Académique Documents

Professionnel Documents

Culture Documents

WP Flwpro 1 PDF

Transféré par

jjiménez_142046Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

WP Flwpro 1 PDF

Transféré par

jjiménez_142046Droits d'auteur :

Formats disponibles

The Essential Guide to ABB manufactures more types of flowmeters than any other manufacturer and is the

only manufacturer who can give totally unbiased advice as to which flowmeter is

suitable for a given application. This wall-chart details the major flow measurement

Process Flow Measurement

AdviseIT

AnalyzeIT

techniques ABB offers, their capabilities and their suitability for an application.

FieldIT

MeasureIT Electromagnetic Mass Vortex / Swirl Variable Area

Service: Electrically conductive liquids or slurries (>0.05µsec/cm). Coriolis Effect Thermal Vortex Shedding (Bluff body) Swirlmeter Service: Liquids and gases including steam (metal tube only).

OperateIT

Design Pressure: Up to 3600 psig (250 bar). Service: Liquids and slurries. Gas Service: Liquids and gases including steam. Liquids, gases and steam. Design Pressure: Up to 300 psig (20 bar) glass tube, up to 900 psig (64 bar)

Design Pressure: Up to 1400 psig (100 bar). Up to 560 psig (100 bar). Design Pressure: Up to 2400 psig (160 bar). Up to 1650 psig (110 bar). metal tube.

Design Temperature: Up to 360°F (180°C).

OptimizeIT

Design Temperature: Up to 360°F (180°C). Up to 570° F (300°C). Design Temperature: Up to 750°F (400°C). -40°F to 550°F (-40 to 280°C). Design Temperature: Up to 250°F (120°C) glass tube, up to 790°F (420°C) metal tube.

Flow Range: 4 cc/min to 1,100,000 gpm (240 cm3/h to

Flow Range: Up to 11,000 kg/min. Up to 900m3/h. Flow Range: 3 to 10, 586 gpm (0.4 to 2400m3/h) liquid; 0.3 to 6600 gpm (0.1 to 1800m3/h)

250,000m3/h). Flow Range: Liquids 0.01 cc/min to 530 gpm (0.6cm3/h to 120m3/h)

Up to 3 million kg/h (for DN 3000). 100 to 720,000 acfh (20,000m3/h) gases. liquid; 88 to 706,300 acfh (2.5 to

Scale: Linear. 20,000m3/h) gases. gases 0.3cc/min to 2000 scfm (5Ncm3/h to 3600 Nm3/h) gasses.

Scale: Linear. Linear.

Signal: Analog electronic; digital; Smart protocols; Scale: Linear at high Reynolds No. Linear at high and low Reynolds No. Scale: Linear.

Accuracy: ±0.15% of rate or better. ±1% of rate.

Bus protocols. Rangeability: 40:1 or better. 150:1 or better. Signal: Frequency or Analog electronic Pulse or analog output. Signal: Visual; electronic or analog.

Accuracy: up to ± 0.15% of rate: factory calibrated. End Connections: Threaded, Flanged, Sanitary Threaded, flanged, hose. Accuracy: ±0.75% of rate or better on liquid: ±0.5% of rate or better; liquids, Accuracy: ± 1.0% of rate to ± 10% of full scale

factory calibrated; ± 1% of rate on gas. gas or steam. depending on type, size, and calibration.

Rangeability: up to 1500:1. Sizes: 1/16” to 6” (1.5mm to 150mm). 1/8” to 10” (3mm to 250mm)

Probe available for pipes up to Rangeability: 20:1. 25:1 turn down average Rangeability: 5:1 to 12.1.

End Connections: Flanged, Sanitary, Wafer and

3000mm; bypass type available. (determined by size, application)

Screw Connections available. End Connections: Female pipe threaded, flanged or sanitary connections.

Advantages: Measures mass flow temperature Measures mass flow directly. End Connections: Flanged, Threaded, Wafer or Insert; Flanged.

