Académique Documents

Professionnel Documents

Culture Documents

Troubleshooting the 41TE Transmission in 2003-Later Caravans

Transféré par

Autof Ferreira0 évaluation0% ont trouvé ce document utile (0 vote)

25 vues4 pagesThis document provides troubleshooting steps for electrical problems on 2003-and-later Dodge Caravans with a 41TE transmission. It identifies 4 types of problems: 1) PCM communication issues, 2) input sensor problems, 3) solenoid problems, and 4) incorrect gear ratio or slipping transmission clutch unit issues. Testing procedures are outlined to check the transmission control module communication, input sensors like speed and position sensors, pressure switch circuits, and transmission solenoid pack. Proper voltage testing and an understanding of electrical systems is required to accurately diagnose transmission problems.

Description originale:

chrysler2007

Titre original

chrysler2007_08_30

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document provides troubleshooting steps for electrical problems on 2003-and-later Dodge Caravans with a 41TE transmission. It identifies 4 types of problems: 1) PCM communication issues, 2) input sensor problems, 3) solenoid problems, and 4) incorrect gear ratio or slipping transmission clutch unit issues. Testing procedures are outlined to check the transmission control module communication, input sensors like speed and position sensors, pressure switch circuits, and transmission solenoid pack. Proper voltage testing and an understanding of electrical systems is required to accurately diagnose transmission problems.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

25 vues4 pagesTroubleshooting the 41TE Transmission in 2003-Later Caravans

Transféré par

Autof FerreiraThis document provides troubleshooting steps for electrical problems on 2003-and-later Dodge Caravans with a 41TE transmission. It identifies 4 types of problems: 1) PCM communication issues, 2) input sensor problems, 3) solenoid problems, and 4) incorrect gear ratio or slipping transmission clutch unit issues. Testing procedures are outlined to check the transmission control module communication, input sensors like speed and position sensors, pressure switch circuits, and transmission solenoid pack. Proper voltage testing and an understanding of electrical systems is required to accurately diagnose transmission problems.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

Troubleshooting

the 604 (41TE)

by David Skora

O ver the years, it’s become

obvious that the existing trou-

bleshooting procedures won’t

solve all of its electrical problems. This

article will help you troubleshoot the

Type 1 Problems:

TCM and TCM

Communications

These problems include no codes,

the PCM. The other signal is called the

Serial Communication (SCI) which is

dedicated to TCM data. To check for PCI

communication, check for varying volt-

age at pin 38 of the C1 connector. With

difficult problems on 2003-and-later no communication, or TCM codes scan tool connected and engine running,

Caravans with the 41TE transmission. P0604, P0605, P0613, P1652, P1687, voltage should be between zero and 7

These vehicles now use the PCM to P1694 or P1793. volts. If data stream activity appears to

control the transmission. If you can’t communicate with the be present, you scan tool or software

Before you dig into the comput- TCM: may not be compatible with the PCM.

er system, always start with the basic • Erase all trouble codes from other To check the SCI data stream, con-

checks for connections, grounds, and modules. nect a scan tool and have the engine

so on. • Check pin 29 of the C1 connector. running. The voltage at pin 27 of the C1

• The battery must be fully charged; (Figure 1) connector should toggle between zero

12.45 minimum rest voltage. • Check all grounds and key-on volt- and 5 volts (Figure 2). If the circuits

• Some tests require testing with live age pins at all PCM connectors. don’t work as described, the PCM may

voltage. • Verify that the crank (start) signal at have a problem. For more information

• Some tests require you check the pin 30 of the C1 connector works as on communication problems, see the

current flow in a circuit. described in the 41TE Terminal ID 2007 seminar manual.

