Académique Documents

Professionnel Documents

Culture Documents

Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle Size

Transféré par

sebaversaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle Size

Transféré par

sebaversaDroits d'auteur :

Formats disponibles

Model CBL 900-1800 HP Boilers

Table A5-11. CBL Recommended Steam Nozzle Size

BOILER HP

OPERATING PRESSURE

800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800

PSIG

12 18 18 20 20 24 24 24 24 24 24 24

30 14 16 16 16 18 18 18 20 20 20 20

50 12 12 12 14 16 16 16 16 16 16 16

75 10 10 12 12 12 12 12 14 14 14 14

100 10 10 10 10 12 12 12 12 12 12 14

125 8 10 10 10 10 10 12 12 12 12 12

150 8 8 8 10 10 10 10 10 10 10 12

200 8 8 8 8 10 10 10 10 10 10 10

225 6 8 8 8 8 10 10 10 10 10 10

NOTES:

Steam nozzle sizes given in inches.

All standard steam nozzle sizes for the 150 psig design pressure or greater are the same as 125 psig operating pressure on

the above table. To increase or decrease the standard size, request the change with your local Cleaver-Brooks authorized

representative.

Table A5-12. CBL Steam Volume and Disengaging Areas

STEAM RELIEVING AREA

BOILER SQUARE FOOT BHP STEAM VOLUME (CU-FT)

(SQ-IN)

OF HEATING SURFACE

4 SQ.FT. 5 SQ.FT. HIGH PRESSURE (A) HIGH PRESSURE (A)

4000 1000 800 155 20566

4500 1100 900 174 23105

5000 1200 1000 250 24141

5500 1300 1100 273 26372

6000 1500 1200 300 28908

6500 1600 1300 352 28918

7000 1700 1400 379 31079

7500 1800 1500 405 33242

NOTES:

Based on normal water level.

Values are based on standard controls. Optional controls may result in different values.

A. Based on 150 psig design pressure.

Section A5-16 Rev. 03-08

Model CBL 900-1800 HP Boilers

Table A5-13. CBL Recommended Non-Return Valve Size

CAPACITY OPERATING PRESSURE

BOILER HP

LBS.PER HR. 50 75 100 125 150 175 200 225

900 31050 8 66 6 6 6 6 5

1000 34500 8 6* 6 6 6 6 6 5

1100 37950 8 86 6 6 6 6 6

1200 41400 8 88 6 6 6 6 6

1300 44850 8 88 8 6 6 6 6

1400 48300 8 88 8 8 6 6 6

1500 51750 8 88 8 8 8 6 6

1600 55200 10 10 8 8 8 8 8 6

1700 58650 10 10 8 8 8 8 8 8

1800 62100 10 10 10 8 8 8 8 8

NOTE:

Valve sizes (300# flanges) given in inches).

Standard non-return valve selections limited to a maximum 2 to 1 turndown (50% of full boiler output); selection based on

typical valve sizing recommendations. For final valve selection contact your authorized C-B representative. For high

turndown applications see Boiler Book Section I3, Table I3-3.

*Indicates pressure drop of less than 7.5 psig. All other selections are less than 6 psig pressure drop.

Table A5-14. CBL Blowdown Tank Sizing Information

BOILER SQUARE FOOT OF BHP

WATER (GAL)

HEATING SURFACE 4 SQ.FT. 5 SQ.FT.

4000 1000 800 356

4500 1100 900 400

5000 1200 1000 418

5500 1300 1100 460

6000 1500 1200 500

6500 1600 1300 500

7000 1700 1400 538

7500 1800 1500 575

NOTE: Quantity of water removed from boiler by lowering normal water line 4". Optional level controls can alter water

quantities.

