Académique Documents

Professionnel Documents

Culture Documents

User'S Guide: FX - 4Ad-Tc Special Function Block

Transféré par

dliyaxDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

User'S Guide: FX - 4Ad-Tc Special Function Block

Transféré par

dliyaxDroits d'auteur :

Formats disponibles

(1) Buffer Memory BFM #0: Thermocouple type K or J selection mode

3 INSTALLATION NOTES AND USAGE BFM #0 is used to select K or J type thermocouples for each channel. Each digit of a 4 digit hexadecimal number

3.1 Environmental specification corresponds to one channel, the least significant digit being channel 1.

[ Example ] H 3 3 1 0

Item Specification

CH1 0 = K type

Environmental specifications (excluding following) Same as those for the FX2N base unit CH2 1 = J type

CH3 3 = Not used

Dielectric withstand voltage 500VAC, 1min (between all terminals and ground) CH4

FX2N-4AD-TC SPECIAL FUNCTION BLOCK 3.2 Power supply specification • A/D conversion time is 240ms per channel. When “3" (not used) is set for a channel, A/D conversion is not executed

for that channel and so the total conversion time is decreased. In the above example, the conversion time is as

USER’S GUIDE Item Specification follows:

240ms (conversion time per channel) × 2channels (number of channels being used) = 480ms (total conversion time)

Analog circuits 24V DC ±10%, 60mA

(2) Buffer Memory BFMs #1 to #4: Number of temperature readings to be averaged

Digital circuits 5V DC, 40mA (internal power supply from base unit

JY992D65501A When the number of temperature readings to be averaged is specified for BFMs #1 to #4, the averaged data is stored in

BFMs #5 to #8 (°C) and #13 to #16 (°F). Only the range 1 to 256 is valid for the number of temperature readings to be

This manual contains text, diagrams and explanations which will guide the reader in the correct installation and averaged. If a value outside of this range is input, the default value of 8 is used.

operation of the FX2N-4AD-TC special function block and should be read and understood before attempting to install or (3) Buffer Memory BFMs #9 to #12 and #17 to #20: Present temperature

use the unit.

Further information can be found in the FX PROGRAMMING MANUAL and FX2N SERIES HARDWARE MANUAL . These BFMs store the present value of the input data. This value is stored in units of 0.1°C or 0.1°F, but the resolution

is only 0.4°C or 0.72°F for type K and 0.3°C or 0.54°F for type J.

3.3 Performance specification 3.5 Status Information

1 INTRODUCTION Analog Inputs (1) Buffer Memory BFM #28: Digital range error latch

• The FX2N-4AD-TC analog block amplifies the signal from four thermocouple sensors (type K or J) and converts the Centigrade (°C) Fahrenheit (°F) BFM #29 b10(digital range error) is used to judge whether the measured temperature is within the unit’s range or not.

data into 12 bit reading’s stored in the FX2N base unit. Both Centigrade (°C) and Fahrenheit (°F) can be read. Item BFM #28 latches the error status of each channel and can be used to check for thermocouple disconnection.

Both °C and °F are available by reading the appropriate buffer memory (BFM).

Reading resolution is 0.4°C/0.72°F of type K and 0.3°C/0.54°F of type J.

Input signal Thermocouple: type K or J (either can be used for each channel), 4 channels, JIS 1602-1981 b15 or b8 b7 b6 b5 b4 b3 b2 b1 b0

• All data transfers and parameter settings are adjusted through software control of the FX2N-4AD-TC ; by use of the

High Low High Low High Low High Low

TO/FROM applied instructions in the FX2N PC. Rated temprature Type K -100°C to +1,200°C Type K -148°F to +2,192°F

Not used

range

• The FX2N-4AD-TC occupies 8 points of I/O on the FX2N expansion bus. The 8 points can be allocated from either Type J -100°C to +600°C Type J -148°F to +1,112°F CH4 CH3 CH2 CH1

inputs or outputs. The FX2N-4AD-TC draws 40mA from the 5V rail of the FX2N base unit or powered extension unit. 12 bit conversion stored in 16 bit 2’s complement form

Low : Latches ON when temperature measurement data goes below the lowest temperature

• Thermocouples with the following specifications can be used: Type K (JIS 1602-1981) Digital output Type K -1,000 to 12,000 Type K -1,480 to 21,920 measurement limit.

Type J (JIS 1602-1981) Type J -1,000 to 6,000 Type J -1,480 to 11,120 High : Turns ON when temperature measurement data goes above the highest temperature

Type K 0.4°C Type K 0.72°F measurement limit, or when a thermocouple is disconnected.

Resolution

Type J 0.3°C Type J 0.54°F When an error occurs the temperature data before the error is latched. If the measured value returns to within valid

limits the temperature data returns to normal operation. (Note: The error remains latched in (BFM #28))

Overall accuracy ± (0.5% full scall +1°C) An error can be cleared by writing K0 to BFM #28 using the TO instruction or turning off the power.

Calibration point Freezing point of pure water 0°C / 32°F

Conversion speed (240ms ± 2%) × 4 channels (unused channels are not converted)

Note : Earth-tipped thermocouples are not suitable for use with this unit.

1.1 EXTERNAL DIMENSIONS Weight: Approx. 0.3 kg (0.66 lbs) Dimensions: mm (inches) Analog Inputs continued... (2) Buffer Memory BFM #29: Error status

Accessories: Self adhesive labels for special function block number

identification. Conversion Bit devices of BFM #29 ON OFF

(Type K) (Type K)

87(3.43) 55(2.17) 55(2.17) Characteristics +12,000 +21,920 When either b2 or b3 is ON

b0 : Error No error

Mounting holes 4(0.16) A/D conversion is stopped for the error channel

(Type J) (Type J)

4.5mm(0.18) dia. +6,000 +11,120 b1 : Not used

Readings given at calibration b2 : Power source 24VDC power supply failure power supply normal

-148°F

24+

24+

-100°C

reference point 0°C/32°F (0/320)

24- SLD L-

b3 : Hardware error A/D converter or other hardware failure Hardware Normal

24- SLD L-

+600°C +1,200°C +1,112°F +2,192°F

respectively. -1,000 (Type J) (Type K) -1,480 (Type J) (Type K) b4 to b9 : Not used

CH1

CH1

L+

L+

(subject to the overall accuracy)

DIN rail POWER

b10 : Digital range error

Digital output/analog input value is outside the

Digital output value is normal.

mounting slot Miscellaneous specified range.

80(3.15)

90(3.54)

SLD L- SLD

CH2 CH3

35mm(1.38) b11 : Averaging number Selected number of averaged results is outside Averaging is normal.

L+

Item Specification

error the available range -see BFM #1 to #4 (between 1 to 256)

Photo-coupler isolation between analog and digital circuits. b12 to b15 : Not used

Isolation DC/DC converter isolation of power from FX2N base unit.

L+

FX2N-4AD-TC

L- SLD L-

24V No isolation between analog channels. (3) Identification Code Buffer Memory BFM #30

CH4

24V

LED 8 points taken from the FX2N expansion bus The identification code or ID number for a Special Block is read from buffer memory BFM #30 using the FROM

L+

A/D A/D Number of occupied I/O points command. This number for the FX2N-4AD-TC unit is K2030. The programmable controller can use this facility in its

(can be either inputs or outputs)

LED program to identify the special block before commencing data transfer to and from the special block.

9(0.35) Extension cable 4(0.16) Terminal screws M3 (0.12)

and connector

3.4 Buffer memory assignment 3.6 Installation location

2 TERMINAL LAYOUTS The FX2N-4AD-TC communicates with the This unit measures temperature according to the temperature difference between the temperature measurement part

BFM CONTENTS programmable controller through use of buffer

*1: The compensating cables that can be used for connecting with (themocouple) and the terminal block. If this unit is installed in a place where the temperature of the terminal block

Thermocouuple type K or J selection mode. memories. varies rapidly, a measuring error may occur. For this reason, the unit should be installed in a place free from excessive

Thermocouple 1 SLD the thermocouple are the following. *#0

shielded CH1 3KW CH1 Type K: KX-G, KX-GS, KX-H, KX-HS,WX-G,WX-H,VX-G At shipment: H0000 BFMs #21 to #27 and #31 are reserved. temperature variation.

L+

L- Type J: JX-G, JX-H CH1 to CH4 Averaged temperature reading to be All non reserved BFMs can be read by the

For every 10Ω of line resistance, the compensating cable will *#1-#4 programmable controller using the FROM

averaged (1 to 256) Default = 8

Thermocouple 1 indicate a temperature 0.12°C higher than actual. command. 3.7 Using crimp terminations

shielded CH4 3KW CH4

Check the line resistance before using. Long compensating #5-#8 CH1 to CH4 Averaged temprature in 0.1°C units

BFMs (buffer memories) marked with an “*” can

L+

L- cables are more prone to noise interference, therefore a short #9-#12 CH1 to CH4 Present temprature in 0.1°C units be written to, from the programmable controller

less than

6.2mm(0.24")

• Use crimp terminations of the type indicated on the left.

(less than 100m) compensating cable is recommended. using the TO command.

SLD

Temperature

Unused channels should have a wire link connected between #13-#16 CH1 to CH4 Averaged temprature in 0.1°F units • Secure the termination using a tightening torque of between 5 and 8

their + and - terminals to prevent an error being detected on Use M3(0.12") kg⋅cm.

compensation #17-#20 CH1 to CH4 Present temprature in 0.1°F units

2 circuit that channel.