Sizes: 1/25” to 120” (1mm to 3m) probe available. and fluid density directly. Very low pressure loss. also can be used as by-pass meter Sizes: Up to 4" (100mm) also used as a by-pass meter

Advantages: Universal industrial flowmeter for conductive liquids.Widely used in the water Handles difficult applications. Good for low velocity around mainline orifice. around a mainline orifice for larger pipe sizes.

industry for both clean and dirty water applications excellent for slurry measurements. gas measurement. Sizes: 1.2" to 12" (15mm to 300mm) 0.5" to 16" (15mm to 300mm). Advantages: Inexpensive; constant pressure drop; insensitive

Unit maybe calibrated (sampling and by-pass types available).

Unaffected by changes in fluid density viscosity; zero head loss; bi-directional; no flow to viscosity variations below

for any shape

obstruction; low voltage dc, battery and loop powered versions available. Advantages: No moving parts: suitable for wide No moving parts, 3 upstream pipe a given threshold; direct indicating; no power

of ducting.

variety of fluids: excellent combination diameters, ideal for light gases, required; can be direct mass device;

Limitations: Liquids or slurries only; required minimum electrical conductivity varies Limitations: Installation requirements vary with Affected by significant of price and performance. Direct works with entrained liquid. Direct

with manufacturer. manufacturer. Head loss may be high. coatings. no straight upstream piping required. Versions available with

steam mass flow. steam mass flow.

Sensitive to fluid pulsation. Care must Some designs PTFE liners.

Limitations: Straight piping required; sensitive to Limited viscosity range.

Partially Full Electromagnetic be taken with 2 phase flow. are fragile.

increasing viscosity below a given

Reynolds number.

Limitations: Requires accessories for data transmission; must be vertically

mounted: gas use requires minimum backpressure.

Service: Water and effluent duty in partially filled pipelines /channels

Direct alternative to high maintenance weirs and flumes

Design pressure: Up to 40 bar depending on liner / flange rating

Clean

Liquids

Dirty

Liquids

Corrosive

Liquids

Viscous

Liquids

Abrasive

Slurries

Fibrous

Slurries

Low Velocity

Flows

Vapor

or Gas

Hi Temp.

Service

Cryogenic

Service

Semi-filled

Pipes

Non-

Newtonians

Open

Channel

Ultrasonic

Design temperature: Up to 130°C depending on liner material Service: Natural Gas

Flow range: Up to 10 m/sec velocity Magnetic Design Pressure: Sensor up to 100 bar

Scale: Linear

Mass Coriolis Design Temperature: -25° to +85 ° C

Signal: Analogue / pulse / datalink / Fieldbus protocols

Flow Range: Up to 60 m/sec velocity

Accuracy: +/- 1% to +/- 5% of reading, dependent Thermal

Scale: Linear.

on fill level.

Oscillatory Vortex Shedding Signal: Analogue / pulse / datalink

Fill level limits: 10% to 100% of meter (15% to

100% of meter for DN150 size) Swirlmeter Accuracy: +/- 0.2% of rate for calibrated four path meter

Size range: DN150 to DN2000 End Connections: Flanged, ANSI or DIN

End connections: Flanged, ANSI or DIN (others on request) Turbine Sizes: DN100 (4") to DN400 (16")

Advantages: No additional pressure loss Ultrasonic Transit Time Advantages: High accuracy over wide turndown range

No moving parts No additional pressure loss

No maintenance requirements for most applications Differential Pressure Orifice Obstructionless design

Surface solids do not impede measurement accuracy

Venturi Bi-directional measurement

Low installation cost compared to open channel techniques

No moving parts

Limitations: Must be installed in downward slope of 0.5 to 5%; Minimum size 150mm Flow Nozzles & Tubes

ATEX version available for hazardous area use

Pilot Tubes Very low energy consumption - can be used

Level Metering for Weirs and Flumes with battery or solar power sources

Wedge

Service: Liquids in open channels. Limitations: Restricted size range; Clamp-on version not available.

Flow Range: From 1/2 gpm (0.1m3/h) and upward. Variable Area

Scale: Proportional to the measured head to the 3/2 power for rectangular and Weirs and Flumes Level

trapezoidal weirs and parshall flumes; proportional to the measured head to the

5/2 power for V-notch weirs. Flowmeter Applications Designed for this Service Normally applicable Applicable for this service under certain Not applicable

for this service conditions, consult manufacturer for this service

Signal: Analog electronic.

