Académique Documents

Professionnel Documents

Culture Documents

Mycalex Machining Guidelines 2012 1

Transféré par

elmirbolicCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mycalex Machining Guidelines 2012 1

Transféré par

elmirbolicDroits d'auteur :

Formats disponibles

MACHINING GUIDELINES OF GLASS-MICA COMPOSITE MATERIALS

Standard machine shop equipment can be used in machining glass-mica composite materials. For best results, tools

must be sharp and checked frequently. Despite its machinability, the material is still abrasive, causing some wear of

cutting edges. Clamp work firmly; however, avoid point loading.

LUBRICANT

Plenty of water is the most satisfactory lubricant. Keep a continuous stream pouring on the work and cutting tools to

keep it cool – insufficient cooling can result in chipping and rapid tool wear. Add water-soluble oil to the water to

reduce tooling rust.

CUTTING

Wheel cutting is the most satisfactory method of cutting glass-mica composites. Use a bonded silicon-carbide type

abrasive cut-off wheel. If available, bonded diamond wheels are preferred. Cut across the grain whenever possible.

Work slowly and steadily, do not force the tools, and keep tool speed to suggested levels. Cut down into the work –

never up from the bottom. Keep the speed between 2000 and 2500 rpm and advance the work by “feel”. The wheel

should cut steadily without dragging.

SAWING

Silicon carbide or diamond cut off wheels work best

An economic alternative is a carbide grit blade i.e. band saw

TURNING

Carbide tools are recommended. Use tool bits of Carboloy 883 or silicon carbide wheels with a tool post grinder.

CUTTING SPEED 70-85 surface feet per minute

FEEDING RATE .002-.005 inches per revolution

DEPTH OF CUT .125-.200 inches/cut depending on conditions

DRILLING

Carbide drills, preferably Carboloy 883, will give the best results. Run at 1100 rpm up to ¼” diameter; 900 rpm up to ½”

diameter; proportionately slower for larger sizes. To avoid chipping, do not drill hole all the way through. Work from

one side, then turn the piece over and work from the other side. Accurately made two-sided hardened bushed drill jigs

will assure the most accurate work. One side template drilling is also satisfactory, but it is difficult to maintain accurate

hole sizes because of tool wear. Drills must be touched-up when they dull. Use pecking motion when drilling, no more

than .125” deep per peck.

DRILL SIZE SPINDLE SPEED FEEDING RATE

Up to ¼” diameter ≈ 1100 RPM .003 inches per revolution

¼” diameter ≈ 1100 RPM .004 inches per revolution

½” diameter ≈ 900 RPM .005 inches per revolution

¾” diameter ≈ 600 RPM .006 inches per revolution

1.0” diameter ≈ 400 RPM .010 inches per revolution

NOTES: Allow 1/16” of extra material on drill break through side for grinding cleanup after drilling.

For best results use a pecking motion while drilling.

Drill “sharpness” will affect the above rates.

MILLING

Carbide tools are recommended. Use tool bits of Carboloy 883 or silicon carbide wheels with a tool post grinder

CUTTING SPEED 70-85 surface feet per minute

DEPTH OF CUT .150-.200 inches/cut depending on conditions

THREADING

Use a tungsten carbide tool bit and chase threads as with metals. Keep tools sharp.

For internal threads, make clearance holes slightly larger than standard tap drill recommendations. Chamfer both sides

of hole prior to tapping to minimize chipping and fracture. Turn up in the direction of threads only, a back and forth

motion will create chipping on the minimum thread diameter. You must use plenty of water for flushing chips away from

the lead cutting edge.

FLYCUTTING

Use tungsten carbide tools at slow speed. Cut halfway through, then reverse the work and complete the cut from the

opposite side. Use a pilot hole at least ¼” in diameter.

SLOTTING

Slotting may be done in one of two ways: use a metal bonded diamond wheel or silicon carbide wheel of proper width

on a cutter or milling machine; alternatively, use a milling cutter, preferably with tungsten carbide tip. Take small cuts –

not more than .025” and plenty of water.

GRINDING

To grind flat surfaces on any surface grinder, use silicon carbide resin bonded wheels at speeds recommended by the

manufacturer of the equipment. For heavy grinding, use a soft, coarse-grained wheel; for polishing, use hard, fine-

grained wheels. To prolong the life of grinding wheels, it is advisable to use 1% of soluble oil in the lubricant (50 gallons

of oil to 5,000 gallons of water).