• Improper testing could damage the and Voltage charts. (Figure 1)

vehicle or your meter. Type 2 Problems:

If any terminal is out of range, dis- Input Signals

To begin troubleshooting, identify connect the PCM and retest all battery These problems are input sen-

which area the problem falls into. and key-on voltage circuits at the PCM. sor codes, such as TSS, OSS, pressure

Type 1: These are codes related to the If the circuits check out okay with the switches, gear select, crank sensor, TPS

PCM. There are no TCM codes, and PCM disconnected, the PCM may be at and temperature sensor. Test TSS and

you can’t access the TCM data. fault. (Figure 2) OSS inputs with a lab scope or AC volt-

Type 2: These codes indicate an electri- Repair any circuits that are out of meter. See the PCM Connector ID and

cal problem with an input sensor, range. Then reconnect the PCM. If you Voltage chart for specifications.

including speed sensors, gear posi- still can’t communicate with the PCM, TSS and OSS Sensors

tion, pressure switches, temperature try a different scan tool or update your To test the sensor’s operation, use a

and the TPS. scan tool’s software. lab scope or multimeter to monitor the

Type 3: These codes indicate an electri- There are 2 types of data signals circuits directly. Use the PCM Connector

cal problem with a solenoid. which TCM data can be requested. One ID and Voltage chart to identify sensor

Type 4: These codes indicate an incor- is the Programmable Communication terminals at the PCM (Figure 3).

rect gear ratio, CVI numbers are (PCI) BUS, which includes data from Use a scan tool to watch the TCM

incorrect, or the TCC is slipping.

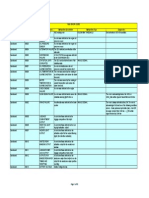

PCM Black Connector C1 Id & Voltage Chart

CAUTION: These procedures Pin Wire Color Function Value

require an excellent understanding of 9 Black/Brown Ground Less Than 0.01V

11 Pink/Grey Ignition 12V Ign. ON

Ohm’s Law, that you have a lab scope,

18 Black/Dk. Green Ground Less Than 0.01V

DVOM or ammeter, and know how to 29 Orange/Red Fused B+ 12.45V Min at Rest

use it. Current tests require that your 30 Yellow Start 12V Start 0V Ign. On

amp probe or ammeter have a current 37 Dr. Green/Yellow SCI Transmit 0V Toggles 0-5

rating of at least 10 amps. Improper when scantool cont. Requests data

testing or procedures could damage the 38 White/Violet PCI BUS Toggles 0-7V cont. When Data

vehicle or your meter, or could cause Present

personal harm. Figure 1

30 GEARS August 2007

30skora807.indd 30 7/13/07 7:34:07 AM

lockup on. Both sen- • Move the gear selector to Drive.

sors should read right • Connect a voltmeter to the L/R

about engine RPM. pressure switch terminal at PCM C4

Accelerate and deceler- connector. See the PCM Connector

ate the vehicle. Make ID and Voltage chart for the pin

sure that both sensor number. The voltmeter should

signals vary with engine display 12V.

RPM. If not, either a • Apply air pressure to the L/R pres-

clutch is slipping or the sure tap. The voltmeter should dis-

speed sensor needs fur- play 0V.

ther testing. • Release the air pressure and 12V

should reappear.

HINT: Bad grounds,

connectors, alternator If the switch circuit tests okay but

Figure 2 diodes, and EMI can there’s a code for the pressure switch,

affect speed sensors. If look for a hydraulic crossleak or a faulty

process the signals: clutches are good and you can’t find any PCM. If the switch fails the test, check

• In Park, the TSS should read close external problems, suspect a faulty PCM. the circuits or replace the solenoid pack.

to engine RPM. The OSS should L/R, 2-4 and OD Pressure Repeat the test for the 2-4 and OD

read zero. Switches pressure switch circuits. Reconnect the

• At a stop in drive, both sensors To troubleshoot the pressure switch PCM.

should read zero, even during a circuits: HINT: A pressure switch trouble

stall test. If the TSS reads more • Disconnect the PCM. code may be caused by valve body

than zero RPM, a clutch is slipping • Connect a jumper between pin 29 of crossleaks. For example, a 2-4 or a L/R

or the TSS circuit is generating a the C1 PCM connector and pin 56 pressure switch code; these problems

false signal because of EMI or a and 18 of the C4 PCM connector. can be caused by a bad solenoid pack,

bad ground. The ETAX relay should energize the a sticky solenoid switch valve, or a

• Operate the vehicle in 3rd gear with circuits. (Figure 3) warped valve body.

