Académique Documents

Professionnel Documents

Culture Documents

Design of Industrial Warehouse IJERTV7IS020170

Transféré par

Anonymous Uf0LDX6GCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design of Industrial Warehouse IJERTV7IS020170

Transféré par

Anonymous Uf0LDX6GDroits d'auteur :

Formats disponibles

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 7 Issue 02, February-2018

Design of Industrial Warehouse

Shivani Meher1 Ruchita Nar2

Department of Civil Engineering Department of Civil Engineering

Vidyavardhini’s College of Engineering and Technology Vidyavardhini’s College of Engineering and Technology

Vasai, India Vasai, India

Sadichha Jagadale3 Gautami Kalal4

Department of Civil Engineering Department of Civil Engineering

Vidyavardhini’s College of Engineering and Technology Vidyavardhini’s College of Engineering and Technology

Vasai, India Vasai, India

Asst. Prof. Viren Chandanshive5

Department of Civil Engineering

Vidyavardhini’s College of Engineering and Technology

Vasai, India

Abstract— In India, due to rapid growth of industrialization, A. General

there arise a need of storage and manufacturing of goods which

Typically the bays in industrial buildings have frames

can be fulfilled by proper designed industrial warehouse. This

study gives an idea to carry out the design of an industrial spanning the width direction. Several such frames are arranged

warehouse. This topic of work is decided as to know the different at suitable spacing to get the required length. Depending upon

types of force/load effects to be considered while designing the requirement, several bays may be constructed adjoining

industrial warehouse with the help of literature review. This each other. The horizontal and vertical bracings, employed in

structure is proposed to design according to IS 800:2007 and the single and multi-storey buildings, and also trusses are used

dead, live, the wind load analysis is done according to IS primarily to resist wind and other lateral loads. These bracings

875:1987 (Part-I, Part-II, Part-III). The area for proposed minimize the differential deflection between the different

warehouse design was decided and proper architectural plan was frames due to crane surge in industrial buildings. They also

prepared according to the requirements. The forces acting on the

provide lateral support to columns in small and tall buildings,

adjacent members when one of the members is under loading and

calculating the excess stresses and ratios induced in these thus increasing the buckling strength. Sheeting, purlin and

connected members and also, the moments and forces produced supporting roof trusses supported on column provide common

are obtained and mentioned. Then different members of structural roof system for industrial buildings (Fig.I). Truss

warehouse for e.g. Truss members, columns and connections, etc. includes members such as Top Chord, Bottom Chord, and

were designed and final result are obtained. Finally the Web Member.

conclusion is made that warehouse can be designed easily

adopting simple design procedure and IS specifications. B. Loads and load combinations

• Dead load

Keywords— Warehouse, Load Combination ,Dead Load, Live Dead load comprises of self-weight of the structure,

Load, Wind Load, Nodes. weights of roofing, G.I. sheets, gantry girder, crane girder,

purlins, sag rods, bracings and other accessories.

I. INTRODUCTION

An industrial shed is any building structure used by the • Live load

industry to store raw materials or for manufacturing products According to IS : 875 (Part 2) – 1987, for roof with no

of the industry is known as an industrial building. Industrial access provided, the live load can be taken as 0.75 kN/m2 with

buildings may be categorized as Normal type industrial a reduction of 0.02 kN/m2 for every one degree above 10

buildings and Special type industrial buildings. Normal types degrees of roof slope.

of industrial building are shed type buildings with simple roof

structures on open frames. These buildings are used for • Wind load

workshop, warehouses etc. These building require large and Wind load is calculated as per IS: 875 (Part 3) – 1987. The basic

clear areas unobstructed by the columns. The large floor area wind speed for the location of the building is found to be 15km/h.

provides sufficient flexibility and facility for later change in the The wind load over the roof can be provided as point loads acting

production layout without major building alterations. Special outward over the CSB panel points.

types of industrial buildings are steel mill buildings used for • Load combinations:-

manufacture of heavy machines, production of power etc. The Following codes are used for deciding load combinations

function of the industrial building dictates the degree of and for designing members according to it.

sophistication. A structure is a collective result of idea, design,

material, man power, time, finance etc. As need is the mother IS CODE-

of invention, similarly, type of construction and its proper 1. IS 875-1987 for load calculation

required design is a necessity.