FINISHING THE EDGES OF DISCS

There are three suggested methods: use a resin-bonded silicon carbide wheel with a tool-post grinder on the lathe; use

a tungsten carbide tool bit on the lathe; or use a wet sanding belt with suitable holder. Sanding must be done

individually, but several discs can be placed on a mandrel, if desired, for turning operations. Run at slow speed, and use

plenty of water.

Vous aimerez peut-être aussi

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosD'EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosPas encore d'évaluation

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsD'EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsÉvaluation : 5 sur 5 étoiles5/5 (1)

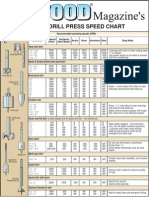

- Drill Press Speed ChartDocument1 pageDrill Press Speed ChartFerdinand ValdezPas encore d'évaluation

- MachinesDocument8 pagesMachinesrazanymPas encore d'évaluation

- How To Buff and PolishDocument20 pagesHow To Buff and Polishcaswellinc100% (3)

- Whetstone: The Complete Guide To Using A Knife Sharpening Stone; Learn How To Sharpen Your Knives And Achieve The Ultimate Japanese Blade Cut With The Waterstone Sharpener TechniqueD'EverandWhetstone: The Complete Guide To Using A Knife Sharpening Stone; Learn How To Sharpen Your Knives And Achieve The Ultimate Japanese Blade Cut With The Waterstone Sharpener TechniqueÉvaluation : 5 sur 5 étoiles5/5 (30)

- Ch-10 Grinding and FinishingDocument83 pagesCh-10 Grinding and FinishingPrateek Bayal100% (1)

- Grinding MachineDocument54 pagesGrinding Machineravi upadhyay100% (4)

- Lapping, Honing and BroachingDocument59 pagesLapping, Honing and Broachingsai leena100% (2)

- Drill Speed ChartDocument2 pagesDrill Speed ChartArmySGT100% (2)

- BurrDocument9 pagesBurrOmsri VinashaPas encore d'évaluation

- 11 FishingDocument23 pages11 FishingIgnatius FebriantaPas encore d'évaluation

- Junk Milling - Description and UsageDocument2 pagesJunk Milling - Description and UsageCarlos Alberto100% (1)

- Roll Pass Design Evauluation Using Software ApplicationDocument34 pagesRoll Pass Design Evauluation Using Software ApplicationAbed Alrahman NashwanPas encore d'évaluation

- Gear Manufacturing To TeachDocument44 pagesGear Manufacturing To Teachvijchoudhary16Pas encore d'évaluation

- Ch-10 Grinding and FinishingDocument84 pagesCh-10 Grinding and FinishingNitin TembhurnikarPas encore d'évaluation

- Regrind End Mills and VikDocument1 pageRegrind End Mills and VikMawan BentzPas encore d'évaluation

- Super CatalogueDocument8 pagesSuper CatalogueITL200_UPas encore d'évaluation

- Biax Electronic Scraper and AccessoriesDocument16 pagesBiax Electronic Scraper and AccessoriesPaisaje Silencioso100% (1)

- MillingDocument33 pagesMillingRavichandran G0% (1)

- LNT Sharpen Instruct 2021 2Document5 pagesLNT Sharpen Instruct 2021 2pianorx2Pas encore d'évaluation

- Double Roll CrusherDocument6 pagesDouble Roll Crusherjaswanth60% (5)

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingD'EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingPas encore d'évaluation

- Abarbanel - 1996 - Analysis of Observed Chaotic Data PDFDocument277 pagesAbarbanel - 1996 - Analysis of Observed Chaotic Data PDFFGR2711Pas encore d'évaluation

- QUEST® Parts List PDFDocument332 pagesQUEST® Parts List PDFMontserrat GuPas encore d'évaluation

- Fundamentals of Roller Mill Grinding - 1478460003Document46 pagesFundamentals of Roller Mill Grinding - 1478460003Felipe ZapataPas encore d'évaluation

- Metal Machining: ME 482 - Manufacturing SystemsDocument24 pagesMetal Machining: ME 482 - Manufacturing SystemsmusthakmechPas encore d'évaluation

- Platines Et Percage IPE 240Document7 pagesPlatines Et Percage IPE 240ol bePas encore d'évaluation

