Académique Documents

Professionnel Documents

Culture Documents

Precommissioning Checklist

Transféré par

Pankaj Pandey0 évaluation0% ont trouvé ce document utile (0 vote)

299 vues2 pagesDISPERSER CHECKLIST

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDISPERSER CHECKLIST

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

299 vues2 pagesPrecommissioning Checklist

Transféré par

Pankaj PandeyDISPERSER CHECKLIST

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

Project Name:

Location: Project #:

Issued By: Date Issued:

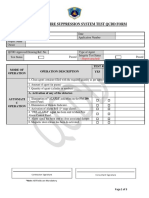

PRE COMMISSIONING CHECKLIST

All points below must be answered. If you feel that certain point’s isn’t applicable to your

installation then mark N/A. This checklist must be sent to Cellwood together with the request to

dispatch a Commissioning Engineer.

We recommend that you give 3 weeks notice before intended arrival of Commissioning Engineer

for our planning purposes. Then this list has to be sent together with the confirmed request 1 week

before arrival of our Commissioning Engineer.

If work is still in progress and you are 100% sure that it will be done before arrival of our

Commissioning Engineer then mark column “PLN”.

Mechanical Installation NO N/A YES PLN

1. Are all machines installed and secured according to installation

manual?

2. Are all gearboxes installed and aligned? Save alignment records for

Commissioning Engineer.

3. Are all motors installed and aligned? Save alignment records for

Commissioning Engineer.

4. Are the frames welded to foundation and is the final grouting

performed?

5. Are all gearboxes filled with the correct oil to the appropriate level?

For oil type see maintenance manual or plaque on the gear.

6. Are all couplings aligned and greased? Save alignment records for

Commissioning Engineer.

Electrical Installation NO N/A YES PLN

10. Are all motors connected to the starting equipment (MCC)?

11. Are the overload protection correctly sized for each motor and are

the settings OK?

Does the motor cable for the Disperser allow for the movement of

12. the Disperser? The cable has to be long and flexible enough to

open the Disperser 900mm (KD-450/710) or 1500mm (KD-1050).

13. Is the Disperser connection box wired to the local control panel?

Does the cable between panel/disperser allow for the movement of

14. the Disperser? The cable has to be long and flexible enough to

open the Disperser 900mm (KD-450/710) or 1500mm (KD-1050).

15. Has the Hardware interlock connection been wired directly between

the panel and the Disperser starter in the MCC?

16. Has the connections between Disperser and Panel been tested so

that all terminations are correct?

17. Has all the connections between panel and DCS been made and

tested?

18. Has all the connections between MCC and DCS been made and

tested?

Pre Commissioning Checklist

Cellwood Machinery AB

Project Name:

Location: Project #:

Issued By: Date Issued:

Piping NO N/A YES PLN

20. Is the pulp feed piping to the Dewaterers/Screwpress finished and

supported?

Is the Backwater piping from Dewaterers/Screwpress finished and

21. supported? If Screwpress is of type KSR is the backwater pipe for

internal dewatering connected to the main pipe?

22. Is the bleeding pipe installed on the Screwpress?

23. Is the steam pipe installed and well supported?

24. Is the Disperser outlet piping finished and strongly supported in 3

directions?

25. Is the piping for sealing and cooling water installed? Both supply

and drain piping.

Instrumentation NO N/A YES PLN

30. Is Dewaterer/Screwpress inlet flow meter installed, calibrated,

grounded and connected to DCS AI?

31. Is Dewaterer/Screwpress inlet pressure transmitter installed,

calibrated and connected to DCS AI?

32. Is steam pressure transmitter installed, calibrated and connected to

DCS AI?

33. Is Preheater temperature transmitter installed, calibrated and

connected to DCS AI?

34. Is steam control valve installed, calibrated and connected to DCS

and pneumatics?

35. Is Plugscrew temperature transmitter installed, calibrated and

connected to DCS AI?

36. Is Disperser consistency transmitter installed, calibrated and

connected to DCS AI?

37. Is consistency control valve installed, calibrated and connected to

DCS and pneumatics?

38. Is Disperser back pressure transmitter installed, calibrated and

connected to DCS AI?

39. Is Disperser back pressure control valve installed, calibrated and

connected to DCS and pneumatics?

40. Are Dewaterer/Screwpress pneumatic solenoids connected and

tested?

