Académique Documents

Professionnel Documents

Culture Documents

Sterile and Non Sterile

Transféré par

Kishore VfçTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sterile and Non Sterile

Transféré par

Kishore VfçDroits d'auteur :

Formats disponibles

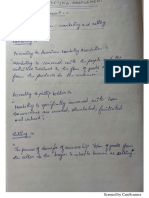

Sterile & Non Sterile Manufacturing Operation Manuals

Manufacturing Documentation

Appropriate details of each process step must be described in chronological order and in sufficient

detail to assure consistency from batch to batch. The equipment to be used must be identified and

any necessary settings specified.

Appropriate environmental requirements for processing must be specified where necessary (e.g.

temperature, humidity, air classification, etc). References to Standard Operating Procedures and

check-lists must be given when applicable. Checks and double-checks to be made must be indicated,

where these are required.

In-process controls, including alert/action/specification limits must be included. Any samples required

must be included. Appropriate reconciliation checks and yield limits for major processing steps must

be specified.

A statement of theoretical weight or measure for major processing steps must be included.

A statement of theoretical yield including the maximum and minimum percentages of theoretical yield

must be included.

The identity of individual major equipment items and lines used must be identified.

Format and Layout:

Sufficient space should be provided where data are to be entered, e.g. starting and finishing times,

material control numbers, equipment settings, process parameter, observations, calculations and

confirming initials.

Space should be provided for documenting the name and batch number of the preceding product

prepared in major pieces of equipment to be entered, and for documenting verification of equipment

cleaning. Alternatively, this information can be recorded in equipment logs, providing that the retention

and disposal of such logs satisfy the requirements given in Section 5.3 - Retention and Disposal.

Read Full Document www.gmpsop.com

Maintenance and Calibration of GMP Critical Item

SOPs must exist which describe the overall calibration and maintenance program. Including:

- Identification of critical items requiring calibration and maintenance

- Establishing calibration and maintenance requirements and review during item

lifecycle.

- Description of the workflow for calibration and maintenance.

- Management of ‘out of tolerance’ conditions and remedial actions

- Requirements for trend reviews (e.g. calibration failures, maintenance frequencies)

- Prevention from use of ‘un-calibrated’ and ‘out of service’ items

- Acceptance of items as suitable for use

- Use of contractor calibration and maintenance providers

- Documentation requirements

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying prohibited. Page 1 of 16

Non Sterile Solid Dosage Drug (Capsule)

Calibration and maintenance activities are key components of the codes of good pharmaceutical

manufacturing practice and therefore must be conducted by staff with appropriate training and will be

the subject of self-inspection programs/audits, as defined in local procedures. Written procedures may

also include details of how calibration and maintenance is conducted in support of other legislation

such as Safety Health and Environment requirements.

Critical items:

Written procedures will describe the processes for review of inventory items (and their function) and

agreeing which are critical and require calibration and maintenance. This must include review of an

inventory of equipment that is prepared during initial qualification of a facility or laboratory as well as

consideration of subsequent changes and additions to facilities, systems and laboratories.

The rationale used for classification of items as critical will be documented in local SOPs. A suitable

rationale for declaring an item as critical is if it has the potential to;

- Affect the safety, quality or efficacy of a product

- Alter the physical, chemical or biological properties of a product,

- And/if testing/certification/maintenance is a local mandatory requirement (e.g.

pressure vessel testing)

Alternative rationales for determining criticality, such the ‘direct impact’ approach described in the

ISPE/GAMP Good Practice Guide: Calibration Management may also be acceptable.

Read Full Document www.gmpsop.com

Retreatment and Blending of API & Formulated Product

The re-treatment of products including rejected or sub-standard product should be by exception only.

Where the batch integrity has been altered retreatment should not be carried out.

If retreatment is used for a majority of batches such processing should be included as part of the

standard manufacturing process.

Continuation of a process step after an in-process control test has shown that the step is incomplete

is considered to be part of the normal process and is not reprocessing.

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying prohibited. Page 2 of 16

Retreatment should only be allowed if the quality of the product will not be adversely affected by the

retreatment, it is carried out in accordance with a defined procedure, and has been authorized by QA

after evaluation of the risks involved, including any possible effect on product shelf life.

Proposals for retreatment of product manufactured at a contractor must be referred to the product

Lead Site (site managing the contract or sponsor) for consideration and written approval prior to

commencement of the retreatment activities.

The need for and extent of the validation requirements of all retreatment procedures should be

carefully evaluated for each case of retreatment and approved by QA. All retreatment procedures that

are intended to be a supplement to, or a part of the established manufacturing process should be

validated by a prospective approach or at a minimum by a concurrent approach.

Retreatment should be carried out according to a written procedure and batch documentation should

provide full traceability of all materials and operations performed.

Out of Specification batches must not be blended for the purpose of meeting specification.

Where blending is carried out blended batches must be traceable back to individual batches and the

blend must be tested for conformance to specification and have expiry or retest life based on the

oldest material used in the blend.

Read Full Document www.gmpsop.com

In-Process Testing, Checks and Sampling

In-process controls should have the ability to identify when corrective actions are needed and control

the performance of processing steps that cause variability in the quality characteristics of products

including intermediates and APIs.

In-process control activities should be based on the Master Formula or the Chemistry Manufacturing

and Control (CMC) Documentation and on local process capability.

Written in-process control instructions must contain information about for example sample size,

sampling frequency, test methods and locally established control limits. Samples must be

representative of the batch.

When possible, established statistical techniques should be applied and where appropriate, the test

methods validated.

The instructions for in-process controls could be given in Batch Records, procedures or in separate

in-process control records. The records must have space for entering and signing test results. All raw

data generated must be maintained with these records.