- U.S. Diamond Wheel: AbrasivesDocument1 pageU.S. Diamond Wheel: AbrasivesArvin BabuPas encore d'évaluation

- MachiningDocument12 pagesMachiningwardendavid5591100% (1)

- Cutting SpeedDocument5 pagesCutting Speedokooy erusPas encore d'évaluation

- LNT Sharpening Instructions 4-11-19 2Document2 pagesLNT Sharpening Instructions 4-11-19 2octavio araujoPas encore d'évaluation

- CP Carrillo HardwareDocument23 pagesCP Carrillo HardwarePaul ZiddyPas encore d'évaluation

- Cutting Speed and Feedrate SouthbayDocument5 pagesCutting Speed and Feedrate SouthbayShahed FacebookPas encore d'évaluation

- 05 MachiningDocument12 pages05 MachiningVisvas RajyaguruPas encore d'évaluation

- Tormek Diamond Wheels Make Sharpening Cleaner, Quicker, Easier and AccurateDocument8 pagesTormek Diamond Wheels Make Sharpening Cleaner, Quicker, Easier and AccurateSayyid AbulkhairPas encore d'évaluation

- Basic Plane Blade SharpeningDocument3 pagesBasic Plane Blade SharpeningJoshua HPas encore d'évaluation

- Speeds & Feeds For Knurling: ImportantDocument4 pagesSpeeds & Feeds For Knurling: Importantardionan100% (1)

- Machining GuidelinesDocument34 pagesMachining GuidelinesHamsini712Pas encore d'évaluation

- Air Grinder For Button Bits Operation Service Guide enDocument16 pagesAir Grinder For Button Bits Operation Service Guide enDreyfus W van HeerdenPas encore d'évaluation

- Super FinishingDocument8 pagesSuper FinishingUttara GargPas encore d'évaluation

- Air Grinder For Button Bits Operation Service Guide enDocument13 pagesAir Grinder For Button Bits Operation Service Guide enNelson de la RosaPas encore d'évaluation

- 08 Design For Manual AssemblyDocument13 pages08 Design For Manual AssemblyvengadeshPas encore d'évaluation

- Prepared By: Parth Shah Dharamjeet Jadeja Sanjay Parmar Purav VyasDocument26 pagesPrepared By: Parth Shah Dharamjeet Jadeja Sanjay Parmar Purav VyasNordiana IdrisPas encore d'évaluation

- Hobbing CutterDocument4 pagesHobbing CutterJunshen KazamaPas encore d'évaluation

- CP Instructionsheet V4262012Document2 pagesCP Instructionsheet V4262012Jean Paul BésPas encore d'évaluation

- CatalogDocument46 pagesCataloglangtu2011Pas encore d'évaluation

- Microfinishing Machines and OperationsDocument70 pagesMicrofinishing Machines and OperationsLibin AbrahamPas encore d'évaluation

- Gearfinishingprocesses 180316171706Document16 pagesGearfinishingprocesses 180316171706rs100788Pas encore d'évaluation

- Rotary Cutting Instruments1Document30 pagesRotary Cutting Instruments1Rishabh Madhu SharanPas encore d'évaluation

- Surface Grinding MachineDocument26 pagesSurface Grinding MachinejohnPas encore d'évaluation

- 1 Power Band and Circular SawsDocument51 pages1 Power Band and Circular SawsJiggy Lawrence BathanPas encore d'évaluation

- Bansal Institute of Engineering and Technology, LucknowDocument59 pagesBansal Institute of Engineering and Technology, LucknowSunnyVermaPas encore d'évaluation

- Buff BookDocument20 pagesBuff Bookdecio ventura rodrigues miraPas encore d'évaluation

- GridingDocument12 pagesGridingYam BlackPas encore d'évaluation

- 1537CylinderBor 00000001942Document6 pages1537CylinderBor 00000001942wahyufirmansyah.officePas encore d'évaluation

- Weather Ford Drillout ProcedureDocument1 pageWeather Ford Drillout Proceduretonze1Pas encore d'évaluation

- Fordia BitsDocument2 pagesFordia BitsEvan HenshallPas encore d'évaluation

- Knurling Manual PDFDocument1 pageKnurling Manual PDFgordomanotasPas encore d'évaluation

- MFT Lab - 1 - Surface GrindingDocument3 pagesMFT Lab - 1 - Surface GrindingsivaeinfoPas encore d'évaluation