GEARS August 2007 31

30skora807.indd 31 7/13/07 7:34:25 AM

Troubleshooting the 604 (41TE)

PCM Green Connector C4 ID & Voltage Chart

high or low, look for a problem in the

Terminal Wire Color Application Values

11 Yellow/Grey OD Solenoid 6.5-7.5 Amps In 3rd & 4th circuit. If the current is correct, suspect

2 Yellow/Light UD Solenoid 6.5-7.5 Amps In 1st-3rd a bad PCM.

Blue To verify the other solenoid circuits,

6 Yellow/Dark 2-4 Solenoid 6.5-7.5 Amps In 2nd & 4th repeat the current flow test for the other

Blue solenoid circuits at pins 1, 2 or 6 of the

10 Dark/White L/R Solenoid 6.5-7.5 Amps Commanded On PCM C4 connector.

13 & 14 Black/Light Grounds Less than

Green 0.01V As a final test, cycle the suspect

15 Dk. Green PRNDL 12V in P,OD,L 0V in R,N,D circuit on and off for one second, about

Light/Blue 10-12 times. This will heat up the sole-

16 Dk. Green/ PRNDL 12V in R,N,OD 12V in P,3/2,L noid windings. If the solenoid circuit

Dark/Blue still reads 6.5-7.5 amps, the circuit and

18 Yellow/Brown Relay Control 12V ign. ON solenoid are good. This indicates that

19, 28 & 38 Yellow/Orange Relay Output 12.45V Min. Engine Running

the PCM is likely at fault. Reconnect the

22 Dk. Green/Tan OD psi Switch 12V in 1st/2nd 0V in 3rd& 4th

27 Dk. Green/Grey PRNDL 12V in R, OD, 0V in P, N PCM when finished.

3/2, L

29 Yellow/Tan L/R psi Switch 12V 2,3,4 0V 1St, Rev Type 4 Problems:

30 Yellow/Dark 2-4 psi Switch 0V in 2nd & 4th 12V All Other Gears Gear Ratio Errors

Green Gear ratio errors are detected by the

32 Dark Output Speed 550-600Hz or

PCM calculating signals from the input

Green/Brown Sensor 3VAC@30mph

33 Dark Green/ Input Speed 4-6 VAC or @9VAC or and output sensors. Make sure both sen-

White Sensor 1000Hz @Idle 3100Hz @ 3000rpm sors are working. See Type 2 Problems

34 Dark Green/ Speed Sensor Less Than for testing procedures. If they’re work-

Violet Ground 0.01V ing, the clutches are slipping, a hub or

35 Dark Green/ Trans Temp 1.8V @ 140ʼF shell may be stripped, or the solenoid

Orange Sensor

pack is faulty.

37 Dark Green/ PRNDL 12V in 3/2, OD 0V in P, R, N, L

Yellow TIP: Code P0944 is usually caused

Figure 3

by a clogged filter, warped valve body,

or worn pump.

Codes P01770, P1771 or P1772

ficult to fix. This is partially (CVI Codes) indicate clutch clearance

because the TCM goes into limp problems. These codes can also be set by

mode by turning the ETAX relay faulty speed sensors, crossleaks, wrong

off. Since the solenoid circuits stall converter, temperature too high or

are off, testing is limited and too low, or a bad PCM.

inconclusive. This test is based A TCC slip code maybe caused by

on a code P0750 for faulty L/R a bad converter or pump, or a warped

solenoid circuit: valve body. Test the TCC operation by

• Make sure the battery is fully monitoring the TCC release pressure

charged with a minimum rest tap. With TCC applied, TCC release

voltage of 12.45 volts. pressure should be less than 10-15 psi

• Disconnect the PCM C4 con- (depending on ECCM command).

