Académique Documents

Professionnel Documents

Culture Documents

Model CB 15-100 HP Boilers: Sound Level

Transféré par

sebaversaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Model CB 15-100 HP Boilers: Sound Level

Transféré par

sebaversaDroits d'auteur :

Formats disponibles

Model CB 15-100 HP Boilers

Sound Level

Table A6-17 summarizes predicted sound pressure levels for Model CB Boilers.

Table A6-18 and A6-19 give detailed octave band sound pressure levels for each boiler.

These values are based on standard motors. Optional motor types and altitude conditions

can increase sound levels.

Units

The units for the sound level tables are dBA (decibels, measured on the A-weighted

scale) in reference to 0.0002 microbars (20 micro-Newtons per square meter). They are

standardly referenced in specifying and reporting sound pressure levels on industrial

equipment.

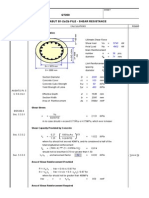

Table A6-13. Steam Volume and Disengaging Area

STEAM VOLUME CU-FT STEAM RELIEVING AREA, SQ-IN

BOILER HP

HIGH PRESSUREA LOW PRESSUREB HIGH PRESSUREA LOW PRESSUREB

15 2.9 5.9 1356 1637

20 2.9 5.9 1356 1637

25 & 30 3.9 7.9 1817 2195

40 5.3 10.8 2485 2999

50 9.7 16.0 2959 3372

60 9.7 16.0 2959 3372

70 14.3 23.7 4367 4975

80 14.3 23.7 4367 4975

100 16.6 27.4 5053 5757

NOTE: Based on normal water level.

A. Based on 150 psig design pressure.

B. Based on 15 psig design pressure.

Table A6-14. Water Circulation Rate and Temperature Drop for Hot Water Boiler

BOILER SYSTEM TEMPERATURE DROP - DEGREES F

BOILER OUTPUT 10 20 30 40 50 60 70 80 90 100

HP (1000)

BTU/HR MAXIMUM CIRCULATING RATE - GPM

15 500 100 50 33 25 20 17 14 12 11 10

20 670 134 67 45 33 27 22 19 17 15 13

30 1005 200 100 67 50 40 33 29 25 22 20

40 1340 268 134 89 67 54 45 38 33 30 27

50 1675 335 168 112 84 67 56 48 42 37 33

60 2010 402 201 134 101 80 67 58 50 45 40

70 2345 470 235 157 118 94 78 67 59 52 47

80 2680 536 268 179 134 107 90 77 67 60 54

100 3350 670 335 223 168 134 112 96 84 75 67

NOTES:

1. Minimum recommended return water temperature is 150 °F. Minimum recommended outlet temperature for Model CB Hot

Water Boilers is 170 °F. Contact your local Cleaver-Brooks authorized representative for special hot water application

information.

2. See Section H2 for over-pressure requirements.

Section A6-18 Rev. 07-10

Model CB 15-100 HP Boilers

Table A6-15. Recommended Steam Nozzle Size (To Maintain 4000 to 5000 fpm Nozzle Velocity)

BOILER HP

OPERATING

15 20 25 30 40 50 60 70 80 100

PRESSURE PSIG

15 4 4 4 46 6 6 6 6 8

30 2 2 2.5 2.5 3 4 4 4 4 6

40 2 2 2.5 2.5 3 3 4 4 4 6

50 1.5 2 2 2.5 2.5 3 3 4 4 4

75 1.5 2 2 2 2.5 3 3 3 4 4

100 1.5 1.5 2 22 3 3 3 3 4

125 1.5 1.5 2 22 3 3 3 3 4

150 1.5 1.5 2 22 2.5 2.5 2.5 2.5 2.5

200 1.5 1.5 2 22 2.5 2.5 2.5 2.5 2.5

250 1.5 1.5 2 22 2 2 2 2 2

NOTES:

1. Steam nozzle sizes given in inches.

2. Recommended steam nozzle sizes based on 4000 to 5000 fpm steam velocity. Spool

pieces (300 lb flanges) are available in the following sizes (in inches): 3x2-1/2x30,

4x3x30, 6x4x36, 8x6x48, 10x8x48, and 12x8x48.

