Académique Documents

Professionnel Documents

Culture Documents

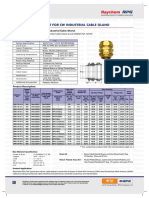

Cable Gland Types E1W, E2W, E1X, E2X, E1U & E2U

Transféré par

Widhi ImranovichTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cable Gland Types E1W, E2W, E1X, E2X, E1U & E2U

Transféré par

Widhi ImranovichDroits d'auteur :

Formats disponibles

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

INSTALLATION INSTRUCTIONS FOR

CMP CABLE GLAND TYPE “E”

TECHNICAL DATA

CABLE GLAND TYPE : E** Family of Glands

INGRESS PROTECTION : IP66, IP67, IP68

PROCESS CONTROL SYSTEM : BS EN ISO 9001

INSTALLATION INSTRUCTIONS FOR TERMINATION OF CABLES WITH WIRE BRAID, TAPE ARMOUR (STA/DSTA), STRIP ARMOUR &

Installation should only be performed by a competent person using the correct tools. Read all instructions before beginning installation.

SINGLE WIRE ARMOUR (SWA) (WITH LEAD INNER SHEATH ON “E2” VARIANT).

ACCESSORIES

The following accessories are available from CMP Products, as optional extras, to assist with fixing, sealing and earthing :-

Locknut | Earth Tag | Serrated Washer | Entry Thread (I.P.) Sealing Washer | Shroud

CABLE GLAND TYPES

E1W, E2W, E1X, E2X,

Available Entry Threads Armour Wire Diameter Ordering

Cable Beding Overall Cable Across Across

Cable Thread Reference PVC

Diameter Diameter Flats Corners Protrusion

Gland Standard Option Length Grooved Cone Stepped Cone (Brass Metric) Shroud

Length

*

Size metric Reference

Metric NPT NPT Min Max Min Max Min Max Min Max Max Max

E1U & E2U

20S/16 M20 1/2” 3/4” 10.0 3.1 8.6 6.1 11.5 0.15 0.5 0.9 1.0 24.0 25.9 58.5 20S16E1W1RA PVC04

20S M20 1/2” 3/4” 10.0 6.1 11.6 9.5 15.9 0.15 0.5 0.9 1.25 24.0 25.9 58.5 20SE1W1RA PVC04

20 M20 1/2” 3/4” 10.0 6.5 13.9 12.5 20.9 0.2 0.5 0.9 1.25 30.5 32.9 60.5 20E1W1RA PVC06

25S M25 3/4” 1” 10.0 11.1 19.9 14.0 22.0 0.2 0.6 1.25 1.6 37.5 40.5 67.5 25SE1W1RA PVC09

25 M25 3/4” 1” 10.0 11.1 19.9 18.2 26.2 0.2 0.6 1.25 1.6 37.5 40.5 67.5 25E1W1RA PVC09

Cable Gland Selection Table

32 M32 1” 1-1/4” 15.0 17.0 26.2 23.7 33.9 0.2 0.6 1.6 2.0 46.0 49.7 69.5 32E1W1RA PVC11

40 M40 1-1/4” 1-1/2” 15.0 22.0 32.1 27.9 40.4 0.2 0.8 1.6 2.0 55.0 59.4 78.0 40E1W1RA PVC15

50S M50 1-1/2” 2” 15.0 29.5 38.1 35.2 46.7 0.2 0.8 2.0 2.5 60.0 64.8 75.5 50SE1W1RA PVC18

50 M50 2” 2-1/2” 15.0 35.6 44.0 40.4 53.1 0.3 0.8 2.0 2.5 70.0 75.6 80.5 50E1W1RA PVC21

63S M63 2” 2-1/2” 15.0 40.1 49.9 45.6 59.4 0.3 0.8 2.0 2.5 75.0 81.0 91.5 63SE1W1RA PVC23

63 M63 2-1/2” 3” 15.0 47.2 55.9 54.6 65.9 0.3 0.8 2.0 2.5 80.0 86.4 92.0 63E1W1RA PVC25

75S M75 2-1/2” 3” 15.0 52.8 61.9 59.0 72.1 0.3 0.8 2.0 2.5 89.0 96.1 99.0 75SE1W1RA PVC28

75 M75 3” 3-1/2” 15.0 59.1 67.9 66.7 78.5 0.3 0.8 2.5 3.0 99.0 106.9 102.0 75E1W1RA PVC30

90 M90 3” 3-1/2” 24.0 66.6 79.9 76.2 90.4 0.4 0.8 3.0 3.5 114.0 123.1 120.0 90E1W1RA PVC32

100 M100 - - 24.0 76.0 90.9 86.1 101.5 0.4 0.8 3.15 4.0 123.0 132.8 148.0 100E1W1RA LSF33

115 M115 - - 24.0 86.0 97.9 101.5 110.3 0.4 0.8 3.15 4.0 133.4 144.1 169.0 115E1W1RA LSF34

130 M130 - - 24.0 97.0 114.9 114.2 123.3 0.4 0.8 3.15 4.0 146.0 157.8 183.0 130E1W1RA LSF35

Dimensions are displayed in millimeters unless otherwise stated

CMP Document No. FI417 Issue 4 01/13

* Order codes shown are for E1W glands

For e.g. E1X glands substitue E1W for E1X - e.g. 20E1X1RA

E1W - SWA Armour

Please note that the overall maximum cable bedding diameter for “E2” variants should be reduced by 1mm to allow for the inner lead sheath.