Software / DCS NO N/A YES PLN

50. Is the Start and Stop sequences programmed according to Start

and Stop description document?

51. Are the interlockings for motors and valves programmed according

to Start and Stop description document?

Others NO N/A YES PLN

50. Will there be pulp available at the Dispersing system for continuous

running within 4 days of the Commissioning Engineers arrival?

Inspected by:_______________________ Date:____________

Pre Commissioning Checklist

Cellwood Machinery AB

Vous aimerez peut-être aussi

- Cable Test Sheet On DrumDocument2 pagesCable Test Sheet On DrumAhmad Dagamseh100% (1)

- Check List For UPSDocument1 pageCheck List For UPSsiruslara6491Pas encore d'évaluation

- Pre Commissioning ChecklistDocument57 pagesPre Commissioning ChecklistSkill IndiaPas encore d'évaluation

- Novec 1230 Fire Suppression SystemDocument1 pageNovec 1230 Fire Suppression SystemvivekvpsfePas encore d'évaluation

- Foam Water Deluge System Test QCDD FormDocument3 pagesFoam Water Deluge System Test QCDD FormMahmoud Hassan100% (1)

- Safe Work Method Statement For Testing & Commissioning of DX Split UnitsDocument5 pagesSafe Work Method Statement For Testing & Commissioning of DX Split Unitsvin ssPas encore d'évaluation

- Clean Agent Fire Suppression System Test QCDD FormDocument3 pagesClean Agent Fire Suppression System Test QCDD FormMahmoud HassanPas encore d'évaluation

- Testing and Commissioning Split ACDocument2 pagesTesting and Commissioning Split ACNuratiqah SharifahPas encore d'évaluation

- Method Statement For Testing & Commissioning of AHUDocument4 pagesMethod Statement For Testing & Commissioning of AHUsamsul maarif100% (1)

- Testing and Commissioning Method Statement For Fire Fighting PumpsDocument2 pagesTesting and Commissioning Method Statement For Fire Fighting PumpsHumaid Shaikh100% (1)

- 0734 Refrigerant Installation ChecklistDocument1 page0734 Refrigerant Installation ChecklistMubashir KhanPas encore d'évaluation

- Insp Checklist - LO FlushingDocument3 pagesInsp Checklist - LO Flushingaanouar7750% (2)

- Pre Action System Testing and Commissioning Method Statement - Method Statement HQ PDFDocument5 pagesPre Action System Testing and Commissioning Method Statement - Method Statement HQ PDFjajaka100% (2)

- Commissioning Plan TemplateDocument22 pagesCommissioning Plan Templaten.hartonoPas encore d'évaluation

- Testing and Commissioning of IG 100 System: Inspection Test Plan (ITP)Document3 pagesTesting and Commissioning of IG 100 System: Inspection Test Plan (ITP)Samboy DionisioPas encore d'évaluation

- Testing & Commissioning of CCUDocument2 pagesTesting & Commissioning of CCUamg007100% (1)

- Visual and Technical Checking of Instrumentation and Control SystemDocument13 pagesVisual and Technical Checking of Instrumentation and Control SystemzhangyiliPas encore d'évaluation

- Cold Test Report 3Document1 pageCold Test Report 3Venkitesh PG100% (1)

- Itr Ew 01a - EngDocument2 pagesItr Ew 01a - Engwassim nasriPas encore d'évaluation

- SKM Chiller Pre-Commissioning Check List Rev 20.06.2022Document2 pagesSKM Chiller Pre-Commissioning Check List Rev 20.06.2022Riju Scaria/EMD/QTRPas encore d'évaluation

- Pre-Commissioning Check List (SAMSUNG DVMS)Document3 pagesPre-Commissioning Check List (SAMSUNG DVMS)Uzair JavedPas encore d'évaluation

- Safe Work Method Statement: (Installation of Wet Sprinkler System)Document10 pagesSafe Work Method Statement: (Installation of Wet Sprinkler System)balaji100% (1)

- Installation Check Sheet For Ahu FahuDocument2 pagesInstallation Check Sheet For Ahu FahuSamer AliPas encore d'évaluation

- Sprinkler Pre InspectionchecDocument3 pagesSprinkler Pre Inspectionchecdewi100% (1)