3. All standard steam nozzle sizes for 150 psig design pressure or greater are the same

as 125 psig operating pressure on the above table. To increase or decrease the

standard size, request the change with your local Cleaver-Brooks authorized

representative.

Table A6-16. Model CB Blowdown Tank Sizing Information

BOILER HP WATER (GAL.)

15-20 26

25-30 34

40 47

50-60 55

70-80 80

100 93

NOTE: Quantity of water removed from boiler by lowering

normal water line 4".

Table A6-17. Sound Pressure Level Summary (50-100 hp)

BOILER HP 50 60 70 80 100

HFO, dBA 79 79 79 79 81

LFO, dBA 78 78 78 78 79

HFG, dBA 77 77 78 78 78

LFG, dBA 72 73 74 75 75

NOTES:

1. Boiler No. followed by an “a” designates hot water boilers furnished in a

smaller vessel size with additional tubes in the upper portion of the vessel.

2. Sound Pressure levels measured on boilers operating in various locations

and expressed in dBA are as follows:

NOTE: ABBREVIATIONS: HF = High Fire LF = Low Fire O = Oil G = Gas

Section A6-19 Rev. 07-10

Model CB 15-100 HP Boilers

Table A6-18. Model CB Boiler Sound Pressure Level Details (40 hp)

FIRING SOUND OCTAVE BAND SOUND PRESSURE LEVELS IN dB RE .0002 MICROBAR

RATE LEVEL

FUEL dBA 31Hz 63Hz 125Hz 250Hz 500Hz 1kHz 2kHz 4kHz 8kHz 16kHz

A

40HP

LFG 76 73 75 72 74 76 70 67 68 64 57

LFO 77 73 75 75 76 75 72 67 66 66 58

HFG 79 81 78 74 80 78 71 69 68 64 58

HFO 79 72 77 77 81 78 73 69 66 66 58

A. The data shown above was taken on the 40 hp. Since the highest Sound Level is below 80 dBA, no additional 36"

diameter Firetubes were tested. If Sound Level predictions are required for the 15 thru 30 hp, use the values shown for the

40 hp.

NOTE: ABBREVIATIONS: HF = High Fire LF = Low Fire O = Oil G = Gas

Table A6-19. Model CB Boiler Sound Pressure Level Details (50 - 100 hp)

SOUND OCTAVE BAND SOUND PRESSURE LEVELS IN dB RE .0002 MICROBAR

FIRING

LEVEL

RATE FUEL 31Hz 63Hz 125Hz 250Hz 500Hz 1kHz 2kHz 4kHz 8kHz 16kHz

dBA

50 HP

LFG 72 71 65 71 71 70 68 63 60 53 46

LFO 78 71 76 78 73 72 72 76 61 56 54

HFG 77 72 68 75 76 74 74 66 61 54 47

HFO 79 72 70 75 75 77 77 70 63 56 54

60 HP

LFG 73 70 75 72 72 73 68 61 56 50 45

LFO 78 68 77 74 74 75 74 71 58 53 48

HFG 77 73 75 72 72 75 76 63 55 50 44

HFO 79 75 75 75 75 77 77 72 59 52 45

70 HP

LFG 74 70 70 75 74 73 71 62 56 51 46

LFO 78 70 73 77 74 75 74 70 59 53 57

HFG 78 72 72 77 78 75 76 68 58 52 57

HFO 79 73 73 80 77 77 76 70 60 54 48

80 HP

LFG 75 70 75 75 73 75 76 66 62 62 53

LFO 78 69 77 76 74 76 74 73 63 62 57

HFG 78 72 74 78 75 75 76 57 61 59 52

HFO 79 75 75 75 74 76 75 69 62 59 54

100 HP

LFG 75 69 69 75 76 73 71 65 63 59 50

LFO 79 68 73 78 78 75 79 76 63 59 54

HFG 78 69 70 77 77 74 74 69 63 59 50

HFO 81 68 70 77 78 78 77 71 64 59 57

NOTES: ABBREVIATIONS: HF = High Fire LF = Low Fire O = Oil G = Gas

Boiler HP followed by an “A” designates hot water boilers furnished in a smaller vessel size with additional tubes in the

upper portion of the vessel.