3. IS 800:2007 for load calculation

IJERTV7IS020170 www.ijert.org 302

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 7 Issue 02, February-2018

II. LITERATURE STUDY A plan according to requirement and considering

This section discusses the literature reviewed related to architectural aspects was prepared. The plan for the proposed

design of industrial warehouse. industrial warehouse is given in Fig.III.

M. Suneetha completed a numerical study and concluded Trapezoidal truss was adopted with roof slope 1:5. For this

that Weight of single Truss utilizing Angle and Pipe both is span length, the trapezoidal trusses would be normally efficient

less compared to PEB yet because of Weight of Channel and economical. Approximate span to depth ratio is about L/8

Purlin, Weight of Steel Truss Building is on higher side. to L/12. Truss Spacing may be in the range of 1/4th to 1/5th of

the span length. Depth of truss, spacing of trusses, spacing of

Vaibhav B. Chavan, determined optimum span length for purlins were decided according to specifications.

economy.

Size of GI sheeting varies from 8 to 11 corrugations per

Author C.M. Meera made a comparative study between sheet. The weights of sheet varies from 50-156 N/m2. Selection

Pre-Engineered Building (PEB) and Conventional Steel of gravity loads generally control the bay size. For buildings

Building (CSB) and analyzing the design frames using without cranes, a 9m bay is the most suitable and economical

structural analysis and design software STAAD PRO. choice. Function of bracing is to transfer horizontal loads from

Subhrakant Mohakul designed an Industrial warehouse and the frames to foundation. Purlins acts as lateral bracings to the

did a thorough study of behaviour of members due to effect of compression chords. The lateral ties provide similar functions

failure at connecting joints. to the bottom chord members when they are subjected to

compression due to reversal of loading. Purlin is a part of roof

Manan D.Maisuri stated that the consumption of steel of bracing system. The weight of purlin in the total weight of steel

whole industrial building can be reduced by deciding structure could vary from 10-25%. The weight of purlin may

appropriate geometry of truss and by using hollow steel section be equal to or greater than the weight of the trusses. Spacing of

with compare to conventional steel section. Thus stating tube purlin depends largely on the maximum safe span of roof

sections are most economical. covering and the glazing sheets. The purlin spacing may vary

Research paper by Shaiv Parikh emphasis on the from 1.5-1.75m. The depth of the truss determines its stiffness

importance of compression members and gives brief in relation to its span and also its economy. Roof depth range

description about the characteristics and the behaviour of steel from 1/12 to 1/8 of the span for continuous trusses.

compression members. Loading consideration is as follows: dead load calculation

A.Jayaraman presents a study on behavior and economical includes GI sheeting weight, fixings, services, roof dead load,

of roof trusses and channel section purlins by comparison of weight of purlin, and self-weight of one truss. Then calculation

LSM and WSM. is carried out for nodal dead loads. As per IS 875 (Part 3)-1987

wind load calculated by considering basic wind speed in

Yash Patel states the importance of tubular sections and Mumbai=44m/s. Wind load F on roof truss by static wind

concludes the economic advantages of tubular sections. method is given by (clause 6.2.3.2 of IS 875) as follows:

III. OBJECTIVE OF STUDY F=(Cpi-Cpe)*A*Pd

• To identify various loads and load combinations acting After getting wind load, calculation of wind pressure were

on the structure. carried out and results are tabulated. (Table II). For designing

• To design the industrial warehouse as per its drawing one should consider critical wind pressure/loads given in Table

details. III. After calculations of all the loads, load combinations

• To check the structure as per is code, with all the adopted are as follows:

members as per the drawings.

(Clause 3.5.1 and 5.3.3 IS 800: 2007)

IV. METHODOLOGY ADOPTED

In this research, the region for proposed structure and (DL*1.5)+ (LL*1.5)

dimensions were fixed according to the requirement and (DL*1.5)+ (WL*1.5)

considering different parameters like storage space required,

In the design of any industrial shed design of truss member

adequate lighting, etc. The details about warehouse are given

is most important part. There are various types of truss:- King

below;

TABLE I: DETAILS OF WAREHOUSE Post Truss, Pitched Pratt Truss, Fan Truss, Queen Post Truss,

Sr.no. Particulars Description Trapezoidal Truss, Mansard Truss, Cambered Truss, etc. For