Section A5-17 Rev. 03-08

Model CBL 900-1800 HP Boilers

Table A5-15. CBL Gas Train Connection Size and Gas Pressure Requirements

4 ft2/bhp

3-pass 4-pass

Boiler HP std 30 ppm std 30 ppm

Gas train Pressure Gas train Pressure Gas train Pressure Gas train Pressure

connection required connection required connection required connection required

1000 2.5 8.2 2.5 8.3 2.5 8.1 2.5 8.2

1100 3 5.4 3 5.4 3 5.4 3 5.6

1200 3 6.3 3 6.3 3 6.3 3 6.4

1300 3 7.2 3 7.3 3 7.2 3 7.3

1400 3 8.4 3 8.5 3 8.3 3 8.5

1500 4 5.4 4 5.5 4 5.6 4 5.8

2

4.5 ft /bhp

3-pass 4-pass

Boiler HP std 30 ppm std 30 ppm

Gas train Pressure Gas train Pressure Gas train Pressure Gas train Pressure

connection required connection required connection required connection required

900 2.5 7.4 2.5 7.4 2.5 7.3 2.5 7.4

1000 2.5 8.2 2.5 8.3 2.5 8.1 2.5 8.2

1100 3 5.3 3 5.4 3 5.3 3 5.4

1200 3 6.3 3 6.3 3 6.2 3 6.4

1300 3 7.2 3 7.3 3 7.2 3 7.3

1400 3 8.4 3 8.4 3 8.2 3 8.3

1500 4 5.4 4 5.5 4 5.4 4 5.6

2

5 ft /bhp

3-pass 4-pass

Boiler HP std 30 ppm std 30 ppm

Gas train Pressure Gas train Pressure Gas train Pressure Gas train Pressure

connection required connection required connection required connection required

800 2.5 6.0 2.5 6.1 2.5 5.9 2.5 6.0

900 2.5 7.4 2.5 7.4 2.5 7.3 2.5 7.4

1000 2.5 8.2 2.5 8.2 2.5 7.9 2.5 8.0

1100 3 5.3 3 5.4 3 5.3 3 5.4

1200 3 6.3 3 6.3 3 6.2 3 6.3

1300 3 7.2 3 7.2 3 7.1 3 7.2

1400 3 8.4 3 8.4 3 8.2 3 8.3

1500 4 5.4 4 5.5 4 5.4 4 5.6

Notes: 3-pass boilers are based on 80% efficiency

4-pass boilers are based on 82% efficiency

Pressure shown is minimum required and is listed as psi

Incoming pressure is not to exceed 10 psi

Ultra Low NOx (9 and 15ppm) are handled on a case by case basis

Table is based on Siemens gas train, which includes a regulating actuator.

Section A5-18 Rev. 03-08

Model CBL 900-1800 HP Boilers

Table A5-16. Altitude Correction for Gas

ALTITUDE (FT) CORRECTION FACTOR ALTITUDE (FT) CORRECTION FACTOR

1000 1.04 6000 1.25

2000 1.07 7000 1.30

3000 1.11 8000 1.35

4000 1.16 9000 1.40

5000 1.21 - -

To obtain minimum required gas pressure at altitudes above 700 feet, multiply the pressure by the listed factors:

inches WC x 0.577 = oz/sq-in.

oz/sq-in x 1.732 = inches WC.

inches WC x 0.0361= psig.

oz/sq-in x 0.0625 = psig.

psig x 27.71 = Inches WC.

psig x 16.0 = oz/sq-in.

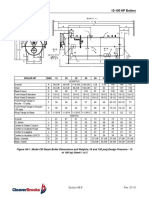

Figure A5-5. No. 2 Oil Piping, Single Boiler Figure A5-6. No. 6 Oil Piping, Single Boiler

Installation, Oil Pump Integral With Boiler Installation, Remote Oil Pumps

BOILER SQUARE BHP A B

FOOT OF HEATING SURFACE 4 sq.ft. 5 sq.ft.

4000 1000 800 610 484

4500 1100 900 670 514

5000 1200 1000 606 489

5500 1300 1100 654 513

6000 1500 1200 700 536

6500 1600 1300 642 515

7000 1700 1400 680 534

7500 1800 1500 718 553

NOTE: A = Minimum length based on removing tubes in the boiler room.

B = Minimum length based on removing tubes through a wall opening.

Section A5-19 Rev. 03-08

Model CBL 900-1800 HP Boilers

Figure A5-7. Boiler Room Length (Typical Layout)

1. Shortest boiler room length (Dwg A) is obtained by allowing for possible future tube replacement from front of boiler

through a window or doorway. Allowance is only made for minimum door swing at each end of the boiler. This

arrangement provides sufficient aisle space at the front of the boiler but a “tight” space condition at the rear.

