Académique Documents

Professionnel Documents

Culture Documents

Operating QSV Diesel Engines

Transféré par

William Ruiz0 évaluation0% ont trouvé ce document utile (0 vote)

126 vues13 pagesThis document provides an overview of operating procedures for Cummins QSV diesel engines. It outlines the learning objectives, agenda, control systems, starting procedures, monitoring parameters, normal operation, shutdown procedures, and engine isolation steps. The document is intended to familiarize operators with safe operation of these engines.

Description originale:

Titre original

Module 4 - Oper.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document provides an overview of operating procedures for Cummins QSV diesel engines. It outlines the learning objectives, agenda, control systems, starting procedures, monitoring parameters, normal operation, shutdown procedures, and engine isolation steps. The document is intended to familiarize operators with safe operation of these engines.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

126 vues13 pagesOperating QSV Diesel Engines

Transféré par

William RuizThis document provides an overview of operating procedures for Cummins QSV diesel engines. It outlines the learning objectives, agenda, control systems, starting procedures, monitoring parameters, normal operation, shutdown procedures, and engine isolation steps. The document is intended to familiarize operators with safe operation of these engines.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 13

QSV Diesel Engines

Module 4 - Operating

Cummins Corporate Training

QSV Diesel CUMMINS CORPORATION

Cummins Corporate Training

D / Operating / BMG / 01-01 / Rev. 03

Operating Module

Learning Objectives

To familiarise the operator with the procedures for safe operation of the

engine.

Agenda

☛ Control Systems (Industrial / Marine).

☛ Engine Starting.

☛ Engine Monitoring.

☛ Operating Parameters.

☛ Engine Shutdown.

☛ Engine Isolation Procedure.

QSV Diesel CUMMINS CORPORATION

Cummins Corporate Training

D / Operating / BMG / 01-01 / Rev. 03

2

Onan Power Command - Industrial Genset Control System

QSV Diesel CUMMINS CORPORATION

Cummins Corporate Training

D / Operating / BMG / 01-01 / Rev. 03

3

Marine Power Generation & Propulsion

PLC controller with LCD display

QSV Diesel CUMMINS CORPORATION

Cummins Corporate Training

D / Operating / BMG / 01-01 / Rev. 03

4

Engine Starting

• Check engine oil level.

• Check coolant level, pre-heated to

40º C and circulating.

• Check fuel level, valve open.

• Check all covers in place.

• Check engine control system on.

• Check pre-lube operated 0.5Bar.

• Check starting air 100psi min.

• Fuel control lever ‘Run’ position.

• Start engine from control panel.

• Check for oil pressure within 15

seconds.

• Idle 3-5 min. before load 40-60º C.

QSV Diesel CUMMINS CORPORATION

Cummins Corporate Training

D / Operating / BMG / 01-01 / Rev. 03

5

Engine Starting

After Extended Shutdown (+48 Hrs)

Follow normal starting procedure checks, then;

• Vent air from oil filter housing with pre-lube pump running.

• Check coolant level in header tank.

• Check that the control shaft system and injection pump racks

move freely.

• Bar the engine over two revolutions with the fuel control

lever in the stop position - check for coolant at cylinder

plugs.

• Prime the fuel system.

Every three to four weeks during extended shutdown;

• Turn crank to new position.

QSV Diesel CUMMINS CORPORATION

Cummins Corporate Training

D / Operating / BMG / 01-01 / Rev. 03

6

Engine Monitoring 1 of 2

Typical System Monitoring Devices

Cooling System Thermometers:

• Water temperature before central water cooler.

• Water temperature after central water cooler.

• HT Water circuit after engine.

• HT Water circuit after Turbocharger.

Cooling System Manometers:

• System pressure before central water cooler.

• System pressure after central water cooler.

• HT Pressure after pump (Flow to engine and turbo).

• LT Pressure after pump (Flow to LOC / CAC).

Exhaust System Pyrometers:

• Cylinder Exhaust Temperature.

QSV Diesel CUMMINS CORPORATION

Cummins Corporate Training

D / Operating / BMG / 01-01 / Rev. 03

7

Engine Monitoring 2 of 2

Lubrication system.

• Lubricating oil temperature.

• Lubricating oil pressure.

Fuel System.

• Fuel oil pressure.

• Fuel temperature.

Air System.

• Charge air temperature

• Charge air pressure

Starting System.

• Starting air pressure.

Speed Probes.