24VDC±10% 50mA

24+ +15V

#21-#27 Reserved less than

6.2mm(0.24")

• Wire only to the module terminals discussed in this manual. Leave

DC/DC *2: If there is excessive electrical noise, connect the SLD all others vacant.

4 3 AG *#28 Digital range error latch

24- converter -15V terminal to the ground terminal on the unit.

*3: Connect the ground terminals of the FX2N-4AD-TC unit and #29 Error status

Class 3 FX2N-4AD-TC the base unit. Use class 3 grounding on the base unit. #30 Identification code K2030

Grounding PC

Analog Input Block *4: The 24V DC built-in supply of the programmable controller #31 Reserved

(100 Wor less)

Extension cable

may be used as the power supply.

(1) Buffer Memory BFM #0: Thermocouple type K or J selection mode

3 INSTALLATION NOTES AND USAGE BFM #0 is used to select K or J type thermocouples for each channel. Each digit of a 4 digit hexadecimal number

3.1 Environmental specification corresponds to one channel, the least significant digit being channel 1.

[ Example ] H 3 3 1 0

Item Specification

CH1 0 = K type

Environmental specifications (excluding following) Same as those for the FX2N base unit CH2 1 = J type

CH3 3 = Not used

Dielectric withstand voltage 500VAC, 1min (between all terminals and ground) CH4

FX2N-4AD-TC SPECIAL FUNCTION BLOCK 3.2 Power supply specification • A/D conversion time is 240ms per channel. When “3" (not used) is set for a channel, A/D conversion is not executed

for that channel and so the total conversion time is decreased. In the above example, the conversion time is as

USER’S GUIDE Item Specification follows:

240ms (conversion time per channel) × 2channels (number of channels being used) = 480ms (total conversion time)

Analog circuits 24V DC ±10%, 60mA

(2) Buffer Memory BFMs #1 to #4: Number of temperature readings to be averaged

Digital circuits 5V DC, 40mA (internal power supply from base unit

JY992D65501A When the number of temperature readings to be averaged is specified for BFMs #1 to #4, the averaged data is stored in

BFMs #5 to #8 (°C) and #13 to #16 (°F). Only the range 1 to 256 is valid for the number of temperature readings to be

This manual contains text, diagrams and explanations which will guide the reader in the correct installation and averaged. If a value outside of this range is input, the default value of 8 is used.

operation of the FX2N-4AD-TC special function block and should be read and understood before attempting to install or (3) Buffer Memory BFMs #9 to #12 and #17 to #20: Present temperature

use the unit.

Further information can be found in the FX PROGRAMMING MANUAL and FX2N SERIES HARDWARE MANUAL . These BFMs store the present value of the input data. This value is stored in units of 0.1°C or 0.1°F, but the resolution

is only 0.4°C or 0.72°F for type K and 0.3°C or 0.54°F for type J.

3.3 Performance specification 3.5 Status Information

1 INTRODUCTION Analog Inputs (1) Buffer Memory BFM #28: Digital range error latch

• The FX2N-4AD-TC analog block amplifies the signal from four thermocouple sensors (type K or J) and converts the Centigrade (°C) Fahrenheit (°F) BFM #29 b10(digital range error) is used to judge whether the measured temperature is within the unit’s range or not.

data into 12 bit reading’s stored in the FX2N base unit. Both Centigrade (°C) and Fahrenheit (°F) can be read. Item BFM #28 latches the error status of each channel and can be used to check for thermocouple disconnection.

Both °C and °F are available by reading the appropriate buffer memory (BFM).

Reading resolution is 0.4°C/0.72°F of type K and 0.3°C/0.54°F of type J.

Input signal Thermocouple: type K or J (either can be used for each channel), 4 channels, JIS 1602-1981 b15 or b8 b7 b6 b5 b4 b3 b2 b1 b0

• All data transfers and parameter settings are adjusted through software control of the FX2N-4AD-TC ; by use of the

High Low High Low High Low High Low

TO/FROM applied instructions in the FX2N PC. Rated temprature Type K -100°C to +1,200°C Type K -148°F to +2,192°F

Not used

range

• The FX2N-4AD-TC occupies 8 points of I/O on the FX2N expansion bus. The 8 points can be allocated from either Type J -100°C to +600°C Type J -148°F to +1,112°F CH4 CH3 CH2 CH1

inputs or outputs. The FX2N-4AD-TC draws 40mA from the 5V rail of the FX2N base unit or powered extension unit. 12 bit conversion stored in 16 bit 2’s complement form

Low : Latches ON when temperature measurement data goes below the lowest temperature

• Thermocouples with the following specifications can be used: Type K (JIS 1602-1981) Digital output Type K -1,000 to 12,000 Type K -1,480 to 21,920 measurement limit.

Type J (JIS 1602-1981) Type J -1,000 to 6,000 Type J -1,480 to 11,120 High : Turns ON when temperature measurement data goes above the highest temperature

Type K 0.4°C Type K 0.72°F measurement limit, or when a thermocouple is disconnected.

Resolution

Type J 0.3°C Type J 0.54°F When an error occurs the temperature data before the error is latched. If the measured value returns to within valid

limits the temperature data returns to normal operation. (Note: The error remains latched in (BFM #28))

Overall accuracy ± (0.5% full scall +1°C) An error can be cleared by writing K0 to BFM #28 using the TO instruction or turning off the power.

Calibration point Freezing point of pure water 0°C / 32°F

Conversion speed (240ms ± 2%) × 4 channels (unused channels are not converted)

Note : Earth-tipped thermocouples are not suitable for use with this unit.

1.1 EXTERNAL DIMENSIONS Weight: Approx. 0.3 kg (0.66 lbs) Dimensions: mm (inches) Analog Inputs continued... (2) Buffer Memory BFM #29: Error status

Accessories: Self adhesive labels for special function block number

identification. Conversion Bit devices of BFM #29 ON OFF

(Type K) (Type K)

87(3.43) 55(2.17) 55(2.17) Characteristics +12,000 +21,920 When either b2 or b3 is ON

b0 : Error No error

Mounting holes 4(0.16) A/D conversion is stopped for the error channel

(Type J) (Type J)

4.5mm(0.18) dia. +6,000 +11,120 b1 : Not used

Readings given at calibration b2 : Power source 24VDC power supply failure power supply normal

-148°F

24+

24+

-100°C

reference point 0°C/32°F (0/320)

24- SLD L-

b3 : Hardware error A/D converter or other hardware failure Hardware Normal

24- SLD L-

+600°C +1,200°C +1,112°F +2,192°F

respectively. -1,000 (Type J) (Type K) -1,480 (Type J) (Type K) b4 to b9 : Not used

CH1

CH1

L+

L+

(subject to the overall accuracy)

DIN rail POWER

b10 : Digital range error

Digital output/analog input value is outside the

Digital output value is normal.

mounting slot Miscellaneous specified range.

80(3.15)

90(3.54)

SLD L- SLD

CH2 CH3

35mm(1.38) b11 : Averaging number Selected number of averaged results is outside Averaging is normal.

L+

Item Specification

error the available range -see BFM #1 to #4 (between 1 to 256)

Photo-coupler isolation between analog and digital circuits. b12 to b15 : Not used

Isolation DC/DC converter isolation of power from FX2N base unit.

L+

FX2N-4AD-TC

L- SLD L-

24V No isolation between analog channels. (3) Identification Code Buffer Memory BFM #30

CH4

24V

LED 8 points taken from the FX2N expansion bus The identification code or ID number for a Special Block is read from buffer memory BFM #30 using the FROM

L+

A/D A/D Number of occupied I/O points command. This number for the FX2N-4AD-TC unit is K2030. The programmable controller can use this facility in its

(can be either inputs or outputs)

LED program to identify the special block before commencing data transfer to and from the special block.

9(0.35) Extension cable 4(0.16) Terminal screws M3 (0.12)

and connector

3.4 Buffer memory assignment 3.6 Installation location

2 TERMINAL LAYOUTS The FX2N-4AD-TC communicates with the This unit measures temperature according to the temperature difference between the temperature measurement part

BFM CONTENTS programmable controller through use of buffer

*1: The compensating cables that can be used for connecting with (themocouple) and the terminal block. If this unit is installed in a place where the temperature of the terminal block

Thermocouuple type K or J selection mode. memories. varies rapidly, a measuring error may occur. For this reason, the unit should be installed in a place free from excessive

Thermocouple 1 SLD the thermocouple are the following. *#0

shielded CH1 3KW CH1 Type K: KX-G, KX-GS, KX-H, KX-HS,WX-G,WX-H,VX-G At shipment: H0000 BFMs #21 to #27 and #31 are reserved. temperature variation.

L+

L- Type J: JX-G, JX-H CH1 to CH4 Averaged temperature reading to be All non reserved BFMs can be read by the

For every 10Ω of line resistance, the compensating cable will *#1-#4 programmable controller using the FROM

averaged (1 to 256) Default = 8

Thermocouple 1 indicate a temperature 0.12°C higher than actual. command. 3.7 Using crimp terminations

shielded CH4 3KW CH4

Check the line resistance before using. Long compensating #5-#8 CH1 to CH4 Averaged temprature in 0.1°C units

BFMs (buffer memories) marked with an “*” can

L+

L- cables are more prone to noise interference, therefore a short #9-#12 CH1 to CH4 Present temprature in 0.1°C units be written to, from the programmable controller

less than

6.2mm(0.24")

• Use crimp terminations of the type indicated on the left.

(less than 100m) compensating cable is recommended. using the TO command.

