Académique Documents

Professionnel Documents

Culture Documents

Fundamental Design Calculationsdoc 09 Nov 2011 PDF

Transféré par

Charles NunezTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Fundamental Design Calculationsdoc 09 Nov 2011 PDF

Transféré par

Charles NunezDroits d'auteur :

Formats disponibles

FUNDAMENTAL ELECTRICAL SYSTEM

DESIGN CALCULATIONS AND SYSTEM

ARCHITECTURES

for Commercial and Residential Buildings

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

CONTENTS

I. Design Criteria for Main Equipment Sizing

II. Low Voltage Wires and Cables

III. Busduct Sizing

IV. Overcurrent Protection

V. Reserved

VI. Lighting & Power Circuits

VII. Motor Circuits

VIII. Fire Pump Motor Circuit

IX. Power Factor Correction

X. Basic Panelboard Design

XI. Standard Electrical System Architecture

A. Malls

B. BPO

C. High Rise Residential

XII. Reserved

XIII. Reserved

XIV. References

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

I. Sizing of Main Equipment

A. General Considerations

The main equipments for the building’s electrical system are the transformers and

generator sets. The sizes of these equipments are determined during the schematic

design stage, which depend on load estimate calculation. The load estimate is derived

from load densities defined for areas in each type of the building to be designed, which

depends on the nature of the building and its corresponding electrical requirement.

1. Transformers

Main transformer is sized based from load estimation after the application of

demand factor defined by the designing electrical engineer.

2. Generator Sets

Generator(s), on the other hand, is/are sized depending on building requirement;

that is, same size as the main transformer(s) if the building is intended to have

100% backup power. Also, generator sets are sized based on ‘standby’ rating.

Below are the common load groups that are considered in load estimation –

1. Lighting – Interior, exterior, normal, emergency.

2. Small Power Loads – Receptacle outlets, appliances.

3. Air-conditioning – Chillers, AHU’s, Fans, etc.

4. Plumbing and Sanitation – Domestic pumps, booster pumps, transfer pumps,

sump pump, water heaters.

5. Fire protection – Fire pumps, FDAS.

6. Transportation – Elevators, Escalators.

7. Food preparation – Cooking, refrigerating, dishwashing, ovens, etc.

8. Special Loads – Loads in theaters, etc

9. Miscellaneous loads – Auxiliary systems, etc

This design calculation standard will only address the following types of building –

1. Residential Buildings

2. Malls

3. BPOs

4. Hotels

B. System Voltage Consideration

The utilization voltage considered in this design calculation standard is 3-phase, four-

wire, 400V / 230 V, 60 Hz. Three phase loads shall be served at 400V, while single

phase loads shall be served at 230V line-to-neutral.

Primary voltage shall be based from available power utility supply.

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

C. Prescriptive Design Parameters

The load densities to be used in load estimation and initial main equipment sizing will be

based from the parameters defined below. These parameters were derived from

historical design parameters, code requirements, and actual building performance of

existing Ayala buildings. However, the external designer is given liberty to review and

adjust these parameters based from his experience.

1. Residential Buildings

The load considerations for residential buildings in terms of power are typically the

same – household loads and admin/common area loads.

Split-type ACU A/C Lighting Receptacle Misc Total

Residential (ACCU)

kw / tr tr / sqm pf VA / sqm VA / sqm VA / sqm VA / sqm VA / sqm

Res Units 1.3 0.05 0.8 81 24 8 37 150

Office 1.3 0.06 0.8 90 28 30 0 148

Core Areas (Non-AC) n/a n/a n/a 0 4 4 4 12

Non - food 1.3 0.06 0.8 90 24 8 0 122

Food 1.3 0.10 0.8 163 16 8 18 205

Parking n/a n/a n/a 0 4 4 0 8

2. Malls

Load density considerations for malls are – Retail loads (Food and Non-food), and

common area / admin loads.

Centralized ACU A/C Lighting Receptacle Misc Total

Malls (Chillers)

kw / tr tr / sqm pf VA / sqm VA / sqm VA / sqm VA / sqm VA / sqm

Retail Shop (non-food) 1.26 0.06 0.8 88 24 8 0 120

Food 1.26 0.10 0.8 158 16 8 18 200

Banks / Offices 1.26 0.06 0.8 88 28 30 0 146

Common Areas 1.26 0.05 0.8 79 4 4 4 91

Parking n/a n/a n/a 0 4 4 0 8

For developments having a District Cooling System, the chiller loads are not

included in the building load estimation.