Qualified production department personnel can perform in-process controls. Sufficient space and

qualified testing equipment should be available for the in-process controls.

Whilst normally in-process controls have associated control limits there may be occasions when

additional testing is conducted to gather additional information and there are no control limits. If such

testing is carried out it must be identified as ‘for information only’ and the purpose of gathering the

data should be clearly understood.

Read Full Document www.gmpsop.com

Management of Returned Goods

Returned goods shall be clearly labelled as such, on receipt at the site and segregated from other

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying prohibited. Page 3 of 16

stock. If a validated computerized storage system is used this segregation does not need to be

physical, unless the returned goods falls under section 5.1.3. Where stock is returned from multiple

sources, the stock from each source should be independently stored, i.e. the stocks should not be

combined to form a batch.

Read Full Document www.gmpsop.com

Receipt Handling and Storage of Starting & Packaging Materials

Care must be taken that only one status is indicated on a container. This can be achieved by sticking

the “Released” or “Rejected” label next to the “Quarantine” label, which should be crossed over. The

labelling system should permit a check of identity on “Quarantine” label against the identity on

“Released” or “Rejected” label to ensure that the right container is released or rejected. All labels

should be stuck on the container body, not on the lid.

An individual assigned this responsibility and based on written instructions should perform the

labelling operation. Read Full Document www.gmpsop.com

Control of Packaging Operation

The activities required to fill the bulk formulated product into primary containers and seal or fit closure.

This includes addition of desiccants, wadding, etc., if contained within the sealed/closed primary pack.

In the case of sterile products, the primary packaging operation is carried out as an integral part of the

manufacturing operation.

In the case of non-sterile products, the primary packing operation may be discontinuous with the

manufacture of the bulk formulated product, and may be done in a different facility/site.

The primary packaging operation may include the addition/attachment of the legal labeling to the

primary container.

Read Full Document www.gmpsop.com

Packaging Control Labelling

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying prohibited. Page 4 of 16

Requirements for Facilities For Sterile and Non-sterile Drug Manufacture

Sterile manufacturing must take place in clean areas. The areas should be classified in accordance

with the regulatory requirements.

All areas must be built and validated to meet these requirements.

The particulate conditions for Grade A should be maintained in the zone immediately surrounding the

product whenever the product or open container is exposed to the environment. It is accepted that it

may not always be possible to demonstrate conformity with particulate standards at the point of fill

when filling is in progress, for example due to the generation of particles and droplets from the

product itself. There should be written justifications for any situation or process steps where this could

apply.

The particulate conditions for the at rest state should normally be achieved in the unmanned state

after a short clean up period of 15 - 20 minutes after completion of operations. This cleanup period

should be validated and periodically monitored.

In some cases, the processing room and the adjacent clean rooms have the same classification.

Maintaining a pressure differential between the processing rooms and the adjacent rooms can provide

beneficial separation.

In order to reach Grade A, B and C the number of air changes should be related to the activity of the

room.

Re-circulation of air within clean areas should not be practiced where the activities are creating dust.

Re-circulation should preferably not be used to re-circulate air from areas where different products are

handled. In cases where re-circulation is practiced the air should pass a filter system of an

appropriate filter efficiency to minimize the potential for cross-contamination.

The following activities performed during sterile manufacturing must be conducted in area classified in

accordance with the tables below.

Read Full Document www.gmpsop.com

Labelling and Packaging of Investigational Medicinal Products and APIs in R&D

There must be documented procedures to ensure that correct packaging materials and labels are

used.

Label operations must be designed to prevent mix-ups. There must be physical or spatial separation

from other unlabelled materials/batches.

Each container of isolated intermediate or API must be labelled as soon as possible during

processing, with at least the following information:

- Batch number

- Product name/code

- Storage conditions, when such information is critical to ensure quality

- Material status (written or encrypted)

Note: Purchased API intermediates should be labelled to include the same information.

If the material is intended to be transferred outside the control of the site’s material management

system, the name and address of the manufacturing site, quantity of contents, special transportation

requirements, if any, and any special legal requirements must be included on the label.

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying prohibited. Page 5 of 16

Intermediate or API containers that are transported outside of the site’s control must be sealed in a

manner such that, if the seal is breached or missing, the recipient will be altered to the possibility that

the contents may have been altered.

For material with expiration or retest dates, these must be included on the label and/or certificate of

analysis.

Packaged or labelled materials must be examined to ensure that that they have the correct label.

This examination must be part of the packaging operation and documented in the production records.

Labelling for APIs intended for use in clinical trials should identify the material as being for

investigational use. The “investigational use” label is not required for commercial API being used for

clinical trials, or for investigational API stored within the own site, which is controlled through an

electronic inventory system.

The applicable guidance given for IMP below should be applied for any pre-printed labeling used for

API.

Read Full Document www.gmpsop.com

Principles and Responsibilities for the Management of Change in Operations

All manufacturing sites shall establish a formal, documented system that evaluates the effectiveness

of all changes proposed.

The impact of the change on the validation and registration status must be assessed. Risk

management must be a part of this process.

The local QA unit must be involved in reviewing and approving all changes proposed.

The implementation procedure for all changes must ensure that regulatory and GMP compliance is

maintained.

The operation of the system shall ensure adequate control and monitoring of change projects.

The system shall be designed to ensure the complete and accurate recording of the decisions to

approve or reject a change and the history of the change from inception to implementation.

The system shall ensure that relevant documentation is updated accordingly.

All sites shall appoint a Site Change Manager with clearly defined roles and responsibilities.

All site should appoint a lead team which is responsible for the contractors are ensuring that

appropriate links are established and maintained between the contractor and coordinated MCM

process.