- Anand Engineering Products Private Limited: Before Welding Inspection Check ListDocument1 pageAnand Engineering Products Private Limited: Before Welding Inspection Check ListAnilkumarGopinathanNairPas encore d'évaluation

- Project: Contract Ref: Project No: Location: Drawing Ref: Rfi No: Descrption: VRF System Installation Inspection ChecklistDocument2 pagesProject: Contract Ref: Project No: Location: Drawing Ref: Rfi No: Descrption: VRF System Installation Inspection ChecklistWasim AhmedPas encore d'évaluation

- TR001 Control Cable CFA901-Continuity TestDocument4 pagesTR001 Control Cable CFA901-Continuity TestCharlie MendozaPas encore d'évaluation

- Saudi Aramco Pre-Commissioning Form: LightingDocument2 pagesSaudi Aramco Pre-Commissioning Form: LightingHaleem Ur Rashid Bangash100% (1)

- Testing and Commissioning of Emergency Light SystemDocument1 pageTesting and Commissioning of Emergency Light SystemUmair BaBerPas encore d'évaluation

- RL-HVAC - Fan Coil Unit - Yearly - RRDocument2 pagesRL-HVAC - Fan Coil Unit - Yearly - RRobaidur_rehman_3Pas encore d'évaluation

- Air Handling Unit QC Checklist: AHU InformationDocument5 pagesAir Handling Unit QC Checklist: AHU InformationRaheel AhmedPas encore d'évaluation

- Method Statement For Precommissioning & Commissioning of Close Control Units CCU'sDocument3 pagesMethod Statement For Precommissioning & Commissioning of Close Control Units CCU'svin ssPas encore d'évaluation

- "Fan Coil Unit": Testing and Commissioning Method Statement ForDocument16 pages"Fan Coil Unit": Testing and Commissioning Method Statement Forselcuk pekenPas encore d'évaluation

- PRECOMMISSIONING and COMMISSIONING METHOD STATEMENT FOR FIRE HOSE RACKS and FIRE HOSE REELDocument2 pagesPRECOMMISSIONING and COMMISSIONING METHOD STATEMENT FOR FIRE HOSE RACKS and FIRE HOSE REELHumaid ShaikhPas encore d'évaluation

- 006 ChecklistDocument1 page006 ChecklistAbdul HakkimPas encore d'évaluation

- Inspection Report For Installation of JB, Juncation BoxDocument1 pageInspection Report For Installation of JB, Juncation BoxnayumPas encore d'évaluation

- cOMMISSIONING 1 - WorksheetDocument60 pagescOMMISSIONING 1 - WorksheetPramod Dhir100% (1)

- Checklist For Smoke TestDocument1 pageChecklist For Smoke TestBelal AlrwadiehPas encore d'évaluation

- Cooling Tower TNCDocument6 pagesCooling Tower TNCAarol Hatta100% (1)

- Testing & Commissioning For Fire PumpDocument1 pageTesting & Commissioning For Fire PumpSalim BakhshPas encore d'évaluation

- Checklist For Testing & Commissioning of Sprinkler SystemDocument2 pagesChecklist For Testing & Commissioning of Sprinkler Systembeho2000100% (6)

- Method Statement For FA SystemDocument6 pagesMethod Statement For FA SystemsanthilalPas encore d'évaluation

- PPRDocument10 pagesPPRachusanachuPas encore d'évaluation

- Air Cooled Chiller ChecklistDocument3 pagesAir Cooled Chiller ChecklistDevendra DhumalPas encore d'évaluation

- Precommissioning & Commissioning Method Statement For Fire Hose Racks & Fire Hose ReelDocument3 pagesPrecommissioning & Commissioning Method Statement For Fire Hose Racks & Fire Hose Reelvin ss0% (1)

- Testing and Commissioning Domestic Water ChecklistDocument6 pagesTesting and Commissioning Domestic Water ChecklistIwan Tristiawan100% (1)

- AHU Commissioning Report DF016eDocument8 pagesAHU Commissioning Report DF016evishwas salunkhePas encore d'évaluation

- Check List For: Installation of Fahu: Project Name & LogosDocument2 pagesCheck List For: Installation of Fahu: Project Name & LogosSamer AliPas encore d'évaluation

- Commissioning Responsibility MatrixDocument1 pageCommissioning Responsibility Matrixvin ssPas encore d'évaluation