Centralized ACU A/C Lighting Receptacle Misc Total

Malls (DCS)

kw / tr tr / sqm pf VA / sqm VA / sqm VA / sqm VA / sqm VA / sqm

Retail Shop (non-food) 0.56 0.06 0.8 39 24 8 0 71

Food 0.56 0.10 0.8 70 16 8 18 112

Banks / Offices 0.56 0.06 0.8 39 28 30 0 97

Common Areas 0.56 0.05 0.8 35 4 4 4 47

Parking n/a n/a n/a 0 4 4 0 8

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

3. BPO Buildings

Design considerations for BPOs are different from typical office buildings. The

occupant density is higher for BPOs resulting from higher cooling and power

requirement. However, the design for BPO is often just ‘core-and-shell’, since

detailed design for tenant spaces are handled by tenants. Therefore, power

allotment for tenant units should be carefully considered to anticipate tenant

power requirement.

Centralized ACU A/C Lighting Receptacle Misc Total

BPO (Chillers)

kw / tr tr / sqm pf VA / sqm VA / sqm VA / sqm VA / sqm VA / sqm

Core Areas 1.26 0.05 0.8 79 4 4 4 91

BPO Offices 1.26 0.10 0.8 158 28 60 0 246

Parking n/a n/a n/a 0 4 4 0 8

For developments having a District Cooling System, the chiller loads are not

included in load estimation.

Centralized ACU A/C Lighting Receptacle Misc Total

BPO (DCS)

kw / tr tr / sqm pf VA / sqm VA / sqm VA / sqm VA / sqm VA / sqm

Core Areas 0.56 0.05 0.8 35 4 4 4 47

BPO Offices 0.56 0.10 0.8 70 28 60 0 158

Parking n/a n/a n/a 0 4 4 0 8

4. Hotels

Centralized ACU A/C Lighting Receptacle Misc Total

Hotel Units

kw / tr tr / sqm pf VA / sqm VA / sqm VA / sqm VA / sqm VA / sqm

Core Areas 1.26 0.05 0.8 79 4 4 4 91

Hotel Units 1.26 0.05 0.8 79 24 8 8 119

Parking n/a n/a n/a 0 4 4 0 8

D. Minimum Demand Factors

1. Residential Buildings

a. Residential Loads = Connected Load x 23% (for 62 units or more)

b. Admin / Common Area Loads = Connected Load x 70%

2. Malls

a. Retail Loads = Connected Load x 70%

b. Admin / Common Area Loads = Connected Load x 70%

3. BPO Buildings

a. Tenant Areas = Connected Load x 80%

b. Common Areas / Admin = Connected Load x 70%

4. Hotels

a. Hotel Unit Areas = Connected Load x 60%

b. Common Areas / Admin = Connected Load x 70%

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

II. Low Voltage Wires and Cables

A. Sizing of wires and cables shall be based from the following considerations:

1. Wire/cable sizing should be rated maximum of–

a. 100% for non-continuous (cyclic) loads.

b. 80% for continuous loads (loads that operate for 3hrs or more).

2. Wire/cable shall be sized to meet Code defined voltage drop limits at its

design load current.

a. Voltage Drop Considerations

Where:

VD = Voltage Drop

NV = Nominal Voltage at Source

I = 1.15* FLC for running condition or

I = LRC for starting condition

R = DC resistance ohm/305m

L = Feeder wire length

3. Selected wire/cable temperature rating shall be coordinated with all

temperature limits, particularly at its terminations.

a. Select 60 ˚C temperature rating up to 100A

b. Select 75 ˚C temperature rating for more than 100A

4. Wire/cable short circuit withstand current and time shall be coordinated with

that of its upstream circuit breakers.

B. STANDARD ELECTRICAL WIRING SCHEDULE (Not applicable for motors)

Table VII.1 Standard Wiring Schedule for Low Voltage Systems

ELECTRICAL WIRING SCHEDULE GROUND CONDUIT

OCPD

WIRE CODE WIRE SIZE AMPACITY WIRE IMC/PVC

3Ø 3W+G 3Ø 4W+G 1Ø 2W+G mm2 THWN THHN AT mm2 mm Φ in Φ

T0 Y0 S0 3.5 25 30 20AT 3.5 15 1/2

T1 Y1 S1 5.5 35 40 30AT 3.5 20 3/4

T2 Y2 S2 8 50 55 40AT 5.5 25 1

T3 Y3 S3 14 65 70 50AT 8 25 1

T4 Y4 S4 22 85 90 70AT 8 32 1 1/2

T5 Y5 S5 30 110 115 100AT 8 32 1 1/2

T7 Y6 S7 50 145 150 125AT 14 50 2

T8 Y7 S8 60 160 170 150AT 22 50 2

T9 Y8 S9 80 195 205 175AT 22 50 2

T10 Y9 S10 100 220 225 200AT 30 65 2 1/2

T11 Y10 S11 125 255 265 250AT 30 65 2 1/2

T12 Y11 S12 150 280 295 30 80 3

T13 Y12 S13 175 305 345 300AT 30 80 3

T14 Y13 S14 200 330 355 30 80 3

T15 Y14 S15 250 375 400 400AT 50 90 3 1/2

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

C. Allowable Short Circuit Current Calculation

The allowable short circuit current for low-voltage thermoplastic (PVC) insulated

wire/cable is given by-

Where:

Isc = Allowable short circuit current

A = cross sectional area of copper conductors, mm2

t =time of short circuit current, seconds

K = 104.484, computed constant for thermoplastic copper conductor where

the rated wire operating temperature is 75 ˚C and the maximum short circuit

temperature is 150 ˚C

Table VII.1 Maximum Short Circuit Withstand of Low Voltage Cables

CU WIRE

Maximum Short-Circuit Withstand Current in Amperes

SIZE

mm2 1/2 Cycles 1 Cycle 2 Cycles 3 Cycles 4 Cycles 5 Cycles 6 Cycles

3.5 4,006 2,833 2,003 1,635 1,416 1,267 1,156

5.5 6,295 4,451 3,148 2,570 2,226 1,991 1,817

8 9,157 6,475 4,578 3,738 3,237 2,896 2,643

14 16,024 11,331 8,012 6,542 5,665 5,067 4,626

22 25,180 17,805 12,590 10,280 8,903 7,963 7,269

30 34,337 24,280 17,168 14,018 12,140 10,858 9,912

50 57,228 40,466 28,614 23,363 20,233 18,097 16,520

60 68,674 48,560 34,337 28,036 24,280 21,717 19,824

80 91,565 64,746 45,783 37,381 32,373 28,955 26,433

100 114,456 80,933 57,228 46,727 40,466 36,194 33,041

125 143,071 101,166 71,535 58,408 50,583 45,243 41,301

150 171,685 121,399 85,842 70,090 60,700 54,291 49,561

175 200,299 141,633 100,149 81,772 70,816 63,340 57,821

200 228,913 161,866 114,456 93,453 80,933 72,389 66,081

250 286,141 202,332 143,071 116,817 101,166 90,486 82,602

D. SIZING OF CONDUITS

Percent Conductor Fill formula is given by-

Where:

D = interior diameter of conduit

d = diameter of conductor (wire)

n = number of conductors

According to PEC Table 9.1.1.1 the percent fill of (more than two) conductors in a conduit

should not exceed 40%.

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

III. BUSDUCT SYSTEM

Busduct system shall be considered to be used for main feeders and risers. Busduct

may be of copper or aluminum conductor material; whichever the project budget

dictates.

A. Busduct Sizing shall be based on the following considerations –

5. The voltage rating of the busduct shall be 600V.

6. The busduct rating shall not be less than the demand load to be served.

7. Voltage drop not exceeding 2% shall be considered in sizing the busduct.

8. The ambient temperature consideration in sizing the busduct shall be 40°C.

9. The kAIC rating of busduct shall be selected to withstand the maximum available

short circuit current and shall be coordinated with that of its upstream OCPD.

IV. Overcurrent Protection not over 600V

Circuit Breakers shall be the standard overcurrent protective devices of equipment and

conductors for low voltage systems. Air Circuit Breakers shall be used for main

switchgears and synchronizing panels. Molded Case Circuit Breakers shall be used for

distribution, power, and lighting panelboards.

A. Sizing of Circuit Breakers shall be based from the following considerations:

1. The next higher size of circuit breaker above the ampacity of the conductors

being protected shall be permitted up to 800A circuit breaker rating except –

a. The conductors being protected supply branch circuit muti-outlet

receptacles.

b. The conductors being protected supply motor branch circuit.

2. Where the circuit breaker exceeds rating over 800A, the ampacity of the

conductor it protects shall be equal or greater than the rating of the circuit

breaker.

3. The interrupting capacity of the circuit breaker shall be greater than the

maximum available three-phase short circuit current.

V. Reserved

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

VI. LIGHTING AND RECEPTACLE OUTLET CIRCUIT

A. Lighting Circuits

1. Individual lighting circuit shall be sized on the maximum of 2500VA.

a. If not otherwise specified, each lighting fixture shall be assumed with a

minimum of 100VA rating.

b. A voltage drop not exceeding 3% shall be considered in each branch circuit.

2. Lighting circuit installation shall be in accordance with PEC.

3. Lighting system design criteria shall be based on Ayala Land Inc. Building

Standards.

B. Receptacle Outlet Circuits

1. Individual receptacle outlet circuit shall be sized on the maximum of 1800VA.

a. Each receptacle outlet shall be assumed with a minimum of 180VA rating.

b. A voltage drop not exceeding 3% shall be considered in each branch circuit.