Figure 4

nector. Connect a jumper wire A TCC slip code maybe caused by

Codes P1775 and/or P1776 may be between B+ and pin 18 or the a bad converter or pump, or a warped

caused by a warped valve body. PCM C4 connector. This should valve body. Test the TCC operation by

energize the ETAX relay and sup- monitoring the TCC release pressure

Temperature and TPS Inputs ply battery voltage to the solenoid tap. With TCC applied, TCC release

The PCM should be connected for circuits (Figure 3). pressure should be 15-60 psi, (depend-

this test. Use a lab scope or multimeter. • Make sure pin 10 at the PCM C4 ing on ECCM command). With TCC

Check the temperature sensor voltage at connector has battery voltage. fully applied, release pressure should be

pin 35 or the PCM C4 connector. Locate • Energize the L/R solenoid circuit below 5 psi.

pin 21 on the PCM C2 connector. See from pin 10 through an ammeter, Once you’ve verified that all cir-

the PCM Connector ID and Voltage lab scope or jumper wire with an cuits related to the problem or symptom

chart for specifications (Figure 3). inductive current clamp to monitor are working properly, the most likely

current (Figure 4). problem is a bad PCM. By performing

Type 3 Problems: these tests, you should be able to identify

Solenoid Circuits Errors As soon as you measure the cur- and isolate most electrical problems in

Solenoid circuit codes P0750, rent, remove the jumper wire. Current any 41TE transaxle.

P0755, P0760 and P0765 can be dif- flow should be 6.5-7.5 amps. If it’s too

32 GEARS August 2007

30skora807.indd 32 7/13/07 7:34:52 AM

Bygone Service 2.pdf 8/25/2006 4:12:23 PM

CM

MY

CY

CMY

Vous aimerez peut-être aussi

- Techniques Troubleshooting: .Implication Note 163-1Document30 pagesTechniques Troubleshooting: .Implication Note 163-1JC ZuletPas encore d'évaluation

- CAN Data Link - TestDocument7 pagesCAN Data Link - TestNay SoePas encore d'évaluation

- 2010 Suzuki Swift OBD2 Code U0100 Lost Communication With ECMDocument2 pages2010 Suzuki Swift OBD2 Code U0100 Lost Communication With ECMMarlon D. VirtucioPas encore d'évaluation

- Capacitance Meter ManualDocument2 pagesCapacitance Meter ManualStan MetzgerPas encore d'évaluation

- Поиск 1Document6 pagesПоиск 1suriantoPas encore d'évaluation

- PSP-00024A6D 2023/09/12 09:32:28+08:00 RENR9324 © 2023 Caterpillar IncDocument8 pagesPSP-00024A6D 2023/09/12 09:32:28+08:00 RENR9324 © 2023 Caterpillar IncZiFiEPas encore d'évaluation

- Test SteeringDocument9 pagesTest SteeringpricopdanielPas encore d'évaluation

- PCM not receiving password from BCM causes P1626 codeDocument6 pagesPCM not receiving password from BCM causes P1626 codeDennis BaumannPas encore d'évaluation

- Bajo Voltaje en SolenoidesDocument7 pagesBajo Voltaje en SolenoidesMAXIMILIANO CASTILLO ANTONIOPas encore d'évaluation

- Carmix.: Carmix Troubleshooting Procedures I General Components and DescriptionsDocument3 pagesCarmix.: Carmix Troubleshooting Procedures I General Components and DescriptionsSuniv ShresthaPas encore d'évaluation

- Engineering Manual v1.0: CL3000 Series Asynchronous Control SystemDocument6 pagesEngineering Manual v1.0: CL3000 Series Asynchronous Control SystemJaime VillamizarPas encore d'évaluation

- MUX Demux: Name:-Rahul VoraDocument8 pagesMUX Demux: Name:-Rahul VoraRAHUL VORAPas encore d'évaluation

- P0562-Battery Voltage LowDocument7 pagesP0562-Battery Voltage Lowguillermoal539100% (1)

- C13, C15, and C18 Engines Troubleshooting - Soot Sensor - Test - Caterpillar Engines TroubleshootingDocument4 pagesC13, C15, and C18 Engines Troubleshooting - Soot Sensor - Test - Caterpillar Engines TroubleshootingmihaivulpePas encore d'évaluation

- 2007 GMC Yukon 5.3L Eng VIN 0 Base U1814 00Document2 pages2007 GMC Yukon 5.3L Eng VIN 0 Base U1814 00AlainbravopaezPas encore d'évaluation