- Mels Constuction Limitada: Commercial Management Mechanical Completion CertificateDocument1 pageMels Constuction Limitada: Commercial Management Mechanical Completion CertificateDeonPas encore d'évaluation

- Fire Fighting Piping System Installation Method StatementDocument2 pagesFire Fighting Piping System Installation Method StatementDong VanraPas encore d'évaluation

- Switchgear Inspection Checklist: Section A - Customer DataDocument1 pageSwitchgear Inspection Checklist: Section A - Customer Data20082012Pas encore d'évaluation

- Check List FCUDocument2 pagesCheck List FCUsarmad009Pas encore d'évaluation

- Testing & Commissioning ChecklistDocument2 pagesTesting & Commissioning Checklistbeho2000100% (1)

- Testing & Commissioning of Fire Suppression SystemDocument5 pagesTesting & Commissioning of Fire Suppression Systemmyanmarfire100% (2)

- Precommissioning Checklist of Pa SystemDocument1 pagePrecommissioning Checklist of Pa SystemTamer EidPas encore d'évaluation

- Fire Hydrant ChecklistDocument1 pageFire Hydrant ChecklistTushar BabarPas encore d'évaluation

- Commissioning Check List For Access Control SystemDocument2 pagesCommissioning Check List For Access Control SystemTamer Eid50% (2)

- TD Commissioning Protocol Rev07 07gbDocument10 pagesTD Commissioning Protocol Rev07 07gbPanupan ThakongPas encore d'évaluation

- Job Procedure 02 For TRANSFORMERDocument7 pagesJob Procedure 02 For TRANSFORMERSoumik KarPas encore d'évaluation

- Pump Motors 22KW & Above Millwide - JAN 19Document22 pagesPump Motors 22KW & Above Millwide - JAN 19Pankaj PandeyPas encore d'évaluation

- Sizes & Weights of Seamless Pipes As Per ASTM A 106/53 Gr.A/B Available With Us Ex-StockDocument3 pagesSizes & Weights of Seamless Pipes As Per ASTM A 106/53 Gr.A/B Available With Us Ex-StockMontuJoshiPas encore d'évaluation

- Equipment Upload FormatDocument80 pagesEquipment Upload FormatPankaj PandeyPas encore d'évaluation

- Super CellDocument2 pagesSuper CellPankaj PandeyPas encore d'évaluation

- Intercome List - NEW Jan 2019Document9 pagesIntercome List - NEW Jan 2019Pankaj PandeyPas encore d'évaluation

- Fans-Blowers Detail MillwideDocument7 pagesFans-Blowers Detail MillwidePankaj PandeyPas encore d'évaluation

- AFT Screen DatasheetDocument3 pagesAFT Screen DatasheetPankaj PandeyPas encore d'évaluation

- MINUTES OF MEETING EverestDocument2 pagesMINUTES OF MEETING EverestPankaj PandeyPas encore d'évaluation

- 1 Grub Screw Allen High - Ten 16X25Mm: N.R.Agarwal Industries LTD NO Material DescriptionDocument9 pages1 Grub Screw Allen High - Ten 16X25Mm: N.R.Agarwal Industries LTD NO Material DescriptionPankaj PandeyPas encore d'évaluation

- DIETDocument3 pagesDIETPankaj PandeyPas encore d'évaluation

- Catalog Gear CouplingsDocument2 pagesCatalog Gear CouplingsDev Misra0% (1)

- Roll Covering Letter LathiaDocument6 pagesRoll Covering Letter LathiaPankaj PandeyPas encore d'évaluation

- MINUTES OF MEETING EverestDocument2 pagesMINUTES OF MEETING EverestPankaj PandeyPas encore d'évaluation

- Training ManualDocument63 pagesTraining ManualMohamad Dpr100% (1)

- Remark SN Particulars: Left TOP Front Left TOP FrontDocument6 pagesRemark SN Particulars: Left TOP Front Left TOP FrontPankaj PandeyPas encore d'évaluation

- Catalog Gear CouplingsDocument2 pagesCatalog Gear CouplingsDev Misra0% (1)

- Material For Roll CastingDocument5 pagesMaterial For Roll CastingPankaj PandeyPas encore d'évaluation

- LIME CalciumOxideDocument2 pagesLIME CalciumOxideduwociPas encore d'évaluation

- The Power of Gayatri MantraDocument4 pagesThe Power of Gayatri MantraxxxpressionPas encore d'évaluation

