Académique Documents

Professionnel Documents

Culture Documents

Copeland AE1287 Demand Cooling

Transféré par

gigiCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Copeland AE1287 Demand Cooling

Transféré par

gigiDroits d'auteur :

Formats disponibles

AE4-1287

AE4-1287-R2 COPELAND DISCUS DEMAND COOLING September 2003

Introduction reached, the module energizes a long life injection

valve which meters a controlled amount of saturated

HCFC-22, when used in a properly designed and

refrigerant into the compressor suction cavity to cool

controlled refrigeration system, is a realistic low tem-

the suction gas. This process controls the discharge

perature refrigerant alternative to CFC-502, which

temperature to a safe level. If, for some reason, the

must be phased out due to its high ozone depletion

discharge temperature rises above a preset maximum

potential. However, experience has shown that

level. the Demand Cooling module will turn the com-

HCFC-22 can present problems as a low temperature

pressor off (requiring a manual reset) and actuate its

refrigerant because under some conditions the inter-

alarm contact. To minimize the amount of refrigerant

nal compressor discharge temperature exceeds the

which must be injected, the suction gas cooling pro-

safe temperature limit for long term stability of refrig-

cess is performed after the gas has passed around

eration oil.

and through the motor.

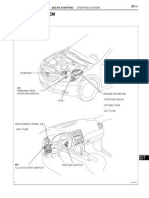

The Copeland Demand Cooling System (see Fig-

Injection valve orifices have been carefully chosen

ure 1) uses modern electronics to provide a reliable cost

for each body style to be large enough to provide the

effective solution to this problem. It is required for all

necessary cooling when required but not so large that

single stage HCFC-22 applications with saturated

dangerous amounts of liquid are injected, or that

suction temperatures below -10°F.

excessive system pressure fluctuation occurs during

Demand Cooling is compatible with single (con- injection valve cycling. Normally, pressure fluctua-

ventional) units as well as parallel racks. tions are no greater than 1 to 2 psi. It is important to

use the correct valve for each compressor body style.

The Demand Cooling module uses the signal of a

discharge head temperature sensor to monitor dis- Performance data for Demand Cooling compres-

charge gas temperature. If a critical temperature is sors includes the effects of injection when it is

DEMAND COOLING SYSTEM

Figure 1

1 © 2002-2003 Copeland Corporation.

Printed in the U.S.A.

AE4-1287

Figure 2

required. The approximate conditions where injection pressor protection control much as the oil failure con-

occurs are shown in Figure 2. At the conditions trol protects the compressor during periods of low oil

where Demand Cooling is operating, the performance pressure. Demand Cooling will be called to operate

values are time averages of the instantaneous values, only during those periods when condensing tempera-

since small fluctuations in suction and discharge tures and return gas temperatures are high or in peri-

conditions occur as the Demand Cooling injection ods where a system failure (such as an iced

valve cycles. evaporator, an expansion valve which does not con-

trol superheat, blocked condenser, or a failed con-

While the refrigerant injection concept has been denser fan) raises condensing temperatures or return

widely recognized for some time, its application has gas temperatures to abnormally high levels or lowers

not been widely used since the early 1960’s because suction pressure to abnormally low levels.

of the widespread availability of CFC-502, reduction

of capacity and efficiency, and poor reliability of injection Operating Range

systems.

Demand Cooling is designed to protect the com-

The Copeland Demand Cooling system addresses pressor from high discharge temperatures over the

the capacity and efficiency issues by limiting injection evaporating and condensing temperature ranges

to those times when it is required to control discharge shown in Figure 2 at a maximum return gas tempera-

temperatures to safe levels. For most applications this ture of 65ºF.

will only be during periods of high condensing tem-

peratures, high return gas temperatures, or abnormally Demand Cooling System Design

low suction pressure. The Demand Cooling system When Demand Cooling operates, it “diverts” refrig-

has been designed to meet the same high reliability eration capacity in the form of injected saturated

standards as Discus compressors. refrigerant from the evaporator to the compressor

In most cases, with floating head systems where (See Figure 3 for a typical single system schematic).

condensing temperatures are low during most of the The effect of this diversion on evaporator capacity is

year. Demand Cooling will operate primarily as a com- minimal because the diverted capacity is used to cool

© 2002-2003 Copeland Corporation. 2

Printed in the U.S.A.