- PM135 QuickstartDocument4 pagesPM135 QuickstartNguyen Danh HuyPas encore d'évaluation

- OmniMeter Universal Smart Meter User Manual EKM MeteringDocument3 pagesOmniMeter Universal Smart Meter User Manual EKM MeteringAdam BrouwerPas encore d'évaluation

- Codigo P076aDocument6 pagesCodigo P076aOscar VillaseñorPas encore d'évaluation

- How To - Fault Find On Can BusDocument13 pagesHow To - Fault Find On Can BusIvan PalominoPas encore d'évaluation

- HP-AN376-1 - Biasing Three-Terminal Devices For TestDocument8 pagesHP-AN376-1 - Biasing Three-Terminal Devices For Testsirjole7584Pas encore d'évaluation

- Automatic - 62Te-Electrical Diagnostics DTC Troubleshooting P0750-Lr Solenoid Circuit Circuit SchematicDocument9 pagesAutomatic - 62Te-Electrical Diagnostics DTC Troubleshooting P0750-Lr Solenoid Circuit Circuit SchematicEdwinferPas encore d'évaluation

- BEE Record BookDocument57 pagesBEE Record BookIT039- Jeel KalariyaPas encore d'évaluation

- Electronic Controller Logik 25-SDocument2 pagesElectronic Controller Logik 25-SUmair GujjarPas encore d'évaluation

- Measuring Electricity Using Multi MeterDocument6 pagesMeasuring Electricity Using Multi MeterAddiPas encore d'évaluation

- Emona Volume 1 Experiment PCM-codingDocument18 pagesEmona Volume 1 Experiment PCM-codingJuan Miguel TevesPas encore d'évaluation

- Mid 039 - Cid - FMI 08: TroubleshootingDocument4 pagesMid 039 - Cid - FMI 08: TroubleshootinganiroPas encore d'évaluation

- Diagnostic Trouble Codes (DTC) : DTC U0032 (Previously U1301) J1850 (Class 2) Serial Data Communication Link HighDocument3 pagesDiagnostic Trouble Codes (DTC) : DTC U0032 (Previously U1301) J1850 (Class 2) Serial Data Communication Link Highluis eduardo corzo enriquezPas encore d'évaluation

- Basic Stamp - Digital Signal ConditioningDocument27 pagesBasic Stamp - Digital Signal ConditioningRussellPas encore d'évaluation

- CONDOR PGN-201 Service ManualDocument21 pagesCONDOR PGN-201 Service ManualMNAOUARPas encore d'évaluation

- Challeger Testeo y AjusteDocument304 pagesChalleger Testeo y AjusteCarlos Irabedra100% (1)

- User Manual: CMM366A-ET Cloud Monitoring Communication ModuleDocument15 pagesUser Manual: CMM366A-ET Cloud Monitoring Communication ModuleJuan GuayanPas encore d'évaluation

- PM135 Quick Start Manual: Win A Tablet!Document4 pagesPM135 Quick Start Manual: Win A Tablet!Vũ MinhPas encore d'évaluation

- circutor max12-This manual is an easy guide for the use and operation of the Computer max 6/max 12. For more information, the complete manual can be downloaded from the web site of Circutor: www.circutor.es Any manipulation or use of the equipment out of the conditions specified by the manufacturer may put in risk the user safety. Before any maintenance operation the equipment must be disconnected from power supply. In case of miss operation or protection fault the equipment must be disconnected from supply and remain out of service ensuring against anyDocument2 pagescircutor max12-This manual is an easy guide for the use and operation of the Computer max 6/max 12. For more information, the complete manual can be downloaded from the web site of Circutor: www.circutor.es Any manipulation or use of the equipment out of the conditions specified by the manufacturer may put in risk the user safety. Before any maintenance operation the equipment must be disconnected from power supply. In case of miss operation or protection fault the equipment must be disconnected from supply and remain out of service ensuring against anybaguspermana7Pas encore d'évaluation