Accuracy: 1% to 5% full scale.

Rangeability: 75:1 rectangular, trapezoidal weirs, Parshall flumes; 50:1 V-notch weirs;

Palmer-Bowlus flumes 10:1.

Advantages: Ideal for water and waste flows, flumes have low head loss, low cost.

Limitations: Weirs are more accurate than flumes but require cleaning; flumes are

self cleaning.

Differential Pressure

Orifice Venturi Flow Nozzles and tubes Pitot Wedge

Service: Liquids and gases including steam. Liquids and gases including steam. Liquids and gases including steam. Liquids and gases. Liquids and gases. For technical advice and further

Design Pressure: Determined by transmitter. Determined by transmitter. Determined by transmitter. Determined by transmitter. Determined by transmitter.

Design Temperature: Determined by materials.

Flow Range: From 0.1 cc/min (0.1cm /m) and upward

3

Determined by materials.

From 5 gpm (1m /h) liquid; 20 scfm (30 Nm /h) gas;

3 3

Determined by materials.

From 5 gpm (1m /h) liquid; 20 scfm (30 Nm /h)

3 3

Determined by materials.

Determined by pipe size.

Determined by materials.

Determined by pipe size.

information on the ABB range of

Signal:

or gas equivalent.

Analog electronic or pneumatic.

and upward, determined by pipe size.

Analog electronic or pneumatic.

gas and upwards.

Analog electronic or pneumatic. Analog electronic or pneumatic. Analog electronic or pneumatic.

process flow products call:

0870 600 6122

Accuracy: ± 0.6% of max flow uncalibrated including ± 1% of max flow or better; uncalibrated ± 1%full scale including transmitter, ± 1% full scale or better including ± 0.5% of actual flow when operated in

transmitter; sizes smaller than 2” usually calibrated. including transmitter. flow calibration recommended. transmitter. the calibrated range.

Rangeability: 4:1 for given transmitter span setting. 4:1 for given transmitter span setting. 4:1 for given transmitter span setting. 4:1 for given transmitter 4:1 for given transmitter span setting.

End Connections: Mounts between flanges. Flanged. Flanged or mounted between flanges. span setting. Flanged or mounted between flanges.

or refer to the Assist Direct –

Sizes: Determined by pipe size. Up to 72” (1800mm) larger possible 3” to 48” (80mm to 1200mm). Insert probe. Up to 48” (1200mm).

Advantages: Easy-to-install; uses one transmitter Low permanent loss; good for slurries Economical, low permanent loss; uses Unlimited probe length. Very economical; easy-to-install; uses

regardless of pipesize; low cost; wide and dirty fluids; uses one transmitter one transmitter regardless of pipe size; Very low cost; uses one transmitter one transmitter regardless of pipe size;

variety of types and material available;

easy-to-change capacity.

regardless of pipe size. Extremely robust

construction.

nozzle commonly used for steam and

has higher capacity for same generated D P.

regardless of pipe size.

Averaging types available.

can be bi-directional; low pressure loss.

Minimum upstream Instrumentation Catalogue

Limitations: Uses eccentric orifices or segmental plates for very dirty Most expensive D P producer; Flow tubes lack extensive background data Doesn’t sample full stream; piping required.

liquids or slurries; quadrant orifice for viscous liquids; generally limited to air and compared to orifice plates; application limited accuracy. Low differential Not good for very

venturi, flow tube, pitot, or elbow taps to reduce energy water; big and heavy on viscous liquids limited. Calibration pressure for given flow rate. low velocity.

consumption; straight run of upstream and especially in larger recommended for optimum performance.

downstream piping required. Some fluid must leave pipe pipe sizes.

except when chemical seal protectors are used. Accuracy affected by wear.