2. Receptacle outlet circuit installation shall be based on PEC and Ayala

Land Inc. Building Standards.

INTENTIONALLY LEFT BLANK

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

VII. MOTOR ELECTRICAL DESIGN (NOT applicable for fire pump motor)

A. Motor Electrical System Design shall be based on the following considerations:

1. Size the branch circuit wire not less than 125% of the PEC-defined motor full load

current.

a. Since the operating temperature of motors is above 30°C (i.e., mostly 40°C) , the

branch circuit wire shall be coordinated to this temperature rating, by dividing the

PEC-defined motor full load current to the ambient temperature correction factor,

then sizing the branch circuit wire using this corrected ampacity.

2. Size the motor disconnect not less than 115% of the PEC defined motor full load

current. For uniformity, the size of motor disconnect shall be equal to the ampacity

of the branch circuit wire.

3. From PEC Table 4.30.4.2 size the Inverse time circuit breaker OCPD at 250% of

the PEC defined motor full load current.

4. Motor controller, including overload protection will be the scope of Mechanical /

Sanitary contractor, subject to Electrical Design Engineer’s review.

Table VII.1 Motor Electrical System Design, Sizing of Feeders and Circuit Breakers

Motor HP Full Load Currents, 3Φ SIZE OF WIRES SIZE OF ITCB

hp 230V 400V 460V 230V 400V 460V 230V 400V 460V

1/2 2.2 1.3 1.1 3.5mm2 3.5mm2 3.5mm2 20AT 20AT 20AT

3/4 3.2 1.8 1.6 3.5mm2 3.5mm2 3.5mm2 20AT 20AT 20AT

1 4.2 2.3 2.1 3.5mm2 3.5mm2 3.5mm2 20AT 20AT 20AT

1 1/2 6 3.3 3 3.5mm2 3.5mm2 3.5mm2 20AT 20AT 20AT

2 6.8 4.3 3.4 3.5mm2 3.5mm2 3.5mm2 20AT 20AT 20AT

3 9.6 6.1 4.8 3.5mm2 3.5mm2 3.5mm2 30 AT 20AT 20AT

5 15.2 9.7 7.6 5.5mm2 3.5mm2 3.5mm2 40 AT 30 AT 20AT

7 1/2 22 14 11 8.0 mm2 5.5mm2 3.5mm2 70AT 40 AT 30 AT

10 28 18 14 8.0 mm2 5.5mm2 5.5mm2 70AT 50 AT 40 AT

15 42 27 21 22 mm2 8.0 mm2 5.5mm2 100 AT 70AT 70AT

20 54 34 27 30 mm2 14 mm2 8.0 mm2 150 AT 100 AT 70AT

25 68 44 34 38 mm2 22 mm2 14 mm2 175 AT 125 AT 100 AT

30 80 51 40 38 mm2 30 mm2 22 mm2 200 AT 125 AT 100 AT

50 130 83 65 80 mm2 50 mm2 38 mm2 400 AT 200 AT 175 AT

60 154 103 77 100 mm2 50 mm2 38 mm2 400 AT 300 AT 200AT

75 192 128 96 150 mm2 80 mm2 50 mm2 500 AT 400 AT 250 AT

100 248 165 124 250 mm2 125 mm2 80 mm2 800 AT 500 AT 400 AT

125 312 208 156 2-125mm1 200 mm2 125 mm2 800 AT 600 AT 400 AT

150 360 240 180 2-150mm2 250 mm2 125 mm2 1000 AT 600 AT 500 AT

200 480 320 240 2-250mm2 2-125mm2 250 mm2 1200 AT 800 AT 500 AT

250 - 403 302 2-200 mm2 2-125mm2 1000 AT 800 AT

300 - 482 361 2-250mm2 2-150 mm2 1200 AT 1000 AT

*Based from PEC 4.30.14.4

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

B. Airconditioning and Refrigerating Equipment Electrical System Design shall be

based on the following considerations:

1. Size the branch circuit wire not less than 125% of the motor – compressor rated –

load current or the branch – circuit selection current, whichever is greater.

a. Since the operating temperature of motors is above 30°C (i.e., mostly 40°C) , the

branch circuit wire shall be coordinated to this temperature rating, by dividing the

motor – compressor rated – load current to the ambient temperature correction

factor, then size the branch circuit wire using this corrected ampacity.

2. Size the motor disconnect not less than 115% of the motor – compressor rated –

load current. For uniformity, the size of motor disconnect shall be equal to the

ampacity of the branch circuit wire.

3. From PEC Table 4.30.4.2 size the Inverse time circuit breaker OCPD at 250% of

the motor – compressor rated – load current.

4. Motor controller, including overload protection will be the scope of Mechanical /

Sanitary contractor, subject to Electrical Design Engineer’s review.