AE4-1287

the gas entering the compressor. As the gas is 3) Suction pressure: Evaporator design and sys-

cooled, it naturally becomes more dense, increasing tem control settings should provide the maxi-

the mass flow through the compressor, which partly mum suction pressure consistent with the ap-

compensates for the capacity diverted from the plication in order to have as low a compression

evaporator. ratio as possible.

If there is substantial heat gain along the suction Demand Cooling Compressors

line, injection may result in a substantial loss in

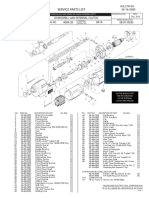

evaporator capacity during Demand Cooling opera- No new compressor models have been introduced

tion. In order to minimize this loss, good practice indi- for Demand Cooling. Instead, existing low tempera-

cates Demand Cooling operation be kept to a mini- ture Discus CFC-502 compressors have been

mum through proper system design and installation modified and rerated for use with HCFC-22 and

practices. There are three areas which can be ad- Demand Cooling. The modifications are the addition

dressed to minimize the impact of Demand Cooling of an injection port on the compressor body and a

operation on performance. temperature sensor port in the head of the compres-

sor. The locations of these ports are critical and were

1) Compressor Return Gas Temperature: Suction determined through an extensive development pro-

lines should be well insulated to reduce suction gram.

line heat gain. Return gas superheat should be

as low as possible consistent with safe com- The HCFC-22 rating data includes the effects of

pressor operation. Demand Cooling injection when operating conditions

require it.

2) Condensing Temperatures: It is important when

using HCFC-22 as a low temperature Condenser Sizing

refrigerant that condensing temperatures be Condensers should be sized using conventional

minimized to reduce compression ratios and methods. Demand Cooling has virtually no effect on

compressor discharge temperature. system heat of rejection.

Figure 3

3 © 2002-2003 Copeland Corporation.

Printed in the U.S.A.

AE4-1287

Demand Cooling System Components In order to avoid nuisance trips, a one minute

time delay is provided before alarm after a continu-

The Demand Cooling System (see Figure 1) con-

ous high or low resistance reading or over tempera-

sists of: The Demand Cooling Temperature Sensor

ture condition.

(TS), The Demand Cooling Module (CM), and the

Injection Valve (lV). The alarm relay uses a single-pole-double-throw

contact. The contact terminals are “L”, “M”, and

The TS uses a precision Negative Temperature

“A”:

Coefficient (NTC) Thermistor (thermistor resistance

drops on temperature rise) to provide temperature “L” - Common (to “A” and “M”)

signals to the CM.

“L - M” - Normally Closed (compressor run. open on

The IV meters refrigerant flow from the liquid line alarm)

to the compressor. The IV solenoid receives on-off

signals from the CM. When compressor cooling is “L - A” - Normally Open (alarm signal, close on

required the solenoid is energized and opens the IV alarm)

orifice to deliver saturated refrigerant to the compres-

The Normally Closed (NC) contact of the alarm

sor for cooling. The valve orifice is carefully sized to

relay (“L” to “M”) should be wired in the compres-

meet the requirements of each body style of Discus

sor contactor control circuit so that opening this

compressors.

contact removes the compressor from the line and

The CM has three functional groups: removes power to the CM. See Figure 4A, B, C, & D.

A) The Input signal and calculator circuits Figures 4A & B also shows a current sensing relay

compare the temperature sensor input signal to (which must be used with compressors employ-

an internal set-point and decide whether to ing internal overcurrent protection) and Sentronic

energize the IV solenoid or, in the case of a oil pressure switch. The control circuit is purposely

problem. The CM alarm relay. arranged so that an internal overload protector trip

removes power to both the Sentronic and the Demand

B) The output signal to the IV is controlled by Cooling module. This precaution prevents the oil

an electronic switch connected to the IV sole- pressure switch from timing out and the Demand

noid so that, when required, refrigerant vapor Cooling solenoid from injecting when the compressor

can be metered to the compressor to prevent is not operating.

compressor overheating. One side of the elec-

tronic switch is connected internally to “L1” and The alarm relay requires a manual reset in order to

the other side to output terminal “S” (see call attention to a system problem.

Figure 4)

System Information

C) The alarm signal for local or remote control.