1. Type of building Container Warehouse span of 30m trapezoidal truss is most economical. Hence

2. Type of structure Single Storey Industrial Structure trapezoidal type of truss was adopted (fig. II and III).

3. Location Mumbai

4. Area of site 7875sq.m. (84766.5 sq.ft.) Truss consists of members that are: Top chord member,

5. Type of building Steel Building bottom chord member, web member, side runner, tie runner,

6. Area of building 5400sq.m. (58125.6 sq.ft.) etc. Before actual design of members, analysis of truss were

7. Eave height 12m carried out by simple manual procedure. Truss members can

8. Number of spans 2 carry compression or tension force, after analysing maximum

9. Single span width 30 m force is considered for design. The members of the trusses are

10. Total span width 60 m

11. Number of bays 15

made of either rolled steel sections or built-up sections

12. Single bay length 6m depending upon the span length and intensity of loading.

13. Total bay length 90m Rolled steel single or double angles, T sections, hollow section,

square or rectangular sections (Fig. IV) are used in roof trusses

IJERTV7IS020170 www.ijert.org 303

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 7 Issue 02, February-2018

of industrial buildings. Each member is designed and checked

as per IS 800.

Columns are designed as a compression member carrying

loads coming from the roof structure. After all component

members of warehouse connections were designed to join

column to truss and internal connections between truss, etc.

Fig. I. Truss and column design

Fig. IV. Various types of steel section

Fig. II. Component parts of Trapezoidal Truss

Fig. III. Trapezoidal Truss

IJERTV7IS020170 www.ijert.org 304

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 7 Issue 02, February-2018

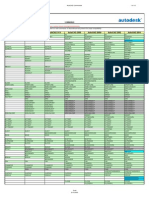

FIG. V. AUTOCAD PLAN

TABLE II. WIND LOAD ON ROOF TRUSS

Wind load

Pressure coefficients

(KN)

Wind Cpe ± Cpi

Cpe

angle A* Pd

Cpi

Windward leeward Windward Leeward Windward Leeward

0o -1.1 -0.4 -0.5 -1.6 -0.9 15.31 -24.624 -15.779

0.5 -0.6 0.1 15.31 -9.186 -0.9186

90o -0.79 -0.79 -0.5 -1.29 -1.29 15.31 -19.749 -19.744

0.5 -0.29 -0.29 15.31 -4.439 -4.439

TABLE III CRITICAL WIND LOADS

windward side Leeward side

Wind angle

End and apex

Intermediate nodes(w3) End and apex nodes(w3/2) Intermediate nodes (w4)

Nodes(w4/2)

0o -24.624 -12.312 -13.779 -6.8895

90o -19.749 -9.8749 -19.749 -9.8745

IJERTV7IS020170 www.ijert.org 305

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 7 Issue 02, February-2018

VIII. CONCLUSION

V. ABBREVATIONS In this dissertation, Numerical study was completed

IS = Indian Standard considering Mumbai Region, the necessary and appropriate

loads and loading combinations were adopted. AUTOCAD

Dl = Dead load

plan was prepared followed by load calculations. Based on

Ll = Live load which different members like truss members, columns,

Wl = Wind load purlins, etc. were selected and designed. The entire process

was completed as per the standards laid down by Indian

Cpi = Internal pressure coefficient Standard. The paper effectively conveys that the industrial

Cpe = External wind coefficient warehouse can be easily designed by simple design procedure

in accordance with the country standards.

A = Area

Pd = Design wind pressure IX. REFERENCES

[1] M.Suneetha1,Naresh Kumar, Gillela Reddy October 2016, “Design and

VI. RESULTS AND DISCUSSION Analysis of Industrial Building with Gable Roof by using STAAD.PRO”

All members are designed according to the loads coming on International Journal of Advance Technology In Engineering and

Science.

the structure and as per IS code specifications. Results obtained

[2] Vaibhav B. Chavan, Vikas N. Nimbalkar And Abhishek P. Jaiswal, Vol.

are as follows: 3, Issue 2, February 2014 “ Economic Evaluation Of Open And Hollow

Stuctural Sections In Industrial Trusses”, Aci Structural Journal.

TABLE IV. SUMMARY OF RESULTS

Member Section provided [3] C.M. Meera, June 2013 “Pre- Engineered Building Design of an

Top chord 2ISA 200*200*24 Industrial warehouse”. International Journal of Engineering Sciences

Bottom chord 2ISA 110*110*8 and Emerging Technologies.