• Turbocharger

• Engine

QSV Diesel CUMMINS CORPORATION

Cummins Corporate Training

D / Operating / BMG / 01-01 / Rev. 03

8

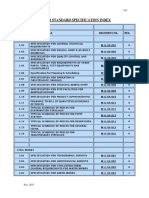

Operating Parameters

QSV ENGINE OPERATING PARAMETERS ( GENSET APPLICATIONS )

Engine Gauge Alarm / Shutdown Limits

Nominal Value Immediate

(Full speed, Shutdown

Meter / Measurement Range full load) Alarm

0 - 12.0Bar 4.2 - 5.0Bar 2.3Bar (low) 2Bar (low /low)

Lube oil pressure ( 0 - 174PSI ) (61 - 72.5 PSI) (33.5 PSI) (29 PSI)

Lube oil temperature

( after oil cooler) 0 - 80º C 60 - 70º C 78º C (high) 80º C (high/high)

Common water inlet

temperature 0 - 55º C 40 - 50º C - -

Common water outlet

temperature 0 - 65º C 55 - 65º C - -

Charge air pressure 0 - 3.0Bar 2.8Bar 2.9Bar

(after CAC) ( 0 - 43.5 PSI ) ( 41 PSI ) ( 42 PSI ) -

Charge air temperature

(after CAC) 0 - 70º C 45 - 60º C 70º C -

0 - 6.0Bar 5.0 - 6.0Bar 4.5Bar

Fuel oil pressure ( 87 PSI ) ( 72.5 - 87 PSI ) ( 65 PSI ) -

0 - 3.5Bar 3.0 - 3.5Bar 0.65Bar

L.T. water pressure ( 51 PSI ) ( 43.5 - 51 PSI ) ( 9.5 PSI ) -

L.T. water temperature

(before CAC) 0 - 60º C 40 - 58º C 60º C -

0 - 4.5Bar 4 - 4.5Bar 0.65Bar

H.T. water pressure ( 0 - 65 PSI ) (58 - 65 PSI) ( 9.5 PSI ) -

MAX 15.0Bar 11.0Bar 7.0Bar

Starting air pressure ( 218 PSI ) ( 160 PSI ) ( 102 PSI ) -

QSV Diesel CUMMINS CORPORATION

Cummins Corporate Training

D / Operating / BMG / 01-01 / Rev. 03

9

Normal Operating Supervision

• Regularly check thermometers, pressure gauges, exhaust pyrometers.

• Listen for unusual changes in engine noise.

• Check indicator for pressure drop over fuel filters, 1.5Bar max.

• Check indicator for pressure drop over oil filters. Filter Bypass valves

open if pressure drop exceeds 2 - 3Bar.

• Check coolant header tank level and for leakage from water pump “Tell

Tale”.

• Check the condensate drain from the charge air cooler is open and not

blocked.

• Check the quantity of leak fuel from the drain pipes.

• Drain water and sediment from the fuel tank and starting air receiver.

-End-

QSV Diesel CUMMINS CORPORATION

Cummins Corporate Training

D / Operating / BMG / 01-01 / Rev. 03

10

Engine Shutdown

• Run engine at no load or idle

for 3-5 minutes before

shutdown.

• Shutdown from control panel

(Key-switch or run/off/auto

switch as fitted)

Emergency shutdown

• Hit the emergency stop button

on the control panel.

or

• Move the fuel control lever to

the ‘STOP’ position.

QSV Diesel CUMMINS CORPORATION

Cummins Corporate Training

D / Operating / BMG / 01-01 / Rev. 03

11

Engine Isolation Procedure

• Shut down the engine and isolate fuel supply.

Stop position

• Move the Stop lever to the stop position and engage the

starter interlock (baring device).

• Isolate control system, first switch off the battery charger, if

fitted, then disconnect control battery.

• Isolate air compressor and drain system -

including engine actuator air receiver.

• Isolate the lubricating oil priming pump and oil make-up

system, if fitted.

• Isolate engine heaters and circulating pump, if fitted. Starter Interlock

• Tag the engine “OUT OF SERVICE ”.

NOTE: On Genset applications ensure the mains or HV

Engine Out

supply is isolated and locked out. Check if a permit to work

of Service

system is in operation.