If space permits, approximately 1.5 additional feet should be allowed at the rear for additional aisle and working space.

2. Next shortest boiler room length (Dwg B) is obtained by allowing for possible future tube replacement from the front of the

boiler. Allowance is only made for minimum door swing at the rear.

If space permits, approximately 1.5 additional feet should be allowed at the rear for additional aisle and working space.

Boiler Square Foot of 4000- 5000- 6500-

Heating Surface 4500 6000 7500

Dimension A (inches) 117 123 129

Dimension B (inches) 198 210 222

For reference to Boiler Horsepower per square foot see A11-7

Figure A5-8. Boiler Room Width (Typical Layouts)

Section A5-20 Rev. 03-08

Vous aimerez peut-être aussi

- TM 9-1751 Cylinder, Radial, Gasoline Engine (Continental Model R975-C1) 1944Document237 pagesTM 9-1751 Cylinder, Radial, Gasoline Engine (Continental Model R975-C1) 1944Kelsey Yuen50% (2)

- Armed Struggle in Africa (1969)Document167 pagesArmed Struggle in Africa (1969)Dr.VolandPas encore d'évaluation

- Denison Gold Cup PDFDocument64 pagesDenison Gold Cup PDFOleg080100% (3)

- Unit 3: The Catering Service Industry Topic: Catering Service Concept Digest (Discussion)Document5 pagesUnit 3: The Catering Service Industry Topic: Catering Service Concept Digest (Discussion)Justin MagnanaoPas encore d'évaluation

- A320 21 Air Conditioning SystemDocument41 pagesA320 21 Air Conditioning SystemBernard Xavier95% (22)

- B-Positioning XA RA XO XDDocument2 pagesB-Positioning XA RA XO XDSorin100% (1)

- RA 8042 and RA 10022 ComparedDocument37 pagesRA 8042 and RA 10022 ComparedCj GarciaPas encore d'évaluation

- Condensate Recovery and Return Systems Sdi / SDS: Data SheetDocument4 pagesCondensate Recovery and Return Systems Sdi / SDS: Data Sheetqdod_waffiPas encore d'évaluation

- SOI EOI Simple CalcDocument4 pagesSOI EOI Simple CalcParus BogdanPas encore d'évaluation

- Technical supplement for piston pumps and motorsDocument20 pagesTechnical supplement for piston pumps and motorsCHEE SENG LEEPas encore d'évaluation

- Transmision Trituradora TesabDocument4 pagesTransmision Trituradora Tesabjorge alfonsoPas encore d'évaluation

- Monopoly - Indian RailwaysDocument35 pagesMonopoly - Indian Railwaysvrj1091Pas encore d'évaluation

- Model CBLE 100-800 HP Boilers: Table A1-25. Model CB-LE Blowdown Tank Sizing Table A1-26. Heating Surface, Model CB-LEDocument4 pagesModel CBLE 100-800 HP Boilers: Table A1-25. Model CB-LE Blowdown Tank Sizing Table A1-26. Heating Surface, Model CB-LEsebaversaPas encore d'évaluation

- Model CBEX Elite Boilers 1300-2200HP Gas Train SizingDocument4 pagesModel CBEX Elite Boilers 1300-2200HP Gas Train SizingsebaversaPas encore d'évaluation

- Vase de Hidrofor AFL ELBIDocument2 pagesVase de Hidrofor AFL ELBIlaid benhamidaPas encore d'évaluation

- Regulador EQA-99Document3 pagesRegulador EQA-99Ronan CristhiamPas encore d'évaluation

- FKL Composite Performance Curve Models: 15-150Document24 pagesFKL Composite Performance Curve Models: 15-150Leydi Johana ParedesPas encore d'évaluation

- Brochure Todas Las PotenciasDocument2 pagesBrochure Todas Las PotenciasCesário GuimarãesPas encore d'évaluation

- LT3 00010 1 - P6 7 8 11 14 24 30 Piston PumpsDocument84 pagesLT3 00010 1 - P6 7 8 11 14 24 30 Piston PumpsNelson PaicoPas encore d'évaluation

- GCDocument64 pagesGCEng-Mohammed SalemPas encore d'évaluation

- Air-Cooled Price ListDocument7 pagesAir-Cooled Price ListM P PRASADPas encore d'évaluation