Section A6-20 Rev. 07-10

Model CB 15-100 HP Boilers

Test Method

The sound pressure levels in the above tables were obtained from tests in accordance

with the "ABMA Test Code for the Measurement of Sound from Packages Boilers." In

accordance with this code, the sound pressure levels reported were measured on the

boiler centerline 4-1/2 feet vertically above the bottom of the base rails and 3 feet

horizontally in front of the end of the blower motor or front surface of the electrical

cabinet.

Sound Level Meter

The sound level meter used complies with ANSI S1.4, Type 1 (Precision). The readings

are taken with the meter set for slow response.

Sound Pressure

On large size boilers, the need for auxiliary equipment, and the necessary

interconnecting piping, make it impractical (and sometimes impossible) to provide a boiler

testing environment that is suitable for obtaining the data needed to develop Sound

Pressure Power levels.

Typical Values

Sound pressure levels (dBA) for identical boilers will vary between boiler rooms. In

addition, variations will occur between different people using different sound meters on

the same boiler. And finally, no two boilers can be expected to give precisely the same

sound levels. For these reasons, we can only predict, but not guarantee, sound levels

(dBA).

Octave Band

When predicting sound pressures in octave bands (e.g., dB at 125 Hz), even greater

variations between boilers, between sound meters, and between operators can be

expected. These larger variations in the low and high frequencies make octave band

levels a less reliable method of reporting than A-scale sound levels. (Since A-scale sound

levels are dominated by mid-frequency sounds, the A-scale sound levels between two

boilers can be in reasonable agreement even though the low and high frequencies of

octave band measurement do not closely correspond).

Gas-Fired Burners

Table A6-20 shows minimum gas pressure requirements for Model CB Boilers.

Table A6-21 shows minimum required gas pressure altitude conversion.

Table A6-22 shows maximum gas consumption for natural gas and propane vapor.

Figure A6-7 shows standard gas train sizes and locations for Model CB Firetube Boilers.

Figure A6-8 shows typical gas train piping layouts for multiple boiler applications.

Figure A6-9 shows gas train components.

Oil-Fired Burners

Fuel oil consumption information is shown on the boiler rating sheets in the Dimensions

and Rating Section.

Figure A6-10 shows the oil connection sizes and locations for Model CB Boilers firing No.

2 oil.

Figure A6-11 shows the oil connection sizes and locations for Model CB Boilers firing No.

5 and No. 6 oil.

Figure A6-12 through Figure A6-14 show typical oil systems and layouts.

Figure A6-15 shows the detail of an oil transfer tank (day tank) typically utilized to provide

a storage reservoir between the oil system supply pump and the boiler oil pump.

Section A6-21 Rev. 07-10

Model CB 15-100 HP Boilers

No. 6 Oil Piping, Storage Tank Heating

If the oil viscosity exceeds 4,000 SSU at the pumping temperature, tank preheating is

required.

Based on the climate conditions for the job location, the minimum pumping temperature

can be predicted, and the viscosity for the particular oil at this pumping temperature can

be determined.

It is recommended to provide for tank and/or line heating on all No. 6 oil installations to

ensure against high viscosities at decreased pumping temperatures. The following are

two common methods:

1. Provide a tank suction heater and bundling the steam or water lines to the heater

with the oil lines.

2. Provide electric heating equipment on the oil lines and/or in the storage tank.

Notice

The temperature in the oil suction line should not exceed 130 °F as higher

temperatures could cause vapor binding of the oil pump and decreased oil flow.

See Figure A6-16 for an example of tank heating method.

Table A6-20. Minimum Required Gas Pressure at Entrance to Gas Train

Gas Supply Pressure Less Than 27" W .C. Gas Supply Pressure Up To 10 Psi

Boiler Train

Hp Size Min. Supply Press Min. Supply Press

Regulator Model* Regulator Model*

"W .C. "W.C.