Accuracy affected by wear.

visit us at www.abbiap.co.uk www.abb.co.uk/instrumentation ABB Limited, Howard Road, St Neots, Cambridgeshire, PE19 8EU, UK. Tel: 0870 600 6122

WP/FLWPRO Issue 1 (07.04)

Vous aimerez peut-être aussi

- All Flowmeter Basics PDFDocument1 pageAll Flowmeter Basics PDFAtharva PathakPas encore d'évaluation

- 16" Steel Model M16: Smith Meter CT Series PD Meter For Crude Transportation SpecificationsDocument4 pages16" Steel Model M16: Smith Meter CT Series PD Meter For Crude Transportation SpecificationsAnnisa RahmadayantiPas encore d'évaluation

- Sulzer Brochure CPE en LDocument19 pagesSulzer Brochure CPE en Lphantuan080213Pas encore d'évaluation

- ABF SeriesDocument7 pagesABF SeriesKAVITAPas encore d'évaluation

- Suresens QPT Elite SLSHDocument2 pagesSuresens QPT Elite SLSHScott BassettPas encore d'évaluation

- MPP High Performance Multi Phase Pump E00601Document6 pagesMPP High Performance Multi Phase Pump E00601chijioke ekekePas encore d'évaluation

- Ge Druck t1300Document8 pagesGe Druck t1300RONALD ALFONSO PACHECO TORRESPas encore d'évaluation

- 16 Steel Model M16Document4 pages16 Steel Model M16JAIME CIFUENTESPas encore d'évaluation

- 12" Steel Model K12: Smith Meter CT Series PD Meter For Crude TransportationDocument4 pages12" Steel Model K12: Smith Meter CT Series PD Meter For Crude Transportationjuan carlosPas encore d'évaluation

- Waste Liquid NozzleDocument4 pagesWaste Liquid Nozzlelbc123Pas encore d'évaluation

- Caudalimetro Magnetico Heinrichs EpxDocument11 pagesCaudalimetro Magnetico Heinrichs EpxBase SistemasPas encore d'évaluation

- Electromagnetic Flowmeter User Manual Combined KFL DCDocument35 pagesElectromagnetic Flowmeter User Manual Combined KFL DCSaravanan Mathi100% (1)

- Cat Vacuum Pumps V71D17C EngDocument16 pagesCat Vacuum Pumps V71D17C Enghoangvubui4632100% (1)

- Model S100-D and S200-D Density Sensor: FeaturesDocument6 pagesModel S100-D and S200-D Density Sensor: FeaturesazitaggPas encore d'évaluation

- Flowmeter Endress+HauserDocument70 pagesFlowmeter Endress+Hausersanach100% (1)

- Hydraulic Pitch Pump: Advanced Solutions For Durable and Robust Pitch ControlDocument2 pagesHydraulic Pitch Pump: Advanced Solutions For Durable and Robust Pitch ControlFernando CastroPas encore d'évaluation

- Complete Pump Coverage: Experience in MotionDocument1 pageComplete Pump Coverage: Experience in MotionJUAN ANTONIO HERNANDEZ SOSAPas encore d'évaluation

- Ti 3Document9 pagesTi 3Dr. U. Shrinivas BalrajPas encore d'évaluation

- GaugesDocument6 pagesGaugeshisaj4uPas encore d'évaluation

- PORTFOLIO 2018 KLDocument69 pagesPORTFOLIO 2018 KLAnonymous r3MoX2ZMTPas encore d'évaluation

- Portfolio 2.4 DuctingDocument69 pagesPortfolio 2.4 Ductingjitendrashukla10836Pas encore d'évaluation

- Ss 01014Document6 pagesSs 01014Bintang SuryoPas encore d'évaluation

- PU LPH 80540 80553 Esite GBDocument7 pagesPU LPH 80540 80553 Esite GBAl-Alamiya TradePas encore d'évaluation

- H010995 WellheadDesanderDocument2 pagesH010995 WellheadDesanderslbclqrkPas encore d'évaluation

- Rotameters series M 200 C dosing devices technical specificationsDocument2 pagesRotameters series M 200 C dosing devices technical specificationszaidPas encore d'évaluation

- Datos Tecnicos FlujometroDocument4 pagesDatos Tecnicos FlujometroJuverCupePas encore d'évaluation

- Bareshaft Blowers: S2H Two Lobe SeriesDocument5 pagesBareshaft Blowers: S2H Two Lobe SeriesMahmoud MagdyPas encore d'évaluation