INTENTIONALLY LEFT BLANK

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

VIII. DESIGN FOR MOTOR DRIVEN FIRE PUMP SYSTEM

B. Fire Pump Electrical System shall be designed to meet the following requirements,

as defined in the Philippine Electrical Code:

1. Dedicated overcurrent protective device (OCPD) and disconnecting means must

be sized to indefinitely carry the locked-rotor current of the fire pump motor(s)

and associated pump(s).

2. The circuit components serving the fire pump must be chosen to withstand the

available short circuit current at the point of installation.

3. Fire pump feeder must be sized to have an ampacity of not less than 125% of the

full load current of the fire pump motor(s) and pressure maintenance motor(s),

considering –

a. The feeder conductor ampacity shall be corrected to coordinate with the

fire pump motor’s design ambient temperature.

b. The voltage at the fire pump controller terminal shall not drop more than

15% below nominal voltage during starting conditions.

c. The voltage at the fire pump controller terminal shall not drop more than

5% below the nominal voltage during running conditions when the motor

is operating at 115% of its full load current (capacity).

Table VII.1 Firepump Electrical System Design, Sizing of Feeders and Circuit Breakers

Firepump Motor

Full Load Locked Rotor Size of Maximum

Rated Size of Feeder

Current* Current 380V** OCPD Circuit Length

Horsepower

hp Amp Amp AT sq.mm. m

20 34 204 200 30 300

25 44 264 250 30 300

30 51 306 300 30 300

40 66 396 400 50 300

50 83 498 500 50 300

60 103 618 600 60 300

75 128 768 800 80 300

100 165 990 1000 125 400

125 208 1248 1200 200 400

150 240 1440 1600 250 400

200 320 1920 2000 2-150 500

250 403 2418 3000 2-200 500

*Based from PEC 4.30.14.4

**Assumed 6-times the motor full load current

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

C. Schematic Design for Fire Pump

Normal Power Source Feeder

Redundant Power Source Feeder

(in separate route)

Fire Pump ATS

Feeder Tap for

Jockey Pump

Fire Pump Motor

Controller

Fire Pump Motor

Jockey Pump Motor

D. Design Calculation Example

A 150hp Nema Design B fire pump motor has a full load current of 240Amp. Its

associated pressure maintenance pump is rated 5hp having a full load current of

9.7Amp. The maximum ambient operating temperature is 40°C. The power supply is

400V, 3Φ, 60hz.

a. Sizing of feeder wire to the fire pump controller

150hp, 380V, 3Φ FLC

240A x 1.25 = 300A

5hp, 380V, 3Φ FLC

9.70A x 1.25 =12.13A

Total FLC =312.13A, say 312A

And so, the minimum ampacity of feeder conductors is 312A. Correcting the

conductor ampacity to 40°C by dividing 0.88, we yield 354A. Using 75˚C

temperature rating of 600V rated building wires; a 250mm2 copper conductor is

the minimum size as per PEC Table 3.10.1.16

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

b. Voltage Drop Considerations

Where:

VD = Voltage Drop

NV = Nominal Voltage at Source

I = 1.15* FLC for running condition or

I = LRC for starting condition

R = DC resistance ohm/305m

L = Feeder wire length

Using the above formula, the feeder wire, 200mm2 copper conductor, must not

exceed 200m length to satisfy both motor starting and running voltage drop

limitations.

c. Sizing of OCPD and ATS

150hp, 380V, 3Φ FLC

240A x 6 = 1,440A (locked rotor current)

5hp, 380V, 3Φ FLC

9.70A x 6 = 58.20A

Total RLC =1,498.20A say, 1,498A

And so, the total locked rotor current is 1,498A, assuming Nema Design B code

F. The next higher standard size of OCPD (circuit breaker) and ATS is

1600AF/AT

INTENTIONALLY LEFT BLANK

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

IX. CAPACITOR BANK SIZING

A. Capacitor Bank design shall satisfy the following basic considerations:

1. The size of the capacitor bank should be able to correct system power factor

from 0.8 to 0.95.

2. The ampacity of the capacitor feeder conductor shall not be less than 135% of

the rated current of the capacitor.

3. The capacitor bank shall be provided with a means of discharging stored energy.

4. Capacitor bank specification must consider harmonic in selecting the type of

capacitor, and contactor switches.

Table VIII.1 Capacitor Bank Sizing based from Main Transformer Sizes

Nominal Transformer Power Factor Before Power Factor After Nominal Capacitor

Rating Compensation Compensation Bank Rating

300 0.8 0.95 100

500 0.8 0.95 150

750 0.8 0.95 250

1000 0.8 0.95 300

1500 0.8 0.95 450

2000 0.8 0.95 600

2500 0.8 0.95 750

3000 0.8 0.95 900

B. Schematic Design of Capacitor Bank

To Low Voltage Switchgear

Capacitor Feeder

Capacitor Overcurrent Protection

Discharge Resistor

Capacitor Bank

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

C. Design Calculation Procedure

Calculate the size of capacitor bank in a 1MVA electrical system, to be able to

correct the system power from 0.8 to 0.95.