- Material For Roll CastingDocument5 pagesMaterial For Roll CastingPankaj PandeyPas encore d'évaluation

- Heat Exchanger SpecificationsDocument1 pageHeat Exchanger SpecificationsPankaj PandeyPas encore d'évaluation

- Motor Lubrication Report: SN Status HP SN Status HPDocument2 pagesMotor Lubrication Report: SN Status HP SN Status HPPankaj PandeyPas encore d'évaluation

- Bevel B1 PDFDocument13 pagesBevel B1 PDFgaurang3005Pas encore d'évaluation

- Cost Evalution For Instruments To Be Calibrated (Iso) : SR - NO. Description Total Instruments Rate/Unit Total CostDocument1 pageCost Evalution For Instruments To Be Calibrated (Iso) : SR - NO. Description Total Instruments Rate/Unit Total CostPankaj PandeyPas encore d'évaluation

- Introduction & Litreture (All)Document63 pagesIntroduction & Litreture (All)Pankaj PandeyPas encore d'évaluation

- Equivalents Chains & BeltsDocument3 pagesEquivalents Chains & BeltsPankaj PandeyPas encore d'évaluation

- Contractor Works For - 2011Document2 pagesContractor Works For - 2011Pankaj PandeyPas encore d'évaluation

- Data Sheet: Induction Motor Champion Series Motor Type: 1SE0 319-4NA80 SDocument3 pagesData Sheet: Induction Motor Champion Series Motor Type: 1SE0 319-4NA80 SPankaj PandeyPas encore d'évaluation

- V Belt ManualDocument116 pagesV Belt ManualPankaj Pandey100% (1)

- Apu Comparison in Igo Fleet PDFDocument19 pagesApu Comparison in Igo Fleet PDFRahul UnnikrishnanPas encore d'évaluation

- ACA0255 Specialty For UreaDocument28 pagesACA0255 Specialty For UreawidiantoekoPas encore d'évaluation

- Ansi B16-104Document1 pageAnsi B16-104Monica Suarez100% (1)

- Aim-To Develop An ELECTRO HYDRAULIC Circuit Apparatus:: SwitchesDocument8 pagesAim-To Develop An ELECTRO HYDRAULIC Circuit Apparatus:: SwitchesashishPas encore d'évaluation

- D6R Series III Track Type Tractor Hydraulic SystemDocument2 pagesD6R Series III Track Type Tractor Hydraulic SystemIH Medrano100% (8)

- Control Loop DiagramsDocument3 pagesControl Loop DiagramsxaffarPas encore d'évaluation

- David-Warner-Jindex Brochure-V5 7 7Document9 pagesDavid-Warner-Jindex Brochure-V5 7 7Raymond BalladPas encore d'évaluation

- Continuous Pan Operation ManualDocument12 pagesContinuous Pan Operation Manualsandi promonoPas encore d'évaluation

- M-018 Tong 14 Con Backup 14.3.4Document57 pagesM-018 Tong 14 Con Backup 14.3.4Francisco AncheytaPas encore d'évaluation

- Advanced Mechatronics QpapersDocument10 pagesAdvanced Mechatronics QpapersSamurai ShinobiPas encore d'évaluation

- Fisher D4 Control Valve ManualDocument24 pagesFisher D4 Control Valve ManualAmiroucheBenlakehalPas encore d'évaluation

- Control Valves - EnggcyclopediaDocument8 pagesControl Valves - EnggcyclopediaazitaggPas encore d'évaluation

- Kraz 255 BDocument10 pagesKraz 255 Bgokulmane117Pas encore d'évaluation

- Varistroke 2Document6 pagesVaristroke 2Jesus C. MedinaPas encore d'évaluation

- ValveDocument29 pagesValveShankey JAlan100% (1)

- Steam Dump EquipmentDocument5 pagesSteam Dump EquipmentsridharPas encore d'évaluation

- Dieu-Khien-Qua-Trinh - 3 - Documentationofplant - (Cuuduongthancong - Com)Document22 pagesDieu-Khien-Qua-Trinh - 3 - Documentationofplant - (Cuuduongthancong - Com)Hưng NguyễnPas encore d'évaluation