Web member 2ISA 150*150*18 [4] Subhrakant Mohakul, Dr. Shaikh Yajdani, Abhay Dhurde,August 2014

Column 1 ISHB 450@87.2 kg “Design of industrial storage shed and analysis of stresses produced on

Column 2 ISWB 600@145.1 kg failure of a joint”. International Journal of Civil Engineering and

Technology.

Rafter bracing ISA 90*90*6

Purlin ISMC 100 [5] Manan D.Maisuri, Hitesh K.Dhameliya, Hiten L.Kheni, Vol.1 Issue 12,

December 2013, “Review Of Comparison Between Conventional Steel

And Tubular Steel Section For Multi Span Industrial Shed With Truss

VII. SCOPE AND APPLICATIONS And Portal Frame” International Journal of Advance Engineering and

Purchase of raw material is an integral part of any business. Research Development.

These raw materials need to be kept in a safe place, hence in [6] Shaiv Parikh ,”Design of Steel Compression Members” (According To

order to rectify this need warehouse are constructed. In future IS: 800)

due to rapid growth in industrialization there will occur a great [7] Yash Patel, Shreepalsinh Gohil, Dr .Tausif Kauswala ,Het Parmar,

need to construct economically efficient warehouses. The volume 3 issue 10, april2006, “Analysis And Design Of Conventional

design will serve the purpose of storage of goods. Industrial Roof Truss And Compare It With Tubular Industrial Roof

Truss” International Journal of Science Technology and Engineering.

Applications: [8] A.Jayaraman, R Geethamani, N Sathyakumar,N Karthiga

Shenbagam,“Design and Economical of Roof Trusses & Purlins

• Various industries requires warehouse to store their (comparison of LSM and WSM)”

goods such as packing warehouses, Railway [9] Design of Steel Structures by N. Subramanian

warehouses, Canal warehouses, Cool warehouses and

cold storage.

• The calculations and design is executed considering

economy and safety factors.. The factors and steps

highlighted while execution of project is important to

design any other industrial shed.

• Efficient designing and analysis for any similar

industrial shed which is to be constructed.

• Getting to know factors affecting the construction.

IJERTV7IS020170 www.ijert.org 306

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Vous aimerez peut-être aussi

- Structural Analysis and Design of An Industrial Building: @seismicisolationDocument54 pagesStructural Analysis and Design of An Industrial Building: @seismicisolationTeme man of TPas encore d'évaluation

- Analysis of Warehouse Structure in Pre-Engineered Building With Conventional Steel BuildingDocument12 pagesAnalysis of Warehouse Structure in Pre-Engineered Building With Conventional Steel BuildingIJRASETPublicationsPas encore d'évaluation

- Seismic Evaluation of Pre-Engineering and Conventional Steel Structure-A ReviewDocument6 pagesSeismic Evaluation of Pre-Engineering and Conventional Steel Structure-A ReviewIJRASETPublicationsPas encore d'évaluation

- Article On 'Pre-Engineered Building (PEB) Industry in India' by Chaitanya Raj GoyalDocument5 pagesArticle On 'Pre-Engineered Building (PEB) Industry in India' by Chaitanya Raj GoyalChaitanya Raj GoyalPas encore d'évaluation

- Staad Pro Editor FileDocument2 pagesStaad Pro Editor Fileanupsingh775Pas encore d'évaluation

- Training Manual RAM Ans STAAD-1Document13 pagesTraining Manual RAM Ans STAAD-1tigersronniePas encore d'évaluation

- STDCE TH Editting 01Document43 pagesSTDCE TH Editting 01lavyPas encore d'évaluation

- Design of Industrial Roof Truss and Analysis of Member ForcesDocument15 pagesDesign of Industrial Roof Truss and Analysis of Member ForcesSUDHIR GAYAKEPas encore d'évaluation

- PEB-Conventional Structure ComparisonDocument18 pagesPEB-Conventional Structure ComparisonTanmay Dutta100% (1)

- (DM) Implementing The New Building Code For Earthquake Proof BldgsDocument14 pages(DM) Implementing The New Building Code For Earthquake Proof BldgsJose Leo MissionPas encore d'évaluation