QSV Diesel CUMMINS CORPORATION

Cummins Corporate Training

D / Operating / BMG / 01-01 / Rev. 03

12

Module 4 - Operating

Team Task

- End -

Cummins Corporate Training

QSV Diesel CUMMINS CORPORATION

Cummins Corporate Training

D / Operating / BMG / 01-01 / Rev. 03

Vous aimerez peut-être aussi

- Wa500-6 Sen00236-04d PDFDocument1 705 pagesWa500-6 Sen00236-04d PDFanggie100% (4)

- New Wiring Diagram Electric EMS2-tad1640ge PDFDocument2 pagesNew Wiring Diagram Electric EMS2-tad1640ge PDFVanHoang95% (22)

- Process CalculationsDocument225 pagesProcess CalculationsIsabel Justiniano Olivera86% (22)

- Liebhaber NESC 2017 ChangesDocument80 pagesLiebhaber NESC 2017 ChangesEdgar ZapanaPas encore d'évaluation

- Cummins Fire Power Digital Panel Operation GuideDocument80 pagesCummins Fire Power Digital Panel Operation GuideSpectrumRaijin100% (2)

- Objective and Scope and Importance of Mineral Beneficiation With Special Reference To IndiaDocument4 pagesObjective and Scope and Importance of Mineral Beneficiation With Special Reference To IndiaVidya Sagar100% (1)

- Water Standard Specification Index As On Dec 2015Document10 pagesWater Standard Specification Index As On Dec 2015afp15060% (1)

- Module 8 - ToolsDocument17 pagesModule 8 - ToolsWilliam RuizPas encore d'évaluation

- Module 6 - OperDocument12 pagesModule 6 - OperWilliam Ruiz100% (1)

- Module 9 - T.shootDocument26 pagesModule 9 - T.shootWilliam RuizPas encore d'évaluation

- Module 8 - MaintDocument19 pagesModule 8 - MaintWilliam RuizPas encore d'évaluation

- Dva 410 Nansc Techno Power TrainingDocument23 pagesDva 410 Nansc Techno Power TrainingcafubodoPas encore d'évaluation

- Maintenance of A.C GeneratorsDocument26 pagesMaintenance of A.C GeneratorsMohamed HamdallahPas encore d'évaluation

- Power Management: Advanced Hands-On Training March 2011Document16 pagesPower Management: Advanced Hands-On Training March 2011Aguilar AlexPas encore d'évaluation

- Operator Training: Panel Kontrol Diesel Engine & Gas Engine Di Fasilitas Produksi Akasia BagusDocument22 pagesOperator Training: Panel Kontrol Diesel Engine & Gas Engine Di Fasilitas Produksi Akasia BagusVERY SYAYIDINAPas encore d'évaluation

- Agn013 CDocument10 pagesAgn013 Cmohsen_cumminsPas encore d'évaluation

- 03 Generator Selection Tool - GENSIZE Bob Patrick Oct08 Form) (Compatibility Mode)Document72 pages03 Generator Selection Tool - GENSIZE Bob Patrick Oct08 Form) (Compatibility Mode)HammadZamanPas encore d'évaluation

- Comparative DMC CumminsDocument8 pagesComparative DMC CumminsJose VarelaPas encore d'évaluation

- QSV 81/91 Gas Engine Component ChangesDocument38 pagesQSV 81/91 Gas Engine Component ChangesWilliam RuizPas encore d'évaluation

- File - Fe1c9e D55e26 68f0ed 62ae34 B44C0C 1a682cDocument4 pagesFile - Fe1c9e D55e26 68f0ed 62ae34 B44C0C 1a682cYasser JaviPas encore d'évaluation

- ComAp Application ModesDocument19 pagesComAp Application ModesgatoPas encore d'évaluation

- EMCP II+ Diagnostic ManualDocument12 pagesEMCP II+ Diagnostic ManualMoctar Sangho100% (1)

- Understanding Generator Set RatingsDocument48 pagesUnderstanding Generator Set RatingsdanePas encore d'évaluation

- Generator Checklist TemplateDocument1 pageGenerator Checklist Templatesmart channelPas encore d'évaluation

- Training AvrDocument64 pagesTraining AvrCamilo Andres Cardozo FajardoPas encore d'évaluation

- STAMFORD AvK Alternator Technology Centre Service TrainingDocument20 pagesSTAMFORD AvK Alternator Technology Centre Service TrainingGraham Mc KenziePas encore d'évaluation

- Parallel Basics ASTCDocument14 pagesParallel Basics ASTCLuis Del Prado SalazarPas encore d'évaluation

- Biodiesel B20 Approval Information: Edward Lyford-Pike Michael O'DonnellDocument29 pagesBiodiesel B20 Approval Information: Edward Lyford-Pike Michael O'DonnelltstkupdhPas encore d'évaluation

