Académique Documents

Professionnel Documents

Culture Documents

Magnetic Properties of Stainless Steel

Transféré par

seeralan balakrishnan0 évaluation0% ont trouvé ce document utile (0 vote)

57 vues2 pagesMagnetic permeability is the ability of a material to carry magnetism. All stainless steels, with the exception of the austenitic group, are strongly attracted to a magnet. Magnetic response can therefore be used as a method for sorting grades of stainless steel, but considerable caution needs to be exercised.

Description originale:

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

DOC, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentMagnetic permeability is the ability of a material to carry magnetism. All stainless steels, with the exception of the austenitic group, are strongly attracted to a magnet. Magnetic response can therefore be used as a method for sorting grades of stainless steel, but considerable caution needs to be exercised.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme DOC, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

57 vues2 pagesMagnetic Properties of Stainless Steel

Transféré par

seeralan balakrishnanMagnetic permeability is the ability of a material to carry magnetism. All stainless steels, with the exception of the austenitic group, are strongly attracted to a magnet. Magnetic response can therefore be used as a method for sorting grades of stainless steel, but considerable caution needs to be exercised.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme DOC, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

Stainless Steel - Magnetic PropertiesTopics CoveredBackgroundAustenitic GradesStress

RelievingCold WorkingMagnetically Soft Stainless SteelsBackgroundMagnetic permeability is the

ability of a material to carry magnetism, indicated by the degree to which it is attracted to a magnet. All

stainless steels, with the exception of the austenitic group, are strongly attracted to a magnet.Austenitic

GradesAll austenitic grades have very low magnetic permeabilities and hence show almost no response

to a magnet when in the annealed condition; the situation is, however, far less clear when these steels

have been cold worked by wire drawing, rolling or even centreless grinding, shot blasting or heavy

polishing. After substantial cold working Grade 304 may exhibit quite strong response to a magnet,

whereas Grades 310 and 316 will in most instances still be almost totally non-responsive.The change in

magnetic response is due to atomic lattice straining and formation of martensite. In general, the higher

the nickel to chromium ratio the more stable is the austenitic structure and the less magnetic response

that will be induced by cold work. Magnetic response can therefore be used as a method for sorting

grades of stainless steel, but considerable caution needs to be exercised.Stress RelievingAny austenitic

(300 series) stainless steel which has developed magnetic response due to cold work can be returned to

a non-magnetic condition by stress relieving. In general this can be readily achieved by briefly heating

to approximately 700 - 800°C (this can be conveniently carried out by careful use of an oxy-acetylene

torch). Note, however, unless the steel is a stabilised grade it could become sensitised to carbide

precipitation. Full solution treatment at 1000 - 1150°C will remove all magnetic response without

danger of reduced corrosion resistance due to carbides.If magnetic permeability is a factor of design or

is incorporated into a specification, this should be clearly indicated when purchasing the stainless steel

from a supplier.Cold WorkingMany cold drawn and/or polished bars have a noticeable amount of

magnetism as a result of the previous cold work. This is particularly the case with grades 304 and 303,

and much less so for the higher nickel grades such as 310 and 316. Even within the chemical

limitations of a single standard analysis range there can be a pronounced variation in the rate of

inducement of magnetic response from cold work.Magnetically Soft Stainless SteelsIn some

applications there is a requirement for a steel to be "magnetically soft". This is often required for

solenoid shafts, where it is necessary for the plunger to respond efficiently to the magnetic field from

the surrounding coil when the current is switched on, but when the current is switched off the magnetic

field induced in the steel must quickly collapse, allowing the plunger to return to its original position.

Steels which behave in this way are said to be magnetically soft. For corrosion resisting applications

there are ferritic stainless steels which are magnetically soft, usually variants of a grade "18/2" (18%

chromium and 2% molybdenum) but with very tightly controlled additions of silicon and often with

sulphur added to make them free machining. Special mill processing guarantees the magnetic

properties of the steels.Source: Atlas Steels AustraliaFor more information on this source please

visitAtlas Steels AustraliaDate Added: Jan 2, 2002Search AZoM ArticlesEmail / ShareKey

SuppliersRequest Quote From All SuppliersBodycote Heat TreatmentAtlas Specialty MetalsKey

ExpertsPeter MooreBooks ASMASM Handbook Volume 01: Properties and Selection: Irons, Steels,

and High-Performance AlloysASM Specialty Handbook: Stainless SteelsLight Microscopy of Carbon

SteelsStainless Steels for Design EngineersBooks ElsevierIntroduction To Materials ScienceBooks

John Wiley & SonsHandbook of Magnetism and Advanced Magnetic Materials, 5 Vol SetΔTopBack

OneCommercialization of Micro-Nano Systems ConferenceOther AZoNetwork Sites|AZoNano.com|

AZoBuild.com|AZoOptics.com|AZoCleantech.com|AZoSensors.com|News-Medical.Net|Partners-Eng-