15 1-1/4 Maxitrol 1-1/4", RV-61 4 Maxitrol 1", 210-D 4

20 1-1/4 Maxitrol 1-1/4", RV-61 7 Maxitrol 1", 210-D 7

30 1-1/2 Maxitrol 1-1/2", RV-81 6 Maxitrol 1-1/4", 210-D 7

40 1-1/2 Maxitrol 1-1/2", RV-81 9 Maxitrol 1-1/4", 210-D 10

50 2 Maxitrol 2", RV-91 6 Maxitrol 1-1/4", 210-D 6

60 2 Maxitrol 2", RV-91 7 Maxitrol 1-1/4", 210-D 8

70 2 Maxitrol 2", RV-91 10 Maxitrol 1-1/4", 210-D 11

80 2 Maxitrol 2", RV-91 12 Maxitrol 1-1/2", 210-D 13

100 2 Maxitrol 2", RV-91 12 Maxitrol 1-1/2", 210-D 14

*Maxitrol RV series is standard; 210 series is optional

Table A6-21. Minimum Required Gas Pressure Altitude Conversion

ALTITUDE CORRECTION ALTITUDE CORRECTION

(FT) FACTOR (FT) FACTOR

1000 1.04 6000 1.25

2000 1.07 7000 1.30

3000 1.11 8000 1.35

4000 1.16 9000 1.40

5000 1.21 - -

To obtain minimum required gas pressure at altitudes

above 700 feet, multiply the pressure by the listed factors:

Inches WC x 0.577 = oz/sq-in.

Oz/sq-in x 1.732 = Inches WC.

Inches WC x 0.0361= psig.

Oz/sq-in x 0.0625 = psig.

Psig x 27.71 = Inches WC.

Psig x 16.0 = Oz/sq-in.

Section A6-22 Rev. 07-10

Vous aimerez peut-être aussi

- Sae J526 PDFDocument1 pageSae J526 PDFkoalaboiPas encore d'évaluation

- Modeling and CFD Analysis of Air FlowDocument15 pagesModeling and CFD Analysis of Air FlowTarik Hassan ElsonniPas encore d'évaluation

- B1-2A Pile ShearDocument8 pagesB1-2A Pile ShearFranklyn P. GenovePas encore d'évaluation

- Technical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionD'EverandTechnical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionPas encore d'évaluation

- Astm D 6546 - 00Document9 pagesAstm D 6546 - 00Khan ShahzebPas encore d'évaluation

- P315, P330, P350, P365Gear PumpDocument17 pagesP315, P330, P350, P365Gear PumpVictor Hugo Benitez Paez100% (3)

- Solution To Manometer Problem PDFDocument5 pagesSolution To Manometer Problem PDFMark Augusto V. AgusPas encore d'évaluation

- Pipe Sizing V2.3Document31 pagesPipe Sizing V2.3Hamdy AdelPas encore d'évaluation

- General Physics 1 Diagnostic TestDocument10 pagesGeneral Physics 1 Diagnostic TestAndria EspejoPas encore d'évaluation

- Drilling Fluids Processing HandbookD'EverandDrilling Fluids Processing HandbookÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Energy Efficient MotorsDocument6 pagesEnergy Efficient MotorsRoumya Darshan RayPas encore d'évaluation

- Design of Pressure VesselDocument19 pagesDesign of Pressure VesselSazzad hussain ProttoyPas encore d'évaluation

- 2014 - Cigre - Guide For Thermal Rating Calculations of Overhead Lines PDFDocument95 pages2014 - Cigre - Guide For Thermal Rating Calculations of Overhead Lines PDFBertrandFocher92% (12)

- Insulation Materials For The Building Sector A 2016 Renewable and SustainableDocument24 pagesInsulation Materials For The Building Sector A 2016 Renewable and SustainableFloreaPas encore d'évaluation

- Calculations of Rain Water Pipe Below Ground Pipe Sizing:: V (M/S) Max. Flow (L/S) Max. Flow (GPM)Document3 pagesCalculations of Rain Water Pipe Below Ground Pipe Sizing:: V (M/S) Max. Flow (L/S) Max. Flow (GPM)Hamdy AdelPas encore d'évaluation

- TS B3 SeriesDocument4 pagesTS B3 SeriesGuadalupe CondoriPas encore d'évaluation

- CatalogueDocument32 pagesCatalogueTom RobertPas encore d'évaluation

- 170M 6809Document2 pages170M 6809bernaPas encore d'évaluation

- Drilling Jar SpecDocument2 pagesDrilling Jar SpecPetroMan CMPas encore d'évaluation

- Butterfly Valve B7GDocument3 pagesButterfly Valve B7GJorgeCabreraCoronelPas encore d'évaluation

- Column Profiles: Optimize SetpointsDocument8 pagesColumn Profiles: Optimize SetpointsAhmed El HawariPas encore d'évaluation