- QSK60 Spec SheetDocument6 pagesQSK60 Spec Sheetbacuoc.nguyen356Pas encore d'évaluation

- Performance: Rebuilds For Your KTA50 G3Document4 pagesPerformance: Rebuilds For Your KTA50 G3Sopian PianPas encore d'évaluation

- 4971389Document10 pages4971389Juan Diego SarangoPas encore d'évaluation

- Module 9 - Compr&iDocument34 pagesModule 9 - Compr&iWilliam Ruiz100% (1)

- Nateria Brochure PDFDocument6 pagesNateria Brochure PDFJavier Alejandro Muralles ReyesPas encore d'évaluation

- 1300 Series Electronic Engine Training Notes SummaryDocument40 pages1300 Series Electronic Engine Training Notes SummaryIbra KribaaPas encore d'évaluation

- CumminsDocument28 pagesCumminsjohnPas encore d'évaluation

- Railway Engine Training-CUMMINS EngineDocument50 pagesRailway Engine Training-CUMMINS EnginemajjisatPas encore d'évaluation

- Power CommandDocument2 pagesPower CommandLaiqPas encore d'évaluation

- Module 7 Fuel SystemDocument28 pagesModule 7 Fuel SystemAguilar AlexPas encore d'évaluation

- Cat Gas Training Provides Overview of Generator Sets and ApplicationsDocument266 pagesCat Gas Training Provides Overview of Generator Sets and ApplicationsDjebali Mourad100% (1)

- MTU OE Genset A5Document41 pagesMTU OE Genset A5Aurelio SerranoPas encore d'évaluation

- Emergency Assembly Point MapDocument68 pagesEmergency Assembly Point MapthainarimePas encore d'évaluation

- Standby Voltage Bus Circuit DiagramsDocument80 pagesStandby Voltage Bus Circuit DiagramsAndrey GrechanikovPas encore d'évaluation

- c120 Cummins Kta50-G3Document2 pagesc120 Cummins Kta50-G3api-25249900850% (2)

- 0908-0101 I2 200910 PDFDocument28 pages0908-0101 I2 200910 PDFAnonymous z0m7zUPir100% (1)

- Every Ton.: For Mining ApplicationsDocument4 pagesEvery Ton.: For Mining ApplicationsRichard Sequeiros AlvarezPas encore d'évaluation

- 5d - Ignition System2Document9 pages5d - Ignition System2agvassPas encore d'évaluation

- A041 J096Document0 pageA041 J096Michal HroudaPas encore d'évaluation

- Transfer Switch Operation and Application 2019-07-25Document50 pagesTransfer Switch Operation and Application 2019-07-25Alda C. IndustrialPas encore d'évaluation

- Woodward EGCP3 Controller Rev 2Document56 pagesWoodward EGCP3 Controller Rev 2Dmytro 1Pas encore d'évaluation

- QSK60 Starting SystemDocument4 pagesQSK60 Starting SystemagvassPas encore d'évaluation

- QSV91G Containerized SpecificationDocument26 pagesQSV91G Containerized SpecificationmackyyoPas encore d'évaluation

- Module 4 Base EngineDocument38 pagesModule 4 Base Enginebenitez1Pas encore d'évaluation

- Rogrammabl e Ogic OntrollersDocument60 pagesRogrammabl e Ogic OntrollersSudarshan NavalePas encore d'évaluation

- InteliSys Gas 1 5 0 Grid Codes GuideDocument667 pagesInteliSys Gas 1 5 0 Grid Codes GuideSebastianx LexPas encore d'évaluation

- QSD2 QSD28 QSD42 Bosch Bosch Marine 4082012Document2 pagesQSD2 QSD28 QSD42 Bosch Bosch Marine 4082012aleman100% (1)

- Engine Governor Systems: A PresentationDocument43 pagesEngine Governor Systems: A PresentationMohamed HamdallahPas encore d'évaluation

- Instrucciones Sistema de Combustible Qsk60 y 23Document15 pagesInstrucciones Sistema de Combustible Qsk60 y 23zzapiechePas encore d'évaluation

- 1800reozm Specification KohlerDocument4 pages1800reozm Specification KohlerTrần Quang TuyênPas encore d'évaluation

- Cummins QSK60G & QSK60G-HE Gas Engines Cooling System OverviewDocument30 pagesCummins QSK60G & QSK60G-HE Gas Engines Cooling System Overviewbenitez1100% (1)