SLD

Temperature

Unused channels should have a wire link connected between #13-#16 CH1 to CH4 Averaged temprature in 0.1°F units • Secure the termination using a tightening torque of between 5 and 8

their + and - terminals to prevent an error being detected on Use M3(0.12") kg⋅cm.

compensation #17-#20 CH1 to CH4 Present temprature in 0.1°F units

2 circuit that channel.

24VDC±10% 50mA

24+ +15V

#21-#27 Reserved less than

6.2mm(0.24")

• Wire only to the module terminals discussed in this manual. Leave

DC/DC *2: If there is excessive electrical noise, connect the SLD all others vacant.

4 3 AG *#28 Digital range error latch

24- converter -15V terminal to the ground terminal on the unit.

*3: Connect the ground terminals of the FX2N-4AD-TC unit and #29 Error status

Class 3 FX2N-4AD-TC the base unit. Use class 3 grounding on the base unit. #30 Identification code K2030

Grounding PC

Analog Input Block *4: The 24V DC built-in supply of the programmable controller #31 Reserved

(100 Wor less)

Extension cable

may be used as the power supply.

(1) Buffer Memory BFM #0: Thermocouple type K or J selection mode

3 INSTALLATION NOTES AND USAGE BFM #0 is used to select K or J type thermocouples for each channel. Each digit of a 4 digit hexadecimal number

3.1 Environmental specification corresponds to one channel, the least significant digit being channel 1.

[ Example ] H 3 3 1 0

Item Specification

CH1 0 = K type

Environmental specifications (excluding following) Same as those for the FX2N base unit CH2 1 = J type

CH3 3 = Not used

Dielectric withstand voltage 500VAC, 1min (between all terminals and ground) CH4

FX2N-4AD-TC SPECIAL FUNCTION BLOCK 3.2 Power supply specification • A/D conversion time is 240ms per channel. When “3" (not used) is set for a channel, A/D conversion is not executed

for that channel and so the total conversion time is decreased. In the above example, the conversion time is as

USER’S GUIDE Item Specification follows:

240ms (conversion time per channel) × 2channels (number of channels being used) = 480ms (total conversion time)

Analog circuits 24V DC ±10%, 60mA

(2) Buffer Memory BFMs #1 to #4: Number of temperature readings to be averaged

Digital circuits 5V DC, 40mA (internal power supply from base unit

JY992D65501A When the number of temperature readings to be averaged is specified for BFMs #1 to #4, the averaged data is stored in

BFMs #5 to #8 (°C) and #13 to #16 (°F). Only the range 1 to 256 is valid for the number of temperature readings to be

This manual contains text, diagrams and explanations which will guide the reader in the correct installation and averaged. If a value outside of this range is input, the default value of 8 is used.

operation of the FX2N-4AD-TC special function block and should be read and understood before attempting to install or (3) Buffer Memory BFMs #9 to #12 and #17 to #20: Present temperature

use the unit.

Further information can be found in the FX PROGRAMMING MANUAL and FX2N SERIES HARDWARE MANUAL . These BFMs store the present value of the input data. This value is stored in units of 0.1°C or 0.1°F, but the resolution

is only 0.4°C or 0.72°F for type K and 0.3°C or 0.54°F for type J.

3.3 Performance specification 3.5 Status Information

1 INTRODUCTION Analog Inputs (1) Buffer Memory BFM #28: Digital range error latch

• The FX2N-4AD-TC analog block amplifies the signal from four thermocouple sensors (type K or J) and converts the Centigrade (°C) Fahrenheit (°F) BFM #29 b10(digital range error) is used to judge whether the measured temperature is within the unit’s range or not.

data into 12 bit reading’s stored in the FX2N base unit. Both Centigrade (°C) and Fahrenheit (°F) can be read. Item BFM #28 latches the error status of each channel and can be used to check for thermocouple disconnection.

Both °C and °F are available by reading the appropriate buffer memory (BFM).

Reading resolution is 0.4°C/0.72°F of type K and 0.3°C/0.54°F of type J.

Input signal Thermocouple: type K or J (either can be used for each channel), 4 channels, JIS 1602-1981 b15 or b8 b7 b6 b5 b4 b3 b2 b1 b0

• All data transfers and parameter settings are adjusted through software control of the FX2N-4AD-TC ; by use of the

High Low High Low High Low High Low

TO/FROM applied instructions in the FX2N PC. Rated temprature Type K -100°C to +1,200°C Type K -148°F to +2,192°F

Not used

range

• The FX2N-4AD-TC occupies 8 points of I/O on the FX2N expansion bus. The 8 points can be allocated from either Type J -100°C to +600°C Type J -148°F to +1,112°F CH4 CH3 CH2 CH1

inputs or outputs. The FX2N-4AD-TC draws 40mA from the 5V rail of the FX2N base unit or powered extension unit. 12 bit conversion stored in 16 bit 2’s complement form

Low : Latches ON when temperature measurement data goes below the lowest temperature

• Thermocouples with the following specifications can be used: Type K (JIS 1602-1981) Digital output Type K -1,000 to 12,000 Type K -1,480 to 21,920 measurement limit.

Type J (JIS 1602-1981) Type J -1,000 to 6,000 Type J -1,480 to 11,120 High : Turns ON when temperature measurement data goes above the highest temperature

Type K 0.4°C Type K 0.72°F measurement limit, or when a thermocouple is disconnected.

Resolution

Type J 0.3°C Type J 0.54°F When an error occurs the temperature data before the error is latched. If the measured value returns to within valid

limits the temperature data returns to normal operation. (Note: The error remains latched in (BFM #28))

Overall accuracy ± (0.5% full scall +1°C) An error can be cleared by writing K0 to BFM #28 using the TO instruction or turning off the power.

Calibration point Freezing point of pure water 0°C / 32°F

Conversion speed (240ms ± 2%) × 4 channels (unused channels are not converted)

Note : Earth-tipped thermocouples are not suitable for use with this unit.

1.1 EXTERNAL DIMENSIONS Weight: Approx. 0.3 kg (0.66 lbs) Dimensions: mm (inches) Analog Inputs continued... (2) Buffer Memory BFM #29: Error status

Accessories: Self adhesive labels for special function block number

identification. Conversion Bit devices of BFM #29 ON OFF

(Type K) (Type K)

87(3.43) 55(2.17) 55(2.17) Characteristics +12,000 +21,920 When either b2 or b3 is ON

b0 : Error No error

Mounting holes 4(0.16) A/D conversion is stopped for the error channel

(Type J) (Type J)

4.5mm(0.18) dia. +6,000 +11,120 b1 : Not used

Readings given at calibration b2 : Power source 24VDC power supply failure power supply normal

-148°F

24+

24+

-100°C

reference point 0°C/32°F (0/320)

24- SLD L-

b3 : Hardware error A/D converter or other hardware failure Hardware Normal

24- SLD L-

+600°C +1,200°C +1,112°F +2,192°F

respectively. -1,000 (Type J) (Type K) -1,480 (Type J) (Type K) b4 to b9 : Not used

CH1

CH1

L+

L+

(subject to the overall accuracy)

DIN rail POWER

b10 : Digital range error

Digital output/analog input value is outside the

Digital output value is normal.

mounting slot Miscellaneous specified range.

80(3.15)

90(3.54)

SLD L- SLD

CH2 CH3

35mm(1.38) b11 : Averaging number Selected number of averaged results is outside Averaging is normal.

L+

Item Specification

error the available range -see BFM #1 to #4 (between 1 to 256)

Photo-coupler isolation between analog and digital circuits. b12 to b15 : Not used

Isolation DC/DC converter isolation of power from FX2N base unit.

L+

FX2N-4AD-TC

L- SLD L-

24V No isolation between analog channels. (3) Identification Code Buffer Memory BFM #30

CH4

24V

LED 8 points taken from the FX2N expansion bus The identification code or ID number for a Special Block is read from buffer memory BFM #30 using the FROM

L+

A/D A/D Number of occupied I/O points command. This number for the FX2N-4AD-TC unit is K2030. The programmable controller can use this facility in its

(can be either inputs or outputs)

LED program to identify the special block before commencing data transfer to and from the special block.

9(0.35) Extension cable 4(0.16) Terminal screws M3 (0.12)

and connector

3.4 Buffer memory assignment 3.6 Installation location

2 TERMINAL LAYOUTS The FX2N-4AD-TC communicates with the This unit measures temperature according to the temperature difference between the temperature measurement part

BFM CONTENTS programmable controller through use of buffer

*1: The compensating cables that can be used for connecting with (themocouple) and the terminal block. If this unit is installed in a place where the temperature of the terminal block

Thermocouuple type K or J selection mode. memories. varies rapidly, a measuring error may occur. For this reason, the unit should be installed in a place free from excessive

Thermocouple 1 SLD the thermocouple are the following. *#0

shielded CH1 3KW CH1 Type K: KX-G, KX-GS, KX-H, KX-HS,WX-G,WX-H,VX-G At shipment: H0000 BFMs #21 to #27 and #31 are reserved. temperature variation.

L+

L- Type J: JX-G, JX-H CH1 to CH4 Averaged temperature reading to be All non reserved BFMs can be read by the

For every 10Ω of line resistance, the compensating cable will *#1-#4 programmable controller using the FROM

averaged (1 to 256) Default = 8

Thermocouple 1 indicate a temperature 0.12°C higher than actual. command. 3.7 Using crimp terminations

shielded CH4 3KW CH4

Check the line resistance before using. Long compensating #5-#8 CH1 to CH4 Averaged temprature in 0.1°C units

BFMs (buffer memories) marked with an “*” can

L+

L- cables are more prone to noise interference, therefore a short #9-#12 CH1 to CH4 Present temprature in 0.1°C units be written to, from the programmable controller

less than

6.2mm(0.24")

• Use crimp terminations of the type indicated on the left.

