Académique Documents

Professionnel Documents

Culture Documents

06infusion PDF

Transféré par

roydityanaziTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

06infusion PDF

Transféré par

roydityanaziDroits d'auteur :

Formats disponibles

227

PREVENTIVE MAINTENANCE PROCEDURE

INFUSION DEVICES - Applies to most types of electromechanical devices

that regulate the delivery of fluids to a patient, including general-

purpose infusion pumps, multichannel pumps, microinfusion pumps,

patient-controlled analgesic (PCA) pumps, syringe pumps, ambulatory

pumps, enteral feeding pumps, and infusion controllers.

For details, refer to Health Devices Inspection and Preventive

Maintenance (IPM) procedure and to the appropriate manufacturers

specifications.

Infusion Devices

ECRI Procedure/Checklist 416-0595

Equipment Needed: electrical safety analyzer; stopwatch; 25 ml

graduated cylinder; pressure gauge; applicable I.V. bag and tubing

1. Qualitative Tests

1.1 Chassis - verify physical integrity, cleanliness

1.2 Mount - verify physical integrity of mounts

1.3 Casters/Brakes - if mounted on IV pole, verify physical

integrity

1.4 AC Plug - verify integrity

1.5 Line Cord - verify proper insulation and integrity

1.6 Strain Reliefs - verify physical integrity at both ends of

line cord

1.7 Circuit Breaker/Fuse - verify integrity of external circuit

breaker and/or value of external fuse

1.9 Cables - inspect drop sensors and external air-in-line

detectors as appropriate

1.10 Connectors examine all cable connectors (drop sensor,

nurse call, etc.)

1.13 Controls/Switches - verify proper operation; inspect membrane

switches

1.18 Indicators/Displays - verify proper illumination and

operation

1.20 Alarms - verify proper operation; specifically verify (as

appropriate) air-in-line, empty container, infusion complete,

open door/misloaded set, nurse call

1.21 Audible Signal - confirm appropriate volume and operation of

volume controls

1.22 Labeling - verify presence and placement of all labels,

placards, instruction cards, etc.

1.23 Accessories - verify physical integrity, connection, and

proper operation of drop sensors and external air-in-line

detectors

1.24 Flow-Stop Mechanisms - verify operation and integrity

1.25 Lockout Interval (PCA Pumps Only) - verify operation

--continued next page--

2. Quantitative Tests

2.1 Grounding Resistance [< 0.5 ohm]

2.2 Chassis Leakage [< 300 microamps]

2.10 Flow Accuracy

=======================================================

FLOW RATE ACCURACY

------------------------------------------------------

Set Rate Duration Desired Volume Flow Error

------------------------------------------------------

60 ml/hr 5 min 5 ml +/- 5%

120 ml/hr 5 min 10 ml +/- 5%

240 ml/hr 5 min 20 ml +/- 5%

=======================================================

2.11 Maximum Pressure/Occlusion Alarms

(exclude infusion controllers) [manufacturers specs]

3. Service/Self Test Mode

Enter service/self test mode and verify proper operation.

Restore settings as they were initially found.

IMED PC-1 - press and hold the "hidden" key during power up.

Keep the “hidden" key pressed until "Maintenance"

Appears on the display. Successive presses of the "hidden"

key will select each test, while pressing the "START" key

will

begin the test.

sis1 03/02/2000

Infusion Device (ECRI)

infusion.doc

Vous aimerez peut-être aussi

- Dash 3000Document2 pagesDash 3000roydityanaziPas encore d'évaluation

- Sphygmomanometer Calibration: Why, How and How Often?Document4 pagesSphygmomanometer Calibration: Why, How and How Often?roydityanaziPas encore d'évaluation

- Dash 3000, 4000 & 5000: GE HealthcareDocument8 pagesDash 3000, 4000 & 5000: GE HealthcareroydityanaziPas encore d'évaluation

- NetProleaflet PDFDocument2 pagesNetProleaflet PDFroydityanaziPas encore d'évaluation

- ID Kajian Deskriptif Retrospektif Regimen DDocument6 pagesID Kajian Deskriptif Retrospektif Regimen DroydityanaziPas encore d'évaluation

- Maintenance Infusion Pump PDFDocument2 pagesMaintenance Infusion Pump PDFroydityanaziPas encore d'évaluation

- CR DDR Product SpecificationsDocument3 pagesCR DDR Product SpecificationsroydityanaziPas encore d'évaluation

- Maintenance Infusion Pump PDFDocument2 pagesMaintenance Infusion Pump PDFroydityanaziPas encore d'évaluation

