Académique Documents

Professionnel Documents

Culture Documents

Rau OpportunitiesforLow-CostCO2Mitigation

Transféré par

BadukwangDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Rau OpportunitiesforLow-CostCO2Mitigation

Transféré par

BadukwangDroits d'auteur :

Formats disponibles

Opportunities for Low-Cost CO2 Mitigation in

Electricity, Oil, and Cement Production

Greg H. Rau , Kevin G. Knauss , Julio Friedmann , Ken Caldeira

1,2 2 2 3

1

University of California, Santa Cruz, CA 95064 (L-103, LLNL, 7000 East Ave., Livermore, CA 94550; 925-423-7990, rau4@llnl.gov)

2

Energy and Environment Directorate, LLNL, Livermore, CA 94550; 3Dept. Global Ecology, Carnegie Institution, 260 Panama St., Stanford, CA 94305

SUMMARY: Several low-cost opportunities exist for scrubbing CO2 CO2 MITIGATION USING PRODUCED WATER:

from waste gas streams, utilizing spontaneous chemical reactions in the On average 10 barrels of water are brought to the surface with each barrel of oil

presence of water and inexpensive or waste alkaline compounds. These produced, and the majority of this water is simply pumped back into the reservoir.

reactions convert CO2 to bicarbonate or carbonate in dissolved or solid Preliminary analysis suggests that most of these waters are significantly

form, thus providing CO2 capture and low-risk CO2 storage underground, undersaturated in CO2 relative to industrial waste gas streams, and also contain

in the ocean, or in some cases on land. Useful by-products and co-benefits significant alkalinity, meaning they have an enhanced capacity to chemically absorb

can also be generated by these processes. In certain settings this and transorm CO2 (e.g. reaction 1).

approach will be significantly less energy intensive, less costly, and less

risky than "conventional" molecular CO2 capture and geologic storage. The average dissolved inorganic carbon content of Texas produced water can be

increased by some 170% through simple equilibration with a 15% CO2 waste gas

stream (Table below). Further uptake of waste CO2 is possible via reaction 1 if

additional carbonate (e.g., waste precipitate or limestone, Fig. below) were added.

WET LIMESTONE SCRUBBING OF FLUE GAS: The water is thus significantly carbon-enriched prior to its routine re-injection

underground. The overall approach allows simple, low-cost CO2 capture combined

CO2 in flue gas can be reacted with water and solid mineral carbonates

with safe geologic storage of waste carbon in mostly dissolved, ionic forms.

(e.g., limestone) to spontaneously form bicarbonates in solution:

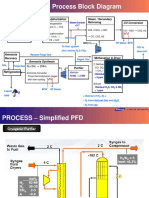

Primary separation:

Total

CO2(g) + CaCO3(s) + H2O(l) ---> Ca2+ + 2HCO3(aq) -. (rctn 1)

gases+CO2

(aq) Dissovled Secondary separation

Inorganic waste CO 2 with CO2 addition:

T, pCO 2, Carbon, consumed, gases

pH deg. C atm mM mM

Possible designs of the required gas-liquid-solids reactor have been

oil

mean of 500 W. Texas oil

previously described (e.g., Rau and Caldeira, US Patent 6,890,497), the produced waters (USGS

data): 6.93 25** 0.0193* 6.6 0 flotation

CO2 + H2O + CO32- -->

2HCO3- water storage,

isolation from

approach being analogous to flue gas desulfurization (FGD) using wet as above and equilibrated

with waste gas @ pCO 2=

solids

flocculation

skimming

air

Produced Water

limestone. While any water source could be used, seawater would be

CO2

0.15 atm 6.41* 25** 0.150** 17.8* 11.2* Oil+Water+ settling + Dissolved

Carbon

Gas Lifting Limestone, waste Injection

especially attractive due to its inherent alkalinity and global abundance. as above and equilibrated

with excess limestone 6.64* 25** 0.150** 22.8* 13.7*

Low-pressure,

carbonates

Coastal power plants, which already pump vast quatantiies of seawater for * calculated

waste CO2

**assumed or specified

cooling, could simply recycle the water for CO2 scrubbing prior to water Possible scheme for CO2 addition to produced Water.

release back in to the ocean. The advantages of this approach are:

➤ Low-tech chemical CO2 capture with geologic sequestration.

