility: Track OverviewDocument5 pagesLectric Mobility: Track Overviewabdo zainPas encore d'évaluation

- Intro To IEC 61850 WebinarDocument56 pagesIntro To IEC 61850 WebinarJosé Miguel Ochoa AcerosPas encore d'évaluation

- Usama Jamil - ResumeDocument2 pagesUsama Jamil - ResumeUsama JamilPas encore d'évaluation

- Chiarg Panchal's Upadte CVDocument7 pagesChiarg Panchal's Upadte CVcpchirag04Pas encore d'évaluation

- M.e.pseDocument95 pagesM.e.pseVigneshwaran KandaswamyPas encore d'évaluation

- Proposal Integrated Digital Electrical Measuring DevicesDocument18 pagesProposal Integrated Digital Electrical Measuring DevicestesfuPas encore d'évaluation

- The Journal of Systems & SoftwareDocument15 pagesThe Journal of Systems & SoftwareVladymirPas encore d'évaluation

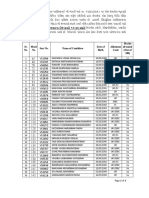

- List-2 30062021Document21 pagesList-2 30062021Pankaj RupaniPas encore d'évaluation

- IcgDocument7 pagesIcgTopRankersPas encore d'évaluation

- Provision Merit List VS JE ELECTDocument20 pagesProvision Merit List VS JE ELECTPankaj RupaniPas encore d'évaluation

- Gujarat Technological UniversityDocument4 pagesGujarat Technological UniversityAbhishek BisoyiPas encore d'évaluation

- Solutions of Week 7 Assignment 1: Ans - (C)Document4 pagesSolutions of Week 7 Assignment 1: Ans - (C)Pankaj RupaniPas encore d'évaluation

- Ticket 3586662689Document2 pagesTicket 3586662689dev dPas encore d'évaluation

- Guide Line For Fill Up The Form of Marriage Ceremony PermissionDocument10 pagesGuide Line For Fill Up The Form of Marriage Ceremony PermissionPankaj RupaniPas encore d'évaluation

- Wind Power in India - WikipediaDocument18 pagesWind Power in India - WikipediaPankaj RupaniPas encore d'évaluation

- Wind EnergyDocument81 pagesWind EnergyManiranjan RoutPas encore d'évaluation

- Scanned by CamscannerDocument15 pagesScanned by CamscannerPankaj RupaniPas encore d'évaluation

- UNIT-3 W P: IND OwerDocument44 pagesUNIT-3 W P: IND OwerPankaj RupaniPas encore d'évaluation

- VSJE Allottment 5Document2 pagesVSJE Allottment 5Pankaj RupaniPas encore d'évaluation

- Dakshin Gujarat Vij Company Limited: Tel No: (0261) 2506100/200 - Fax No-0261-2572636Document7 pagesDakshin Gujarat Vij Company Limited: Tel No: (0261) 2506100/200 - Fax No-0261-2572636Pankaj RupaniPas encore d'évaluation

- Captivate Development Kit: Processor PCB To Panel PCB Connector Haptic Drive CircuitDocument2 pagesCaptivate Development Kit: Processor PCB To Panel PCB Connector Haptic Drive CircuitPankaj Rupani100% (3)

- UCC ElectrolyticCapacitorTechnicalNotes PDFDocument14 pagesUCC ElectrolyticCapacitorTechnicalNotes PDFozmeenPas encore d'évaluation

- Vacancy 469Document7 pagesVacancy 469Swagata BanerjeePas encore d'évaluation

- S No Name of Examination Date of Advt. Closing Date Date of ExamDocument2 pagesS No Name of Examination Date of Advt. Closing Date Date of ExamKavya SivakumarPas encore d'évaluation

- Visual PreviewDocument4 pagesVisual PreviewPankaj RupaniPas encore d'évaluation

- Revnotice 21072020Document1 pageRevnotice 21072020Nitin DangiPas encore d'évaluation

- (List-2) and All Other Posts (List-3)Document3 pages(List-2) and All Other Posts (List-3)Avinash KumarPas encore d'évaluation

- Tfoz (P - (PZ - ! (4 D/U/Jfzgf ZF (H JFZ (!!O# - S, Fs (Lgudlt SR (Zl4 5lòjl LV (,4 ZFHSF ( (8Document3 pagesTfoz (P - (PZ - ! (4 D/U/Jfzgf ZF (H JFZ (!!O# - S, Fs (Lgudlt SR (Zl4 5lòjl LV (,4 ZFHSF ( (8Pankaj RupaniPas encore d'évaluation

- List of Candidates For VSJE - ElectricalDocument2 pagesList of Candidates For VSJE - ElectricalSandeep RamiPas encore d'évaluation

- Marks and Merit List for Admission to Engineering CollegeDocument3 pagesMarks and Merit List for Admission to Engineering CollegePankaj RupaniPas encore d'évaluation

- Gaz - Part - II Jul To Sep PDFDocument552 pagesGaz - Part - II Jul To Sep PDFPankaj RupaniPas encore d'évaluation

- Installed Capacity 06Document7 pagesInstalled Capacity 06Sofia JohnsonPas encore d'évaluation

- Syllabus of VS (Junior Engineer-Electrical)Document1 pageSyllabus of VS (Junior Engineer-Electrical)Pankaj RupaniPas encore d'évaluation