Tips.comversion 2.0 - AZoM™ - The A to Z of Materials

s.no description grade magnetic properties

1

2

and AZojomo - The "AZo Journal of Materials Online"...AZoM™.com Pty.Ltd Copyright © 2000-

2010

Vous aimerez peut-être aussi

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Refrigeration & Air Conditioning: Emerson Flow Controls Expansion ValvesDocument1 pageRefrigeration & Air Conditioning: Emerson Flow Controls Expansion Valvesseeralan balakrishnanPas encore d'évaluation

- CCW - PVC Steel Wire Hose CatalogueDocument1 pageCCW - PVC Steel Wire Hose Catalogueseeralan balakrishnanPas encore d'évaluation

- Shunt Open - Release 24V DC E1/6-T8Document2 pagesShunt Open - Release 24V DC E1/6-T8seeralan balakrishnanPas encore d'évaluation

- P5 product data sheet specsDocument4 pagesP5 product data sheet specsseeralan balakrishnanPas encore d'évaluation

- Pyrometer Tp7: The Universal Infrared Thermometer For Many Fields of ApplicationDocument6 pagesPyrometer Tp7: The Universal Infrared Thermometer For Many Fields of Applicationseeralan balakrishnanPas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

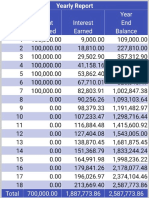

- Smart Scholar CalculationDocument5 pagesSmart Scholar Calculationseeralan balakrishnanPas encore d'évaluation

- Tuv Application Form Saudi Arabia Saso ProgramDocument3 pagesTuv Application Form Saudi Arabia Saso Programseeralan balakrishnanPas encore d'évaluation

- General Combined Brochure RevisedDocument406 pagesGeneral Combined Brochure Revisedseeralan balakrishnanPas encore d'évaluation

- Materials System Specification: 34-SAMSS-010 03 October 2019 Quality Requirements For Pressure Retaining InstrumentsDocument10 pagesMaterials System Specification: 34-SAMSS-010 03 October 2019 Quality Requirements For Pressure Retaining Instrumentsseeralan balakrishnanPas encore d'évaluation

- Itrade Networks Company ProfileDocument8 pagesItrade Networks Company Profileseeralan balakrishnanPas encore d'évaluation

- Singlevoteprice21 1576480252Document1 pageSinglevoteprice21 1576480252seeralan balakrishnanPas encore d'évaluation

- SPECIFICATIONS AND ACCESSORIES FOR THE IH8R HEADLAMPDocument4 pagesSPECIFICATIONS AND ACCESSORIES FOR THE IH8R HEADLAMPseeralan balakrishnanPas encore d'évaluation

- Model Number DetailsDocument1 pageModel Number Detailsseeralan balakrishnanPas encore d'évaluation

- Sewage TreatmentDocument1 pageSewage Treatmentseeralan balakrishnanPas encore d'évaluation

- Nokia E71 Vs Samsung B7330 OmDocument2 pagesNokia E71 Vs Samsung B7330 Omseeralan balakrishnanPas encore d'évaluation

- Hikvision Port Forwarding For CCTVDocument35 pagesHikvision Port Forwarding For CCTVbuzzkillaPas encore d'évaluation

- Professional infrared thermometer for -50°C to 1000°CDocument6 pagesProfessional infrared thermometer for -50°C to 1000°Cseeralan balakrishnanPas encore d'évaluation

- Rail BeamsDocument1 pageRail Beamsseeralan balakrishnanPas encore d'évaluation

- SambarDocument1 pageSambarseeralan balakrishnanPas encore d'évaluation

- Las Tek FillerDocument2 pagesLas Tek Fillerseeralan balakrishnanPas encore d'évaluation

- B 815791 FCDocument3 pagesB 815791 FCseeralan balakrishnanPas encore d'évaluation

- Onion AgmarkDocument33 pagesOnion Agmarkseeralan balakrishnanPas encore d'évaluation

- Compressor Specifications - © Bristol Compressors International, IncDocument1 pageCompressor Specifications - © Bristol Compressors International, Incseeralan balakrishnanPas encore d'évaluation

- Nikola Tesla - Wikipedia, The Free EncyclopediaDocument15 pagesNikola Tesla - Wikipedia, The Free Encyclopediaseeralan balakrishnanPas encore d'évaluation

- 18 Questions and Answers in Planning & SchedulingDocument8 pages18 Questions and Answers in Planning & SchedulingBeni Best100% (3)

- Pharmaceutical Calculation - PDF 2Document31 pagesPharmaceutical Calculation - PDF 2Cheeyongg Lookonthebrightside100% (4)

- Lectra Clean® Heavy Duty Energized Electrical Parts Degreaser, 5 GalDocument2 pagesLectra Clean® Heavy Duty Energized Electrical Parts Degreaser, 5 Galseeralan balakrishnanPas encore d'évaluation