1) Demand Cooling is designed to work on all

The alarm relay is energized, after a one minute

Copeland Discus compressors equipped with

delay, by a continuous, low or high TS tempera-

injection ports. A different kit is required for

ture signal. An alarm signal can indicate the

each compressor body style and control volt-

following:

age. See Table 2 for a listing of Demand Cool-

1) Compressor discharge temperature has ing Kit part numbers.

risen above the level designed to be

2) The system must be clean. A dirty system may

controlled by Demand Cooling.

have foreign material that can lodge in the

2) A shorted sensor. solenoid orifice. Always install a liquid line filter

dryer in the injection valve inlet line capable of

3) An open sensor. removing particles as small as 25 microns.

© 2002-2003 Copeland Corporation. 4

Printed in the U.S.A.

Demand Cooling™ Wiring Schematic

5

Figure 4A Figure 4B

AE4-1287

Figure 4C Figure 4D

© 2002-2003 Copeland Corporation.

Printed in the U.S.A.

AE4-1287

3) Do not use any filters containing materials that Capacity Modulation

con leave the filter and possibly clog the IV

Demand Cooling is not approved as yet for com-

orifice.

pressors with capacity modulation.

4) The liquid refrigerant supply line must be a

Performance Adjustment Factors

minimum of 3/8" and routed so it will not inter-

fere with compressor maintenance. Liquid re- Since compressor discharge temperature depends

frigerant must have sufficient subcooling at the strongly on the return gas temperature. the amount of

injection valve to prevent flashing upstream of injection and its effect on evaporator capacity and

the valve. mass flow will vary somewhat with return gas tem-

perature. The approximate effects of return gas

5) The liquid refrigerant supply line to the IV must

temperature on evaporator capacity and mass flow are

be supported so that it does not place stress on

tabulated in Table 3A and B. These factors should be

the IV and IV tubing or permit excess vibration.

applied to the 65ºF return gas capacity and mass

Failure to make this provision may result in

flow values in the published performance data sheets.

damage to the IV and its tubing and/or refriger-

ant loss. Demand Cooling Specifications

6) A head fan must be used to help lower com- Demand Cooling is designed to operate and protect

pressor discharge temperatures. the compressor within the evaporating and condens-

ing envelope identified in Figure 2. Operating

7) Return gas temperatures must NOT exceed

setpoints and control actions are listed in Table 1.

65°F.

8) System designers are advised to review their

defrost schemes to avoid floodback to the com-

pressor which may occur at defrost termination

with HCFC-22. HCFC-22 has a significantly

higher heat of vaporization than does CFC-

502, and, if the same design parameters used

with CFC-502 are used with HCFC-22.

floodback could occur.

Table 1

© 2002-2003 Copeland Corporation. 6

Printed in the U.S.A.

AE4-1287

Attached is the Demand Cooling Diagnostic Troubleshooting Guide (form number 92-91).

Table 2

7 © 2002-2003 Copeland Corporation.

Printed in the U.S.A.

AE4-1287

Table 3A

DEMAND COOLING EVAPORATOR CAPACITY ADJUSTMENT FACTORS

Table 3B

DEMAND COOLING EVAPORATOR MASS FLOW ADJUSTMENT FACTORS

© 2002-2003 Copeland Corporation. 8

Printed in the U.S.A.

Copeland Demand Cooling Diagnostics

Demand Cooling wire or tiewraps if necessary. There should be no free air

Operating Characteristics movement over the metal part of the taped-sensor.

3) Connect the digital ohmmeter to the two pins on the plug

The Copeland Demand Cooling control uses a Negative of the sensor. Make sure there is a good connection. Do

Temperature Coefficient Thermistor (NTC). Incorporated in not take a sensor resistance measurement until there is

the Demand Cooling Temperature Sensor (hereafter called no change in the ohmmeter display.

“sensor”), is a compressor discharge temperature monitor.

When the temperature sensed by the NTC Thermistor rises, 4) Measure the temperature of the thermometer sensor and

its resistance falls, and when temperature sensed by the find the corresponding calculated sensor resistance value

thermistor drops, its resistance increases. from Table 1. Since the values of Table 1 are not

continuous, you may have to interpolate.