➤ Low energy consumption - piggybacks on existing groundwater injection.

➤ Low cost - probably <$1/tonne CO2 avoided.

➤ May enhance oil-water separation, and eliminate scaling and microbial growth.

MITIGATING CO2 AND CEMENT KILN DUST:

The manufacture of cement globally generates some 1.5 Gt CO2/year. The waste

gas stream can contain >30% CO2. In addition, waste solids (cement kiln dust,

CKD) are generated, composed of a complex, highly alkaline mixture of Ca, Na,

Mg, and K salts, silicates, oxides, and hydroxides. This poses a significant kiln dust

management and storage problem.

Possible schematic for gas/water/ A coastal NG-fired power plant We suggest mitigating both the CO2 and CKD by dissolving in water the soluble

limestone contactor for CO2 Moss Landing, CA - candidate components of the CKD, in particular the metal oxides (e.g., CaO), forming

capture and conversion to HCO3-. for wet limestone scrubbing. hydroxides such as Ca(OH)2. Equilibration of this with CO2 waste would form

The advantages of this approach are: dissolved metal carbonates and bicarbonates and would significantly lower solution

pH, e.g.: 2CO2 + Ca(OH)2 ---> Ca2+ + 2HCO3-. Subsequent exposure to air would

➤ Limestone and seawater are global very abundant; there is a very large precipitate the captured carbon as CaCO3, which could be recycled for cement

CO2 sequestration capacity using this method. production, or stored as a CO2 sequestrant. E.g.:

CO2

➤ CO2 is spontaneously converted to dissolved bicarbonate, avoiding CO2 and Kiln Dust

costly and risky capture, purification, transport and storage of molecular CaCO3+ Mitigation in Cement

cement Manufacture

CO2. sand +

high heat

➤ Existing power plants can be retrofitted with this technology alkaline cement

kiln dust (CKD)

e.g., Ca(OH)2 + 2CO2---> Ca2+ + 2HCO3- --->

➤ The simplicity of the approach makes is highly applicable to deveolping H2O

Ca2+ + 2HCO3- H2O + CaCO3 + CO2

countries, as is seawater FGD.

C

<--CaCO3 recycle -and/or- sequestration

➤ The carbonate alkalinity added to the ocean by this method will help to as CaCO3

offset the present loss of seawater carbonate and biological The advantages of this approach are:

calcification that is occurring via air-->sea invasion of anthropogenic CO2 ➤ Simple re-routing and wetting of CO2 and CKD waste streams results in

mitigation of both streams

Further work is needed to better evaluate the cost/benefit and potential

➤ Low-tech, low-energy, and low-cost approach that that has co-benefits, and is

market of this CO2 mitigation approach and those discussed on right.

widely applicable to the cement industry.

Vous aimerez peut-être aussi

- CHE 262 Chemical Processes and Sustainability: Prepared By: Mohd Shahrul Nizam Bin SallehDocument24 pagesCHE 262 Chemical Processes and Sustainability: Prepared By: Mohd Shahrul Nizam Bin SallehMohd Shahrul Nizam SallehPas encore d'évaluation

- High Strength Precipitation Hardening and Duplex Stainless Steel Bolting For Special Purpose ApplicationsDocument6 pagesHigh Strength Precipitation Hardening and Duplex Stainless Steel Bolting For Special Purpose ApplicationsDanZel DanPas encore d'évaluation

- Carbon Capture and StorageDocument26 pagesCarbon Capture and StorageRamachandra Rao Maddali100% (1)

- Designing and Maintaining Steam Coil Air Pre Heaters For Reliability and EffectivenessDocument8 pagesDesigning and Maintaining Steam Coil Air Pre Heaters For Reliability and EffectivenessBadukwangPas encore d'évaluation

- Loesche Coal MillDocument20 pagesLoesche Coal MillBadukwang100% (6)

- Chlorine Institute Manual 2000Document68 pagesChlorine Institute Manual 2000Misael RamírezPas encore d'évaluation

- M1 Part3Document88 pagesM1 Part3Mohamed YahiaPas encore d'évaluation

- SPE 161207 Managing The Corrosion Impact of Dense Phase Co Injection For An EOR PurposeDocument11 pagesSPE 161207 Managing The Corrosion Impact of Dense Phase Co Injection For An EOR PurposeTurqay İsgəndərliPas encore d'évaluation