Read Full Document www.gmpsop.com

Alternatives Methods to Formaldehyde Fogging of Clean Rooms

There are regulatory expectations for the periodic sanitization of clean rooms to ensure conformance

to expected environmental bioburden levels though none of these explicitly require the use of fogging

(2), (3), (4).

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying prohibited. Page 6 of 16

For biological facilities where viral contamination is a concern, there may be regulatory reasons to

sanitize via fogging with some frequency as both Annex 2 of the European Commission and the

World Health Organization’s GMPs for biological products mention the terms “shall” and “should” with

regards to fumigation (4), (5).

Aseptic Area Cleaning

Many non-biologics facilities successfully meet the general regulatory expectations for sanitization

through the use of only liquid sanitizers, disinfectants, and sterilants. However, fogging can be very

effective and may offer advantages over the use of liquid sanitizers in certain situations (e.g. very high

ceilings, inaccessible surfaces that require sanitization, etc).

Fortunately there are other chemicals that can be used to fog clean rooms. Although there are others,

three potential replacement options are listed below along with some advantages and disadvantages

of each. It should be noted that what is considered an advantage is highly dependent on the specific

application. These chemicals are all considered sterilants under certain conditions though the

concentration of the agent that is required to achieve destruction of bacterial endospores varies

greatly. With proper design and validation, all can have good distribution throughout the clean room

on a consistent basis. Labor costs are still typically lower than with liquid sanitizers because the

chemical can be distributed by airflow instead of by personnel.

Read Full Document www.gmpsop.com

Cleaning and Sterilization Practice of Aseptic Manufacturing Equipment

Preventive Maintenance of CIP/SIP Systems should include, and not be limited to, the following:

• Calibration of Instruments and Elements (I/Es);

• Verification of cycle parameters (e.g., length of each cycle, amount of

CIP chemicals used during the various cycles, pH);

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying prohibited. Page 7 of 16

• Inspection of the CIP/SIP system for rusting, pitting, or corrosion; and Passivation, as

required.

Read Full Document www.gmpsop.com

Sterile Product-Package and Container Integrity Testing

Challenged Containers that Show Microbial Growth Upon Microbial Ingress Testing should be

inspected to determine whether defects in the container closure seal permitted microbial ingress. All

defects observed should be described and documented. An investigation should be conducted to

determine the cause of the contamination, including a comparison of the contaminant organism(s) to

the challenge organism.

Non-Microbial Methods for Container Closure Integrity Testing should be based on validated studies

that correlate the test method to microbial ingress testing. Non-microbial integrity tests should be used

during routine processing, at a minimum:

• During equipment set-up;

• As an In-Process Control (IPC) test;

• On representative samples of the finished batch/lot; and

• On stability samples during the shelf life and at lot expiration date.

Read Full Document www.gmpsop.com

Microbial Bioburden and Quality Control of Oral Solid Dosage Forms in Pharmaceuticals

The most common microbial hazards that can jeopardize product quality of solid oral dosage forms

can often be attributed to contaminated raw materials. Microbial hazards may be introduced into a

manufacturing process due to the improper sanitary design of the manufacturing equipment;

especially equipment used for aqueous processing steps (i.e., wet granulation or tablet coating).

For example, microbial contamination can arise from entrapped water or product residues that remain

hidden from procedural cleaning processes due to threaded pipe fittings, non-sanitary valves, piping

dead legs, non-sloping pipes, equipment crevices, recessed access ports, bottom discharge valves,

and pocket flow meters. Inadequate equipment maintenance may also serve as a potential microbial

hazard. For example, misaligned, damaged, or over torqued gaskets between piping connections may

harbor a reservoir of trapped microorganisms.

Read Full Document www.gmpsop.com

Defining and Equating Worst Case Conditions for Aseptic Process Simulations

First it is important to note that the definition of “worst case” does not mean execution of a media fill at

processing failure points where media fill failure would likely occur. Instead, it is the expectation that

“worst-case” conditions within the media fill are designed to be performed at the normal operating

limits of the production process. Also, “worst-case” conditions should be considered and defined

within the media fill simulation program for product holding times, process filling times, filling line

speed, container sizes, interventions and personnel.

Members within the regulatory community agree that “media fill studies should closely simulate

aseptic manufacturing operations incorporating, as appropriate, worst-case activities and conditions

that provide a challenge to aseptic operations”. Practical ways to help determine appropriate process

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying prohibited. Page 8 of 16

“worst-case” conditions include reviewing routine production batch records as well as observations

performed as part of routine aseptic manufacturing operations.

A preferred “worst-case” application would be to hold the bulk for a timethat just exceeds the

maximum time for holding product during routine manufacturing operations. The holding time

simulation for holding vessels containing sterilized product “should be covered by a process

simulation test on a regular basis unless a validated, pressure hold or vacuum hold test is routinely

performed”.

Read Full Document www.gmpsop.com

How Does Gamma Radiation Sterilization Works

Establishment of a Sterilization Dose Using AAMI Method 1 for a Single Production Batch includes

the following steps:

a. Determine the average indigenous bioburden of the API, drug product, medical

device, or non-product item using ten (10) randomly collected samples;

b. Determine the verification dose for a Sterility Assurance Level (SAL) of 10-2 from an

AAMI table using the average bioburden (see ANSI/AAMI/ISO 11137-2:2006);

c. Verify that the verification dose does not exceed the established maximum

sterilization dose limit;

d. Irradiate one hundred (100) samples of the product batch at the verification dose;

e. Perform a sterility test on each of the one hundred (100) samples

f. If there are no more than two (2) samples with positive sterility tests, then accept the

verification dose; and

g. Using the AAMI table, determine the sterilization dose for the required SAL (e.g., 10-

6) based on the average bioburden for the batch.