The sensor resistance signal is coupled to the Demand

Cooling Module (hereafter called “module”). The module uses 5) The sensor resistance reading should be within +/- 5% of

the signal to determine when the compressor discharge the calculated resistance value of Step 4.

temperature has risen to a point where Demand Cooling is End of Test

required. When Demand Cooling is required the module

energizes the Demand Cooling Injection Valve (hereafter TABLE 1

called “injection valve”) and the injection valve inject s

saturated refrigerant into the compressor suction cavity until Thermomter Calculated Sensor

the discharge temperature drops to an acceptable level. Temp. (F°) Resistance (Ohms)

Whenever the compressor starts and the module first 59 141426

receives power, there is a one minute delay during which 60.8 135000

the Demand Cooling system injects saturated refrigerant if it 62.6 128907

is required, but waits for compressor discharge temperature 64.4 123129

to stabilize before checking for alarm conditions. After one 66.2 117639

minute, if the resistance of the probe is too low (the resistance

equivalent of 310°F), or too high (the resistance equivalent 68 112437

69.8 107478

of 4°F) the module will trip and deenergize the compressor. 71.6 102762

73.4 98289

Bench Testing Demand Cooling Components 75.2 94041

77 90000

Bench Check of the Sensor 78.8 86139

80.6 82476

Required Equipment: 82.4 78984

84.2 75663

• A digital thermometer of +/- 1 % full scale accuracy. The

thermometer probe should be checked for calibration in 86 72504

an ice water bath or compared with another accurately 87.8 69480

known temperature source. 89.6 66609

91.4 63864

• A digital ohmmeter capable of +/- 1 % accuracy. The 93.2 61254

ohmmeter should be checked for accuracy with a known 95 58770

resistance value such as a +1 % resistor. 96.8 56394

Room temperature should be stable and between 60°F and 98.6 54126

100.4 51966

110°F. 102.2 49914

1) Wrap the end of the digital thermometer probe and the 104 47943

metal end of the Demand Cooling sensor probe together 105.8 46053

with electrical tape or “Velcro”. The end of the probe and 107.6 44262

the end of the thermometer must touch. 109.4 42543

2) Place the wrapped probe-sensor inside an insulation

shield to protect it from air currents. Use a material such

as “Permagum” or piping insulation such as “ArmafleX”.

The insulating material should be tightly wrapped around

the taped-sensor and the wrap should be secured with

Bench Check of the Module and Injection Valve 6) After one minute, the module should trip. The run cont act

“L” to “M” should open, and the alam contact “L” to “A”

Required equipment: should close. Deenergize the module, disconnect the

injection valve, read zero ohms between “L” and “A” and

• A controlled voltage source the same as the rating of the an open circuit between “L” and “M”

module and the injection valve.

7) Reset the module. Remove the jumper from the module

• A multimeter. probe plug so there is an open circuit at the plug input.

• If the jumper supplied on the sensor plug of the module is 8) Energize the module.

not available you may use a small paper clip for the test.

When the sensor connection to the Demand Cooling

Before starting the test, make sure you have the correct Module (module) is opened the very high resistance is

module and injection valve. interpreted by the module as a very low temperature.

1) With the module control voltage disconnected, short the Consequently no injection signal is sent to the injection

module sensor plug female terminals with the jumper or valve.

the paperclip. Press the module reset button. 9) The injection valve should be energized. A recheck of

2) Attach the injection valve leads to terminals “L2” and “S” Step 5 will confirm this.

of the module. The injection valve should be propped in 10)Refer to the test of Step 6 to check the alarm circuit.

an upright position. Reset the module after the test. If the module or injection

3) You should read zero ohms between the “L” and “M” valve fails any of the checks it should be replaced.

terminals of the module. This is the Normally Closed (NC) End of Test

contact of the Single Pole Double Throw (SPDT) module

alarm relay. You should read an open circuit between “L”

and “A”. This is Normally Open (NO) contact of the alarm Installed System Checks of

relay. Demand Cooling Components

4) Energize the module by bringing module rated voltage When the Demand Cooling control injects saturated

to terminals “Ll” and “L2”. refrigerant into the suction cavity of the compressor, the

*When the sensor connection at the module is shorted, outlet tube of the injection valve frosts. If the module

a very low resistance is seen by the module as a very sensor connection is opened or shorted while the module

high temperature, and an injection signal is sent to the is energized, the module will trip after one minute of

injection valve. operation and must be reset to continue.