(less than 100m) compensating cable is recommended. using the TO command.

SLD

Temperature

Unused channels should have a wire link connected between #13-#16 CH1 to CH4 Averaged temprature in 0.1°F units • Secure the termination using a tightening torque of between 5 and 8

their + and - terminals to prevent an error being detected on Use M3(0.12") kg⋅cm.

compensation #17-#20 CH1 to CH4 Present temprature in 0.1°F units

2 circuit that channel.

24VDC±10% 50mA

24+ +15V

#21-#27 Reserved less than

6.2mm(0.24")

• Wire only to the module terminals discussed in this manual. Leave

DC/DC *2: If there is excessive electrical noise, connect the SLD all others vacant.

4 3 AG *#28 Digital range error latch

24- converter -15V terminal to the ground terminal on the unit.

*3: Connect the ground terminals of the FX2N-4AD-TC unit and #29 Error status

Class 3 FX2N-4AD-TC the base unit. Use class 3 grounding on the base unit. #30 Identification code K2030

Grounding PC

Analog Input Block *4: The 24V DC built-in supply of the programmable controller #31 Reserved

(100 Wor less)

Extension cable

may be used as the power supply.

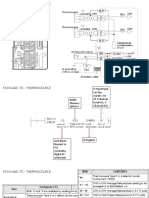

4 SYSTEM BLOCK DIAGRAM 6 DIAGNOSTICS

6.1 _Preliminary checks

POWER I. Check whether the input/output wiring and/or extension cables are properly connected on FX2N-4AD-TC analog

LED 5V Power Gain and special function block

FX2N series Supply offset values

are stored in

II. Check that the FX2N system configuration rules have not been broken, i.e. the number of special function blocks

Buffer

Command

TO Memory EEPROM does not exceed 8 and the total system I/O is equal or less than 256, I/O.

information Analog Input

RAM III. Ensure that the correct operating range has been selected for the application.

write and Photocoupler

data status CPU IV. Check that there is no power overload on either the 5V or 24V power sources, remember the loading on the FX2N

read base unit or a powered extension unit varies according to the number of extension blocks or special function

FROM Converted CH1

data blocks connected.

A/D CH2

System V. Put the FX2N base unit into RUN.

CH3

ROM converter

Control CH4

signals Non-

DC24V contact

Power ±15V A/D analog

Source LED switch

DC/DC Cyclic switching

5V

converter 24V

FX2N-4AD-TC Analog Block LED

6.2 Error checking

5 EXAMPLE PROGRAM If the FX2N-4AD-TC special function blcok does not seem to operate normally, check the following items.

In the program shown below, the FX2N-4AD-TC occupies the position of special block number 2 ( that is the third closest

block to the programmable controller). A type K thermocouple is used on CH1 and a type J on CH2. CH3 and CH4 are • Check the status of the POWER LED.

not used. The averaging count is four. The averaged values in degrees C of input channels CH1 and CH2 are stored Lit : The extension cable is properly connected.

respectively in data registers D0 and D1. Otherwise : Check the connection of the extension cable.

• Check the external wiring.

M8002 FNC79

K2 K0 H3310 K1

Specify the type of thermocouple.

H3310 → Block No.2 BFM#0

• Check the status fo the “24V” LED (top right corner of the FX2N-4AD-TC).

Initial TO Lit : FX2N-4AD-TC is ON, 24VDC power source is ON.

CH4 and CH3: not used Otherwise : Possible 24VDC power failure, if ON possible FX2N-4AD-TC failure.

Pulse CH2: type J(1)

M8002 FNC78

K2 K30 D2 K1

CH1: type K(0) • Check the status fo the “A/D” LED (top right corner of the FX2N-4AD-TC).

FROM Block No.2 BFM #30 → (D2) Lit : A/D conversion is proceeding normally.

Initial Identification code Otherwise : Check buffer memory #29 (error status). If any bits (b0, b2, b3) are ON, then this is why

Pulse

the A/D LED is OFF.

FNC10

K2030 D2 M0 When (K2030) = (D2), M1 = ON.

CMP

i.e. When identification code is K2030, M1 = ON.

This initial step checks that the special function block placed at position 2 is actually an

FX2N-4AD-TC, i.e. its unit identification number is 2030 (BFM #30). This step is optional,

but it provides a software check that the system has been configured correctly.

M8000 Block No.2 BFM #29 → (K4M10) 6.3 Checking special function block numbers

FNC78

K2 K29 K4M10 K1 Transfer the error status to (M25 to M10).

FROM Other special units of blocks that use FROM/TO commands, such as analog input blocks, analog output blocks and

RUN When error is found, M10 = ON

high-speed counter blocks, can be directly connected to the base unit of the FX2N programmable controller or to the

monitor right side of other extension blocks or units. Each special block is consecutively numbered from 0 to 7 beginning from

M10 Guidelines for the safety of the user and protection of the FX2N-4AD-TC special function block

Represents b0 BFM #29 the one closest to the base unit. A maximum of eight special blocks can be connected.

M3 • This manual has been written to be used by trained and competent personnel. This is defined by

Error found

the European directives for machinery, low voltage and EMC.

This step provides optional monitoring of the FX2N-4AD-TC Error Buffer Memory (#29).

If there is an Error on the FX2N-4AD-TC, bit b0 of BFM #29 will be set on. This can be read L N

COM X0

24+ X1

X2 X4

X5

X6

X7

X10

X13

X14

X15

X16

X17

X20

X21

X22

X23

X24

X25 L N

COM

24+

X0

X1

X2

X3

X4

X5

X6

X7

X10

X11

X12

X13

X14

X15

X16

X17

• If in doubt at any stage during the installation of the FX2N-24AD-TC always consult a professional

by this program step, and output as a bit device in the FX2N programmable controller (M3 in IN

0 1 2 3 4 5 6 7 20 21 22 23 24 25 26 27

10 11 12 13 14 15 16 17

POWER

POWER POWER

IN

0 1 2 3 4 5

10 11 12 13 14 15 16 17

6 7 POWER electrical engineer who is qualified and trained to the local and national standards. If in doubt

POWER

this example). Additional Error devices can be output in a similar manner, e.g. b10 BFM T.V

about the operation or use of the FX2N-4AD-TC please consult the nearest Mitsubishi Electric

#29 Digital range error. (see below) FX2N-48MR-ES/UL

6 7 20 21 22 23 24 25 26 27

16 17

PROG.E

CPU.E

FX2N-4AD FX2N-4DA

OUT

0 1 2 3 4 5

10 11 12 13 14 15 16 17

6 7

distributor.

Y0 Y2 Y4 Y6 Y10 Y14 Y20 Y22 Y24 Y26 COM5 Y0 Y2 Y4 Y6 Y10 Y12 Y14 Y16

• Under no circumstances will Mitsubishi Electric be liable or responsible for any consequential

COM1 Y3 COM2 Y5 Y7 COM3 Y13 COM4 Y15 Y21 Y23 Y25 Y27 COM1 Y1 Y3 COM2 Y5 Y7 COM3 Y11 Y13 COM4 Y15 Y17

A/D D/A 24V

24V

M8000 FNC78

24V A/D

damage that may arise as a result of the installation or use of this equipment.

K2 K29 K4M10 K1

FROM

• All examples and diagrams shown in this manual are intended only as an aid to understanding

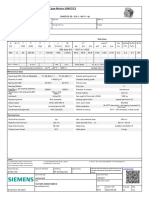

M10 FX 2N -48MR-ES/UL FX 2N -4AD FX 2N -16EX FX 2N -4DA FX 2N -32ER FX 2N-4AD-TC the text, not to guarantee operation. Mitsubishi Electric will accept no responsibility for actual

M3 Represents b0 BFM #29

X000-X027 Special block X030 Special block X050-X067 Special block use of the product based on these illustrative examples.

Y000-Y027 No.0 -X047 No.1 Y030-Y047 No.2

M20

M4 Represents b10 BFM #29

M1 (K4) → (BFM #1), (K4) → (BFM #2)

FNC79

TO P

K2 K1 K4 K2 Number of samples is changed to four on both CH1 and CH2. 7 EMC CONSIDERATIONS

Electromagnetic compatibility or EMC must be considered before using the FX2N-4AD-TC. Manual number : JY992D65501

(BFM #5) → (D0), (BFM #6) → (D1) Mitsubishi recommend that the thermocouple sensors used, should be fitted with a form of seild or screening as Manual revision :A

FNC78

FROM

K2 K5 D0 K2 Transfer the averaged temperature value in °C to the data protection against EMC noise. Date : JUNE 1997

registers.

If some form of cable protection is used, the “Shield” must be terminated at the SLD terminals as shown in

This step is the actual reading of the FX2N-4AD-TC input channels. It is essentially the only chapter 2.

program step which is needed. The “TO” instruction in this example, sets the input

channels, CH1 and CH2, to take the average reading of four samples. Because of the delicate nature of all analog signals, failure to take good EMC precautions could lead to EMC noise

The “FROM” instruction reads the average temperatures (BFM #5 and #6) for input induced errors ; up to ±10% of actual values. This is an absolute worst case figure, users who do take good

channels CH1 and CH2 of the FX2N-4AD-TC. If direct temperature readings are required precautions can expect operation within normal tolerances.