Based from the power triangle,

S = 1000 KVA

Cos Φ1 = 0.8 ; Φ1 = 36.87°

Cos Φ2= 0.95 ; Φ2 = 18.19°

Also,

Sin Φ1 = Q1/S

Q1 = S*sinΦ1

Q2 = S*sinΦ2

Solving for Qc,

Qc = Q1 - Q2

Qc = S (sinΦ1 - sinΦ2)

= 1000(0.6 - 0.312)

Qc = 288 KVAR say, 300kVAR

And so, the rating of the capacitor is 300kVAR. Selecting capacitor sensitivity of 5%-

15%, provide 6 – steps of 50kVAR.

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

X. PANELBOARD DESIGN 400 / 230V Systems

A. Design Load Schedule for 3-phase 400 / 230V System

PANEL : DP-TEMPLATE MAIN CIRCUIT BREAKER : 100 AF 80 AT, 3-POLE, CENTER MAIN

FED FROM : (ENCODE PANEL SOURCE) MAIN FEEDER SIZE : Y4 (SEE WIRING LEGEND)

SYSTEM VOLTAGE : 230 VOLTS

BRANCH AMPERE LOAD BRANCH CIRCUIT BREAKER BRANCH CIRCUIT WIRING

CKT VOLT-

LOAD DESCRIPTION AMPERE- AMPERE-

NO. ØAN ØBN ØCN 3Ø AMPERE POLE CODE WIRE RACEWAY

FRAME TRIP

1 (Encode Loads) 12.00 2,760 1P 50 30 S1 THWN PVC SCH 40

2 (Encode Loads) 8.00 1,840 1P 50 20 S0 THWN PVC SCH 40

3 (Encode Loads) 6.52 1,500 1P 50 20 S0 THWN PVC SCH 40

4 (Encode Loads) 6.52 1,500 1P 50 20 S0 THWN PVC SCH 40

5 (Encode Loads) 10.00 2,300 1P 50 20 S0 THWN PVC SCH 40

6 (Encode Loads) 12.00 2,760 1P 50 20 S0 THWN PVC SCH 40

7 (Encode Loads) 5.00 1,150 1P 50 20 S0 THWN PVC SCH 40

8 (Encode Loads) 6.00 1,380 1P 50 20 S0 THWN PVC SCH 40

9 (Encode Loads) 8.00 1,840 1P 50 20 S0 THWN PVC SCH 40

10 (Encode Loads) 8.00 1,840 1P 50 20 S0 THWN PVC SCH 40

11 (Encode Loads) 10.00 2,300 1P 50 20 S0 THWN PVC SCH 40

12 (Encode Loads) 10.00 2,300 1P 50 20 S0 THWN PVC SCH 40

13 - 1P 50 20 S0 THWN PVC SCH 40

14 - 1P 50 20 S0 THWN PVC SCH 40

15 - 1P 50 20 S0 THWN PVC SCH 40

16 - 1P 50 20 S0 THWN PVC SCH 40

17 - 1P 50 20 S0 THWN PVC SCH 40

18 - 1P 50 20 S0 THWN PVC SCH 40

TOTAL CONNECTED LOAD: 31.00 29.04 42.00 0.00 23,469

LOCATION : (ENCODE PANEL LOCATION) MAIN CB KAIC RATING : kAIC

ENCLOSURE : (ENCODE TYPE OF ENCLOSURE, NEMA RATING) BRANCH CB KAIC RATING : kAIC

MOUNTING : (SURFACE, FREE-STANDING, FLUSH-MOUNTED, ETC) APPLIED DEMAND FACTOR : 80 %

Table IX.1 Load Schedule Template 3-phase 400 / 230V System

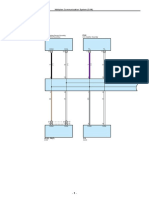

B. Three-Phase 4-wire + ground 400V / 230V Systems

To 400V 4W+G 3-phase Source

3-Pole Main

Circuit Breaker

to 400V 3-phase Loads,

other panelboards, etc.

to 230V single-phase

Loads

ΦA ΦB ΦC N

G

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

XI. STANDARD SYSTEM ARCHITECTURE

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

XII. Reserved

XIII. Reserved

XIV. References

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

STANDARD Fundamental Design Calculations

Electrical System

Rev 00 – November 2011

Prepared by:

Nathaniel S. Acosta

Technical Services Engineer

Noted by: Approved by:

Artemio C. Pugat Jr. Roger N. Tiguelo

Electrical Section Head CG-MEPF Head

MAKATI DEVELOPMENT CORPORATION

GF, Bonifacio Technology Center

st nd

31 Street cor. 2 Avenue, Bonifacio Global City

Taguig 1634, Metro Manila, Philippines

Tel Nos. (02) 717-5500 to 30

www.mdc.com.ph

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Leaf springs and stress concentration in machine componentsDocument122 pagesLeaf springs and stress concentration in machine componentsCharles NunezPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Writeups 2Document1 pageWriteups 2Charles NunezPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Excuse Letter 3eDocument2 pagesExcuse Letter 3eCharles NunezPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- CapitalizationDocument7 pagesCapitalizationCharles NunezPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Solving Problems on Lines and Angles in Coordinate GeometryDocument33 pagesSolving Problems on Lines and Angles in Coordinate GeometryCharles NunezPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Approval Sheet English 3eDocument1 pageApproval Sheet English 3eCharles NunezPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Anselm's Ontological Argument ExplainedDocument8 pagesAnselm's Ontological Argument ExplainedCharles NunezPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Water Block FinalDocument4 pagesWater Block FinalCharles NunezPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Reviewer PresentationDocument201 pagesReviewer PresentationCharles NunezPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- Types of Resume English 3eDocument7 pagesTypes of Resume English 3eCharles NunezPas encore d'évaluation

- Common Proofreading SymbolsDocument7 pagesCommon Proofreading SymbolsCharles NunezPas encore d'évaluation

- Different Type of Writing (English 2)Document11 pagesDifferent Type of Writing (English 2)Charles NunezPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Solving Problems on Lines and Angles in Coordinate GeometryDocument33 pagesSolving Problems on Lines and Angles in Coordinate GeometryCharles NunezPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Trigo Analytic Integral Calc Review PresentationDocument53 pagesTrigo Analytic Integral Calc Review PresentationCharles NunezPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- MCD 2Document21 pagesMCD 2Charles Nunez100% (2)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Linx Refresh April 2010 Mathematics With Answer Key OKDocument17 pagesLinx Refresh April 2010 Mathematics With Answer Key OKCharles Nunez100% (2)

- Differential and Integral Calculus Formulas, Concepts, ExamplesDocument6 pagesDifferential and Integral Calculus Formulas, Concepts, ExamplesDayLe Ferrer AbapoPas encore d'évaluation

- Math 1Document84 pagesMath 1Bitoy Aguila100% (1)

- Refrigeration and HVAC systems guideDocument53 pagesRefrigeration and HVAC systems guideCharles NunezPas encore d'évaluation

- Refrigeration and HVAC systems guideDocument53 pagesRefrigeration and HVAC systems guideCharles NunezPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Manually Operated Reverse Osmosis Water DesalinationDocument5 pagesManually Operated Reverse Osmosis Water DesalinationCharles NunezPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- PIPE InhouseDocument25 pagesPIPE InhouseCharles NunezPas encore d'évaluation

- Manually Operated Reverse Osmosis Water DesalinationDocument5 pagesManually Operated Reverse Osmosis Water DesalinationCharles NunezPas encore d'évaluation

- Adjustable Lug WrenchDocument11 pagesAdjustable Lug WrenchCharles Nunez50% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Manually Operated Reverse Osmosis Water DesalinationDocument5 pagesManually Operated Reverse Osmosis Water DesalinationCharles NunezPas encore d'évaluation

- Fundamental 4 Participation ReportDocument1 pageFundamental 4 Participation ReportCharles NunezPas encore d'évaluation

- Auditing HealthcareDocument82 pagesAuditing Healthcareafraz_xecPas encore d'évaluation

- 5 Machine SafetyDocument8 pages5 Machine SafetyCharles NunezPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- P&IDDocument18 pagesP&IDhectornicolauPas encore d'évaluation

- Ain Shams University Automotive Engineering Department Introduction to Autotronics Part 1Document17 pagesAin Shams University Automotive Engineering Department Introduction to Autotronics Part 1Moussa SaidPas encore d'évaluation

- Portfolio in TleDocument16 pagesPortfolio in TleAileen Javines50% (2)

- Inter-Discipline Check Routing Sheet: PEC-EN-FRM-X-2387 Rev 2Document1 pageInter-Discipline Check Routing Sheet: PEC-EN-FRM-X-2387 Rev 2sathishPas encore d'évaluation

- 1.3.1 General: 1.3.1.1 Drawing Sheet SizesDocument4 pages1.3.1 General: 1.3.1.1 Drawing Sheet SizesEDEN JIMENEZPas encore d'évaluation

- Air Cadet Pumps ManualDocument12 pagesAir Cadet Pumps ManualEdgar Campusano SanchezPas encore d'évaluation