- Communication Troubleshooting GuideDocument10 pagesCommunication Troubleshooting GuideHani SweetiePas encore d'évaluation

- Design of a High Speed Multi-Channel Data Acquisition SystemDocument16 pagesDesign of a High Speed Multi-Channel Data Acquisition SystemVinod HandiPas encore d'évaluation

- DC LAB MANUAL FinalDocument39 pagesDC LAB MANUAL FinalTushar MaruPas encore d'évaluation

- Beee-Unit 4Document115 pagesBeee-Unit 4Sano ManjiroPas encore d'évaluation

- ECE3710 Lab 1: Resistors and Basic Resistive CircuitsDocument6 pagesECE3710 Lab 1: Resistors and Basic Resistive CircuitsParker Santo DomingoPas encore d'évaluation

- Beee-Unit 4Document116 pagesBeee-Unit 4MOHAN RuttalaPas encore d'évaluation

- M82 PXCX NOT XxxA XXX CAT2 X eDocument13 pagesM82 PXCX NOT XxxA XXX CAT2 X egerman gualavisi50% (2)

- EKM Omnimeter Pulse v.4 Spec SheetDocument4 pagesEKM Omnimeter Pulse v.4 Spec SheetAdam BrouwerPas encore d'évaluation

- Cat Data Link Circuit - Test (RENR5096)Document2 pagesCat Data Link Circuit - Test (RENR5096)Josip MiškovićPas encore d'évaluation

- PCM CodigoDocument14 pagesPCM CodigoLeux GuillenPas encore d'évaluation

- Eye Blink DocumentDocument38 pagesEye Blink Documentpavani13Pas encore d'évaluation

- Digital Weighing Scale DesignDocument3 pagesDigital Weighing Scale DesignChristine Kate Bernardino JungPas encore d'évaluation

- Troubleshooting: 6-1 Checkpoints by Error ModeDocument10 pagesTroubleshooting: 6-1 Checkpoints by Error Modegilberto gutierrezPas encore d'évaluation

- Basic Troubleshooting PDFDocument6 pagesBasic Troubleshooting PDFTecniAutos AguilonPas encore d'évaluation

- E1 Backhaul Testing FieldDocument2 pagesE1 Backhaul Testing Fieldapi-281601506Pas encore d'évaluation

- HZFD 400 Battery Charge and Discharge TesterDocument17 pagesHZFD 400 Battery Charge and Discharge TesterMohammed A. AliPas encore d'évaluation

- Troubleshooting SMPS Problems: (PWM Type)Document4 pagesTroubleshooting SMPS Problems: (PWM Type)Jibon DasPas encore d'évaluation

- Interfacing Relays Using The Parallel Port: ContentsDocument11 pagesInterfacing Relays Using The Parallel Port: ContentsAgoi GilbertPas encore d'évaluation

- CISE 204 Digital System Design Lab Manual PDFDocument44 pagesCISE 204 Digital System Design Lab Manual PDFEng-Mohammed KayedPas encore d'évaluation

- I-Monitor Motor Controller Manual Rev 7 6Document72 pagesI-Monitor Motor Controller Manual Rev 7 6elch310scridbPas encore d'évaluation

- Digital Logic Design: Laboratory ManualDocument7 pagesDigital Logic Design: Laboratory ManualLovely Jutt0% (1)

- Debugging Power-Supply Startup Issues: by Robert Taylor, Ryan ManackDocument5 pagesDebugging Power-Supply Startup Issues: by Robert Taylor, Ryan ManackvaishnaviPas encore d'évaluation

- Basic PLCDocument24 pagesBasic PLCanjalilahariya100% (2)

- Circuit Description: o o o o o oDocument3 pagesCircuit Description: o o o o o oManabu WakisakaPas encore d'évaluation

- Digital LED Thermometer with Microcontroller AVR ATtiny13D'EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Évaluation : 5 sur 5 étoiles5/5 (1)

- Automotive Electronic Diagnostics (Course 2)D'EverandAutomotive Electronic Diagnostics (Course 2)Évaluation : 4 sur 5 étoiles4/5 (2)

- F430 Error CodesDocument63 pagesF430 Error CodesIsrael Negrete Dominguez100% (2)