HEAD OFFICE:MITSUBISHI DENKI BLDG MARUNOUCHI TOKYO 100 TELEX:J24532 CABLE MELCO TOKYO

BFM #9 and #10 should be read instead, e.g. HIMEJI WORKS:840, CHIYODA CHO, HIMEJI, JAPAN

EMC considerations should include selection of good quality cables, good routing of those cables away from potential

noise sources.

FNC78

K2 K29 K4M10 K1

FROM

special FX2N-4AD-TC result No. of

Additionally it is recommended that signal averaging is used as this will reduce the effects of random noise “spikes”.

block No.2 BFM number destination words read

Effective JUN. 1997

Specifications are subject to

JY992D65501A change without notice

4 SYSTEM BLOCK DIAGRAM 6 DIAGNOSTICS

6.1 _Preliminary checks

POWER I. Check whether the input/output wiring and/or extension cables are properly connected on FX2N-4AD-TC analog

LED 5V Power Gain and special function block

FX2N series Supply offset values

are stored in

II. Check that the FX2N system configuration rules have not been broken, i.e. the number of special function blocks

Buffer

Command

TO Memory EEPROM does not exceed 8 and the total system I/O is equal or less than 256, I/O.

information Analog Input

RAM III. Ensure that the correct operating range has been selected for the application.

write and Photocoupler

data status CPU IV. Check that there is no power overload on either the 5V or 24V power sources, remember the loading on the FX2N

read base unit or a powered extension unit varies according to the number of extension blocks or special function

FROM Converted CH1

data blocks connected.

A/D CH2

System V. Put the FX2N base unit into RUN.

CH3

ROM converter

Control CH4

signals Non-

DC24V contact

Power ±15V A/D analog

Source LED switch

DC/DC Cyclic switching

5V

converter 24V

FX2N-4AD-TC Analog Block LED

6.2 Error checking

5 EXAMPLE PROGRAM If the FX2N-4AD-TC special function blcok does not seem to operate normally, check the following items.

In the program shown below, the FX2N-4AD-TC occupies the position of special block number 2 ( that is the third closest

block to the programmable controller). A type K thermocouple is used on CH1 and a type J on CH2. CH3 and CH4 are • Check the status of the POWER LED.

not used. The averaging count is four. The averaged values in degrees C of input channels CH1 and CH2 are stored Lit : The extension cable is properly connected.

respectively in data registers D0 and D1. Otherwise : Check the connection of the extension cable.

• Check the external wiring.

M8002 FNC79

K2 K0 H3310 K1

Specify the type of thermocouple.

H3310 → Block No.2 BFM#0

• Check the status fo the “24V” LED (top right corner of the FX2N-4AD-TC).

Initial TO Lit : FX2N-4AD-TC is ON, 24VDC power source is ON.

CH4 and CH3: not used Otherwise : Possible 24VDC power failure, if ON possible FX2N-4AD-TC failure.

Pulse CH2: type J(1)

M8002 FNC78

K2 K30 D2 K1

CH1: type K(0) • Check the status fo the “A/D” LED (top right corner of the FX2N-4AD-TC).

FROM Block No.2 BFM #30 → (D2) Lit : A/D conversion is proceeding normally.

Initial Identification code Otherwise : Check buffer memory #29 (error status). If any bits (b0, b2, b3) are ON, then this is why

Pulse

the A/D LED is OFF.

FNC10

K2030 D2 M0 When (K2030) = (D2), M1 = ON.

CMP

i.e. When identification code is K2030, M1 = ON.

This initial step checks that the special function block placed at position 2 is actually an

FX2N-4AD-TC, i.e. its unit identification number is 2030 (BFM #30). This step is optional,

but it provides a software check that the system has been configured correctly.

M8000 Block No.2 BFM #29 → (K4M10) 6.3 Checking special function block numbers

FNC78

K2 K29 K4M10 K1 Transfer the error status to (M25 to M10).

FROM Other special units of blocks that use FROM/TO commands, such as analog input blocks, analog output blocks and

RUN When error is found, M10 = ON

high-speed counter blocks, can be directly connected to the base unit of the FX2N programmable controller or to the

monitor right side of other extension blocks or units. Each special block is consecutively numbered from 0 to 7 beginning from

M10 Guidelines for the safety of the user and protection of the FX2N-4AD-TC special function block

Represents b0 BFM #29 the one closest to the base unit. A maximum of eight special blocks can be connected.

M3 • This manual has been written to be used by trained and competent personnel. This is defined by

Error found

the European directives for machinery, low voltage and EMC.

This step provides optional monitoring of the FX2N-4AD-TC Error Buffer Memory (#29).

If there is an Error on the FX2N-4AD-TC, bit b0 of BFM #29 will be set on. This can be read L N

COM X0

24+ X1

X2 X4

X5

X6

X7

X10

X13

X14

X15

X16

X17

X20

X21

X22

X23

X24

X25 L N

COM

24+

X0

X1

X2

X3

X4

X5

X6

X7

X10

X11

X12

X13

X14

X15

X16

X17

• If in doubt at any stage during the installation of the FX2N-24AD-TC always consult a professional

by this program step, and output as a bit device in the FX2N programmable controller (M3 in IN

0 1 2 3 4 5 6 7 20 21 22 23 24 25 26 27

10 11 12 13 14 15 16 17

POWER

POWER POWER

IN

0 1 2 3 4 5

10 11 12 13 14 15 16 17

6 7 POWER electrical engineer who is qualified and trained to the local and national standards. If in doubt

POWER

this example). Additional Error devices can be output in a similar manner, e.g. b10 BFM T.V

about the operation or use of the FX2N-4AD-TC please consult the nearest Mitsubishi Electric

#29 Digital range error. (see below) FX2N-48MR-ES/UL

6 7 20 21 22 23 24 25 26 27

16 17

PROG.E

CPU.E

FX2N-4AD FX2N-4DA

OUT

0 1 2 3 4 5

10 11 12 13 14 15 16 17

6 7

distributor.

Y0 Y2 Y4 Y6 Y10 Y14 Y20 Y22 Y24 Y26 COM5 Y0 Y2 Y4 Y6 Y10 Y12 Y14 Y16

• Under no circumstances will Mitsubishi Electric be liable or responsible for any consequential

COM1 Y3 COM2 Y5 Y7 COM3 Y13 COM4 Y15 Y21 Y23 Y25 Y27 COM1 Y1 Y3 COM2 Y5 Y7 COM3 Y11 Y13 COM4 Y15 Y17

A/D D/A 24V

24V

M8000 FNC78

24V A/D

damage that may arise as a result of the installation or use of this equipment.

K2 K29 K4M10 K1

FROM

• All examples and diagrams shown in this manual are intended only as an aid to understanding

M10 FX 2N -48MR-ES/UL FX 2N -4AD FX 2N -16EX FX 2N -4DA FX 2N -32ER FX 2N-4AD-TC the text, not to guarantee operation. Mitsubishi Electric will accept no responsibility for actual

M3 Represents b0 BFM #29

X000-X027 Special block X030 Special block X050-X067 Special block use of the product based on these illustrative examples.

Y000-Y027 No.0 -X047 No.1 Y030-Y047 No.2

M20

M4 Represents b10 BFM #29

M1 (K4) → (BFM #1), (K4) → (BFM #2)

FNC79

TO P

K2 K1 K4 K2 Number of samples is changed to four on both CH1 and CH2. 7 EMC CONSIDERATIONS

Electromagnetic compatibility or EMC must be considered before using the FX2N-4AD-TC. Manual number : JY992D65501

(BFM #5) → (D0), (BFM #6) → (D1) Mitsubishi recommend that the thermocouple sensors used, should be fitted with a form of seild or screening as Manual revision :A

FNC78

FROM

K2 K5 D0 K2 Transfer the averaged temperature value in °C to the data protection against EMC noise. Date : JUNE 1997

registers.

If some form of cable protection is used, the “Shield” must be terminated at the SLD terminals as shown in

This step is the actual reading of the FX2N-4AD-TC input channels. It is essentially the only chapter 2.

program step which is needed. The “TO” instruction in this example, sets the input

channels, CH1 and CH2, to take the average reading of four samples. Because of the delicate nature of all analog signals, failure to take good EMC precautions could lead to EMC noise

The “FROM” instruction reads the average temperatures (BFM #5 and #6) for input induced errors ; up to ±10% of actual values. This is an absolute worst case figure, users who do take good

channels CH1 and CH2 of the FX2N-4AD-TC. If direct temperature readings are required precautions can expect operation within normal tolerances.

HEAD OFFICE:MITSUBISHI DENKI BLDG MARUNOUCHI TOKYO 100 TELEX:J24532 CABLE MELCO TOKYO

BFM #9 and #10 should be read instead, e.g. HIMEJI WORKS:840, CHIYODA CHO, HIMEJI, JAPAN

EMC considerations should include selection of good quality cables, good routing of those cables away from potential

noise sources.

FNC78

K2 K29 K4M10 K1

FROM

special FX2N-4AD-TC result No. of

Additionally it is recommended that signal averaging is used as this will reduce the effects of random noise “spikes”.

block No.2 BFM number destination words read

Effective JUN. 1997

Specifications are subject to

JY992D65501A change without notice

4 SYSTEM BLOCK DIAGRAM 6 DIAGNOSTICS

6.1 _Preliminary checks

POWER I. Check whether the input/output wiring and/or extension cables are properly connected on FX2N-4AD-TC analog

LED 5V Power Gain and special function block

FX2N series Supply offset values

are stored in

II. Check that the FX2N system configuration rules have not been broken, i.e. the number of special function blocks

Buffer

Command

TO Memory EEPROM does not exceed 8 and the total system I/O is equal or less than 256, I/O.

information Analog Input

RAM III. Ensure that the correct operating range has been selected for the application.

write and Photocoupler

data status CPU IV. Check that there is no power overload on either the 5V or 24V power sources, remember the loading on the FX2N

read base unit or a powered extension unit varies according to the number of extension blocks or special function

FROM Converted CH1

data blocks connected.