- 05 Feb 2019054119 PMDocument2 pages05 Feb 2019054119 PMPankaj RupaniPas encore d'évaluation

- 2.1 Active Components 2.2 Passive Components 2.3 Node, Branch and Loop 2.4 Kirchhoff ' S LawsDocument22 pages2.1 Active Components 2.2 Passive Components 2.3 Node, Branch and Loop 2.4 Kirchhoff ' S LawsIan BagunasPas encore d'évaluation

- 02 HandoutDocument6 pages02 HandoutPankaj RupaniPas encore d'évaluation

- 03 May 2018100331 PMDocument22 pages03 May 2018100331 PMPankaj RupaniPas encore d'évaluation

- Cost Systems: TermsDocument19 pagesCost Systems: TermsJames BarzoPas encore d'évaluation

- Marketing of Agriculture InputsDocument18 pagesMarketing of Agriculture InputsChanakyaPas encore d'évaluation

- Reaction CalorimetryDocument7 pagesReaction CalorimetrySankar Adhikari100% (1)

- Carbapenamses in Antibiotic ResistanceDocument53 pagesCarbapenamses in Antibiotic Resistancetummalapalli venkateswara raoPas encore d'évaluation

- List of StateDocument5 pagesList of StatedrpauliPas encore d'évaluation

- The Top 10 Strategic Technology Trends For 2020: Tomas Huseby Executive PartnerDocument31 pagesThe Top 10 Strategic Technology Trends For 2020: Tomas Huseby Executive PartnerCarlos Stuars Echeandia CastilloPas encore d'évaluation

- KG ResearchDocument257 pagesKG ResearchMuhammad HusseinPas encore d'évaluation

- Yamaha RX-A3000 - V3067Document197 pagesYamaha RX-A3000 - V3067jaysonPas encore d'évaluation

- Dwarf Boas of The Caribbean PDFDocument5 pagesDwarf Boas of The Caribbean PDFJohn GamesbyPas encore d'évaluation

- CM Template For Flora and FaunaDocument3 pagesCM Template For Flora and FaunaJonathan Renier Verzosa0% (1)

- SRC400C Rough-Terrain Crane 40 Ton Lifting CapacityDocument1 pageSRC400C Rough-Terrain Crane 40 Ton Lifting CapacityStephen LowPas encore d'évaluation

- A. What Is Balanced/objective Review or Criticism?Document11 pagesA. What Is Balanced/objective Review or Criticism?Risha Ann CortesPas encore d'évaluation

- Chapter One: Business Studies Class XI Anmol Ratna TuladharDocument39 pagesChapter One: Business Studies Class XI Anmol Ratna TuladharAahana AahanaPas encore d'évaluation

- Monitoring Tool in ScienceDocument10 pagesMonitoring Tool in ScienceCatherine RenantePas encore d'évaluation

- Assessment of Benefits and Risk of Genetically ModDocument29 pagesAssessment of Benefits and Risk of Genetically ModSkittlessmannPas encore d'évaluation

- Maturity Mode Agile BookDocument110 pagesMaturity Mode Agile BookSai VenkatPas encore d'évaluation

- UFO Midwest Magazine April2011Document16 pagesUFO Midwest Magazine April2011Jimi HughesPas encore d'évaluation

- Alpha Phi Omega National Service Fraternity Strategic PlanDocument1 pageAlpha Phi Omega National Service Fraternity Strategic Planlafay3ttePas encore d'évaluation

- Surveying 2 Practical 3Document15 pagesSurveying 2 Practical 3Huzefa AliPas encore d'évaluation

- AP World History: Islamic Empires and Scientific AdvancementDocument55 pagesAP World History: Islamic Empires and Scientific AdvancementJa'TasiaPas encore d'évaluation

- PH Miracle Complete Whole Body Alkalizing Program-1201724Document20 pagesPH Miracle Complete Whole Body Alkalizing Program-1201724joao carlos100% (1)

- Lay Out New PL Press QltyDocument68 pagesLay Out New PL Press QltyDadan Hendra KurniawanPas encore d'évaluation

- Liu030 Nepal Bans Solo Mountain ClimbersDocument2 pagesLiu030 Nepal Bans Solo Mountain Climberssanti.miranda.parrillaPas encore d'évaluation

- WCM - March 2017-Final Version PDF - 4731677 - 01Document211 pagesWCM - March 2017-Final Version PDF - 4731677 - 01Antonio VargasPas encore d'évaluation

- Differentiation: Vehicle Network SolutionsDocument1 pageDifferentiation: Vehicle Network SolutionsДрагиша Небитни ТрифуновићPas encore d'évaluation

- Rpo 1Document496 pagesRpo 1Sean PrescottPas encore d'évaluation

- Mutaz Abdelrahim - Doa - MT-103Document17 pagesMutaz Abdelrahim - Doa - MT-103Minh KentPas encore d'évaluation

- Rev F AvantaPure Logix 268 Owners Manual 3-31-09Document46 pagesRev F AvantaPure Logix 268 Owners Manual 3-31-09intermountainwaterPas encore d'évaluation

- Publications FireSafetyDesign SDocument369 pagesPublications FireSafetyDesign SJayachandra Reddy AnnavaramPas encore d'évaluation

- Roll Covering Letter LathiaDocument6 pagesRoll Covering Letter LathiaPankaj PandeyPas encore d'évaluation