- Technical Report StaadDocument48 pagesTechnical Report StaadochukoikoghoPas encore d'évaluation

- RamConcept ManualDocument654 pagesRamConcept ManualMike JuniorPas encore d'évaluation

- Strengthening of RC Columns by Steel Angles and StripsDocument12 pagesStrengthening of RC Columns by Steel Angles and StripsGema Putra PratamaPas encore d'évaluation

- Pre-Engineered Metal Buildings The Latest Trend in Building ConstructionDocument6 pagesPre-Engineered Metal Buildings The Latest Trend in Building ConstructionAshish SharmaPas encore d'évaluation

- MS RHSDocument4 pagesMS RHSashaswamyPas encore d'évaluation

- Staad FileDocument15 pagesStaad Fileakhlaq_hssainkotaPas encore d'évaluation

- Structural Analysis ReportDocument3 pagesStructural Analysis ReportLandz GanzonPas encore d'évaluation

- Steel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiDocument6 pagesSteel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- ETABS RC Slab Design v19Document366 pagesETABS RC Slab Design v19Mike Smith100% (1)

- LDA 1505 Stantec Structural Foundation DesignDocument280 pagesLDA 1505 Stantec Structural Foundation DesignPreetham PjPas encore d'évaluation

- Analysis and Design of High-Rise Building (G+30) UsingDocument4 pagesAnalysis and Design of High-Rise Building (G+30) UsingShaikh Muhammad AteeqPas encore d'évaluation

- Zamil Steel Vietnam (ZSV) : Total Steel Building SolutionsDocument80 pagesZamil Steel Vietnam (ZSV) : Total Steel Building SolutionsTuan Hung TrinhPas encore d'évaluation

- Pre-Engineered Building Solutions - FUXIN Steel Buildings Co., Ltd. 2015Document28 pagesPre-Engineered Building Solutions - FUXIN Steel Buildings Co., Ltd. 2015vannethny100% (2)

- Steel Design Practical Design NotesDocument4 pagesSteel Design Practical Design NotesrangarajanPas encore d'évaluation

- Project Report of Pre Engineered Steel BuildingDocument114 pagesProject Report of Pre Engineered Steel Buildinganon_10826711184% (37)

- A Report On Structure Analysis and Design of Residential BuildingDocument12 pagesA Report On Structure Analysis and Design of Residential BuildingBinod Raj GiriPas encore d'évaluation

- UFGS Metal Building SystemsDocument45 pagesUFGS Metal Building SystemsMayyouPas encore d'évaluation

- Design of Industrial BuildingsDocument29 pagesDesign of Industrial Buildingsbrownpepper30100% (2)

- Structural Design Basic ReportDocument4 pagesStructural Design Basic Reportvaidehisarathy1857Pas encore d'évaluation

- Tutorial - STAAD - Pro Link: 1 How To Activate The LinkDocument19 pagesTutorial - STAAD - Pro Link: 1 How To Activate The LinkDass MPas encore d'évaluation

- Tekla Structures Catalog ProfilesDocument144 pagesTekla Structures Catalog ProfilesNeenu VsPas encore d'évaluation

- 7 Stair DesignDocument16 pages7 Stair Designkriengsak ruangdechPas encore d'évaluation

- Project Report-12Document89 pagesProject Report-12Sri RamyaPas encore d'évaluation

- Session 4 - Structural Design CriteriaDocument34 pagesSession 4 - Structural Design CriteriaEdeline AnsayPas encore d'évaluation

- Comparison of Design Procedures For Pre Engineering Buildings PEB A Case StudyDocument26 pagesComparison of Design Procedures For Pre Engineering Buildings PEB A Case StudyFauziah AminatunPas encore d'évaluation

- Design of Long Span Steel Structures and Hangars.Document15 pagesDesign of Long Span Steel Structures and Hangars.Supri OlixPas encore d'évaluation

- Metal Building Systems: Pdhonline Course S120 (1 PDH)Document11 pagesMetal Building Systems: Pdhonline Course S120 (1 PDH)SunilBhargavSanathiPas encore d'évaluation

- Design of Pre Engineered Steel Building For Aircraft Hangar Using Staad Pro V8iDocument2 pagesDesign of Pre Engineered Steel Building For Aircraft Hangar Using Staad Pro V8iDharma banothuPas encore d'évaluation