- KCG 2006 - 7Document48 pagesKCG 2006 - 7bkchoi5690Pas encore d'évaluation

- Ihp QP Nov - 2022Document3 pagesIhp QP Nov - 2022ranjitrvyavaharePas encore d'évaluation

- Unit#2 Turbine Mov/Actuators S.No Valves Name KKSDocument22 pagesUnit#2 Turbine Mov/Actuators S.No Valves Name KKSAmaresh NayakPas encore d'évaluation

- Pneumatic PosisionerDocument10 pagesPneumatic Posisionerwong_arifPas encore d'évaluation

- ELFI Valve (Prop - DC ValveDocument9 pagesELFI Valve (Prop - DC ValvealoordominicPas encore d'évaluation

- Electro-Pneumatic Positioner Tzidc: Data SheetDocument26 pagesElectro-Pneumatic Positioner Tzidc: Data Sheetkuro lucirufurPas encore d'évaluation

- Becker Control ValvesDocument16 pagesBecker Control ValvesBlak2011Pas encore d'évaluation

- (FESTECH) Pneumatics Exercise (Basic)Document155 pages(FESTECH) Pneumatics Exercise (Basic)IndahPas encore d'évaluation

- ControlsDocument26 pagesControlsLucky Okote0% (1)

- Ball Valve: Zhejiangbeiercontrol Valveco.,LtdDocument16 pagesBall Valve: Zhejiangbeiercontrol Valveco.,LtdSandipan GhoshPas encore d'évaluation

- RCV-UM-00562-EN - Research Control Valves Installation ManualDocument20 pagesRCV-UM-00562-EN - Research Control Valves Installation ManuallorenzoPas encore d'évaluation

- Fisher 8560 Eccentric Disc Butterfly Control ValveDocument16 pagesFisher 8560 Eccentric Disc Butterfly Control ValveoscarPas encore d'évaluation

- DSH CatalogueDocument20 pagesDSH Catalogueनिखिल बायवारPas encore d'évaluation

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesD'EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- Introduction to Power System ProtectionD'EverandIntroduction to Power System ProtectionÉvaluation : 5 sur 5 étoiles5/5 (1)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsD'EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsPas encore d'évaluation

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!D'EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Pas encore d'évaluation

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterD'EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterPas encore d'évaluation

- Shorting the Grid: The Hidden Fragility of Our Electric GridD'EverandShorting the Grid: The Hidden Fragility of Our Electric GridÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressD'EverandNuclear Energy in the 21st Century: World Nuclear University PressÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceD'EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResiliencePas encore d'évaluation

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsD'EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Practical Power Distribution for IndustryD'EverandPractical Power Distribution for IndustryÉvaluation : 2.5 sur 5 étoiles2.5/5 (2)

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977D'EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Pas encore d'évaluation

- A Pathway to Decarbonise the Shipping Sector by 2050D'EverandA Pathway to Decarbonise the Shipping Sector by 2050Pas encore d'évaluation

- Renewable Energy: A Very Short IntroductionD'EverandRenewable Energy: A Very Short IntroductionÉvaluation : 4.5 sur 5 étoiles4.5/5 (12)

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsD'EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsPas encore d'évaluation

- Renewable Energy Sources - Wind, Solar and Hydro Energy Revised Edition : Environment Books for Kids | Children's Environment BooksD'EverandRenewable Energy Sources - Wind, Solar and Hydro Energy Revised Edition : Environment Books for Kids | Children's Environment BooksPas encore d'évaluation

- Heat Transfer Engineering: Fundamentals and TechniquesD'EverandHeat Transfer Engineering: Fundamentals and TechniquesÉvaluation : 4 sur 5 étoiles4/5 (1)

- Global Landscape of Renewable Energy FinanceD'EverandGlobal Landscape of Renewable Energy FinancePas encore d'évaluation

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successD'EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Practical Reservoir Engineering and CharacterizationD'EverandPractical Reservoir Engineering and CharacterizationÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerD'EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerPas encore d'évaluation

- An Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksD'EverandAn Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksPas encore d'évaluation

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyD'EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyÉvaluation : 5 sur 5 étoiles5/5 (3)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentD'EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsD'EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsPas encore d'évaluation

- Electric Motors and Drives: Fundamentals, Types and ApplicationsD'EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsÉvaluation : 4.5 sur 5 étoiles4.5/5 (12)