5) The injection valve will be energized by the closing of an Before starting the test, make sure you have the correct

electronic switch in the module. The control voltage to module and injection valve.

energize the injection valve may be measured across

module terminals “S” and “L2”.

If the Injection Valve is not Injecting

*Because this measurement is made across an electronic

switch some “leakage” voltage may be measured when 1) With the system deenergized, disconnect the sensor from

the switch is deenergized. This voltage is much less than the module and jumper the terminals of the module

the control voltage which is measured when the electronic connector. Energize the system so the compressor is

switch is closed. running and the module energized. The injection valve

should begin injecting, and frost should form on the outlet

5a) The injection valve operation may also be checked by

tube of the injection valve. If frost forms, go to Step 4

listening to the “click” heard each time the coil of the

otherwise go to Step 2.

injection valve is energized and the injection valve

solenoid plunger seats itself. 2) If frost does not form in Step 1, check to see if there is

control voltage on the coil of the injection valve (terminals

5b)If background noise prevents an audible check of the

“L2” and “S” of the module).

injection valve coil and magnant operation, grip the

injection valve magnet housing and loosen its housing *Because this measurement is made across an electronic

cover screw until magnant vibration is felt. This proves switch in the module some “leakage” voltage may be

solenoid operation. Retighten the magnet housing cover measured when the switch is deenergized. This voltage

screw after this check. is much less than the control voltage which is measured

when the switch is closed. If correct control voltage is

not present, replace the module.

3) If correct control voltage is present, make sure there is a 4) If frosting stops when the sensor is disconnected, check

full sight glass of liquid from the receiver at the injection the system for high suction and/or condensing

valve. If there is not a full sight glass of liquid, the piping temperatures before proceeding. As suction and/or

from the receiver should be checked before proceeding. discharge temperatures rise toward the Demand Cooling

limits (40° F evaporator temperature, 130°F condensing

Piping connections and sizes must be chosen to assure temperature), Demand Cooling will call for injection for

a full sight glass of liquid for the injection valve during

longer periods of time and may appear to be continuously

any phase of the refrigeration system operation. Piping

injecting. Use Figure 1 to check Demand Cooling

that is too small, or connections taken from the tops of

operating areas. Figure 1 shows where injection begins

manifolds rather from the bottom may result in a lack of

for two return gas temperatures (65°F and 20°F). The

refrigerant available for the injection valve just when it

arrows marked (A) and (B) on the graph show the lowest

needs it most, such as after a defrost.

allowable evaporating temperatures using a given

If a full sight glass is present and frost still does not form, condensing temperature.

replace the injection valve.

Point (A) shows that with 65°F return gas and 110° F

4) With the module sensor connector shorted or open and condensing temperature, the lowest evaporating

the module and compressor running, the module should temperature without Demand Cooling injection is -5°F.

trip in one minute and stop the compressor. Point (B) shows that if the return gas temperature can be

lowered to -20°F, while still at a condensing temperature

If the compressor does not stop, check the control circuit of 110°F, the evaporating temperature may be lowered

wiring to be sure the module is wired to stop the to 20°F without Demand Cooling operation.

compressor when the module trips. If the wiring is correct,

replace the module. Your injection point can be approximated by drawing a

line representing your return gas temperature in between

5) Check the discharge temperature by performing Steps and parallel to the two return gas temperatures on the

1-6 of the Injection Valve is Cycling On and Off test. Figure 1 (Area 2). The higher your return gas temperature

If the discharge temperature is higher than the allowable is, the closer it will be to the “65°F line”. The lower it is,

Table 2 selection, remove the sensor from the compressor the closer it will be to the “20°F line”. You can then draw

and use the Bench Check of the Sensor Test to check your own dotted lines representing your condensing and

the probe. Replace the sensor if necessary. evaporating temperatures to see if you are in the in a

Demand Cooling injection zone.

End of Test

The higher your condensing and suction temperatures

If the Injection Valve is Continually Injecting are for a given evaporating temperature, the more

injection is required until finally Demand Cooling may be

1) Make sure there is a full sight glass of liquid from the energized constantly.

receiver. If there is not a full sight glass of liquid, there

may not be enough liquid to allow Demand Cooling to If the suction and condensing temperatures are lower

cycle because it uses all available liquid to keep the than, or borderline to the injection areas of Figure 1 then

discharge temperature below a dangerous level. The go to Step 5.

piping from the receiver to the injection valve should be

checked before proceeding. If they are much higher the system should be corrected

to lower the temperatures or there may be occasional

Piping connections and sizes must be chosen to assure Demand Cooling trips. If lowering system temperatures

a full sight glass of liquid for the injection valve during corrects the continuous problem, the test is ended, if not

any phase of the refrigeration system operation. If the go to Step 5.

suction pressure rises then go to Step 6.