- Bolivia Process (Parts of KOM Material)Document4 pagesBolivia Process (Parts of KOM Material)arielPas encore d'évaluation

- 5-CO2 Capture, Storage Utilize - 20190321042222Document42 pages5-CO2 Capture, Storage Utilize - 20190321042222Rameish Subarmaniyan0% (1)

- Material Safety Data Sheet Hdpe: Section 1 - Chemical Product and Company IdentificationDocument4 pagesMaterial Safety Data Sheet Hdpe: Section 1 - Chemical Product and Company IdentificationruksfarhanPas encore d'évaluation

- Cement Industry Environmental Consortium: Carbon Capture and Reuse ProjectDocument27 pagesCement Industry Environmental Consortium: Carbon Capture and Reuse ProjectHala RiadPas encore d'évaluation

- SWEETENING (Chemical Absorption) PresentationDocument54 pagesSWEETENING (Chemical Absorption) Presentationarsalan amirpour75% (4)

- CCUS Chap - 6 030521Document18 pagesCCUS Chap - 6 030521Ali AltowilibPas encore d'évaluation

- Sub Critical Utility BoilersDocument25 pagesSub Critical Utility BoilersceddievanPas encore d'évaluation

- Proses Pengolahan GasDocument66 pagesProses Pengolahan GasWahyu HaryadiPas encore d'évaluation

- T20 Retractable SootblowerDocument4 pagesT20 Retractable SootblowerBadukwangPas encore d'évaluation

- Combined Effect of Carbon Dioxide, Hydrogen Sulfide, and Acetic Acid On Bottom-of-the-Line CorrosionDocument16 pagesCombined Effect of Carbon Dioxide, Hydrogen Sulfide, and Acetic Acid On Bottom-of-the-Line CorrosionTevriyudha MardikaPas encore d'évaluation

- Hopper Heating Design GuideDocument4 pagesHopper Heating Design GuideBadukwangPas encore d'évaluation

- MAYOR Nebres Concept Paper 2021Document8 pagesMAYOR Nebres Concept Paper 2021Azul Mae MayorPas encore d'évaluation

- Cquestrate PresentationDocument14 pagesCquestrate PresentationchrisunittPas encore d'évaluation

- Carbon Dioxide Capture and Storage: Sally M. Benson Franklin M. Orr, JRDocument3 pagesCarbon Dioxide Capture and Storage: Sally M. Benson Franklin M. Orr, JRGamal HamiresaPas encore d'évaluation

- Carbon Dioxide Capture and Storage: April 2008Document5 pagesCarbon Dioxide Capture and Storage: April 2008chirag sabhayaPas encore d'évaluation

- CO Mitigation in Thermo-Chemical Hydrogen Processes: Thermo-Environomic Comparison and OptimizationDocument9 pagesCO Mitigation in Thermo-Chemical Hydrogen Processes: Thermo-Environomic Comparison and OptimizationLaura Cristina BrandPas encore d'évaluation

- Equilibrium ModelingDocument9 pagesEquilibrium ModelingVineet SinghPas encore d'évaluation

- Dimethyl EtherDocument2 pagesDimethyl EtheraisyahPas encore d'évaluation

- Conceptual Design of A CO2 Capture and Utilisation Process Based On Calcium and Magnesium Rich BrinesDocument9 pagesConceptual Design of A CO2 Capture and Utilisation Process Based On Calcium and Magnesium Rich Brinesronuka19Pas encore d'évaluation

- Criteria For Intermediate Storage of Carbon Dioxide in Geological FormationsDocument11 pagesCriteria For Intermediate Storage of Carbon Dioxide in Geological Formationsshen shenPas encore d'évaluation

- Risk Assessment of CO Injection Processes and Storage in Carboniferous Formations: A ReviewDocument18 pagesRisk Assessment of CO Injection Processes and Storage in Carboniferous Formations: A ReviewbrengPas encore d'évaluation

- 1.4 Ammonia - Syn Gas PrepDocument56 pages1.4 Ammonia - Syn Gas PrepMahmud Rahman BizoyPas encore d'évaluation

- Capturing and Sequestering Flue-Gas CO Using A Wet Limestone ScrubberDocument6 pagesCapturing and Sequestering Flue-Gas CO Using A Wet Limestone ScrubberMaria Jafar KhanPas encore d'évaluation