- Data Sheet Round Lifting Electromagnets Type EcpDocument1 pageData Sheet Round Lifting Electromagnets Type EcpddiPas encore d'évaluation

- Destockage List Finalised 28.08.17Document8 pagesDestockage List Finalised 28.08.17tagashiiPas encore d'évaluation

- BR WatermeterDocument2 pagesBR Watermeterhamparan nightwatchPas encore d'évaluation

- Multi-Fuel Mobile Power GenerationDocument4 pagesMulti-Fuel Mobile Power Generationjpablop12Pas encore d'évaluation

- Bar Schedules For Circular SlabDocument2 pagesBar Schedules For Circular SlabketemaPas encore d'évaluation

- Muller (MCC & MCF)Document12 pagesMuller (MCC & MCF)Muhammad Nur Shidiq100% (1)

- HVAC Duct Layout and Insulation DetailsDocument31 pagesHVAC Duct Layout and Insulation DetailsRaju KsnPas encore d'évaluation

- 400 KVA Data SheetDocument3 pages400 KVA Data SheetYasirSwatiPas encore d'évaluation

- Eterna Sewerage PumpsDocument4 pagesEterna Sewerage Pumpssatyendra singh50% (2)

- Industrial Pump Performance Curves Model 2WHT 40Document1 pageIndustrial Pump Performance Curves Model 2WHT 40Mario JosePas encore d'évaluation

- PF1000 Series Fixed Displacement Pumps: Contact InformationDocument6 pagesPF1000 Series Fixed Displacement Pumps: Contact InformationMiguel VlntìnPas encore d'évaluation

- Pinbush - Tyre Coupling 2014Document4 pagesPinbush - Tyre Coupling 2014Priyam NandwanaPas encore d'évaluation

- Double Girder DetailsDocument2 pagesDouble Girder DetailsTywapPas encore d'évaluation

- ODF Catalogue Edition 6 Gear PumpsDocument16 pagesODF Catalogue Edition 6 Gear PumpsMathan Selva Kumar APas encore d'évaluation

- LHP Price LIst - LP007 PDFDocument28 pagesLHP Price LIst - LP007 PDFRavichandran S100% (1)

- Rezervoare Apa Rece AR - Izolate Si Neizolat ElbiDocument2 pagesRezervoare Apa Rece AR - Izolate Si Neizolat ElbiCalin CalinPas encore d'évaluation

- DRAIN TYPE FLUID COUPLING For Internal Combustion Engines KPTODocument4 pagesDRAIN TYPE FLUID COUPLING For Internal Combustion Engines KPTOberkahharianPas encore d'évaluation

- Amafilter Cricketfilter For Wet Cake Discharge 20210414Document2 pagesAmafilter Cricketfilter For Wet Cake Discharge 20210414virus40Pas encore d'évaluation

- PORTABLE SCR106PD-SCR126PDDocument1 pagePORTABLE SCR106PD-SCR126PDkwstdbjp5fPas encore d'évaluation

- R T MV: SeriesDocument4 pagesR T MV: SeriesAhmed El-sheshtawyPas encore d'évaluation

- Retail PDFDocument3 pagesRetail PDFGago MaldonadoPas encore d'évaluation

- Daywise Production Plan Nov 2018Document2 pagesDaywise Production Plan Nov 2018premPas encore d'évaluation

- Model CB 15-100 HP Boilers: Sound LevelDocument5 pagesModel CB 15-100 HP Boilers: Sound LevelsebaversaPas encore d'évaluation

- SwivelDocument3 pagesSwivelrodon falathPas encore d'évaluation

- FKL Performance Curves Model: 15 (1.5", .0155 GPR) : 0 Psi 10 Psi 50 Psi 100 Psi 150 Psi 200 PsiDocument2 pagesFKL Performance Curves Model: 15 (1.5", .0155 GPR) : 0 Psi 10 Psi 50 Psi 100 Psi 150 Psi 200 PsiAdrian PortillaPas encore d'évaluation