5) Deenergize the refrigeration system. Close the suction

2) Deenergize the system and disconnect the sensor from service valve. Turn the system on and pump down the

the module. Energize the system so the compressor is compressor to 2-3 PSIG. Turn the system off. Wait one

running. The frosting should stop. minute. The pumpdown should hold and the pressure

If Step 2 is successful, go to Step 4 otherwise go to Step 3. should not rise.

3) If frosting does not stop, with the sensor disconnected, If the suction pressure rises then go to Step 6. If the

deenergize the system. Disconnect the voltage supply suction pressure does not rise the sensor is calling for

to the injection valve and restart the compressor. If frosting injection when it is not required and should be replaced.

does not stop, replace the injection valve. If frosting stops,

replace the module.

6) If the suction pressure rises, the suction service valve If the measured discharge temperature is more than

may not be entirely closed, the valve plate or valve plate 280°F, replace the sensor.

gasket may have been damaged. Damage to the valve

plate or its gasket can cause discharge gas to be End of Test

introduced to the suction cavity, resulting in an artificially

high suction temperature. The artificial suction TABLE 2

temperature, in turn, causes an earlier than required

Demand Cooling injection. Compressor Room Condensing Discharge

Replace the compressor valve plate and gaskets if Model Temperature Temperature Temperature

required. (°F) (°F) (°F)

End of Test 2D 80 80 250-270

110 110 270-280

If the Injection Valve is Cycling On and Off 3D 80 80 240-256

110 110 265-280

When the saturated refrigerant is injected into the compressor

suction cavity it lowers the temperature sensed by the sensor. 4D 80 80 230-260

The lower temperature in turn causes the injection valve to 110 110 260-280

shutoff. After shutoff the temperature in the suction cavity 6D 80 80 250-270

rises again until it is high enough for injection to start. The 110 110 250-270

result of this cycling is that frost on the injection valve outlet

tubing alternately appears during injection, and then

disappears after injection stops.

1) Measure the room temperature. FIGURE 1

2) Connect the temperature sensor probe to the compressor Discus, R-22 Demand Cooling

discharge line 6" from the discharge valve. The probe Areas of Expected Injection

must be tightly secured to the discharge line, and must (See page 3 for chart usage)

be well insulated so that moving air will not produce a

false reading (a poorly insulated probe may cause errors

of more than 30°F!).

3) Use Table 2 to select the family of the test compressor:

2D, 3D, 4D or 6D.

4) Use Table 2 to select the room temperature and

condensing temperature closest to yours. (The

evaporator temperature chosen for the data of Table 2

was 25°F).

5) Because of system variations, there will be deviations

from Table 2. A measurement of +5% or 10% of the

selected Table 2 discharge pressure may be considered

satisfactory.

6) When operating under published conditions, the

discharge temperature should never be more than 280°F

or less than 200°F. If successful, the test is ended.

Otherwise go to the next step.

7) If the measured discharge temperature is lower by more

than 10% of the discharge temperature of Table 2,

perform Steps 5-8 of the “If The Injection Valve Is

Continually Injecting” test.

Copeland Corporation

1675 W. Campbell Rd.

Form No. 92-91 R1 (7/03) Sidney, OH 45365-0669

Emerson Climate Technolgies is a service mark and a trademark of Emerson Electric Co.