Read Full Document www.gmpsop.com

Bottle Filling at Pharmaceuticals Production

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying prohibited. Page 9 of 16

Good Practices of Loading and Unloading Multiple Lyophilizers From a Common Corridor

The FDA, in its Guidance for Industry: Sterile Products Produced by Aseptic Processing – Current

Good Manufacturing Practice requires that “ … partially closed sterile product should be transferred

only in critical areas. Facility design should ensure that the area between a filling line and the

lyophilizer provide for Class 100 (ISO 5) protection. Transport and loading procedures should afford

the same protection.”

The FDA set similar requirements in their earlier Guide for Inspection of Lyophilization of Parenterals.

Here, FDA stated “The transfer and handling, such as loading of the lyophilizer, should take place

under primary barriers, such as the laminar flow hoods under which the vials were filled. Validation of

this handling should also include the use of media fills.”

The EC also requires that “Prior to completion of stoppering, transfer of partially closed containers, as

used in freeze drying should be done either in a grade A environment with a grade B background or in

sealed transfer trays in a grade B environment.

No requirements are stated for unloading the dryers. Here, with internal stoppering, the stoppers have

been fully seated within the protection of the closed dryer. No requirements are stated for separation

(in time or space) of loading and unloading activities or between multiple dryers.

Read Full Document www.gmpsop.com

Trending of Environmental Monitoring and Preventative Actions

When Environmental Monitoring data is analyzed with appropriate statistical and qualitative

techniques, knowledge of the environment becomes more significant and decisions based on this

knowledge easier to defend. The easiest form of trending is to consider a certain number of alert level

excursions equivalent to an action level excursion. This type of trending is good for quickly spotting an

adverse situation over a relatively short timeframe (e.g. weekly trending).

Commonly, three alert level excursions in ten consecutive samples are sufficient to initiate an

investigation. However, the nature of the operations conducted at the particular monitoring point

should be considered when deciding on a number.

This approach can be applied to a single sampling point, or more conservatively, to an entire air

classification within a production suite. While alert level excursions will show adverse trends in the

short term, more advanced statistical treatment is required for longer-term data analysis.

When deciding on a statistical tool for use with Environmental Monitoring trending, it is important to

keep two things in mind. First, make sure the statistical tools are appropriate for their intended use.

Read Full Document www.gmpsop.com

Integrity Assurance of Packaging Materials for Sterile Drug Product and Medical Devices

In-Process Controls used to verify packaging system integrity include and are not limited to, the

following:

Torque monitors for screw-capping equipment;

Headspace analysis for products requiring inert gas headspace; and

Visual inspection of seals.

In-Process Control Sampling and Test Procedures should include and not be limited to:

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying prohibited. Page 10 of 16

Number of samples to be tested per batch/lot;

Test Methods (TM);

Test equipment;

Acceptance criteria; and

Retest criteria and methods.

Read Full Document www.gmpsop.com

Effective Control & Prevention of Cross Contamination in Pharmaceutical Manufacturing

Precautions should be established and maintained to ensure that cross contamination at product

exposure points (e.g., open hatch charging or sampling, packout, heel scraping) is prevented from

overhead equipment and piping. Consideration should be given to such precautions, including, and

are not limited to, the following items:

Booth or canopy over tank hatch openings;

Isolators (e.g., glove boxes);

SOPs defining conditions under which vessels can be opened;

Periodic inspection of overhead piping and ducts to ensure that there are no leaks,

condensation, flaking of paint and/or insulation that might fall into vessel openings;

Drip pans under HVAC units or cold surfaces to collect or contain condensation; and

Facilities designed with minimal overhead ducts and piping.

Read Full Document www.gmpsop.com

Effective Control & Prevention of Fungal Contamination in Tablets Containing Drug Products

The microbial quality of the raw materials and APIs directly impact the microbial quality of the final

tablet product. Fungal populations that may be found in these raw materials can contaminate the final

tablet product. This is because the manufacturing of most tablets does not include processing steps

that can eliminate the indigenous bioburden found originally in the raw material.

Based on the materials contribution to the final drug product and their ability to be validated for their

microbial attributes, it may be necessary to test RMs and API on a routine or periodic basis.

Therefore, it is recommended that raw materials and API’s used in the manufacturing of the tablet be

evaluated for their contribution to Total Yeast and Molds in tablets. This includes the testing of APIs

that are manufactured and/or milled at one site (internal or external) and then transferred to the tablet-

manufacturing site.

Read Full Document www.gmpsop.com

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying prohibited. Page 11 of 16

Cleaning & Sanitation

Managing Rotation of Sanitants in a Routine Sanitization Program

Of primary importance in any sanitization program is the proper selection of a chemical agent to

reduce microbial bioburden. Selection should be based upon the number and specific microorganisms

present in the area where the sanitizing agent is to be routinely applied.

In addition, effective cleaning should precede any application of sanitant. The condition of the

surfaces that are to be sanitized require proper conditioning through cleaning, since deposits can

prevent proper sanitizer contact with target microorganisms. Furthermore, residues on the surface to

be sanitized have been found to inactivate or reduce the effectiveness of some types of sanitizers

(e.g. hypochlorites) rendering the sanitization procedure ineffective”.