- Catalouge GTRDocument2 pagesCatalouge GTRMr Nilesh ShahPas encore d'évaluation

- Joy BoosterDocument2 pagesJoy BoosterAlexsandro TorezinPas encore d'évaluation

- RMG by Honeywell BD 277 Hi-Flo GB 2010-10Document8 pagesRMG by Honeywell BD 277 Hi-Flo GB 2010-10Jorge Henostroza IntiPas encore d'évaluation

- 1 - Flowline CatalogueDocument16 pages1 - Flowline CatalogueRamesh MarimuthuPas encore d'évaluation

- American Block FlowlineDocument16 pagesAmerican Block Flowlineclaudio godinezPas encore d'évaluation

- Engineering Catalog: HL160M Dri-Prime Pump Engineering DataDocument6 pagesEngineering Catalog: HL160M Dri-Prime Pump Engineering DatamuahdibPas encore d'évaluation

- Offshore Process and Cargo Pumps Data SheetDocument2 pagesOffshore Process and Cargo Pumps Data Sheetxm861122Pas encore d'évaluation

- Hitung Wiring DiagramDocument5 pagesHitung Wiring DiagrammepchatimePas encore d'évaluation

- Colum Design ACIDocument8 pagesColum Design ACIمحمود حلمىPas encore d'évaluation

- Construction BOQ SummaryDocument2 pagesConstruction BOQ SummaryRenuka TekumudiPas encore d'évaluation

- Operating Data GEV: Gas Ejector For Single-Stage Liquid Ring Vacuum PumpsDocument4 pagesOperating Data GEV: Gas Ejector For Single-Stage Liquid Ring Vacuum Pumpsrebelde1986Pas encore d'évaluation

- Pump Sizing Exercise Nodal AnalysisDocument125 pagesPump Sizing Exercise Nodal Analysiss pPas encore d'évaluation

- FLC Van TirDocument5 pagesFLC Van TirDestiny OZPas encore d'évaluation

- MCPP SERIES CENTRIFUGAL PROCESS PUMPDocument8 pagesMCPP SERIES CENTRIFUGAL PROCESS PUMPOmar SunasaraPas encore d'évaluation

- Trade payables unearned revenue equity revenue expenses drawings r&sDocument6 pagesTrade payables unearned revenue equity revenue expenses drawings r&sJithin MohanPas encore d'évaluation

- Technical Specifications for Oilgear PVWH PumpsDocument4 pagesTechnical Specifications for Oilgear PVWH PumpsEdison YesidPas encore d'évaluation

- Techno AppliancesDocument11 pagesTechno AppliancesJenel Ionovici100% (1)

- Perkins Data Sheet PCS100-150PDocument4 pagesPerkins Data Sheet PCS100-150PGerman E.Pas encore d'évaluation

- Leistritz Re Eng L3 Pump WebDocument4 pagesLeistritz Re Eng L3 Pump WebChuong DongPas encore d'évaluation

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaPas encore d'évaluation

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocument5 pagesModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaPas encore d'évaluation

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaPas encore d'évaluation

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 pagesModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaPas encore d'évaluation

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaPas encore d'évaluation

- Efficient 15-100 HP Boilers for BuildingsDocument5 pagesEfficient 15-100 HP Boilers for BuildingssebaversaPas encore d'évaluation

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaPas encore d'évaluation

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocument5 pagesModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaPas encore d'évaluation

- 900-1800 HP Steam Boilers: Features, Dimensions and Engineering DataDocument5 pages900-1800 HP Steam Boilers: Features, Dimensions and Engineering DatasebaversaPas encore d'évaluation

- Features and Benefits: Model CB 15-100 HP BoilersDocument5 pagesFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaPas encore d'évaluation

- Model CB 15-100 HP Boilers: Sound LevelDocument5 pagesModel CB 15-100 HP Boilers: Sound LevelsebaversaPas encore d'évaluation

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaPas encore d'évaluation

- 900-1800 HP Boiler SpecsDocument5 pages900-1800 HP Boiler SpecssebaversaPas encore d'évaluation

- 15-100 HP Boilers Dimensions SpecsDocument5 pages15-100 HP Boilers Dimensions SpecssebaversaPas encore d'évaluation

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaPas encore d'évaluation

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocument5 pagesModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaPas encore d'évaluation