- 1 s2.0 S2352854022000493 MainDocument11 pages1 s2.0 S2352854022000493 MainAhmad AmirhilmiPas encore d'évaluation

- Basic Investigations On Enhanced Gas Recovery by Gas-Gas DisplacementDocument12 pagesBasic Investigations On Enhanced Gas Recovery by Gas-Gas DisplacementEleonora LetorPas encore d'évaluation

- Water QualityDocument52 pagesWater QualityRbc bPas encore d'évaluation

- Savile & Lalonde. 2011. Biotechnology For The Acceleration of Carbon Dioxide Capture and SequestrationDocument6 pagesSavile & Lalonde. 2011. Biotechnology For The Acceleration of Carbon Dioxide Capture and SequestrationHamidah Itha'atur Rif'ahPas encore d'évaluation

- 1A Ocean Carbon 2022Document7 pages1A Ocean Carbon 2022g9ydjynjqyPas encore d'évaluation

- Chemical Engineering Journal: Yafei Guo, Chuanwen Zhao, Changhai Li, Ye WuDocument9 pagesChemical Engineering Journal: Yafei Guo, Chuanwen Zhao, Changhai Li, Ye WuFarah Talib Al-sudaniPas encore d'évaluation

- IBA Carbonation 2006 B128 73 RefDocument7 pagesIBA Carbonation 2006 B128 73 RefMike LiuPas encore d'évaluation

- 13V12 Clark Reduction Pathways ForDocument22 pages13V12 Clark Reduction Pathways ForMorteza alizadehPas encore d'évaluation

- GAS - by BASF - 1 PDFDocument12 pagesGAS - by BASF - 1 PDFD K SPas encore d'évaluation

- Chemical CO2 Recycling Via Dry and Bi Reforming of Methane Using Ni - SN - Al2O3 and Ni - SN - CeO2 - Al2O3 CatalystDocument11 pagesChemical CO2 Recycling Via Dry and Bi Reforming of Methane Using Ni - SN - Al2O3 and Ni - SN - CeO2 - Al2O3 CatalystLiang Yann YUANPas encore d'évaluation

- Metals: Metals Production, CO Mineralization and LCADocument16 pagesMetals: Metals Production, CO Mineralization and LCAwebPas encore d'évaluation

- Evaluation of CO Purification Requirements and The Selection of Processes For Impurities Deep Removal From The CO Product StreamDocument8 pagesEvaluation of CO Purification Requirements and The Selection of Processes For Impurities Deep Removal From The CO Product Streamait hssainPas encore d'évaluation

- 1 s2.0 S0360319920304262 MainDocument6 pages1 s2.0 S0360319920304262 MainBharatSuryaPas encore d'évaluation

- Trabajo 2 Segundo SemestreDocument11 pagesTrabajo 2 Segundo SemestreSergio AlejandroPas encore d'évaluation

- Effect of Water On CO2 Adsorption On CaNaY Zeolite: Formation of Ca2+ (H2O) (CO2), Ca2+ (H2O) (CO2) 2 and Ca2+ (H2O) 2 (CO2) ComplexesDocument19 pagesEffect of Water On CO2 Adsorption On CaNaY Zeolite: Formation of Ca2+ (H2O) (CO2), Ca2+ (H2O) (CO2) 2 and Ca2+ (H2O) 2 (CO2) ComplexesКонстантин ХаджиивановPas encore d'évaluation

- Cquestrate ArticleDocument2 pagesCquestrate ArticlechrisunittPas encore d'évaluation

- FREECORP BackgroundDocument85 pagesFREECORP BackgroundHache OrtizPas encore d'évaluation

- Carbon Dioxide in Soil: CO + H O - H CODocument1 pageCarbon Dioxide in Soil: CO + H O - H COAgastyanPas encore d'évaluation

- Acs Energyfuels 6b01205Document11 pagesAcs Energyfuels 6b01205Aurora SesitaPas encore d'évaluation

- Aqueous Inorganic Geochemistry of Natural Waters: Self StudyDocument24 pagesAqueous Inorganic Geochemistry of Natural Waters: Self StudyNguyen tiendungPas encore d'évaluation

- Journal of CO2 Utilization: Maciej Zajac, Jørgen Skibsted, Frank Bullerjahn, Jan SkocekDocument17 pagesJournal of CO2 Utilization: Maciej Zajac, Jørgen Skibsted, Frank Bullerjahn, Jan SkocekksrinivasPas encore d'évaluation