- Design Basis For Roof TrussDocument22 pagesDesign Basis For Roof TrussUmer AziqPas encore d'évaluation

- Structure Design Calculation For General Cargo Warehouse & CFSDocument170 pagesStructure Design Calculation For General Cargo Warehouse & CFSAugusto Rafael PereiraPas encore d'évaluation

- Steel Use in Architectural Appearance PurposeDocument51 pagesSteel Use in Architectural Appearance Purposeparth bhavsarPas encore d'évaluation

- Pre-Engineering Metal BuildingsDocument20 pagesPre-Engineering Metal BuildingsAbhishek GandhiPas encore d'évaluation

- Staad Course MatlDocument24 pagesStaad Course MatlAbhishek Kumar Gupta67% (3)

- Comparative Study of STAAD, SAP & ETABS SoftwareDocument14 pagesComparative Study of STAAD, SAP & ETABS SoftwareGaurav DattaPas encore d'évaluation

- Design Basis ReportDocument71 pagesDesign Basis ReportMohammed Ikramali100% (1)

- Using STAAD Pro 2005 CoursewareDocument83 pagesUsing STAAD Pro 2005 Coursewaredktiong100% (2)

- 1 How To Activate The LinkDocument6 pages1 How To Activate The LinkThinh Vipro100% (1)

- Ijstev2i10284 PDFDocument6 pagesIjstev2i10284 PDF081382991318Pas encore d'évaluation

- Analysis and Design of Conventional Industrial Roof Truss and Compare It With Tubular Industrial Roof TrussDocument6 pagesAnalysis and Design of Conventional Industrial Roof Truss and Compare It With Tubular Industrial Roof TrussIJSTEPas encore d'évaluation

- Design of Industrial Steel Building by Limit State MethodDocument11 pagesDesign of Industrial Steel Building by Limit State MethodbharathikrishnaPas encore d'évaluation

- Study For Comparison On Design of Steel Frame Using Rolled, Fabricated and PEB SectionsDocument5 pagesStudy For Comparison On Design of Steel Frame Using Rolled, Fabricated and PEB SectionsEditor IJTSRDPas encore d'évaluation

- Irjet V7i9576Document4 pagesIrjet V7i9576umashankaryaligarPas encore d'évaluation

- Fin Irjmets1654415377Document6 pagesFin Irjmets1654415377Ali Asghar LangahPas encore d'évaluation

- Wind and Seismic Analysis of Pre-Engineered BuildingDocument10 pagesWind and Seismic Analysis of Pre-Engineered BuildingIJRASETPublicationsPas encore d'évaluation

- Research Paper On Analysis and Design ofDocument16 pagesResearch Paper On Analysis and Design ofPalesaPas encore d'évaluation

- A Comparative Study of Conventional Steel Building and Pre-Engineered Steel Building Structure Using STAAD PRODocument7 pagesA Comparative Study of Conventional Steel Building and Pre-Engineered Steel Building Structure Using STAAD PROIJRASETPublicationsPas encore d'évaluation

- A Comparative Study On Analysis & Design of Pre-Engineered & Conventional Industrial BuildingDocument7 pagesA Comparative Study On Analysis & Design of Pre-Engineered & Conventional Industrial BuildingAyush GargPas encore d'évaluation

- IJCRT2303651Document4 pagesIJCRT2303651pankaj645924Pas encore d'évaluation

- A Comparative Study On Analysis & Design of Pre-Engineered & Conventional Industrial BuildingDocument6 pagesA Comparative Study On Analysis & Design of Pre-Engineered & Conventional Industrial BuildingIJIRSTPas encore d'évaluation

- Final PDFDocument9 pagesFinal PDFSagar B KatariyaPas encore d'évaluation

- Math Lesson Plan-Topic 8.4 - Tens and OnesDocument4 pagesMath Lesson Plan-Topic 8.4 - Tens and Onesapi-352123670Pas encore d'évaluation

- Chapter Eighteen: Creating Competitive AdvantageDocument34 pagesChapter Eighteen: Creating Competitive AdvantageSana MehmoodPas encore d'évaluation

- Axial Piston Fixed Motor AA2FM Series 6x: AmericasDocument30 pagesAxial Piston Fixed Motor AA2FM Series 6x: AmericasKaian OliveiraPas encore d'évaluation