- Column Profiles: Optimize SetpointsDocument8 pagesColumn Profiles: Optimize SetpointsAhmed El HawariPas encore d'évaluation

- CCI - Casing - Gas CompressorDocument30 pagesCCI - Casing - Gas CompressorManuel ChPas encore d'évaluation

- Centrifugal Pump Ebara 3DDocument3 pagesCentrifugal Pump Ebara 3Dsalman alfarisiPas encore d'évaluation

- Juntas Fluroflex N3 y N4Document1 pageJuntas Fluroflex N3 y N4Alberto Alfaro CerdaPas encore d'évaluation

- H CG 2018 BrochureDocument4 pagesH CG 2018 BrochureramatajamaPas encore d'évaluation

- SOAL A Penentuan Illuminasi - HARDI IBNU ZUKAI 20191330033Document8 pagesSOAL A Penentuan Illuminasi - HARDI IBNU ZUKAI 20191330033ZzzzPas encore d'évaluation

- Section 05 - RB 9Document1 pageSection 05 - RB 9sanshinde10Pas encore d'évaluation

- Steam Pipe SizingDocument2 pagesSteam Pipe SizingONLY PHYSICSPas encore d'évaluation

- Auto RunDocument8 pagesAuto RunAhmed El HawariPas encore d'évaluation

- UPVC Pipe SizeDocument2 pagesUPVC Pipe Sizeahmedomar_953724702Pas encore d'évaluation

- Final Year Design Lectures - Feb/Mar 2019: List of AttachmentsDocument12 pagesFinal Year Design Lectures - Feb/Mar 2019: List of AttachmentsMuzammil IqbalPas encore d'évaluation

- Catalog Standard Motor LTS PDFDocument20 pagesCatalog Standard Motor LTS PDFYogesh BadhePas encore d'évaluation

- Double ISA B-B Equal AngleDocument18 pagesDouble ISA B-B Equal AngleKasiPas encore d'évaluation

- Water Dynamic LoadDocument27 pagesWater Dynamic LoadsolarpolPas encore d'évaluation

- Chapter 5. Control Valve Selection: Cast Carbon Steel (ASTM A216 Grade WCC) - WCC Is The Most PopDocument8 pagesChapter 5. Control Valve Selection: Cast Carbon Steel (ASTM A216 Grade WCC) - WCC Is The Most PopRedzaPas encore d'évaluation

- Technical Specifications - Three Phase MotorsDocument1 pageTechnical Specifications - Three Phase MotorsNirmal mehtaPas encore d'évaluation

- Coupling Catalog oDocument3 pagesCoupling Catalog oGanesh KhandarePas encore d'évaluation

- Flexible Coupling PDFDocument4 pagesFlexible Coupling PDFSatPas encore d'évaluation

- Ultra High Pressure Water Jetting: AirblastDocument2 pagesUltra High Pressure Water Jetting: AirblastahmedPas encore d'évaluation

- Hyundai-Lifeboat - GRP Pipe BrochureDocument9 pagesHyundai-Lifeboat - GRP Pipe Brochure유연호Pas encore d'évaluation

- MOHAMADOU AWALOU PGE 5 Forage 16A181EMDocument13 pagesMOHAMADOU AWALOU PGE 5 Forage 16A181EMAwalou MohamadPas encore d'évaluation

- Stag en MainDocument8 pagesStag en MainFederico AlarconPas encore d'évaluation

- CESECO 2016 Execises VF DIFF.Document140 pagesCESECO 2016 Execises VF DIFF.Awalou MohamadPas encore d'évaluation

- U BoltsDocument14 pagesU BoltsLuz DuartePas encore d'évaluation

- Pressure Seal Check ValveDocument2 pagesPressure Seal Check ValveRajeev MaheshwariPas encore d'évaluation

- Nitrogen Spreadsheet JR EditDocument20 pagesNitrogen Spreadsheet JR EditОлександр ЛетюкPas encore d'évaluation

- uPVC Pipe SizeDocument2 pagesuPVC Pipe Sizewado11Pas encore d'évaluation

- UPVC Pipe SizeDocument2 pagesUPVC Pipe SizefebousPas encore d'évaluation

- IFP IP3100/IP5100/IP7600 Gear Pumps and Motors: CharacteristicsDocument1 pageIFP IP3100/IP5100/IP7600 Gear Pumps and Motors: CharacteristicsWalter Pachi Venegas AriasPas encore d'évaluation