E2W - SWA Armour for lead

sheathed cable

E1X - Braid, Tape, etc Armour

E2X - Braid, Tape, etc Armour

for lead sheathed cable

E1U - Universal Gland for all

Armour Types

E2U - Universal Gland for all

Glasshouse Street • St. Peters • NewcastleTel:

upon+44Tyne • NE6490

1BS1547 Armour Types with lead

sheathed cable

(0)191

Tel: +44 191 265 7411 • Fax: +44 191 265 0581

E-Mail: cmp@cmp-products.co.uk • Web: www.cmp-products.com

Fax: +44 (0)191 477 5371

Email: northernsales@thorneandderrick.co.uk

Website: www.cablejoints.co.uk

www.cmp-products.com www.thorneanderrick.co.uk

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH www.cmp-products.com

INSTALLATION INSTRUCTIONS FOR CMP CABLE GLAND TYPES “E”

4. Locate the Armour Cone (3) into its recess in the Main Item (2). (N.B. For E1U and E2U

CABLE GLAND COMPONENTS - It is not necessary to dismantled the cable gland any further than illustrated below variants, make sure the correct side of the cone is outermost - grooved for braid/tape armour and

1. Entry Component

Sub Assembly A Sub Assembly B

stepped for SWA). Pass the cable through sub-assembly “A” until the armour engaged with the

2. Main Item cone. Spread the armour evenly around the cone.

3. Detachable Armour Cone

4. AnyWay Clamping Ring

5. Body

6. Outer Seal Nut

1 2 3 4 5 6

PLEASE READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE INSTALLATION 5. While continuing to push the cable forward to maintain contact between the armour and the

cone, tighten the Main Item (2) by hand until heavy resistance is felt. (This is when the inner seal

1. If required fit shroud over the cable outer sheath; makes contact with the cable inner sheath). Tighten a further full turn using a spanner.

NOTE: The earthing device on E2* type glands will automatically engage the lead sheath.

Prepare the cable by stripping back the cable outer sheath and armour to suit the equipment geometry.

Expose the armour by stripping back the outer sheath further using the table below as a guide.

If applicable remove any tapes or wrappings to expose cable inner sheath.

Tape armour should be further

prepared by cutting the tape

Cable Strip

Length “L”

into strips as shown below:

6. Hold the Main Item (2) with a spanner and tighten sub-assembly “B” onto sub-assembly “A”

using a spanner until all available threads are used.

CABLE GLAND SIZE 20S/16, 20S, 20 25S, 25, 32, 40 50S, 50, 63S, 63 75S, 75, 90, 100, 115, 130

CABLE STRIP LENGTH “L” 12mm 15mm 18mm 20mm

2. Separate the gland into two sub-assemblies “A & B”. Ensuring that the Outer Seal Nut (6) is relaxed,

pass sub-assembly “B” over the cable outer sheath and armour followed by the “AnyWay” clamping ring

(4).

7. Tighten the Outer Seal Nut (6) until it comes to an effective stop. This will occur when:-

Note: On maximum size cables the clamping A) The Outer Seal Nut (6) has clearly engaged the cable and cannot be further tightened

ring may only pass over the armour. without the use of excessive force by the installer.

B) The Outer Seal Nut (6) is metal to metal with the body of the gland (5).

3. Ensure that the inner seal is relaxed by slackening the Main Item (2). Secure sub-assembly “A” into

the equipment either by screwing the Entry Item (1) into a threaded hole or by securing it in a clearance

hole using a locknut as applicable.

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

Vous aimerez peut-être aussi

- CMP PXSS2K Installation Fitting Instructions FI404 Issue 2 1Document2 pagesCMP PXSS2K Installation Fitting Instructions FI404 Issue 2 1Lê Văn TrườngPas encore d'évaluation

- 150 RacDocument1 page150 RacM Umar ChatthaPas encore d'évaluation

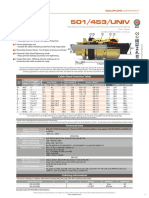

- Hawke 501_423 DatasheetDocument2 pagesHawke 501_423 DatasheetjaybnovemPas encore d'évaluation

- Hazardous Area Cable Gland Dual Certified ATEX & IECExDocument1 pageHazardous Area Cable Gland Dual Certified ATEX & IECExhashmin karuvathilPas encore d'évaluation

- Cable Glands for Hazardous AreasDocument1 pageCable Glands for Hazardous AreasrhomadonaPas encore d'évaluation