- CO2 - Water Content at Hydrate ConditionsDocument7 pagesCO2 - Water Content at Hydrate ConditionsWayne MonneryPas encore d'évaluation

- CO2 Capture From SRUDocument6 pagesCO2 Capture From SRUMustafaPas encore d'évaluation

- CO2 Mitigation Via Capture and Chemical Convertion in SeawaterDocument5 pagesCO2 Mitigation Via Capture and Chemical Convertion in SeawaterJHON JAIRO RAMOS FLOREZPas encore d'évaluation

- 8 Active Materials For Photocatalytic Reduction of CO2Document30 pages8 Active Materials For Photocatalytic Reduction of CO2Yashika ca20m007Pas encore d'évaluation

- 5A2. CO Recovery and Sequestration TechnologyDocument1 page5A2. CO Recovery and Sequestration TechnologyhamidntPas encore d'évaluation

- Notes 7Document18 pagesNotes 7Chini ChineePas encore d'évaluation

- CarbonatesDocument7 pagesCarbonatesJean D. MARIN PADILLLAPas encore d'évaluation

- DecarbonisationTechnology PTLDocument6 pagesDecarbonisationTechnology PTLjmod7867Pas encore d'évaluation

- Development of Novel CO Adsorbents For Capture of CO From Flue GasDocument13 pagesDevelopment of Novel CO Adsorbents For Capture of CO From Flue GasMayurkumar patilPas encore d'évaluation

- Production of Synthetic Gas From The Gasification of Biomass (Rice Husk)Document1 pageProduction of Synthetic Gas From The Gasification of Biomass (Rice Husk)Bilal AhmadPas encore d'évaluation

- Catalysts 12 00363Document32 pagesCatalysts 12 00363Khalid RashidPas encore d'évaluation

- CO2 Capture by Aqueous Na2CO3 Integrated With High-Quality CaCO3 Formation and Pure CO2 Release at Room ConditionsDocument9 pagesCO2 Capture by Aqueous Na2CO3 Integrated With High-Quality CaCO3 Formation and Pure CO2 Release at Room ConditionsJafar KhademPas encore d'évaluation

- 04G PDFDocument32 pages04G PDFRoberta S.Pas encore d'évaluation

- Journal of Petroleum Science and EngineeringDocument24 pagesJournal of Petroleum Science and Engineeringkhuzestan nanonamaPas encore d'évaluation

- Gas ProcessingDocument6 pagesGas ProcessingBouhadPas encore d'évaluation

- Hiller 2011Document20 pagesHiller 2011satya.usct.900450Pas encore d'évaluation

- 1 s2.0 S0961953413001177 MainDocument31 pages1 s2.0 S0961953413001177 MainPtrr TrpperPas encore d'évaluation

- Gas Hydrates 2: Geoscience Issues and Potential Industrial ApplicationsD'EverandGas Hydrates 2: Geoscience Issues and Potential Industrial ApplicationsLivio RuffinePas encore d'évaluation

- HRSG SCR Operation Problem - Vpi-6Document2 pagesHRSG SCR Operation Problem - Vpi-6BadukwangPas encore d'évaluation

- Tendering Tips and TrapsDocument4 pagesTendering Tips and TrapsBadukwangPas encore d'évaluation

- KazaDocument16 pagesKazaBadukwangPas encore d'évaluation

- HRSG SCR Operation Problem - Vpi-6Document2 pagesHRSG SCR Operation Problem - Vpi-6BadukwangPas encore d'évaluation

- NDE For TitaniumDocument5 pagesNDE For TitaniumBadukwangPas encore d'évaluation

- Density Meter Product PDF 30024Document6 pagesDensity Meter Product PDF 30024BadukwangPas encore d'évaluation

- Chapter 3.7 Cooling TowerDocument17 pagesChapter 3.7 Cooling TowerDeep DasPas encore d'évaluation

- GTG Fuel System - FlexibilityDocument37 pagesGTG Fuel System - FlexibilityBadukwangPas encore d'évaluation

- Graham - Steam Jet Ejector Specification SheetDocument1 pageGraham - Steam Jet Ejector Specification SheetBadukwangPas encore d'évaluation