- Victus ManifoldDocument2 pagesVictus ManifoldMahendran KuppusamyPas encore d'évaluation

- Vario El Cube en 2013 Web PDF 1Document16 pagesVario El Cube en 2013 Web PDF 1SutarnoPas encore d'évaluation

- 6-Pes-150 Bap AltptDocument2 pages6-Pes-150 Bap AltptFouad ToumiPas encore d'évaluation

- Piston Compressor New PDFDocument12 pagesPiston Compressor New PDFJunaid AhmedPas encore d'évaluation

- 9851 3139 01 - Cop 1238KDocument2 pages9851 3139 01 - Cop 1238Kbundajoseph148Pas encore d'évaluation

- LPX LPM 9000Document4 pagesLPX LPM 9000besinuxafuPas encore d'évaluation

- TRICOR TCM Coriolis Flow Meters - Range CatalogueDocument26 pagesTRICOR TCM Coriolis Flow Meters - Range CatalogueMedab Abd El MalekPas encore d'évaluation

- ValvDocument12 pagesValvsergio negretePas encore d'évaluation

- A O Smith Meter 2 Inch Steel Model C2Document4 pagesA O Smith Meter 2 Inch Steel Model C2RomankoPas encore d'évaluation

- NewSNSProcessPumpsRange E10364Document2 pagesNewSNSProcessPumpsRange E10364lamariadelbarrioyugaPas encore d'évaluation

- TJ SaniMicro Rotary Spray HeadDocument3 pagesTJ SaniMicro Rotary Spray HeadhtrtheethPas encore d'évaluation

- Liquid Turbine Flowmeter ManualDocument32 pagesLiquid Turbine Flowmeter ManualHammad AshrafPas encore d'évaluation

- LPH 65320 LPH 65327Document9 pagesLPH 65320 LPH 65327Eko WageurPas encore d'évaluation

- WLMONO024Document5 pagesWLMONO024Michał BorzemskiPas encore d'évaluation

- Topic 7 Oil and Gas Pipeline SolutionsDocument17 pagesTopic 7 Oil and Gas Pipeline SolutionsImranMajidli100% (1)

- Model 500-600 Series II (FM-1280 Rev.A)Document6 pagesModel 500-600 Series II (FM-1280 Rev.A)Carlos Miguel LópezPas encore d'évaluation

- Positive Displacement Spur Gear Flow MeterDocument2 pagesPositive Displacement Spur Gear Flow Meterkhaldoun samiPas encore d'évaluation

- Liquid ring vacuum pumps: Two-stage LOH 25003, LOH 25007, LOH 25309Document11 pagesLiquid ring vacuum pumps: Two-stage LOH 25003, LOH 25007, LOH 25309Raciel Leon CarlosPas encore d'évaluation

- Barton 7000 PDFDocument8 pagesBarton 7000 PDFmbloexPas encore d'évaluation

- Caldon Lefm 240ci Ultrasonic Flow Meters: Integral Manifold DesignDocument6 pagesCaldon Lefm 240ci Ultrasonic Flow Meters: Integral Manifold DesignJim LimPas encore d'évaluation

- cHDD-MQ04AB Product-Overview r2sDocument2 pagescHDD-MQ04AB Product-Overview r2sIbrahim RahmatullahPas encore d'évaluation

- Surface Pumps: Performance & SolutionsDocument12 pagesSurface Pumps: Performance & SolutionsBJ Abela100% (1)

- One Tough Animal One Tough Animal: Brushcat Rotary Cutter AttachmentDocument2 pagesOne Tough Animal One Tough Animal: Brushcat Rotary Cutter AttachmentJhon jaider Álvarez BarbozaPas encore d'évaluation

- Models HSG200 HSG400 Gas Burners: NoticeDocument24 pagesModels HSG200 HSG400 Gas Burners: NoticeAnonymous hf5v2JzrZqPas encore d'évaluation

- C Elementar Vario MACRO Cube PDFDocument16 pagesC Elementar Vario MACRO Cube PDFWaleed El-azab100% (1)