- Darex E90 PlaquetteDocument2 pagesDarex E90 PlaquetteLaurent Enfield TricassesPas encore d'évaluation

- Catalogo Ricambi Liste de Pieces Parts Manual ErsatzteillisteDocument156 pagesCatalogo Ricambi Liste de Pieces Parts Manual ErsatzteillistealexPas encore d'évaluation

- Lathe, Lathe Tools and WorksDocument5 pagesLathe, Lathe Tools and WorksHafsah M. MohammadaliPas encore d'évaluation

- Three Wire Measurement For Metric Threads - Smithy - Detroit Machine ToolsDocument1 pageThree Wire Measurement For Metric Threads - Smithy - Detroit Machine ToolsknujdloPas encore d'évaluation

- Gagemaker Catalog 4 2013 Spreads 62Document1 pageGagemaker Catalog 4 2013 Spreads 62Carlos Enrique Guzman CastellonPas encore d'évaluation

- CPT Mill Thread Tool Twin InsertDocument4 pagesCPT Mill Thread Tool Twin InsertÁdám RáczPas encore d'évaluation

- CAM Lab Manual - 2014Document146 pagesCAM Lab Manual - 2014Nithish Kumar K MPas encore d'évaluation

- Asme Section Ii A-2 Sa-675 Sa-675mDocument6 pagesAsme Section Ii A-2 Sa-675 Sa-675mdavid perezPas encore d'évaluation

- Truong5 Axis Lesson 2sample X5Document20 pagesTruong5 Axis Lesson 2sample X5TruonglanaPas encore d'évaluation

- UsmDocument21 pagesUsmshaikh javedPas encore d'évaluation

- Background of Sanyco Grand Industries SDN BHDDocument5 pagesBackground of Sanyco Grand Industries SDN BHDcrewz_19Pas encore d'évaluation

- ME8793 Process Planning and Cost EStimation UNIT 5 NotesDocument26 pagesME8793 Process Planning and Cost EStimation UNIT 5 NotesLEO PRAVIN PPas encore d'évaluation

- (Kurt 2008) Evaluation of Drilled Hole Quality in Al 2024 AlloyDocument10 pages(Kurt 2008) Evaluation of Drilled Hole Quality in Al 2024 AlloyAdelina RomanPas encore d'évaluation

- British Standard Whitworth - Wikipedia, The Free EncyclopediaDocument2 pagesBritish Standard Whitworth - Wikipedia, The Free EncyclopediaIvan DuncanPas encore d'évaluation

- Machining MechAnalysis CHPT 1Document98 pagesMachining MechAnalysis CHPT 1Brahim MouchanePas encore d'évaluation

- Ultrasonic Horn Design For Ultrasonic Machining TechnologiesDocument11 pagesUltrasonic Horn Design For Ultrasonic Machining TechnologiesffeliniPas encore d'évaluation

- SC 6 Bench Lathe MachineDocument26 pagesSC 6 Bench Lathe MachineAbhilash ValathPas encore d'évaluation

- Errata To ASME B47.1-2007 Gage BlanksDocument2 pagesErrata To ASME B47.1-2007 Gage BlanksMark D VillanuevaPas encore d'évaluation

- Unit 9 Tools For Basic Layout: StructureDocument7 pagesUnit 9 Tools For Basic Layout: StructureAkash Kumar DevPas encore d'évaluation

- Design and Fabrication of Polar Cnc-2D-PrinterDocument25 pagesDesign and Fabrication of Polar Cnc-2D-PrinterLovely AtchuthPas encore d'évaluation

- ECM Process Parameter 1Document8 pagesECM Process Parameter 1K O100% (1)

- Labormil Multi-Purpose Lathe N Machine ToolDocument14 pagesLabormil Multi-Purpose Lathe N Machine Toolgotti45Pas encore d'évaluation

- PDF Handout PDFDocument37 pagesPDF Handout PDFGiovani Bruce Caballero CruzPas encore d'évaluation

- Unit 8 PDFDocument43 pagesUnit 8 PDFAnurag RanaPas encore d'évaluation

- Refrigeretor and LatheDocument22 pagesRefrigeretor and LatheShreenivas ThakurPas encore d'évaluation

- Body in White Fixture DesignDocument6 pagesBody in White Fixture DesignSuren NathanPas encore d'évaluation

- MPR Micro Project ReportDocument21 pagesMPR Micro Project Reportvedantbakal043Pas encore d'évaluation