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaPas encore d'évaluation

- Model CBR 125-800 HP BoilersDocument5 pagesModel CBR 125-800 HP BoilerssebaversaPas encore d'évaluation

- 75Document5 pages75sebaversaPas encore d'évaluation

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaPas encore d'évaluation

- 81Document5 pages81sebaversaPas encore d'évaluation

- High-efficiency boiler specifications for 100-800 HP modelsDocument4 pagesHigh-efficiency boiler specifications for 100-800 HP modelssebaversaPas encore d'évaluation

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocument5 pages125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaPas encore d'évaluation

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaPas encore d'évaluation

- 78Document5 pages78sebaversaPas encore d'évaluation

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocument5 pages125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaPas encore d'évaluation

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Document6 pagesModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaPas encore d'évaluation

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaPas encore d'évaluation

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaPas encore d'évaluation

- PM on Union BudgetDocument84 pagesPM on Union BudgetAshok SutharPas encore d'évaluation

- 05 Executive SummaryDocument2 pages05 Executive SummaryHanumanth T Raj YashuPas encore d'évaluation

- Apple Led Cinema Display 24inchDocument84 pagesApple Led Cinema Display 24inchSantos MichelPas encore d'évaluation

- Research Paper About Cebu PacificDocument8 pagesResearch Paper About Cebu Pacificwqbdxbvkg100% (1)

- Chapter 4-Ohm's LawDocument12 pagesChapter 4-Ohm's LawErin LovePas encore d'évaluation

- Web Based Tour Management for Bamboo ParadiseDocument11 pagesWeb Based Tour Management for Bamboo Paradisemohammed BiratuPas encore d'évaluation

- Feb 21Document8 pagesFeb 21thestudentagePas encore d'évaluation

- Acuite-India Credit Risk Yearbook FinalDocument70 pagesAcuite-India Credit Risk Yearbook FinalDinesh RupaniPas encore d'évaluation

- Ap22 FRQ World History ModernDocument13 pagesAp22 FRQ World History ModernDylan DanovPas encore d'évaluation

- TurboVap LV Users ManualDocument48 pagesTurboVap LV Users ManualAhmad HamdounPas encore d'évaluation

- Thesis Statement About Plastic BagsDocument7 pagesThesis Statement About Plastic Bagslyjtpnxff100% (2)

- Risk Assessments-These Are The Risk Assessments Which Are Applicable To Works Onsite. Risk Definition and MatrixDocument8 pagesRisk Assessments-These Are The Risk Assessments Which Are Applicable To Works Onsite. Risk Definition and MatrixTimothy AziegbemiPas encore d'évaluation

- Tối Ưu Hóa Cho Khoa Học Dữ LiệuDocument64 pagesTối Ưu Hóa Cho Khoa Học Dữ Liệuminhpc2911Pas encore d'évaluation

- Patient Safety IngDocument6 pagesPatient Safety IngUlfani DewiPas encore d'évaluation

- Circulation in Vacuum Pans: January 2004Document18 pagesCirculation in Vacuum Pans: January 2004REMINGTON SALAYAPas encore d'évaluation

- NYU Stern Evaluation NewsletterDocument25 pagesNYU Stern Evaluation NewsletterCanadianValuePas encore d'évaluation

- Piroxicam (Wikipedia)Document4 pagesPiroxicam (Wikipedia)Adrian ArnasaputraPas encore d'évaluation

- Office of The Protected Area Superintendent: Mt. Matutum Protected LandscapeDocument3 pagesOffice of The Protected Area Superintendent: Mt. Matutum Protected LandscapeNurah LaPas encore d'évaluation

- GSR Azure High Level ArchitectureDocument4 pagesGSR Azure High Level ArchitectureCSKPas encore d'évaluation

- Draft ASCE-AWEA RecommendedPracticeDocument72 pagesDraft ASCE-AWEA RecommendedPracticeTeeBonePas encore d'évaluation

- 19286711Document8 pages19286711suruth242100% (1)

- Foreign Direct Investment in Mongolia An Interactive Case Study (USAID, 2007)Document266 pagesForeign Direct Investment in Mongolia An Interactive Case Study (USAID, 2007)Oyuna Bat-OchirPas encore d'évaluation

- EasementDocument10 pagesEasementEik Ren OngPas encore d'évaluation