- Brochure Flow-Sensors ENGB 112022 LowDocument18 pagesBrochure Flow-Sensors ENGB 112022 LowVictor ConstantinPas encore d'évaluation

- Electromechanical Sensors For Pressure Control OsiSense XM - SchneiderDocument102 pagesElectromechanical Sensors For Pressure Control OsiSense XM - SchneiderIman FaisalPas encore d'évaluation

- KAFLON - Magnetic Flow Meter-CompressedDocument5 pagesKAFLON - Magnetic Flow Meter-CompressedDicky LeonardoPas encore d'évaluation

- S EPARATEURDocument11 pagesS EPARATEURChristy KlPas encore d'évaluation

- Range of CleanCube DevicesDocument8 pagesRange of CleanCube Devicesduna tarimaPas encore d'évaluation

- Modelling of Vibrations of Overhead Line Conductors: Assessment of the TechnologyD'EverandModelling of Vibrations of Overhead Line Conductors: Assessment of the TechnologyGiorgio DianaPas encore d'évaluation

- Tau Empire PDF FreeDocument130 pagesTau Empire PDF Freejjiménez_142046Pas encore d'évaluation

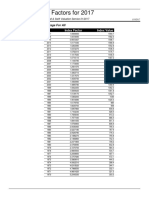

- Marshall & Swift inventory index factors for 2017Document39 pagesMarshall & Swift inventory index factors for 2017Marlen NarroPas encore d'évaluation

- STOAT Installation and User GuideDocument146 pagesSTOAT Installation and User Guidejjiménez_142046Pas encore d'évaluation

- MSPE - Process Model DescriptionsDocument148 pagesMSPE - Process Model DescriptionsBianca DianaPas encore d'évaluation

- Last Alliance Last Alliance: Men of Gondor Banners and Pennants Men of Gondor Banners and PennantsDocument1 pageLast Alliance Last Alliance: Men of Gondor Banners and Pennants Men of Gondor Banners and Pennantsjjiménez_142046Pas encore d'évaluation

- Variable Operating Costs of Wastewater Treatment PlantsDocument7 pagesVariable Operating Costs of Wastewater Treatment Plantsjjiménez_142046Pas encore d'évaluation

- New in STOAT 5Document55 pagesNew in STOAT 5ronywernerPas encore d'évaluation

- STOAT Unit Process DescriptionsDocument322 pagesSTOAT Unit Process Descriptionsjjiménez_142046Pas encore d'évaluation

- WRC STOAT: Tutorials GuideDocument80 pagesWRC STOAT: Tutorials GuideAoife Fitzgerald100% (1)

- Rotating Biological ContactorsDocument18 pagesRotating Biological Contactorsjjiménez_142046Pas encore d'évaluation

- Atv A 200 eDocument34 pagesAtv A 200 eLaurentiu Gheorghita100% (1)

- Kinetics and Effluent Quality in Extended AireationDocument8 pagesKinetics and Effluent Quality in Extended Aireationjjiménez_142046Pas encore d'évaluation

- Atv-Dvwk A 134eDocument48 pagesAtv-Dvwk A 134ejjiménez_142046Pas encore d'évaluation

- Rules and Standards: German Atv-DvwkDocument25 pagesRules and Standards: German Atv-DvwkMehmet Emre Bastopcu100% (2)

- Atv DVWK M - 368eDocument36 pagesAtv DVWK M - 368etallef001Pas encore d'évaluation

- Atv-Dvwk A 134eDocument48 pagesAtv-Dvwk A 134ejjiménez_142046Pas encore d'évaluation

- Lesson 3 - Materials That Undergo DecayDocument14 pagesLesson 3 - Materials That Undergo DecayFUMIKO SOPHIA67% (6)

- GSM Multi-Mode Feature DescriptionDocument39 pagesGSM Multi-Mode Feature DescriptionDiyas KazhiyevPas encore d'évaluation

- 20220720-MODIG-Supply Chain Manager (ENG)Document2 pages20220720-MODIG-Supply Chain Manager (ENG)abhilPas encore d'évaluation

- Market Participants in Securities MarketDocument11 pagesMarket Participants in Securities MarketSandra PhilipPas encore d'évaluation