- RF Planning BibleDocument128 pagesRF Planning BibleDipanka Borah100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Adaptive Teaching Guide SampleDocument2 pagesAdaptive Teaching Guide SampleMai SasaPas encore d'évaluation

- Proposal Defense PresentationDocument52 pagesProposal Defense PresentationJanine TacaisanPas encore d'évaluation

- Transom cw03Document2 pagesTransom cw03Pamps MangampoPas encore d'évaluation

- Carbobond 3028 1Document1 pageCarbobond 3028 1Yan TengPas encore d'évaluation

- Api Melafix Safety Data Sheet PDFDocument10 pagesApi Melafix Safety Data Sheet PDFumaPas encore d'évaluation

- Chemistry Final Cheat SheetDocument1 pageChemistry Final Cheat SheetScott Allred100% (2)

- Anatomy & Physiology Made Incredibly Visual!Document412 pagesAnatomy & Physiology Made Incredibly Visual!Cereal KillerPas encore d'évaluation

- Heat Transfer and Variable Loads Sept 2017 Rev 6 PresentationDocument49 pagesHeat Transfer and Variable Loads Sept 2017 Rev 6 PresentationFritzel OyaoPas encore d'évaluation

- Dale Beggs 1 - Production Optimization Using Nodal Analysis (010-016)Document7 pagesDale Beggs 1 - Production Optimization Using Nodal Analysis (010-016)Luz Mary OrtegaPas encore d'évaluation

- IGS-M-CH-38 (1) Oct IGS. Iranian Gas Standards $ - &' (! ! Odorant To Be Used For Odorization of Natural Gas-1Document12 pagesIGS-M-CH-38 (1) Oct IGS. Iranian Gas Standards $ - &' (! ! Odorant To Be Used For Odorization of Natural Gas-1KHALED KHALEDPas encore d'évaluation

- Debye Specific Heat TheoryDocument3 pagesDebye Specific Heat TheoryJuly T Widya R100% (1)

- Parker SizeTempratureApplicationMediaPressureDocument40 pagesParker SizeTempratureApplicationMediaPressuretrilemmaPas encore d'évaluation

- EnzymeDocument3 pagesEnzymemiriam harriottPas encore d'évaluation

- Unit III Engine Exhaust Emission ControlDocument49 pagesUnit III Engine Exhaust Emission ControlMani Karthi100% (1)

- Ghee Chemistry: Karuna Meghwal Assistant Professor MIDFT, MehsanaDocument50 pagesGhee Chemistry: Karuna Meghwal Assistant Professor MIDFT, MehsanaNamraPas encore d'évaluation

- Leon Scope-62225-TC-7081-1679956348Document8 pagesLeon Scope-62225-TC-7081-1679956348raghavan_gopinathPas encore d'évaluation

- Rock Failure under Confined Brazilian TestDocument9 pagesRock Failure under Confined Brazilian TestMichel SartoPas encore d'évaluation

- Pages From SAES-H-001-19Document1 pagePages From SAES-H-001-19mohammed s fawabPas encore d'évaluation

- MSDS Neopelex FS KAO RevisiDocument7 pagesMSDS Neopelex FS KAO RevisiIbnu SalehPas encore d'évaluation

- Asme Seccion Viii Div 1 - Apartado Uw-2 Restricciones de ServicioDocument3 pagesAsme Seccion Viii Div 1 - Apartado Uw-2 Restricciones de ServicioAlexander CorvinPas encore d'évaluation

- Periodic Table Display Poster A4Document1 pagePeriodic Table Display Poster A4Sarah Khan100% (1)

- Applying Cold Plasma in Food IndustryDocument18 pagesApplying Cold Plasma in Food Industryprachi mahajanPas encore d'évaluation

- Duplex and Superduplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)Document11 pagesDuplex and Superduplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)Mathew CherianPas encore d'évaluation

- Lead Acid Batteries in Critical ApplicationsDocument24 pagesLead Acid Batteries in Critical Applicationsger80100% (1)

- Brochure Covalumine PigmentsDocument3 pagesBrochure Covalumine PigmentsMamadou Lamine FallPas encore d'évaluation

- 0157 - TI - MG - REBOX HLL - SYS - Customer - Reference - A4 - RZ - VIEW - tcm17-526907Document2 pages0157 - TI - MG - REBOX HLL - SYS - Customer - Reference - A4 - RZ - VIEW - tcm17-526907Văn Tuấn NguyễnPas encore d'évaluation

- Molecular Imaging Modalities and ApplicationsDocument42 pagesMolecular Imaging Modalities and ApplicationsSheila KwokPas encore d'évaluation

- EcoFlame B-971 MSDSDocument8 pagesEcoFlame B-971 MSDSZirve PolimerPas encore d'évaluation

- Astm C150Document9 pagesAstm C150npwal0% (1)

- Me8512 4Document4 pagesMe8512 4KARTHIPas encore d'évaluation