- BOXER NH TC35DA TC40DA TC45DA Mount Instructions PDFDocument16 pagesBOXER NH TC35DA TC40DA TC45DA Mount Instructions PDFjwdPas encore d'évaluation

- P-L-N-Statistik 2011Document104 pagesP-L-N-Statistik 2011Ahmad AfandiPas encore d'évaluation

- White Paper - SuperUserDocument16 pagesWhite Paper - SuperUsermdsauberPas encore d'évaluation

- Apache Derby DatabaseDocument4 pagesApache Derby DatabaseJohn KrcmarikPas encore d'évaluation

- Glass Defect CompleteDocument99 pagesGlass Defect CompleteHimanshu Vaid67% (3)

- Practice - Creating A Discount Modifier Using QualifiersDocument37 pagesPractice - Creating A Discount Modifier Using Qualifiersmadhu12343Pas encore d'évaluation

- Exercises 1 FinalDocument2 pagesExercises 1 FinalRemalyn Quinay CasemPas encore d'évaluation

- Crichton, Michael - NextDocument351 pagesCrichton, Michael - NextrtarakPas encore d'évaluation

- P2 Web Architecture WorksheetDocument4 pagesP2 Web Architecture Worksheetvinayv96Pas encore d'évaluation

- SJ 9 PDFDocument52 pagesSJ 9 PDFNicolas X FloresPas encore d'évaluation

- J030 J032 Eu Aa V1.00Document41 pagesJ030 J032 Eu Aa V1.00gkalman_2Pas encore d'évaluation

- Topic 1 Valve and Instrumentation SymbolsDocument8 pagesTopic 1 Valve and Instrumentation SymbolshatiniPas encore d'évaluation

- A Seminar Report On Virtualization Techniques in Cloud - ComputingDocument33 pagesA Seminar Report On Virtualization Techniques in Cloud - ComputingParth AgarwalPas encore d'évaluation

- Intro To Computing SyllabusDocument7 pagesIntro To Computing SyllabusAireen Rose Rabino ManguiranPas encore d'évaluation

- Bohol HRMD Plan 2011-2015Document233 pagesBohol HRMD Plan 2011-2015Don Vincent Bautista Busto100% (1)

- Oil Checks On Linde Reach Stacker Heavy TrucksDocument2 pagesOil Checks On Linde Reach Stacker Heavy TrucksmliugongPas encore d'évaluation

- AeroDocument27 pagesAeroBALAKRISHNANPas encore d'évaluation

- Windpro Directory - 04.02.11Document54 pagesWindpro Directory - 04.02.11Krishnan Veeraraghavan100% (1)

- Yahclick: Satellite InternetDocument6 pagesYahclick: Satellite InternetVasco JosephPas encore d'évaluation

- Essay On The Traffic Conditions in Big CitiesDocument3 pagesEssay On The Traffic Conditions in Big CitiesCeciliaPas encore d'évaluation

- Autocad R12 Autocad R13 Autocad R14 Autocad 2000 Autocad 2000I Autocad 2002 Autocad 2004Document12 pagesAutocad R12 Autocad R13 Autocad R14 Autocad 2000 Autocad 2000I Autocad 2002 Autocad 2004veteranul13Pas encore d'évaluation

- CSC712 - Questions On Chapter 10 - Project ManagementDocument3 pagesCSC712 - Questions On Chapter 10 - Project ManagementKhairiBudayawanPas encore d'évaluation

- Company Work Execution Plan For A Long Form ContractDocument4 pagesCompany Work Execution Plan For A Long Form Contractshojaee1063Pas encore d'évaluation

- The Work of Frei Otto By. Ludwig GlaeserDocument137 pagesThe Work of Frei Otto By. Ludwig GlaeserUntal Aparicio100% (1)

- NTE931 Integrated Circuit 3-Terminal Positive Voltage Regulator 5V, 3ADocument2 pagesNTE931 Integrated Circuit 3-Terminal Positive Voltage Regulator 5V, 3AWilfredo MolinaPas encore d'évaluation

- UNIC Jakarta Internship ApplicationDocument4 pagesUNIC Jakarta Internship ApplicationMuhammad IkhsanPas encore d'évaluation

- Ea295 PDFDocument3 pagesEa295 PDFjhiilPas encore d'évaluation