- Predpazen KlapanDocument2 pagesPredpazen KlapanКирил АлександровPas encore d'évaluation

- Room Name: EMR-G1 EMR-G2 Pabx Room Generator Ats Room LV Room# 3 EMR-G3 EMR-G4 LV Room# 2Document11 pagesRoom Name: EMR-G1 EMR-G2 Pabx Room Generator Ats Room LV Room# 3 EMR-G3 EMR-G4 LV Room# 2JojolasPas encore d'évaluation

- Final Year Design Lectures - Mar 2018: List of AttachmentsDocument9 pagesFinal Year Design Lectures - Mar 2018: List of AttachmentsjayaprinaPas encore d'évaluation

- Ref. DWG No. Augh/ S-202 / Rev. 1Document15 pagesRef. DWG No. Augh/ S-202 / Rev. 1kanatvPas encore d'évaluation

- Curva Compuesta: Tin ToutDocument6 pagesCurva Compuesta: Tin ToutHumberto Gracia NevarezPas encore d'évaluation

- IH系列泵样本Document9 pagesIH系列泵样本Sandy ZhangPas encore d'évaluation

- VAR FinalDocument3 pagesVAR Finalrajat_r226949Pas encore d'évaluation

- FluidDocument8 pagesFluidsgngdth2qgPas encore d'évaluation

- Sodeco Butterfly Pneumatic ValvesDocument19 pagesSodeco Butterfly Pneumatic ValvesCojuhari SergiuPas encore d'évaluation

- Star Delta Motor Power-ConsumptionDocument1 pageStar Delta Motor Power-Consumptionphyo7799Pas encore d'évaluation

- Desch KB 16 GB Lutex LKBDocument6 pagesDesch KB 16 GB Lutex LKBchodgemPas encore d'évaluation

- Figure 3: YP and PV Versus Percent ContaminantDocument13 pagesFigure 3: YP and PV Versus Percent ContaminantYann Emeric KouamePas encore d'évaluation

- 18 BT 01016Document3 pages18 BT 01016Deep GajjarPas encore d'évaluation

- Positive Displacement Pump SelectionDocument3 pagesPositive Displacement Pump SelectionBimlesh Kumar SinghPas encore d'évaluation

- Technical SpecDocument1 pageTechnical SpecKaran GnaniPas encore d'évaluation

- Regulador EQA-99Document3 pagesRegulador EQA-99Ronan CristhiamPas encore d'évaluation

- Estimate Robin - Mepf Excel CalculationDocument7 pagesEstimate Robin - Mepf Excel CalculationiamrealjohnbundangPas encore d'évaluation

- British Commercial Computer Digest: Pergamon Computer Data SeriesD'EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesPas encore d'évaluation

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaPas encore d'évaluation

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 pagesModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaPas encore d'évaluation

- Model CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)Document5 pagesModel CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)sebaversaPas encore d'évaluation

- Model CB 15-100 HP Boilers: LightsDocument5 pagesModel CB 15-100 HP Boilers: LightssebaversaPas encore d'évaluation

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaPas encore d'évaluation

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaPas encore d'évaluation

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocument5 pagesModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaPas encore d'évaluation

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocument5 pagesModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaPas encore d'évaluation

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaPas encore d'évaluation

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaPas encore d'évaluation

- Features and Benefits: Model CB 15-100 HP BoilersDocument5 pagesFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaPas encore d'évaluation

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaPas encore d'évaluation

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaPas encore d'évaluation

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocument5 pagesModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaPas encore d'évaluation

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaPas encore d'évaluation

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaPas encore d'évaluation

- Model CBR 125-800 HP BoilersDocument5 pagesModel CBR 125-800 HP BoilerssebaversaPas encore d'évaluation

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaPas encore d'évaluation

- Model CBL: 900 - 1800 HP Steam Wet-Back Package BurnerDocument5 pagesModel CBL: 900 - 1800 HP Steam Wet-Back Package BurnersebaversaPas encore d'évaluation

- 81Document5 pages81sebaversaPas encore d'évaluation

- Model CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EDocument5 pagesModel CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EsebaversaPas encore d'évaluation

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocument5 pagesModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaPas encore d'évaluation