A/D CH2

System V. Put the FX2N base unit into RUN.

CH3

ROM converter

Control CH4

signals Non-

DC24V contact

Power ±15V A/D analog

Source LED switch

DC/DC Cyclic switching

5V

converter 24V

FX2N-4AD-TC Analog Block LED

6.2 Error checking

5 EXAMPLE PROGRAM If the FX2N-4AD-TC special function blcok does not seem to operate normally, check the following items.

In the program shown below, the FX2N-4AD-TC occupies the position of special block number 2 ( that is the third closest

block to the programmable controller). A type K thermocouple is used on CH1 and a type J on CH2. CH3 and CH4 are • Check the status of the POWER LED.

not used. The averaging count is four. The averaged values in degrees C of input channels CH1 and CH2 are stored Lit : The extension cable is properly connected.

respectively in data registers D0 and D1. Otherwise : Check the connection of the extension cable.

• Check the external wiring.

M8002 FNC79

K2 K0 H3310 K1

Specify the type of thermocouple.

H3310 → Block No.2 BFM#0

• Check the status fo the “24V” LED (top right corner of the FX2N-4AD-TC).

Initial TO Lit : FX2N-4AD-TC is ON, 24VDC power source is ON.

CH4 and CH3: not used Otherwise : Possible 24VDC power failure, if ON possible FX2N-4AD-TC failure.

Pulse CH2: type J(1)

M8002 FNC78

K2 K30 D2 K1

CH1: type K(0) • Check the status fo the “A/D” LED (top right corner of the FX2N-4AD-TC).

FROM Block No.2 BFM #30 → (D2) Lit : A/D conversion is proceeding normally.

Initial Identification code Otherwise : Check buffer memory #29 (error status). If any bits (b0, b2, b3) are ON, then this is why

Pulse

the A/D LED is OFF.

FNC10

K2030 D2 M0 When (K2030) = (D2), M1 = ON.

CMP

i.e. When identification code is K2030, M1 = ON.

This initial step checks that the special function block placed at position 2 is actually an

FX2N-4AD-TC, i.e. its unit identification number is 2030 (BFM #30). This step is optional,

but it provides a software check that the system has been configured correctly.

M8000 Block No.2 BFM #29 → (K4M10) 6.3 Checking special function block numbers

FNC78

K2 K29 K4M10 K1 Transfer the error status to (M25 to M10).

FROM Other special units of blocks that use FROM/TO commands, such as analog input blocks, analog output blocks and

RUN When error is found, M10 = ON

high-speed counter blocks, can be directly connected to the base unit of the FX2N programmable controller or to the

monitor right side of other extension blocks or units. Each special block is consecutively numbered from 0 to 7 beginning from

M10 Guidelines for the safety of the user and protection of the FX2N-4AD-TC special function block

Represents b0 BFM #29 the one closest to the base unit. A maximum of eight special blocks can be connected.

M3 • This manual has been written to be used by trained and competent personnel. This is defined by

Error found

the European directives for machinery, low voltage and EMC.

This step provides optional monitoring of the FX2N-4AD-TC Error Buffer Memory (#29).

If there is an Error on the FX2N-4AD-TC, bit b0 of BFM #29 will be set on. This can be read L N

COM X0

24+ X1

X2 X4

X5

X6

X7

X10

X13

X14

X15

X16

X17

X20

X21

X22

X23

X24

X25 L N

COM

24+

X0

X1

X2

X3

X4

X5

X6

X7

X10

X11

X12

X13

X14

X15

X16

X17

• If in doubt at any stage during the installation of the FX2N-24AD-TC always consult a professional

by this program step, and output as a bit device in the FX2N programmable controller (M3 in IN

0 1 2 3 4 5 6 7 20 21 22 23 24 25 26 27

10 11 12 13 14 15 16 17

POWER

POWER POWER

IN

0 1 2 3 4 5

10 11 12 13 14 15 16 17

6 7 POWER electrical engineer who is qualified and trained to the local and national standards. If in doubt

POWER

this example). Additional Error devices can be output in a similar manner, e.g. b10 BFM T.V

about the operation or use of the FX2N-4AD-TC please consult the nearest Mitsubishi Electric

#29 Digital range error. (see below) FX2N-48MR-ES/UL

6 7 20 21 22 23 24 25 26 27

16 17

PROG.E

CPU.E

FX2N-4AD FX2N-4DA

OUT

0 1 2 3 4 5

10 11 12 13 14 15 16 17

6 7

distributor.

Y0 Y2 Y4 Y6 Y10 Y14 Y20 Y22 Y24 Y26 COM5 Y0 Y2 Y4 Y6 Y10 Y12 Y14 Y16

• Under no circumstances will Mitsubishi Electric be liable or responsible for any consequential

COM1 Y3 COM2 Y5 Y7 COM3 Y13 COM4 Y15 Y21 Y23 Y25 Y27 COM1 Y1 Y3 COM2 Y5 Y7 COM3 Y11 Y13 COM4 Y15 Y17

A/D D/A 24V

24V

M8000 FNC78

24V A/D

damage that may arise as a result of the installation or use of this equipment.

K2 K29 K4M10 K1

FROM

• All examples and diagrams shown in this manual are intended only as an aid to understanding

M10 FX 2N -48MR-ES/UL FX 2N -4AD FX 2N -16EX FX 2N -4DA FX 2N -32ER FX 2N-4AD-TC the text, not to guarantee operation. Mitsubishi Electric will accept no responsibility for actual

M3 Represents b0 BFM #29

X000-X027 Special block X030 Special block X050-X067 Special block use of the product based on these illustrative examples.

Y000-Y027 No.0 -X047 No.1 Y030-Y047 No.2

M20

M4 Represents b10 BFM #29

M1 (K4) → (BFM #1), (K4) → (BFM #2)

FNC79

TO P

K2 K1 K4 K2 Number of samples is changed to four on both CH1 and CH2. 7 EMC CONSIDERATIONS

Electromagnetic compatibility or EMC must be considered before using the FX2N-4AD-TC. Manual number : JY992D65501

(BFM #5) → (D0), (BFM #6) → (D1) Mitsubishi recommend that the thermocouple sensors used, should be fitted with a form of seild or screening as Manual revision :A

FNC78

FROM

K2 K5 D0 K2 Transfer the averaged temperature value in °C to the data protection against EMC noise. Date : JUNE 1997

registers.

If some form of cable protection is used, the “Shield” must be terminated at the SLD terminals as shown in

This step is the actual reading of the FX2N-4AD-TC input channels. It is essentially the only chapter 2.

program step which is needed. The “TO” instruction in this example, sets the input

channels, CH1 and CH2, to take the average reading of four samples. Because of the delicate nature of all analog signals, failure to take good EMC precautions could lead to EMC noise

The “FROM” instruction reads the average temperatures (BFM #5 and #6) for input induced errors ; up to ±10% of actual values. This is an absolute worst case figure, users who do take good

channels CH1 and CH2 of the FX2N-4AD-TC. If direct temperature readings are required precautions can expect operation within normal tolerances.

HEAD OFFICE:MITSUBISHI DENKI BLDG MARUNOUCHI TOKYO 100 TELEX:J24532 CABLE MELCO TOKYO

BFM #9 and #10 should be read instead, e.g. HIMEJI WORKS:840, CHIYODA CHO, HIMEJI, JAPAN

EMC considerations should include selection of good quality cables, good routing of those cables away from potential

noise sources.

FNC78

K2 K29 K4M10 K1

FROM

special FX2N-4AD-TC result No. of

Additionally it is recommended that signal averaging is used as this will reduce the effects of random noise “spikes”.

block No.2 BFM number destination words read

Effective JUN. 1997

Specifications are subject to

JY992D65501A change without notice

(1) Buffer Memory BFM #0: Thermocouple type K or J selection mode

3 INSTALLATION NOTES AND USAGE BFM #0 is used to select K or J type thermocouples for each channel. Each digit of a 4 digit hexadecimal number

3.1 Environmental specification corresponds to one channel, the least significant digit being channel 1.

[ Example ] H 3 3 1 0

Item Specification

CH1 0 = K type

Environmental specifications (excluding following) Same as those for the FX2N base unit CH2 1 = J type

CH3 3 = Not used

Dielectric withstand voltage 500VAC, 1min (between all terminals and ground) CH4

FX2N-4AD-TC SPECIAL FUNCTION BLOCK 3.2 Power supply specification • A/D conversion time is 240ms per channel. When “3" (not used) is set for a channel, A/D conversion is not executed

for that channel and so the total conversion time is decreased. In the above example, the conversion time is as

USER’S GUIDE Item Specification follows:

240ms (conversion time per channel) × 2channels (number of channels being used) = 480ms (total conversion time)

Analog circuits 24V DC ±10%, 60mA

(2) Buffer Memory BFMs #1 to #4: Number of temperature readings to be averaged

Digital circuits 5V DC, 40mA (internal power supply from base unit

JY992D65501A When the number of temperature readings to be averaged is specified for BFMs #1 to #4, the averaged data is stored in

BFMs #5 to #8 (°C) and #13 to #16 (°F). Only the range 1 to 256 is valid for the number of temperature readings to be

This manual contains text, diagrams and explanations which will guide the reader in the correct installation and averaged. If a value outside of this range is input, the default value of 8 is used.

operation of the FX2N-4AD-TC special function block and should be read and understood before attempting to install or (3) Buffer Memory BFMs #9 to #12 and #17 to #20: Present temperature

use the unit.