Read Full Document www.gmpsop.com

Validating Sterilization and Depyrogenation of Pharmaceutical Direct Contact Equipments

For Steam Sterilization Processes, biological indicators are available in four (4) forms:

• Spores added to a carrier (e.g., a disk or strip of filter paper, glass, plastic or other

material) and packaged to maintain the integrity and viability of the inoculated carrier

(preferred and most commonly used in non-product sterilization validation);

• Self-contained packaged indicator that includes the culture medium separated from the

biological indicators (e.g., a paper strip surrounding a sealed ampoule containing culture

medium that is activated after exposure);

• Self-contained packaged indicator that includes the spores suspended in the culture

medium in a sealed ampoule (most often used for submersion in liquids); and

• Spore suspension added to representative units of the product, simulated product, or onto

non-product surfaces (e.g., closures). Such suspensions are most often used for product

terminal sterilization validation.

Read Full Document www.gmpsop.com

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying prohibited. Page 12 of 16

Managing Unplanned Power Outage Time Limit and Recovery Within the Clean room Area

Determination of a time limit consists of extensive environmental monitoring after the APA power has

been interrupted and the critical air handling systems ceases to function. This may also includes

interruptions to the air handling systems of areas adjacent to the APA that would be affected by the

interruption.

The essential monitors to include in the determination are total airborne non-viable particulates, viable

quantitative (active) air and/or viable passive air (settling plates), and pressure differentials. Additional

parameters such as temperature and humidity should be tested if they are critical to the process.

The Non-viable monitors and pressure differential monitors are the most sensitive indicators for

detecting any changes in the quality of the APA environment. The state of microbiological control in

an APA can be directly correlated from these monitors.

Read Full Document www.gmpsop.com

Management of Sterilized Goggles Within the Aseptic (Clean Room) Processing Area

Goggles can be obtained sterile and ready-to-use as disposable or re-sterilizable models. Sources

have been identified that can supply sterilized goggles to virtually any part of the world.

While disposable goggles may be more costly and generate excess waste, this practice eliminates the

need for tracking the sterilization history of the goggles and verification or maintenance of a cleaning

and re-sterilization program. At least two disposable models are available. These goggles are

available triple wrapped, sterilized by ethylene oxide or gamma irradiation. Validation documentation

of the sterilization of these goggles needs to be reviewed and is available from certified vendors.

Read Full Document www.gmpsop.com

Management of Non-Sterile Active Pharmaceutical Ingredient (API) Manufacturing Area

The risk assessment may be conducted on a product or facility-centric basis. This risk assessment

should include consideration of at least the following:

- Type of API manufactured (e.g., small molecule API via chemical synthesis or classical

fermentation);

- For APIs produced by chemical synthesis or classical fermentation, the risk assessment

should be conducted to include the step where the API molecule is formed and on each

of the subsequent step(s) of manufacture, including an evaluation on whether or not

there is further purification of the API;

- For APIs exposed to the environment, the subsequent Drug Product dosage form (e.g.

oral, parenteral, topical, inhalant) should be considered during the risk assessment. For

APIs subsequently used in multiple dosage forms, it is recommended that the most

conservative dosage form with respect to patient safety (e.g., parenteral) is considered in

the risk assessment;

Read Full Document www.gmpsop.com

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying prohibited. Page 13 of 16

Batch Production Record

Water Activity Fundamentals and Applications in Pharmaceutical Operations

Water activity is defined as the ratio of product vapour pressure to pure water vapour pressure. It is a

measure of the water available for chemical or microbiological activity within a product. It is not a

measure of the total water content of an item, as water can be chemically bound and not be available

for use. Its values are typically expressed as a decimal value and can range from 0.0 (completely dry)

up to 1.0 (pure water).

Though the principles of water activity have been used for centuries (e.g. salting, drying,

mummification), its use by the FDA occurred in the 1980’s when water activity testing was added to

existing strategies for microbiological control in food products.

Water activity is significant to the pharmaceutical industry in that it affects the quality of ingredients

and finished product through their chemical stability, a reduced need for chemical preservatives, and

a potential reduction in the need for microbial limits testing.

Microbial growth requires water. Water dissolves solutes within a viable cell and is required for

metabolic function. When an water activity value is associated with a micro-organism it serves as an

indication of potential metabolic activity. While organism proliferation ceases below certain water

activity levels, some species have the ability to adapt slightly and continue to grow at levels below

their optimum range.

Read Full Document www.gmpsop.com

Container / Closure & Environmental Assessment Drug Products of Shipping Processes

A documented risk assessment (for more robust products) or risk assessment plus completed

shipping quality study (for more sensitive products) will provide scientifically-based justification that

the risks have been considered and that, when warranted, risks posed from shipping the drug

products have been appropriately mitigated. An additional benefit provided by this documented

information is that local receipt testing of the drug products by the receiving site, should not be

necessary from a quality control or quality assurance perspective.

Read Full Document www.gmpsop.com

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying prohibited. Page 14 of 16

Cold Chain Management Practice for Bio and Pharmaceutical Materials

Biopharmaceuticals products are generally derived from living material: human, animal or

microorganisms, are complex in structure, and are usually not fully characterized. Many forms of the

same molecule collectively define the drug “heterogeneity profile”.

Unlike small molecular weight drugs, which have a well-defined structure and consistent purity,

biopharmaceuticals are of large molecular size and structural complexity, and display consistent

heterogeneity. Traditional small molecule drug products usually consist of pure chemical substances

that are easily analysed after manufacture.

Biopharmaceutical products are often defined by their manufacturing processes. Changes in the

manufacturing process, equipment or facilities could result in changes to the biological product itself

and potentially require additional clinical studies to demonstrate the product's safety, identity, purity

and potency.

Biopharmaceuticals are further characterized by their high susceptibility to irreversible degradation

and exceptionally high financial value per unit. Temperature, agitation and exposure to light are

among the conditions known to degrade protein and oligonucleotide based materials.