- Kohler 800rozmc SpecDocument4 pagesKohler 800rozmc Speclilama45-1Pas encore d'évaluation

- Operating Manual: HGM6200K Series Automatic Generator ModuleDocument35 pagesOperating Manual: HGM6200K Series Automatic Generator Modulejorgehrdz269Pas encore d'évaluation

- New MTU DS1000 SubmittalDocument74 pagesNew MTU DS1000 Submittalخطاب الشاميPas encore d'évaluation

- ATS OkDocument20 pagesATS Okducabc123Pas encore d'évaluation

- Load Sharing and Voltage Droop Settings for Cummins GeneratorsDocument5 pagesLoad Sharing and Voltage Droop Settings for Cummins GeneratorsQuang PhamPas encore d'évaluation

- MC 10152915 9999Document10 pagesMC 10152915 9999Daniel Dario Greig SalazarPas encore d'évaluation

- MC 10142109 9999Document3 pagesMC 10142109 9999Jaime MelladoPas encore d'évaluation

- Basic Process & Simulation IndryingDocument28 pagesBasic Process & Simulation IndryingNitin MohandasPas encore d'évaluation

- Optimal Configuration District Heating NetworksDocument11 pagesOptimal Configuration District Heating NetworksWilliam RuizPas encore d'évaluation

- TestReport ThermalDocument12 pagesTestReport ThermalDepri YantriPas encore d'évaluation

- Capit-07-2-Pruebas Generadores PDFDocument12 pagesCapit-07-2-Pruebas Generadores PDFWilliam RuizPas encore d'évaluation

- BRAATZ-Fault Detection and Diagnosis in Industrial System PDFDocument300 pagesBRAATZ-Fault Detection and Diagnosis in Industrial System PDFWilliam RuizPas encore d'évaluation

- Electrical and Mechanical Glossary TermsDocument23 pagesElectrical and Mechanical Glossary TermsWilliam RuizPas encore d'évaluation

- Fault Detection and Diagnosis in Industrial System PDFDocument300 pagesFault Detection and Diagnosis in Industrial System PDFWilliam RuizPas encore d'évaluation

- 155.16-Eg3 1010 PDFDocument56 pages155.16-Eg3 1010 PDFArini Rizal0% (1)

- Análisis de Exergia y Pinch en Proceso de FraccionamientoDocument5 pagesAnálisis de Exergia y Pinch en Proceso de FraccionamientoWilliam RuizPas encore d'évaluation

- Exergy, Its Potential and Limitations in EnvironmentalDocument12 pagesExergy, Its Potential and Limitations in EnvironmentalPelita HidupPas encore d'évaluation

- A Comparison of Thermodynamic Loss Models Suitable For Gas Turbine Propulsion: Theory and TaxonomyDocument9 pagesA Comparison of Thermodynamic Loss Models Suitable For Gas Turbine Propulsion: Theory and TaxonomyWilliam RuizPas encore d'évaluation

- Module 12 - Rev & CloseDocument3 pagesModule 12 - Rev & CloseWilliam RuizPas encore d'évaluation

- TestReport ThermalDocument12 pagesTestReport ThermalDepri YantriPas encore d'évaluation

- QSV 81/91 Gas Engine Routine Maintenance CourseDocument53 pagesQSV 81/91 Gas Engine Routine Maintenance CourseWilliam Ruiz100% (1)

- Module 10 - ToolsDocument11 pagesModule 10 - ToolsWilliam RuizPas encore d'évaluation

- Module 7 - Data&SpDocument19 pagesModule 7 - Data&SpWilliam RuizPas encore d'évaluation

- Module 2 - TechDocument24 pagesModule 2 - TechWilliam RuizPas encore d'évaluation

- Module 5 - Eng ContDocument38 pagesModule 5 - Eng ContWilliam Ruiz100% (2)

- Module 10 - Review&CloseDocument3 pagesModule 10 - Review&CloseWilliam RuizPas encore d'évaluation

- QSV 81/91 Gas Engine Component ChangesDocument38 pagesQSV 81/91 Gas Engine Component ChangesWilliam RuizPas encore d'évaluation

- Module 1 - IntroDocument16 pagesModule 1 - IntroWilliam RuizPas encore d'évaluation

- Module 7 - TroubleDocument10 pagesModule 7 - TroubleWilliam RuizPas encore d'évaluation

- Module 3 - SafetyDocument17 pagesModule 3 - SafetyWilliam RuizPas encore d'évaluation