- Trustees Under IndenturesDocument233 pagesTrustees Under IndenturesPaul9268100% (6)

- Chi Square LessonDocument11 pagesChi Square LessonKaia HamadaPas encore d'évaluation

- Java MCQ questions and answersDocument65 pagesJava MCQ questions and answersShermin FatmaPas encore d'évaluation

- Resona I9 Neuwa I9 FDADocument2 pagesResona I9 Neuwa I9 FDAMarcos CharmeloPas encore d'évaluation

- Brightline Guiding PrinciplesDocument16 pagesBrightline Guiding PrinciplesdjozinPas encore d'évaluation

- RF Power Measurements Basic PrinciplesDocument27 pagesRF Power Measurements Basic PrinciplesHector Velasco100% (1)

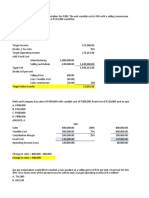

- Courier - Capstone WebApp - Round 3 ReportDocument23 pagesCourier - Capstone WebApp - Round 3 Reportmarmounette26Pas encore d'évaluation

- Vydyne® R533H NAT: Ascend Performance Materials Operations LLCDocument4 pagesVydyne® R533H NAT: Ascend Performance Materials Operations LLCJames FauncePas encore d'évaluation

- Concept, Types, Characteristics and ClassificationsDocument6 pagesConcept, Types, Characteristics and ClassificationsCJ FaPas encore d'évaluation

- M Series CylindersDocument61 pagesM Series CylindersAndres SantanaPas encore d'évaluation

- Acknowledgment: George & Also To Our Group Guide Asst. Prof. Simy M Baby, For Their Valuable Guidance and HelpDocument50 pagesAcknowledgment: George & Also To Our Group Guide Asst. Prof. Simy M Baby, For Their Valuable Guidance and HelpKhurram ShahzadPas encore d'évaluation

- Model Paper 1Document4 pagesModel Paper 1Benjamin RohitPas encore d'évaluation

- Axtraxng™: Networked Access Control Management Software V27.XDocument2 pagesAxtraxng™: Networked Access Control Management Software V27.XChiluvuri VarmaPas encore d'évaluation

- Mechanical PropertiesDocument30 pagesMechanical PropertiesChristopher Traifalgar CainglesPas encore d'évaluation

- The Causes of Cyber Crime PDFDocument3 pagesThe Causes of Cyber Crime PDFInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- 10 Consulting Frameworks To Learn For Case Interview - MConsultingPrepDocument25 pages10 Consulting Frameworks To Learn For Case Interview - MConsultingPrepTushar KumarPas encore d'évaluation

- Jodi Ridgeway vs. Horry County Police DepartmentDocument17 pagesJodi Ridgeway vs. Horry County Police DepartmentWMBF NewsPas encore d'évaluation

- QDA Miner 3.2 (With WordStat & Simstat)Document6 pagesQDA Miner 3.2 (With WordStat & Simstat)ztanga7@yahoo.comPas encore d'évaluation

- Request Letter To EDC Used PE PipesDocument1 pageRequest Letter To EDC Used PE PipesBLGU Lake DanaoPas encore d'évaluation

- CVP Solution (Quiz)Document9 pagesCVP Solution (Quiz)Angela Miles DizonPas encore d'évaluation

- Experienced Leadership Driving Growth at Adlabs EntertainmentDocument38 pagesExperienced Leadership Driving Growth at Adlabs EntertainmentvelusnPas encore d'évaluation

- VBScriptDocument120 pagesVBScriptdhanaji jondhalePas encore d'évaluation

- 2023 Prospectus 2Document69 pages2023 Prospectus 2miclau1123Pas encore d'évaluation

- ProkonDocument57 pagesProkonSelvasatha0% (1)

- Sugar Milling Contract DisputeDocument3 pagesSugar Milling Contract DisputeRomy IanPas encore d'évaluation

- Incident Report Form: RPSG-IMS-F-24 Accident and Investigation Form 5ADocument2 pagesIncident Report Form: RPSG-IMS-F-24 Accident and Investigation Form 5ARocky BisPas encore d'évaluation