A risk assessment should be conducted that examine potential conditions under which the integrity of

each biopharmaceutical materials is known to be compromised. Among the points to consider:

temperature, Exposure to CO2, Agitation/Vibration, Pressure Cycles etc.

Read Full Document www.gmpsop.com

Clean Process Vial Capping Operations in Pharmaceuticals

The routine monitoring program may be designed to monitor both the physical parameters of the air

handler and empirical data (i.e. non-viable particulates) in order to provide information on the air

source to the capping operation since this ensures that the monitoring is focused on verification of air

quality being supplied to the capping process versus the process itself.

Read Full Document www.gmpsop.com

Recovered and Recycled Solvents from the Active Pharmaceutical Ingredients Manufacturing

Validated Solvent Recovery Processes that undergo major changes to incoming used solvent streams

(e.g., those requiring a new solvent recovery process, or a stream that does not fit established

criteria) require revalidation. In addition, major changes to equipment, facility, procedures or the

solvent recovery process may require revalidation. Minor changes may not require revalidation but

may require a documented, expanded test program or other formal evaluation.

Read Full Document www.gmpsop.com

Metal Detection Systems for Pharmaceuticals Preparation

All Metal Detectors used in Manufacturing Operations (including, but not limited to, encapsulation and

tabletting) should be qualified and subsequently set-up and operated such that the detectors will, 100

percent of the time, detect and isolate spherical 0.5mm ferrous, spherical 0.5mm non-ferrous, and

spherical 0.8mm stainless steel metal embedded in discs or cylinder carriers that are used to

challenge the system.

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying prohibited. Page 15 of 16

All Metal Detectors used in Packaging Operations should be qualified and subsequently set-up and

operated such that the detectors will, 100 percent of the time, detect and isolate spherical 1.0mm

ferrous, spherical 1.0mm non-ferrous, and spherical 1.5mm stainless steel metal embedded in discs

or cylinder carriers that are used to challenge the system.

Read Full Document www.gmpsop.com

Storage, Handling, Cleaning and Maintenance of Hose in Pharmaceuticals

GMP sites should have procedures defining the use, specification, storage, handling, cleaning and

maintenance of hoses used in cleaning and production of intermediates and APIs in accordance with

cGMP guidelines. Flexible hoses should be adequately identified, maintained, and cleaned.

Section 5.2 - Q7A, emphasizes written procedures should be established for cleaning equipment and

its subsequent release for use in manufacture of intermediates and APIs. In addition, sites should

have standardized hose management practices, including management of change, with written

procedures that identify factors to be considered and evaluated.

Read Full Document www.gmpsop.com

In-Process Control Chart

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying prohibited. Page 16 of 16

Vous aimerez peut-être aussi

- Manual 056 Environmental MonitoringDocument4 pagesManual 056 Environmental MonitoringJapsja Ja100% (1)

- Calibration and Metrology PDFDocument10 pagesCalibration and Metrology PDFMano NegraPas encore d'évaluation

- Working Party On Control of Medicines and InspectionsDocument11 pagesWorking Party On Control of Medicines and InspectionsStrazdas100% (2)

- Sterlization ProtocolsDocument10 pagesSterlization ProtocolsSarathchandran BalachandranPas encore d'évaluation

- A Final Floor Show For Bugs (Sandle)Document4 pagesA Final Floor Show For Bugs (Sandle)Tim Sandle100% (1)

- GMP FinalDocument37 pagesGMP FinalekramPas encore d'évaluation

- Blood Bags (JTP)Document7 pagesBlood Bags (JTP)arthisoundaryaPas encore d'évaluation

- Clean RoomDocument16 pagesClean RoomApoloTrevinoPas encore d'évaluation

- Protocol PQDX 241 v4 Capillary BloodDocument18 pagesProtocol PQDX 241 v4 Capillary Bloodludi100% (1)

- Product Catalogue Biological Indicators, Process Challenge Devices and Accessories PDFDocument24 pagesProduct Catalogue Biological Indicators, Process Challenge Devices and Accessories PDFscribdddcPas encore d'évaluation

- OriginalDocument32 pagesOriginalAlexandra MilenkovicPas encore d'évaluation

- CTD CMC-Information-Human-Gene-Therapy-IND-Applications - Jan - 2020Document56 pagesCTD CMC-Information-Human-Gene-Therapy-IND-Applications - Jan - 2020Shiraz KhanPas encore d'évaluation

- ПЕТ Центар- Производство и Контрола На Квалитет- Е. ЈанеевиќDocument30 pagesПЕТ Центар- Производство и Контрола На Квалитет- Е. ЈанеевиќEmilija Janevik100% (1)

- Aka GMP Audit FormDocument8 pagesAka GMP Audit FormAlpian BosixPas encore d'évaluation

- Recovery Factor Determination in Cleaning ValidationDocument1 pageRecovery Factor Determination in Cleaning ValidationPrince MoniPas encore d'évaluation

- Adopting The Product Lifecycle ApproachDocument4 pagesAdopting The Product Lifecycle Approach刘朝阳Pas encore d'évaluation

- F Ex of e Nadine Hydrochloride Master Batch RecordDocument18 pagesF Ex of e Nadine Hydrochloride Master Batch RecordKrisnanti Angela SariPas encore d'évaluation

- CreatingaCleaningValidationPlan TOCDocument1 pageCreatingaCleaningValidationPlan TOCOnichan21Pas encore d'évaluation

- Guidlines On Recall by CDSCODocument28 pagesGuidlines On Recall by CDSCONAVNEET BAGGA100% (1)