- Honda IDSI SM - 5 PDFDocument14 pagesHonda IDSI SM - 5 PDFauto projectPas encore d'évaluation

- Mosfet Irf 2204Document10 pagesMosfet Irf 2204Milagros Mendieta VegaPas encore d'évaluation

- Beam Master Gleeson ReelDocument2 pagesBeam Master Gleeson ReelhecsaorPas encore d'évaluation

- Transmission Corporation of Telangana Limited: Vidyut Soudha, HyderabadDocument5 pagesTransmission Corporation of Telangana Limited: Vidyut Soudha, Hyderabadsatyam_scribdPas encore d'évaluation

- Top221 227Document20 pagesTop221 227JEVG1Pas encore d'évaluation

- Last Herb 204 SLDocument3 pagesLast Herb 204 SLlastbikesPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Daily LPG Cylinder Leakage TestDocument2 pagesDaily LPG Cylinder Leakage TestLwandziso DlaminiPas encore d'évaluation

- Hydrostatic Pump (Manual Controls, AHC & ACS) (Right Half) - S300Document4 pagesHydrostatic Pump (Manual Controls, AHC & ACS) (Right Half) - S300Alfredo GuzmánPas encore d'évaluation

- 8085 VerilogDocument21 pages8085 VerilogvatsalyatPas encore d'évaluation

- TBR at Aw03-72leDocument19 pagesTBR at Aw03-72lehayyeuanh_duchimotla83% (18)

- Evolution of Intel Microprocessors PDFDocument2 pagesEvolution of Intel Microprocessors PDFErikaPas encore d'évaluation

- Catalogo l375 20 So30002Document12 pagesCatalogo l375 20 So30002Alexis SanchezPas encore d'évaluation

- Interacoustics As216 Screening AudiometerDocument34 pagesInteracoustics As216 Screening Audiometerjuvillegas0% (1)

- Hardlock Set Screw: AdvantagesDocument4 pagesHardlock Set Screw: AdvantagesJayden BarnesPas encore d'évaluation

- Auto Trans Diagnosis Mitsubishi MonteroDocument25 pagesAuto Trans Diagnosis Mitsubishi Monteronicamarcos100% (3)

- Multiplex Communication System (CAN) Connector DiagramDocument4 pagesMultiplex Communication System (CAN) Connector DiagramHenryHutabaratPas encore d'évaluation

- Cabinas MT UNIMIX-JTI PDFDocument26 pagesCabinas MT UNIMIX-JTI PDFpedrommm2Pas encore d'évaluation

- PRO1 10E Introduction Micromaster PDFDocument20 pagesPRO1 10E Introduction Micromaster PDFTinhNguyenPas encore d'évaluation

- Switch Yard REVISEDocument28 pagesSwitch Yard REVISEPratheek ReddyPas encore d'évaluation

- Field Wireable Connectors: Features and Selection GuidesDocument7 pagesField Wireable Connectors: Features and Selection GuidesCarloss Ruiz RPas encore d'évaluation

- Radiator Connection MethodsDocument1 pageRadiator Connection Methodsgox458Pas encore d'évaluation

- Master Ride 150 Manual de Serviços (Ingles) TRES150 PDFDocument255 pagesMaster Ride 150 Manual de Serviços (Ingles) TRES150 PDFCharles SaraivaPas encore d'évaluation

- Parallel Parking InstructionsDocument5 pagesParallel Parking Instructionsbra9tee9tiniPas encore d'évaluation

- Ad5280 5282Document10 pagesAd5280 5282diorginer silvaPas encore d'évaluation

- Zelio Relays RXM4AB2P7Document5 pagesZelio Relays RXM4AB2P7Cristian Ramos MoralesPas encore d'évaluation

- A Place of My Own: The Architecture of DaydreamsD'EverandA Place of My Own: The Architecture of DaydreamsÉvaluation : 4 sur 5 étoiles4/5 (241)

- An Architect's Guide to Construction: Tales from the Trenches Book 1D'EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1Pas encore d'évaluation

- Building Construction Technology: A Useful Guide - Part 1D'EverandBuilding Construction Technology: A Useful Guide - Part 1Évaluation : 4 sur 5 étoiles4/5 (3)

- Building Construction Technology: A Useful Guide - Part 2D'EverandBuilding Construction Technology: A Useful Guide - Part 2Évaluation : 5 sur 5 étoiles5/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsD'EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedD'EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedÉvaluation : 5 sur 5 étoiles5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationD'EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationÉvaluation : 4 sur 5 étoiles4/5 (18)

- Civil Engineer's Handbook of Professional PracticeD'EverandCivil Engineer's Handbook of Professional PracticeÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsD'EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)