- BMW 03 CIP ProgrammingDocument20 pagesBMW 03 CIP ProgrammingSalisburPas encore d'évaluation

- Manual Cambio PDFDocument122 pagesManual Cambio PDFrogerioPas encore d'évaluation

- F430 Error CodesDocument63 pagesF430 Error CodesIsrael Negrete Dominguez100% (2)

- MOST Bus Diagnostics: Initial Print Date: 02/04 Revision DateDocument11 pagesMOST Bus Diagnostics: Initial Print Date: 02/04 Revision DateAutof FerreiraPas encore d'évaluation

- Service Bulletin for 1999 Mitsubishi Galant Special SpecsDocument6 pagesService Bulletin for 1999 Mitsubishi Galant Special SpecsAutof FerreiraPas encore d'évaluation

- Powertrain ZF PDFDocument74 pagesPowertrain ZF PDFAnonymous 3rxPUo6Pas encore d'évaluation

- 04 Telephone DiagnosticsDocument19 pages04 Telephone DiagnosticsSalisburPas encore d'évaluation

- 01 - Passive Safety DiagnosticsDocument3 pages01 - Passive Safety DiagnosticsSalisburPas encore d'évaluation

- Powertrain ZF PDFDocument74 pagesPowertrain ZF PDFAnonymous 3rxPUo6Pas encore d'évaluation

- Iveco Daily Euro 4 Repair Manual GuideDocument1 132 pagesIveco Daily Euro 4 Repair Manual Guideroney82% (17)

- DPO Oil CheckDocument3 pagesDPO Oil CheckAutof FerreiraPas encore d'évaluation

- Service BulletinDocument3 pagesService BulletinAutof FerreiraPas encore d'évaluation

- Service BulletinDocument3 pagesService BulletinAutof FerreiraPas encore d'évaluation

- MSB 99E22 001eDocument2 pagesMSB 99E22 001eAutof FerreiraPas encore d'évaluation

- Service BulletinDocument2 pagesService BulletinAutof FerreiraPas encore d'évaluation

- SB ListDocument1 pageSB ListAutof FerreiraPas encore d'évaluation

- MSB 99e42 003eDocument5 pagesMSB 99e42 003eAutof FerreiraPas encore d'évaluation

- MSB 98e54 501Document3 pagesMSB 98e54 501Autof FerreiraPas encore d'évaluation

- 16+Sistema+de+Arranque,+Poleas,+Injectores,+Alternador,+EtcDocument0 page16+Sistema+de+Arranque,+Poleas,+Injectores,+Alternador,+EtcrcvalPas encore d'évaluation

- 17 PDFDocument52 pages17 PDFAutof FerreiraPas encore d'évaluation

- Engine LubricationDocument10 pagesEngine LubricationAutof FerreiraPas encore d'évaluation

- Manual TransmissionDocument10 pagesManual TransmissionAutof FerreiraPas encore d'évaluation

- 23Document70 pages23Autof FerreiraPas encore d'évaluation

- 15Document24 pages15Autof FerreiraPas encore d'évaluation

- 21 PDFDocument8 pages21 PDFAutof FerreiraPas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 26 PDFDocument18 pages26 PDFAutof FerreiraPas encore d'évaluation

- 14 PDFDocument26 pages14 PDFAutof FerreiraPas encore d'évaluation

- Crown FC4500Document192 pagesCrown FC4500Cl LeePas encore d'évaluation

- Orthopanton Villa System MedicalDocument61 pagesOrthopanton Villa System MedicalOscarOcañaHernándezPas encore d'évaluation

- Electro Erf EffectsDocument246 pagesElectro Erf Effectsaeroseb1Pas encore d'évaluation

- Service Manual: Blu-Ray Disc/Dvd ReceiverDocument114 pagesService Manual: Blu-Ray Disc/Dvd ReceiverWILIAM RODRIGUEZPas encore d'évaluation

- SDG1000 ServiceManual SM02010-E01BDocument68 pagesSDG1000 ServiceManual SM02010-E01BjanekiviPas encore d'évaluation