- Ensuring The Air Suplly Rate To A Cleanroom Complies With The Eu GGMP and Iso 14644-3 Recovery Rate RequirementsDocument3 pagesEnsuring The Air Suplly Rate To A Cleanroom Complies With The Eu GGMP and Iso 14644-3 Recovery Rate RequirementsluisPas encore d'évaluation

- Guidance For Industry - ATP - PremisesDocument13 pagesGuidance For Industry - ATP - PremisesFISHPas encore d'évaluation

- Quality Control Analysis of Imported FertilizersDocument14 pagesQuality Control Analysis of Imported FertilizersMostafa FawzyPas encore d'évaluation

- Canada Health Auth Draft Validation Guide GUI 0029 en For Comment 20 Nov 2018 1Document34 pagesCanada Health Auth Draft Validation Guide GUI 0029 en For Comment 20 Nov 2018 1atulbsPas encore d'évaluation

- CETA Compounding Isolator Testing Guide CAG-002-2006 Revised December 8, 2008Document20 pagesCETA Compounding Isolator Testing Guide CAG-002-2006 Revised December 8, 2008Vidya Dhari100% (2)

- AEFIDocument35 pagesAEFIMisha ModiPas encore d'évaluation

- Biocontamination Control for Pharmaceuticals and HealthcareD'EverandBiocontamination Control for Pharmaceuticals and HealthcareÉvaluation : 5 sur 5 étoiles5/5 (1)

- Cleaning Validation Approach 1Document19 pagesCleaning Validation Approach 1Dharmesh PatelPas encore d'évaluation

- Limites Microbianos Por PoissonDocument10 pagesLimites Microbianos Por PoissonJavier GalvanPas encore d'évaluation

- Airlock SystemDocument15 pagesAirlock SystemKhalidaFaseehPas encore d'évaluation

- Aseptic Media FillDocument2 pagesAseptic Media Fillwah100% (1)

- FDA - Quality Issues For Clinical Trial MaterialsDocument37 pagesFDA - Quality Issues For Clinical Trial Materialscokekorea100% (1)

- Quality by Design: Review ArticleDocument13 pagesQuality by Design: Review ArticleIjupbs IjupbsPas encore d'évaluation

- 3 2 - MicrobiologicalQualityControl 1Document37 pages3 2 - MicrobiologicalQualityControl 1Tong ChanPas encore d'évaluation

- Usp 797GCDocument61 pagesUsp 797GCAwni1989Pas encore d'évaluation

- Why The Swab Matters in Cleaning ValidationDocument3 pagesWhy The Swab Matters in Cleaning ValidationYehuda Rahmanu PuteraPas encore d'évaluation

- White Paper 10 Problems With Pharma Plant MaintenanceDocument9 pagesWhite Paper 10 Problems With Pharma Plant MaintenanceAlok Kumar SharmaPas encore d'évaluation

- 2.6.14. Bacterial EndotoxinsDocument8 pages2.6.14. Bacterial EndotoxinsCeangoPas encore d'évaluation

- EDQM PAT Proceedings, 2004Document141 pagesEDQM PAT Proceedings, 2004huynhhaichauchauPas encore d'évaluation

- Blow Fill Seal BFS Technology GuidanceDocument12 pagesBlow Fill Seal BFS Technology Guidanceomurbicer100% (2)

- Basic Principles of GMP: GMP For Sterile Pharmaceutical ProductsDocument19 pagesBasic Principles of GMP: GMP For Sterile Pharmaceutical Productsabhijit_gothoskar6039Pas encore d'évaluation

- 11 Frequently Asked Questions About ISO 11607Document4 pages11 Frequently Asked Questions About ISO 11607Billy Sadhu SharmaPas encore d'évaluation

- GMP BasicsDocument4 pagesGMP BasicsMiranda FigueroaPas encore d'évaluation

- What Is Disinfectant ValidationDocument4 pagesWhat Is Disinfectant Validationrouss1906Pas encore d'évaluation

- Aseptic Technique Sterile Compounding and IVDocument78 pagesAseptic Technique Sterile Compounding and IVKarren ReyesPas encore d'évaluation

- Transport of CellsDocument20 pagesTransport of CellsshneetsPas encore d'évaluation

- Control of Component, Containers and ClosuresDocument56 pagesControl of Component, Containers and ClosuresAbdul Nadeem100% (1)

- Environmental Monitoring Risk AssessmentDocument22 pagesEnvironmental Monitoring Risk AssessmentMarcelo CarvalhoPas encore d'évaluation

- Tier 1 CVSDocument23 pagesTier 1 CVSCHETHAN K SPas encore d'évaluation

- White Paper Tga Audit ReadinessDocument10 pagesWhite Paper Tga Audit ReadinessFaraz Haider100% (1)

- Guide To GMP For Medicinal Products (PIC/S)Document31 pagesGuide To GMP For Medicinal Products (PIC/S)Tumma RamaraoPas encore d'évaluation

- FOB2-3 TS - Technical Manual - Section 2 - Installation SpecificationsDocument10 pagesFOB2-3 TS - Technical Manual - Section 2 - Installation SpecificationsmaghraouiPas encore d'évaluation

- FDA - Level 2 Guidance - Records and ReportsDocument9 pagesFDA - Level 2 Guidance - Records and ReportsaabbPas encore d'évaluation

- Justification of LimitsDocument6 pagesJustification of LimitsRulli SulaemanPas encore d'évaluation

- Validation ICH Q2 1672933932Document45 pagesValidation ICH Q2 1672933932Muqeet76Pas encore d'évaluation

- Environmental Control For Parenteral Production PDFDocument11 pagesEnvironmental Control For Parenteral Production PDFNaffeesuddin Skd100% (1)

- Validation of Sterilization ProcessesDocument3 pagesValidation of Sterilization ProcessesNovitra DewiPas encore d'évaluation