- Module 11 - MarineDocument23 pagesModule 11 - MarineWilliam RuizPas encore d'évaluation

- Module 9 - Compr&iDocument34 pagesModule 9 - Compr&iWilliam Ruiz100% (1)

- Mechatronics Handbook - 02 - Mechatronic Design Approach PDFDocument16 pagesMechatronics Handbook - 02 - Mechatronic Design Approach PDFJosé Fernando TerronesPas encore d'évaluation

- The Design, Development and Future of Electric Vehicle: Prof. Eric ChengDocument18 pagesThe Design, Development and Future of Electric Vehicle: Prof. Eric ChengDeepak ChaurasiaPas encore d'évaluation

- 24th Annual International Pittsburgh Coal 2007 WixDocument10 pages24th Annual International Pittsburgh Coal 2007 WixAmauche OgePas encore d'évaluation

- Microstructural Characterization, Strengthening and Toughening Mechanisms of A Quenched and Tempered Steel Effect of Heat Treatment ParametersDocument22 pagesMicrostructural Characterization, Strengthening and Toughening Mechanisms of A Quenched and Tempered Steel Effect of Heat Treatment ParametersAlmerindo JuniorPas encore d'évaluation

- Inspection GalleryDocument4 pagesInspection GalleryrajmohapatraPas encore d'évaluation

- 2007 Bachu Etal CO2 Storage Capacity EstimationDocument14 pages2007 Bachu Etal CO2 Storage Capacity EstimationArindam Obzi GuptaPas encore d'évaluation

- Cause Effect Analysis of Oil Loss in Edible Oil IndustryDocument60 pagesCause Effect Analysis of Oil Loss in Edible Oil IndustrySaurabh RaiPas encore d'évaluation

- India's Former President APJ Abdul Kalam on Leadership, Knowledge and Managing FailureDocument14 pagesIndia's Former President APJ Abdul Kalam on Leadership, Knowledge and Managing FailureHarsh TiwariPas encore d'évaluation

- Production Range: EUROPIPE. The World Trusts UsDocument8 pagesProduction Range: EUROPIPE. The World Trusts UsIslam-Lotfi Hadj-ArabPas encore d'évaluation

- 10 MW Unit 214.00 709 55.83 1972Document1 page10 MW Unit 214.00 709 55.83 1972Gangadhara P.K.Pas encore d'évaluation

- EXPANSION VALVES SERIES DOCUMENT (THERMOSTATIC & CONSTANT PRESSUREDocument44 pagesEXPANSION VALVES SERIES DOCUMENT (THERMOSTATIC & CONSTANT PRESSURESite EngineeringtiaPas encore d'évaluation

- ME6502 Heat and Mass Transfer SyllabusDocument26 pagesME6502 Heat and Mass Transfer Syllabusamdeva0% (1)

- Easy Genset Control: OperationDocument51 pagesEasy Genset Control: OperationdonothearPas encore d'évaluation

- United States Patent (10) Patent No.: US 8,106,570 B2Document20 pagesUnited States Patent (10) Patent No.: US 8,106,570 B2zahra sdeghiniaPas encore d'évaluation

- PG Parts Catalog1Document179 pagesPG Parts Catalog1Olivier ORMANPas encore d'évaluation

- Chapter 2 Structure of AtomsDocument16 pagesChapter 2 Structure of AtomsCherry T CYPas encore d'évaluation

- Power Generation SystemDocument72 pagesPower Generation SystemAbshir Mohamed HajjiPas encore d'évaluation

- Electrical Properties of Materials Mod-1Document18 pagesElectrical Properties of Materials Mod-1Darshan rajPas encore d'évaluation

- DBB ValveDocument6 pagesDBB ValveshyamPas encore d'évaluation

- 6ra 2620 6d v57 1a Z Simoreg d38035 Siemens Manual 02Document18 pages6ra 2620 6d v57 1a Z Simoreg d38035 Siemens Manual 02Stefan IstratescuPas encore d'évaluation

- Caterpillar Product Line 13Document7 pagesCaterpillar Product Line 13GenneraalPas encore d'évaluation

- SteckDocument354 pagesStecknaruto100% (1)

- Model AR Ellipse® Annular Flow Meter PDFDocument2 pagesModel AR Ellipse® Annular Flow Meter PDFjhorlanPas encore d'évaluation

- Mechanics - Fluid Dynamics: K. Suresh Senanayake 1Document2 pagesMechanics - Fluid Dynamics: K. Suresh Senanayake 1mangsureshPas encore d'évaluation