- 06infusion PDFDocument2 pages06infusion PDFroydityanaziPas encore d'évaluation

- Calibrator Syringe HansrudolphDocument2 pagesCalibrator Syringe HansrudolphroydityanaziPas encore d'évaluation

- 06infusion PDFDocument2 pages06infusion PDFroydityanaziPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Engine Cooling Fan: 1988 Jeep CherokeeDocument11 pagesEngine Cooling Fan: 1988 Jeep Cherokeeexcelente2010Pas encore d'évaluation

- ADB UEL-1-150 DatasheetDocument4 pagesADB UEL-1-150 Datasheethighflyer737Pas encore d'évaluation

- Analog and Digital Electronics by Daniel Adam SteckDocument338 pagesAnalog and Digital Electronics by Daniel Adam SteckepiePas encore d'évaluation

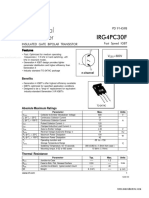

- IRG4PC30F: Features Features Features Features FeaturesDocument8 pagesIRG4PC30F: Features Features Features Features FeaturesKoma TozzPas encore d'évaluation

- InverterDocument2 pagesInverterGabriel Maya AlberdiPas encore d'évaluation

- Longest Life Product For Electric Furnace Applications!: 100,000 Operations No Routine Maintenance Required!Document8 pagesLongest Life Product For Electric Furnace Applications!: 100,000 Operations No Routine Maintenance Required!Bia AlvesPas encore d'évaluation

- JHDocument14 pagesJHghome123Pas encore d'évaluation

- Chapter 4 TransformerDocument20 pagesChapter 4 Transformershahmi nordinPas encore d'évaluation

- CBI245A Data Sheet - R27-DDocument1 pageCBI245A Data Sheet - R27-DJuan Alberto Cayetano GomezPas encore d'évaluation

- Tsi Sap FormatDocument6 pagesTsi Sap FormatmaheshPas encore d'évaluation

- Features Description: 12-Bit, Multiplying D/A ConverterDocument8 pagesFeatures Description: 12-Bit, Multiplying D/A ConverterGabriel RacovskyPas encore d'évaluation

- Polarity Test of TransformerDocument3 pagesPolarity Test of Transformerdebarshi100% (1)

- TRBA-TSRTSF SPMDocument53 pagesTRBA-TSRTSF SPMBeto CastañedaPas encore d'évaluation

- TRIAC-Controlled Power Supply Pre-Regulator Uses Optical FeedbackDocument4 pagesTRIAC-Controlled Power Supply Pre-Regulator Uses Optical FeedbackAlex MarghPas encore d'évaluation

- Driver Backlight PSP 2000Document12 pagesDriver Backlight PSP 2000Jhonny GuillermoPas encore d'évaluation

- Electric Vehicle ArchitectureDocument18 pagesElectric Vehicle ArchitecturePravat Kumar Behera100% (2)

- Serial and Parallel Battery ConfigurationsDocument5 pagesSerial and Parallel Battery ConfigurationsEleazar SyPas encore d'évaluation

- ZX0 - Block Design: Gas-Insulated Medium Voltage Switchgear Instruction Manual BA 439/05 EDocument64 pagesZX0 - Block Design: Gas-Insulated Medium Voltage Switchgear Instruction Manual BA 439/05 Emarco seguelPas encore d'évaluation

- MVAJDocument12 pagesMVAJsales5654100% (3)

- Electrical Equipment Course 230.2Document13 pagesElectrical Equipment Course 230.2room livePas encore d'évaluation

- Petersen Coils - Principle and ApplicationDocument2 pagesPetersen Coils - Principle and ApplicationadauPas encore d'évaluation

- Viper 12ADocument21 pagesViper 12Aahmed hussainPas encore d'évaluation

- Chapter3 DCDocument25 pagesChapter3 DCFauziah RahmadhaniPas encore d'évaluation

- KRC102MDocument6 pagesKRC102MZoran IlićPas encore d'évaluation

- Amb24 3Document2 pagesAmb24 3LuisPas encore d'évaluation

- GEP LED - 2009 CatalogDocument16 pagesGEP LED - 2009 CatalogAdib Darul QuthniPas encore d'évaluation

- Cable Ampacity and Circuit Breaker Coordination PlotDocument1 pageCable Ampacity and Circuit Breaker Coordination Plotrichard heraldPas encore d'évaluation

- Comparison of DTC and FOCDocument5 pagesComparison of DTC and FOCJuseverck JuniorPas encore d'évaluation

- Wiring DiagramDocument74 pagesWiring DiagramJoão Gabriel B Abrantes50% (2)

- LGMV Total ENGDocument47 pagesLGMV Total ENGMarcelo RamirezPas encore d'évaluation