Further information can be found in the FX PROGRAMMING MANUAL and FX2N SERIES HARDWARE MANUAL . These BFMs store the present value of the input data. This value is stored in units of 0.1°C or 0.1°F, but the resolution

is only 0.4°C or 0.72°F for type K and 0.3°C or 0.54°F for type J.

3.3 Performance specification 3.5 Status Information

1 INTRODUCTION Analog Inputs (1) Buffer Memory BFM #28: Digital range error latch

• The FX2N-4AD-TC analog block amplifies the signal from four thermocouple sensors (type K or J) and converts the Centigrade (°C) Fahrenheit (°F) BFM #29 b10(digital range error) is used to judge whether the measured temperature is within the unit’s range or not.

data into 12 bit reading’s stored in the FX2N base unit. Both Centigrade (°C) and Fahrenheit (°F) can be read. Item BFM #28 latches the error status of each channel and can be used to check for thermocouple disconnection.

Both °C and °F are available by reading the appropriate buffer memory (BFM).

Reading resolution is 0.4°C/0.72°F of type K and 0.3°C/0.54°F of type J.

Input signal Thermocouple: type K or J (either can be used for each channel), 4 channels, JIS 1602-1981 b15 or b8 b7 b6 b5 b4 b3 b2 b1 b0

• All data transfers and parameter settings are adjusted through software control of the FX2N-4AD-TC ; by use of the

High Low High Low High Low High Low

TO/FROM applied instructions in the FX2N PC. Rated temprature Type K -100°C to +1,200°C Type K -148°F to +2,192°F

Not used

range

• The FX2N-4AD-TC occupies 8 points of I/O on the FX2N expansion bus. The 8 points can be allocated from either Type J -100°C to +600°C Type J -148°F to +1,112°F CH4 CH3 CH2 CH1

inputs or outputs. The FX2N-4AD-TC draws 40mA from the 5V rail of the FX2N base unit or powered extension unit. 12 bit conversion stored in 16 bit 2’s complement form

Low : Latches ON when temperature measurement data goes below the lowest temperature

• Thermocouples with the following specifications can be used: Type K (JIS 1602-1981) Digital output Type K -1,000 to 12,000 Type K -1,480 to 21,920 measurement limit.

Type J (JIS 1602-1981) Type J -1,000 to 6,000 Type J -1,480 to 11,120 High : Turns ON when temperature measurement data goes above the highest temperature

Type K 0.4°C Type K 0.72°F measurement limit, or when a thermocouple is disconnected.

Resolution

Type J 0.3°C Type J 0.54°F When an error occurs the temperature data before the error is latched. If the measured value returns to within valid

limits the temperature data returns to normal operation. (Note: The error remains latched in (BFM #28))

Overall accuracy ± (0.5% full scall +1°C) An error can be cleared by writing K0 to BFM #28 using the TO instruction or turning off the power.

Calibration point Freezing point of pure water 0°C / 32°F

Conversion speed (240ms ± 2%) × 4 channels (unused channels are not converted)

Note : Earth-tipped thermocouples are not suitable for use with this unit.

1.1 EXTERNAL DIMENSIONS Weight: Approx. 0.3 kg (0.66 lbs) Dimensions: mm (inches) Analog Inputs continued... (2) Buffer Memory BFM #29: Error status

Accessories: Self adhesive labels for special function block number

identification. Conversion Bit devices of BFM #29 ON OFF

(Type K) (Type K)

87(3.43) 55(2.17) 55(2.17) Characteristics +12,000 +21,920 When either b2 or b3 is ON

b0 : Error No error

Mounting holes 4(0.16) A/D conversion is stopped for the error channel

(Type J) (Type J)

4.5mm(0.18) dia. +6,000 +11,120 b1 : Not used

Readings given at calibration b2 : Power source 24VDC power supply failure power supply normal

-148°F

24+

24+

-100°C

reference point 0°C/32°F (0/320)

24- SLD L-

b3 : Hardware error A/D converter or other hardware failure Hardware Normal

24- SLD L-

+600°C +1,200°C +1,112°F +2,192°F

respectively. -1,000 (Type J) (Type K) -1,480 (Type J) (Type K) b4 to b9 : Not used

CH1

CH1

L+

L+

(subject to the overall accuracy)

DIN rail POWER

b10 : Digital range error

Digital output/analog input value is outside the

Digital output value is normal.

mounting slot Miscellaneous specified range.

80(3.15)

90(3.54)

SLD L- SLD

CH2 CH3

35mm(1.38) b11 : Averaging number Selected number of averaged results is outside Averaging is normal.

L+

Item Specification

error the available range -see BFM #1 to #4 (between 1 to 256)

Photo-coupler isolation between analog and digital circuits. b12 to b15 : Not used

Isolation DC/DC converter isolation of power from FX2N base unit.

L+

FX2N-4AD-TC

L- SLD L-

24V No isolation between analog channels. (3) Identification Code Buffer Memory BFM #30

CH4

24V

LED 8 points taken from the FX2N expansion bus The identification code or ID number for a Special Block is read from buffer memory BFM #30 using the FROM

L+

A/D A/D Number of occupied I/O points command. This number for the FX2N-4AD-TC unit is K2030. The programmable controller can use this facility in its

(can be either inputs or outputs)

LED program to identify the special block before commencing data transfer to and from the special block.

9(0.35) Extension cable 4(0.16) Terminal screws M3 (0.12)

and connector

3.4 Buffer memory assignment 3.6 Installation location

2 TERMINAL LAYOUTS The FX2N-4AD-TC communicates with the This unit measures temperature according to the temperature difference between the temperature measurement part

BFM CONTENTS programmable controller through use of buffer

*1: The compensating cables that can be used for connecting with (themocouple) and the terminal block. If this unit is installed in a place where the temperature of the terminal block

Thermocouuple type K or J selection mode. memories. varies rapidly, a measuring error may occur. For this reason, the unit should be installed in a place free from excessive

Thermocouple 1 SLD the thermocouple are the following. *#0

shielded CH1 3KW CH1 Type K: KX-G, KX-GS, KX-H, KX-HS,WX-G,WX-H,VX-G At shipment: H0000 BFMs #21 to #27 and #31 are reserved. temperature variation.

L+

L- Type J: JX-G, JX-H CH1 to CH4 Averaged temperature reading to be All non reserved BFMs can be read by the

For every 10Ω of line resistance, the compensating cable will *#1-#4 programmable controller using the FROM

averaged (1 to 256) Default = 8

Thermocouple 1 indicate a temperature 0.12°C higher than actual. command. 3.7 Using crimp terminations

shielded CH4 3KW CH4

Check the line resistance before using. Long compensating #5-#8 CH1 to CH4 Averaged temprature in 0.1°C units

BFMs (buffer memories) marked with an “*” can

L+

L- cables are more prone to noise interference, therefore a short #9-#12 CH1 to CH4 Present temprature in 0.1°C units be written to, from the programmable controller

less than

6.2mm(0.24")

• Use crimp terminations of the type indicated on the left.

(less than 100m) compensating cable is recommended. using the TO command.

SLD

Temperature

Unused channels should have a wire link connected between #13-#16 CH1 to CH4 Averaged temprature in 0.1°F units • Secure the termination using a tightening torque of between 5 and 8

their + and - terminals to prevent an error being detected on Use M3(0.12") kg⋅cm.

compensation #17-#20 CH1 to CH4 Present temprature in 0.1°F units

2 circuit that channel.

24VDC±10% 50mA

24+ +15V

#21-#27 Reserved less than

6.2mm(0.24")

• Wire only to the module terminals discussed in this manual. Leave

DC/DC *2: If there is excessive electrical noise, connect the SLD all others vacant.

4 3 AG *#28 Digital range error latch

24- converter -15V terminal to the ground terminal on the unit.

*3: Connect the ground terminals of the FX2N-4AD-TC unit and #29 Error status

Class 3 FX2N-4AD-TC the base unit. Use class 3 grounding on the base unit. #30 Identification code K2030

Grounding PC

Analog Input Block *4: The 24V DC built-in supply of the programmable controller #31 Reserved

(100 Wor less)

Extension cable

may be used as the power supply.

4 SYSTEM BLOCK DIAGRAM 6 DIAGNOSTICS

6.1 _Preliminary checks

POWER I. Check whether the input/output wiring and/or extension cables are properly connected on FX2N-4AD-TC analog

LED 5V Power Gain and special function block

FX2N series Supply offset values

are stored in

II. Check that the FX2N system configuration rules have not been broken, i.e. the number of special function blocks

Buffer

Command

TO Memory EEPROM does not exceed 8 and the total system I/O is equal or less than 256, I/O.

information Analog Input

RAM III. Ensure that the correct operating range has been selected for the application.

write and Photocoupler

data status CPU IV. Check that there is no power overload on either the 5V or 24V power sources, remember the loading on the FX2N

read base unit or a powered extension unit varies according to the number of extension blocks or special function

FROM Converted CH1

data blocks connected.

A/D CH2

System V. Put the FX2N base unit into RUN.