- Belt Wyko UK - 91Document6 pagesBelt Wyko UK - 91BadukwangPas encore d'évaluation

- Cheat SheetDocument5 pagesCheat SheetHarshit MisraPas encore d'évaluation

- P Block Elements (Q.B) 13thDocument6 pagesP Block Elements (Q.B) 13thRaju SinghPas encore d'évaluation

- PTFE Cap1Document6 pagesPTFE Cap1RajanSharmaPas encore d'évaluation

- The Millennium School, Kurukshetra UT-I (2021-22) Class XI: EnglishDocument3 pagesThe Millennium School, Kurukshetra UT-I (2021-22) Class XI: EnglishYuvraj SinghPas encore d'évaluation

- Expancel Microspheres BoudDocument14 pagesExpancel Microspheres BoudChris BothaPas encore d'évaluation

- Notes On Q M C Delta TDocument2 pagesNotes On Q M C Delta TDing30180Pas encore d'évaluation

- Explain Why Seed Vigor Determination Is ImportantDocument5 pagesExplain Why Seed Vigor Determination Is ImportantSolomon MbewePas encore d'évaluation

- Producing Malonate in Saccharomyces Cerevisiae Via The Alanine Pathwaysystems Microbiology and BiomanufacturingDocument11 pagesProducing Malonate in Saccharomyces Cerevisiae Via The Alanine Pathwaysystems Microbiology and BiomanufacturingWendy SarmientoPas encore d'évaluation

- Us 4207118Document8 pagesUs 4207118virus40Pas encore d'évaluation

- Welding F22 To F91 (09MAR2018)Document2 pagesWelding F22 To F91 (09MAR2018)Juan Shuna100% (2)

- Modeling Ozone Generators by Using SIMULINKDocument5 pagesModeling Ozone Generators by Using SIMULINKGOGOPas encore d'évaluation

- UntitledDocument27 pagesUntitledapi-256504985Pas encore d'évaluation

- Tutorial 1 (2023)Document2 pagesTutorial 1 (2023)Dr. Aung Ko LattPas encore d'évaluation

- 10 Class Chemistry Guess Paper 2022. EXAM HELD IN 06-05-2022 Unit No. 9: Chemical Equilibrium. Short QuestionsDocument5 pages10 Class Chemistry Guess Paper 2022. EXAM HELD IN 06-05-2022 Unit No. 9: Chemical Equilibrium. Short QuestionsarslanPas encore d'évaluation

- Epoxy Curing Agents and ModifiersDocument3 pagesEpoxy Curing Agents and ModifiersNissim Hazar CasanovaPas encore d'évaluation

- CH 301 Unit 2 Exam-SolutionsDocument9 pagesCH 301 Unit 2 Exam-SolutionsbrunosipodPas encore d'évaluation

- 〈1207.2〉 Package Integrity Leak Test TechnologiesDocument15 pages〈1207.2〉 Package Integrity Leak Test TechnologiesTranNguyenBaoKhangPas encore d'évaluation

- Fracture Characterization of Threaded Rebar and Coupler: February 2016Document5 pagesFracture Characterization of Threaded Rebar and Coupler: February 2016Hotel Green DotPas encore d'évaluation

- A Review of Heat Exchanger Tube Bundle Vibrations in Two-Phase Cross-FlowDocument19 pagesA Review of Heat Exchanger Tube Bundle Vibrations in Two-Phase Cross-FlowPeerasak ArunPas encore d'évaluation

- Analyzer 500.lit - ETA.1111 PDFDocument12 pagesAnalyzer 500.lit - ETA.1111 PDFAlienshowPas encore d'évaluation

- June 2012 (v2) QP - Paper 2 CIE Chemistry A-LevelDocument12 pagesJune 2012 (v2) QP - Paper 2 CIE Chemistry A-LevelNoor ZahraPas encore d'évaluation

- Whey and CaseinDocument12 pagesWhey and CaseinMarcosViníciusSilvaPas encore d'évaluation

- Cambridge International Examinations Cambridge International General Certificate of Secondary EducationDocument20 pagesCambridge International Examinations Cambridge International General Certificate of Secondary EducationAbdulBasitBilalSheikhPas encore d'évaluation

- Automated Plate Load Test: Aplt CapabilitiesDocument2 pagesAutomated Plate Load Test: Aplt CapabilitiesjoseriquPas encore d'évaluation