- Temperature Rise of Power Transformers: Comments and PROPOSALS TO IEC 60076-2:2011Document11 pagesTemperature Rise of Power Transformers: Comments and PROPOSALS TO IEC 60076-2:2011Kuljinder VirdiPas encore d'évaluation

- Emf Seri̇si̇ İngi̇li̇zce El Ki̇tabiDocument11 pagesEmf Seri̇si̇ İngi̇li̇zce El Ki̇tabialperemirPas encore d'évaluation

- Sony Kdl-32ex525 Kdl-40ex525 Chassis Az2-F Rev.1 SM PDFDocument56 pagesSony Kdl-32ex525 Kdl-40ex525 Chassis Az2-F Rev.1 SM PDFRicardo SilvaPas encore d'évaluation

- 29-Range Digital Multimeter: 2200813 User's GuideDocument24 pages29-Range Digital Multimeter: 2200813 User's GuideMohamed Abdel Moniem KamelPas encore d'évaluation

- GSM 900 Mobile Jamar ReportDocument63 pagesGSM 900 Mobile Jamar ReportmoezawPas encore d'évaluation

- Ec2351 Measurements and Instrumentation 3 0 0 3Document1 pageEc2351 Measurements and Instrumentation 3 0 0 3Sean ReynoldsPas encore d'évaluation

- Group 4 Mechatronics System: 1. All Actuators Speed Are SlowDocument10 pagesGroup 4 Mechatronics System: 1. All Actuators Speed Are SlownajafaliPas encore d'évaluation

- Manual Multimetro Serie Ut231Document38 pagesManual Multimetro Serie Ut231Emilio TamayoPas encore d'évaluation

- Lap Report 6 Phy 2Document5 pagesLap Report 6 Phy 2ahmed albualiPas encore d'évaluation

- VRF TSDocument118 pagesVRF TSpablo100% (1)

- KLV 21 SR 2Document75 pagesKLV 21 SR 2Dylan Gonzalez VillalobosPas encore d'évaluation

- TC7129 MultimeterDocument28 pagesTC7129 MultimeterFelipePerezPas encore d'évaluation

- 3320701Document4 pages3320701RajashekarBalyaPas encore d'évaluation

- Unit IVDocument53 pagesUnit IVRiya KatePas encore d'évaluation

- Soda Can Paper - TamannaDocument12 pagesSoda Can Paper - TamannaYoussef NasserPas encore d'évaluation

- 3BHS832702 E20 RevB TroubleshootingGuide ACS 5k INU LKAI20xxDocument151 pages3BHS832702 E20 RevB TroubleshootingGuide ACS 5k INU LKAI20xxPrafulla SupekarPas encore d'évaluation

- Service Manual: CD/DVD PlayerDocument84 pagesService Manual: CD/DVD Playernani_amlprm5912Pas encore d'évaluation

- hw50-1010s-sw Service ManualDocument32 pageshw50-1010s-sw Service ManualAdrian Iulian VladPas encore d'évaluation

- DishwasherDocument37 pagesDishwashersnovovi10% (1)

- Fault Code 242 Vehicle Speed Sensor Circuit Tampering Has Been Detected - Abnormal Rate of ChangeDocument14 pagesFault Code 242 Vehicle Speed Sensor Circuit Tampering Has Been Detected - Abnormal Rate of ChangeAhmedmahPas encore d'évaluation

- Roots Metrology Laboratory CalibrationsDocument105 pagesRoots Metrology Laboratory CalibrationsVikram BillalPas encore d'évaluation

- Keysight 3458A Multimeter: Shattering Performance Barriers of Speed and AccuracyDocument27 pagesKeysight 3458A Multimeter: Shattering Performance Barriers of Speed and AccuracyosewoudtPas encore d'évaluation

- Workshop Manual: Group 30 ADocument70 pagesWorkshop Manual: Group 30 APer Østbø100% (1)

- Tp48300b-n16b2 Tp48600b-n16b2 User ManualDocument53 pagesTp48300b-n16b2 Tp48600b-n16b2 User ManualAbhishek SrivastavaPas encore d'évaluation