- 78Document5 pages78sebaversaPas encore d'évaluation

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Document6 pagesModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaPas encore d'évaluation

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaPas encore d'évaluation

- Model CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EDocument5 pagesModel CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EsebaversaPas encore d'évaluation

- 75Document5 pages75sebaversaPas encore d'évaluation

- Model ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimDocument4 pagesModel ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimsebaversaPas encore d'évaluation

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaPas encore d'évaluation

- Fillet Welds Around Circular Hollow Sections: HENRY GRANJON PRIZE 2018 Winner Category C: Design and Structural IntegrityDocument13 pagesFillet Welds Around Circular Hollow Sections: HENRY GRANJON PRIZE 2018 Winner Category C: Design and Structural IntegrityАлексей ВихляевPas encore d'évaluation

- Calculo AgitadorDocument25 pagesCalculo AgitadorJuan MendozaPas encore d'évaluation

- The Law of Entropy Invcrease - A Lab ExperimentDocument4 pagesThe Law of Entropy Invcrease - A Lab ExperimentINDUSTRIA BIOTECNOLÓGICA DEL SURPas encore d'évaluation

- Fracture Toughness Properties of High-StrengthDocument10 pagesFracture Toughness Properties of High-StrengthEngels OchoaPas encore d'évaluation

- Chemical Engineering Mass Transfer NotesDocument19 pagesChemical Engineering Mass Transfer NotesLebohang Czar NkuPas encore d'évaluation

- 1.1 Introduction To Heat ExchangersDocument20 pages1.1 Introduction To Heat ExchangersphineasphinePas encore d'évaluation

- CVE 202 Lecture Notes - 30062021Document6 pagesCVE 202 Lecture Notes - 30062021odubade opeyemiPas encore d'évaluation

- National Standard Examination in Physics (NSEP) 2015 A Detailed Analysis by ResDocument4 pagesNational Standard Examination in Physics (NSEP) 2015 A Detailed Analysis by ResAnurag PrasadPas encore d'évaluation

- Encit 2016Document9 pagesEncit 2016Gustavo FischerPas encore d'évaluation

- tb13 PDFDocument22 pagestb13 PDFMavis VermillionPas encore d'évaluation

- 22 - MKO 412 - 2013 - Pertemuan 13 - Tangki Dengan Bawah DatarDocument40 pages22 - MKO 412 - 2013 - Pertemuan 13 - Tangki Dengan Bawah DatarKhlisKunPas encore d'évaluation

- Phase Rule 1Document62 pagesPhase Rule 1arpitpandey494Pas encore d'évaluation

- Mapua University: 3 Calorimetry 5 Libo-On, Eldon RyanDocument14 pagesMapua University: 3 Calorimetry 5 Libo-On, Eldon RyanEldon Ryan Sabio Libo-onPas encore d'évaluation

- 2009 City Multi Modular Engineering ManualDocument676 pages2009 City Multi Modular Engineering ManualNiong DavidPas encore d'évaluation

- Design and Analysis of Different Types of Fin Configurations Using AnsysDocument8 pagesDesign and Analysis of Different Types of Fin Configurations Using AnsysPrashasti Bhai PatelPas encore d'évaluation

- GUG-SL-E 7.5-17 .6kW 2023 PI SHEETDocument2 pagesGUG-SL-E 7.5-17 .6kW 2023 PI SHEETdineshverma.dce1Pas encore d'évaluation

- Low Temperature Multiple DesalinationDocument9 pagesLow Temperature Multiple DesalinationyocreoqueestesiPas encore d'évaluation

- H7 Friction LossDocument4 pagesH7 Friction LossHoracio EspinosaPas encore d'évaluation

- Stress Analysis of Gun Barrel Subjected To Dynamic Pressure: H. Babaei, M. Malakzadeh, H. AsgariDocument10 pagesStress Analysis of Gun Barrel Subjected To Dynamic Pressure: H. Babaei, M. Malakzadeh, H. AsgariAmilcarRafaelVitriagoPas encore d'évaluation

- Burning Rate of Solid PropellantsDocument6 pagesBurning Rate of Solid Propellantsedcrfv35Pas encore d'évaluation

- 1.6. Water Diffusion in MeatDocument40 pages1.6. Water Diffusion in MeatPasha TanPas encore d'évaluation