Copeland is a registered trademark of Copeland Corporation. © 1992, 2003 Copeland Corporation. Printed in the USA. copeland-corp.com

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1091)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- 2AZ FE StartingDocument16 pages2AZ FE StartingLuks FernandezPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Cable CalculationDocument32 pagesCable CalculationV.M KULATHILAKEPas encore d'évaluation

- Temperature Measuring Devices ExperimentDocument3 pagesTemperature Measuring Devices ExperimentNoman Iqbal BhattiPas encore d'évaluation

- original-schematic-STM32F411CEU6 WeAct Black Pill V2.0Document1 pageoriginal-schematic-STM32F411CEU6 WeAct Black Pill V2.0Max Pohl100% (1)

- Quadratic Boost Converter With Less Input Current Ripple and Rear-End Capacitor Voltage Stress For Renewable Energy ApplicationsDocument11 pagesQuadratic Boost Converter With Less Input Current Ripple and Rear-End Capacitor Voltage Stress For Renewable Energy ApplicationsSureshkumar AlagarsamyPas encore d'évaluation

- Modeling in Electrochemical EngineeringDocument25 pagesModeling in Electrochemical EngineeringDhya And100% (1)

- Am29LV008B: 8 Megabit (1 M X 8-Bit) CMOS 3.0 Volt-Only Boot Sector Flash MemoryDocument38 pagesAm29LV008B: 8 Megabit (1 M X 8-Bit) CMOS 3.0 Volt-Only Boot Sector Flash MemoryandersonbheringPas encore d'évaluation

- List of Valid Notam A 15 MayDocument22 pagesList of Valid Notam A 15 MaypilotiraniPas encore d'évaluation

- Unit2 - Worksheet - Lesson 3Document6 pagesUnit2 - Worksheet - Lesson 3Zahra RihanePas encore d'évaluation

- CHEM F111 General Chemistry: PilaniDocument57 pagesCHEM F111 General Chemistry: PilaniSunil NahataPas encore d'évaluation

- NexansDocument16 pagesNexansromany allamPas encore d'évaluation

- CHAPTER 10 Fundamentals of The Metal - Oxide - Semiconductor Field Effect TransistorDocument57 pagesCHAPTER 10 Fundamentals of The Metal - Oxide - Semiconductor Field Effect TransistorTAMILSELVI S S TAMILSELVI S SPas encore d'évaluation

- Data Option Bit Pada TV PolytronDocument5 pagesData Option Bit Pada TV PolytronNahnu csPas encore d'évaluation

- ServiceManuals LG TV LCD 32LE5510 32LE5510 Service ManualDocument44 pagesServiceManuals LG TV LCD 32LE5510 32LE5510 Service Manualkemal127Pas encore d'évaluation

- Unit 17Document13 pagesUnit 17ahmed35767% (3)

- Customer Satisfaction Towards WhatsappDocument41 pagesCustomer Satisfaction Towards WhatsappMeher Anusha77% (13)

- Pe Cep A3Document3 pagesPe Cep A3M Hassan BashirPas encore d'évaluation

- ..Document2 pages..eim lenidePas encore d'évaluation

- Doc8385 ATxmega128A1U ManualDocument216 pagesDoc8385 ATxmega128A1U ManualAisa HromadzicPas encore d'évaluation

- 15.3 Nonlinear Applications: 15.3.1 Monostable Multivibrator Using Op-AmpDocument6 pages15.3 Nonlinear Applications: 15.3.1 Monostable Multivibrator Using Op-AmpAryan NagvencarPas encore d'évaluation

- Fall 16 Chapter 10 WDM Concept and ComponentsDocument81 pagesFall 16 Chapter 10 WDM Concept and ComponentssohaibPas encore d'évaluation

- 54 16 5000Document2 pages54 16 5000Anonymous VKPfb3Pas encore d'évaluation

- Microfon Philips SME 570Document2 pagesMicrofon Philips SME 570AramaPas encore d'évaluation

- Facts SeriesandshuntcompensationDocument56 pagesFacts SeriesandshuntcompensationIfranul HaquePas encore d'évaluation

- Imx477 DSDocument25 pagesImx477 DSKaanyaePas encore d'évaluation

- Behringer X-Touch Editor Preset MIDI2LR User Guide and Installation v2.03Document2 pagesBehringer X-Touch Editor Preset MIDI2LR User Guide and Installation v2.03legionc50% (2)

- Atom Transcapsule V-707 Incubator - User Manual PDFDocument64 pagesAtom Transcapsule V-707 Incubator - User Manual PDFsangPas encore d'évaluation

- Scope of Work For The Supply and Installation of Solar Power SystemDocument12 pagesScope of Work For The Supply and Installation of Solar Power SystemAzizullah AlizayPas encore d'évaluation

- BS 4579 2 PDFDocument12 pagesBS 4579 2 PDFSharada PremarathnePas encore d'évaluation