CH3

ROM converter

Control CH4

signals Non-

DC24V contact

Power ±15V A/D analog

Source LED switch

DC/DC Cyclic switching

5V

converter 24V

FX2N-4AD-TC Analog Block LED

6.2 Error checking

5 EXAMPLE PROGRAM If the FX2N-4AD-TC special function blcok does not seem to operate normally, check the following items.

In the program shown below, the FX2N-4AD-TC occupies the position of special block number 2 ( that is the third closest

block to the programmable controller). A type K thermocouple is used on CH1 and a type J on CH2. CH3 and CH4 are • Check the status of the POWER LED.

not used. The averaging count is four. The averaged values in degrees C of input channels CH1 and CH2 are stored Lit : The extension cable is properly connected.

respectively in data registers D0 and D1. Otherwise : Check the connection of the extension cable.

• Check the external wiring.

M8002 FNC79

K2 K0 H3310 K1

Specify the type of thermocouple.

H3310 → Block No.2 BFM#0

• Check the status fo the “24V” LED (top right corner of the FX2N-4AD-TC).

Initial TO Lit : FX2N-4AD-TC is ON, 24VDC power source is ON.

CH4 and CH3: not used Otherwise : Possible 24VDC power failure, if ON possible FX2N-4AD-TC failure.

Pulse CH2: type J(1)

M8002 FNC78

K2 K30 D2 K1

CH1: type K(0) • Check the status fo the “A/D” LED (top right corner of the FX2N-4AD-TC).

FROM Block No.2 BFM #30 → (D2) Lit : A/D conversion is proceeding normally.

Initial Identification code Otherwise : Check buffer memory #29 (error status). If any bits (b0, b2, b3) are ON, then this is why

Pulse

the A/D LED is OFF.

FNC10

K2030 D2 M0 When (K2030) = (D2), M1 = ON.

CMP

i.e. When identification code is K2030, M1 = ON.

This initial step checks that the special function block placed at position 2 is actually an

FX2N-4AD-TC, i.e. its unit identification number is 2030 (BFM #30). This step is optional,

but it provides a software check that the system has been configured correctly.

M8000 Block No.2 BFM #29 → (K4M10) 6.3 Checking special function block numbers

FNC78

K2 K29 K4M10 K1 Transfer the error status to (M25 to M10).

FROM Other special units of blocks that use FROM/TO commands, such as analog input blocks, analog output blocks and

RUN When error is found, M10 = ON

high-speed counter blocks, can be directly connected to the base unit of the FX2N programmable controller or to the

monitor right side of other extension blocks or units. Each special block is consecutively numbered from 0 to 7 beginning from

M10 Guidelines for the safety of the user and protection of the FX2N-4AD-TC special function block

Represents b0 BFM #29 the one closest to the base unit. A maximum of eight special blocks can be connected.

M3 • This manual has been written to be used by trained and competent personnel. This is defined by

Error found

the European directives for machinery, low voltage and EMC.

This step provides optional monitoring of the FX2N-4AD-TC Error Buffer Memory (#29).

If there is an Error on the FX2N-4AD-TC, bit b0 of BFM #29 will be set on. This can be read L N

COM X0

24+ X1

X2 X4

X5

X6

X7

X10

X13

X14

X15

X16

X17

X20

X21

X22

X23

X24

X25 L N

COM

24+

X0

X1

X2

X3

X4

X5

X6

X7

X10

X11

X12

X13

X14

X15

X16

X17

• If in doubt at any stage during the installation of the FX2N-24AD-TC always consult a professional

by this program step, and output as a bit device in the FX2N programmable controller (M3 in IN

0 1 2 3 4 5 6 7 20 21 22 23 24 25 26 27

10 11 12 13 14 15 16 17

POWER

POWER POWER

IN

0 1 2 3 4 5

10 11 12 13 14 15 16 17

6 7 POWER electrical engineer who is qualified and trained to the local and national standards. If in doubt

POWER

this example). Additional Error devices can be output in a similar manner, e.g. b10 BFM T.V

about the operation or use of the FX2N-4AD-TC please consult the nearest Mitsubishi Electric

#29 Digital range error. (see below) FX2N-48MR-ES/UL

6 7 20 21 22 23 24 25 26 27

16 17

PROG.E

CPU.E

FX2N-4AD FX2N-4DA

OUT

0 1 2 3 4 5

10 11 12 13 14 15 16 17

6 7

distributor.

Y0 Y2 Y4 Y6 Y10 Y14 Y20 Y22 Y24 Y26 COM5 Y0 Y2 Y4 Y6 Y10 Y12 Y14 Y16

• Under no circumstances will Mitsubishi Electric be liable or responsible for any consequential

COM1 Y3 COM2 Y5 Y7 COM3 Y13 COM4 Y15 Y21 Y23 Y25 Y27 COM1 Y1 Y3 COM2 Y5 Y7 COM3 Y11 Y13 COM4 Y15 Y17

A/D D/A 24V

24V

M8000 FNC78

24V A/D

damage that may arise as a result of the installation or use of this equipment.

K2 K29 K4M10 K1

FROM

• All examples and diagrams shown in this manual are intended only as an aid to understanding

M10 FX 2N -48MR-ES/UL FX 2N -4AD FX 2N -16EX FX 2N -4DA FX 2N -32ER FX 2N-4AD-TC the text, not to guarantee operation. Mitsubishi Electric will accept no responsibility for actual

M3 Represents b0 BFM #29

X000-X027 Special block X030 Special block X050-X067 Special block use of the product based on these illustrative examples.

Y000-Y027 No.0 -X047 No.1 Y030-Y047 No.2

M20

M4 Represents b10 BFM #29

M1 (K4) → (BFM #1), (K4) → (BFM #2)

FNC79

TO P

K2 K1 K4 K2 Number of samples is changed to four on both CH1 and CH2. 7 EMC CONSIDERATIONS

Electromagnetic compatibility or EMC must be considered before using the FX2N-4AD-TC. Manual number : JY992D65501

(BFM #5) → (D0), (BFM #6) → (D1) Mitsubishi recommend that the thermocouple sensors used, should be fitted with a form of seild or screening as Manual revision :A

FNC78

FROM

K2 K5 D0 K2 Transfer the averaged temperature value in °C to the data protection against EMC noise. Date : JUNE 1997

registers.

If some form of cable protection is used, the “Shield” must be terminated at the SLD terminals as shown in

This step is the actual reading of the FX2N-4AD-TC input channels. It is essentially the only chapter 2.

program step which is needed. The “TO” instruction in this example, sets the input

channels, CH1 and CH2, to take the average reading of four samples. Because of the delicate nature of all analog signals, failure to take good EMC precautions could lead to EMC noise

The “FROM” instruction reads the average temperatures (BFM #5 and #6) for input induced errors ; up to ±10% of actual values. This is an absolute worst case figure, users who do take good

channels CH1 and CH2 of the FX2N-4AD-TC. If direct temperature readings are required precautions can expect operation within normal tolerances.

HEAD OFFICE:MITSUBISHI DENKI BLDG MARUNOUCHI TOKYO 100 TELEX:J24532 CABLE MELCO TOKYO

BFM #9 and #10 should be read instead, e.g. HIMEJI WORKS:840, CHIYODA CHO, HIMEJI, JAPAN

EMC considerations should include selection of good quality cables, good routing of those cables away from potential

noise sources.

FNC78

K2 K29 K4M10 K1

FROM

special FX2N-4AD-TC result No. of

Additionally it is recommended that signal averaging is used as this will reduce the effects of random noise “spikes”.

block No.2 BFM number destination words read

Effective JUN. 1997

Specifications are subject to

JY992D65501A change without notice

Vous aimerez peut-être aussi

- FX1N-4AD - TC ThermocoupleDocument5 pagesFX1N-4AD - TC ThermocouplePK KPas encore d'évaluation

- Port Size: DN 8, G3/8 High Pressure Solenoid Valve Manifold Further Customized Solutions Available Upon RequestDocument3 pagesPort Size: DN 8, G3/8 High Pressure Solenoid Valve Manifold Further Customized Solutions Available Upon RequestEnrique MurgiaPas encore d'évaluation

- Average Temp. Sensor: GeneralDocument2 pagesAverage Temp. Sensor: GeneralaltipatlarPas encore d'évaluation

- Jac Series (6-30A) : Compact and Low Profile, Common Mode Emi/Emc Filters in 150Khz To 1Mhz (1-Stage Filter)Document2 pagesJac Series (6-30A) : Compact and Low Profile, Common Mode Emi/Emc Filters in 150Khz To 1Mhz (1-Stage Filter)Daniel Dusan CruzPas encore d'évaluation

- 1LE1604-3AB59-0GB4-Z B91+D30+D31+M1L Datasheet enDocument2 pages1LE1604-3AB59-0GB4-Z B91+D30+D31+M1L Datasheet enSergio FerrariPas encore d'évaluation

- CH 2.4 - NTC PTCDocument27 pagesCH 2.4 - NTC PTCamirul lexPas encore d'évaluation

- Typical HT and LT Power Cable Sizing PDFDocument26 pagesTypical HT and LT Power Cable Sizing PDF1382ace100% (2)

- FCP 11 N 60Document10 pagesFCP 11 N 60alive ElectronicsPas encore d'évaluation

- FDD5N50Document8 pagesFDD5N50primero marnezPas encore d'évaluation

- Service Manual: CVX-V3/V3PDocument9 pagesService Manual: CVX-V3/V3PsilictronicPas encore d'évaluation

- Creep Calculation by Colin Bayliss & Brain HardyDocument1 pageCreep Calculation by Colin Bayliss & Brain HardyVenkatasubramanian IyerPas encore d'évaluation