- Contamination Control in Pharmaceutical FaclityDocument3 pagesContamination Control in Pharmaceutical FaclityAnkush PandeyPas encore d'évaluation

- Production of Plasma Proteins for Therapeutic UseD'EverandProduction of Plasma Proteins for Therapeutic UseÉvaluation : 3 sur 5 étoiles3/5 (5)

- Marketing ManagementDocument21 pagesMarketing ManagementKishore VfçPas encore d'évaluation

- Unit VI Standard CostingDocument1 pageUnit VI Standard CostingKishore VfçPas encore d'évaluation

- Unit VI Standard CostingDocument1 pageUnit VI Standard CostingKishore VfçPas encore d'évaluation

- Reactor Design Guide1Document27 pagesReactor Design Guide1Chau MaiPas encore d'évaluation

- Jar TestingDocument4 pagesJar TestingSugumar Panneer SelvamPas encore d'évaluation

- Design Equation For Batch:: V R DX N TDocument4 pagesDesign Equation For Batch:: V R DX N TKishore VfçPas encore d'évaluation

- TPDocument18 pagesTPKishore VfçPas encore d'évaluation

- 2022-03-24 ITP For Fabrication and Erection of StructuralDocument7 pages2022-03-24 ITP For Fabrication and Erection of StructuraljaymarPas encore d'évaluation

- PDS Syncade RADocument6 pagesPDS Syncade RAKeith userPas encore d'évaluation

- VMM User Guide PDFDocument1 512 pagesVMM User Guide PDFsvenka3Pas encore d'évaluation

- Overview of EccsDocument57 pagesOverview of EccsLuisManuelCamachoPas encore d'évaluation

- Req Specification ACDocument5 pagesReq Specification ACen ziaPas encore d'évaluation

- A WHO GuideDocument100 pagesA WHO Guidej.k.kumar92% (13)

- AS9100 Mandatory RecordsDocument3 pagesAS9100 Mandatory Recordsocardenas9160Pas encore d'évaluation

- EPRI Tr-017218-R1 CGD SamplingDocument99 pagesEPRI Tr-017218-R1 CGD Samplingwallacebm0% (1)

- GAMP FR PP20201001 001 v0100EN PDFDocument5 pagesGAMP FR PP20201001 001 v0100EN PDFHarish GopinathPas encore d'évaluation

- Validation of HVAC SystemsDocument6 pagesValidation of HVAC Systemsnavas1972Pas encore d'évaluation

- QC Surveillance Report: As Per P.OrderDocument3 pagesQC Surveillance Report: As Per P.OrderRahul MoottolikandyPas encore d'évaluation

- 2015-10 Annex15Document125 pages2015-10 Annex15alejandromfunes1749Pas encore d'évaluation

- WWW - Anabin.de: Continue With Step 2Document1 pageWWW - Anabin.de: Continue With Step 2valluri hitendraPas encore d'évaluation

- Commissioning of A PLCDocument10 pagesCommissioning of A PLCTahir DonPas encore d'évaluation

- 0015 - Planning Using The Project Planning Matrix (PPM) - Method PDFDocument11 pages0015 - Planning Using The Project Planning Matrix (PPM) - Method PDFrohmatul ummahPas encore d'évaluation

- Bsi MD MDR Best Practice Documentation SubmissionsDocument29 pagesBsi MD MDR Best Practice Documentation SubmissionsMichelle Kozmik JirakPas encore d'évaluation

- 1 SMF 2023Document37 pages1 SMF 2023Tareq Al MahmudPas encore d'évaluation

- MEDICALDEVICEguidlinesfor UAEDocument31 pagesMEDICALDEVICEguidlinesfor UAEjaberjoumana9683100% (1)

- USP-Lifecycle Management of Analytical ProceduresDocument15 pagesUSP-Lifecycle Management of Analytical ProceduresNur AcarPas encore d'évaluation

- Aoci Volume 2Document393 pagesAoci Volume 2hemkumar DahalPas encore d'évaluation

- Quality Manual TemplateDocument39 pagesQuality Manual Templaterose_almontePas encore d'évaluation

- Global - Manual - Issue - 6 14001 9001Document37 pagesGlobal - Manual - Issue - 6 14001 9001kishore2648Pas encore d'évaluation

- Pass Through CharacteristicsDocument10 pagesPass Through CharacteristicsmirosekPas encore d'évaluation

- En 13977 2011Document46 pagesEn 13977 2011Елена ВолоховаPas encore d'évaluation

- En 10084 DIN Case Hardening Steels Technical Delivery ConditionsDocument39 pagesEn 10084 DIN Case Hardening Steels Technical Delivery ConditionsAlessandroAleotti100% (1)

- Verification of Safety of Machines According To IEC/EN 60204 Edition 5Document28 pagesVerification of Safety of Machines According To IEC/EN 60204 Edition 5Rosa TipactiPas encore d'évaluation

- Manual Quality Management System en 72626Document31 pagesManual Quality Management System en 72626Stephen Koko100% (1)

- Standard Commissioning Procedure For Exhaust Air Heat Recovery SystemsDocument14 pagesStandard Commissioning Procedure For Exhaust Air Heat Recovery SystemsAbdul Mohid SheikhPas encore d'évaluation

- Quality Plan Power Transformers Manufacturing Customer Sidor Ca Project Power Transformers For r5 Substation Enlargement - CompressDocument28 pagesQuality Plan Power Transformers Manufacturing Customer Sidor Ca Project Power Transformers For r5 Substation Enlargement - CompresssnowfallPas encore d'évaluation

- QA and QC PlanDocument84 pagesQA and QC PlanReehan Aslam100% (2)