- Hawke Gland CatalogDocument1 pageHawke Gland CatalogIon NitaPas encore d'évaluation

- Instrumentation Cable BSDocument42 pagesInstrumentation Cable BSShivaniPas encore d'évaluation

- CMP A2F Installation Fitting Instructions FI413 Issue 1 1010Document2 pagesCMP A2F Installation Fitting Instructions FI413 Issue 1 1010Lê Văn TrườngPas encore d'évaluation

- Pipes Flexnetflexible Pipes-2020Document12 pagesPipes Flexnetflexible Pipes-2020Bengaluru CommonmanPas encore d'évaluation

- Hawke CableGland 501 453 RAC Compression V6Document2 pagesHawke CableGland 501 453 RAC Compression V6Ing ZenerPas encore d'évaluation

- HAWKE GLAND-type OnlyDocument1 pageHAWKE GLAND-type OnlyJaaffer AliPas encore d'évaluation

- 501/421 Cable Gland Type: Flameproof and Increased SafetyDocument1 page501/421 Cable Gland Type: Flameproof and Increased Safetywe202Pas encore d'évaluation

- Cable Gland: Type 153 IndustrialDocument2 pagesCable Gland: Type 153 IndustrialLucas ElliottPas encore d'évaluation

- Unarmored Hawke Gland Datasheet 501-421Document1 pageUnarmored Hawke Gland Datasheet 501-421Sudeep SPas encore d'évaluation

- CABLE GLAND COMPRESSION SERIES TECHNICAL SPECSDocument2 pagesCABLE GLAND COMPRESSION SERIES TECHNICAL SPECSMohammad Nabil AbdullahPas encore d'évaluation

- Install cable gland E seriesDocument2 pagesInstall cable gland E seriessubramanyaPas encore d'évaluation

- Hawke CableGland 501 423 Compression June2019Document1 pageHawke CableGland 501 423 Compression June2019m4Lacc4 ray4Pas encore d'évaluation

- Cable Glands: IndustrialDocument1 pageCable Glands: IndustrialM Umar ChatthaPas encore d'évaluation

- 501/453/universal Cable Gland Type: Flameproof and Increased SafetyDocument1 page501/453/universal Cable Gland Type: Flameproof and Increased SafetymahdimaziniPas encore d'évaluation

- Cable Gland Types E1FW/M, E1FX/M, E1FU/M E1Fw/Mf, E1Fx/Mf, E1Fu/MfDocument2 pagesCable Gland Types E1FW/M, E1FX/M, E1FU/M E1Fw/Mf, E1Fx/Mf, E1Fu/MfRyan Mesina De GuzmanPas encore d'évaluation

- 501/453/UNIV: Cable Gland Selection TableDocument1 page501/453/UNIV: Cable Gland Selection TableAkmalPas encore d'évaluation

- Tuberia CplastDocument2 pagesTuberia CplastRosmery Solis QuispePas encore d'évaluation

- Catalog 12 28 10 1957Document32 pagesCatalog 12 28 10 1957sojanpaPas encore d'évaluation

- Hawke CableGland 153 UNIV Industrial V2Document1 pageHawke CableGland 153 UNIV Industrial V2Saqib JavedPas encore d'évaluation

- Hawke CableGland 153 UNIV Industrial Jan-2022Document2 pagesHawke CableGland 153 UNIV Industrial Jan-2022RamzzzPas encore d'évaluation

- Cable Glands & Bushings: DQM-II Series Explosion-Proof Options (Ex d IIC Ex e IICDocument2 pagesCable Glands & Bushings: DQM-II Series Explosion-Proof Options (Ex d IIC Ex e IICLucas MorenoPas encore d'évaluation

- HKE 114 Industrial Cable-Gland DatasheetDocument1 pageHKE 114 Industrial Cable-Gland DatasheetSai KamalaPas encore d'évaluation

- App 2037023000Document6 pagesApp 2037023000danielPas encore d'évaluation

- CMP A2 FI436 Issue 5Document2 pagesCMP A2 FI436 Issue 5Gokul MuraliPas encore d'évaluation

- 501,453 Classified GlandDocument1 page501,453 Classified GlandMuhammad RamzanPas encore d'évaluation

- Type 501-453-Universal PDFDocument1 pageType 501-453-Universal PDFwe202Pas encore d'évaluation

- Installation Instructions For CMP Cable Gland Types T3Cds & T3CdspbDocument2 pagesInstallation Instructions For CMP Cable Gland Types T3Cds & T3CdspbLailyMLPas encore d'évaluation

- Installation Instructions For A2Fhc Cable GlandDocument2 pagesInstallation Instructions For A2Fhc Cable GlandFelisbeloPas encore d'évaluation

- M12 Power Cables & Connectors for Electrical MonitoringDocument3 pagesM12 Power Cables & Connectors for Electrical MonitoringtadiganeshPas encore d'évaluation

- Medium Voltage Copper/Aluminum XLPE Cables SpecsDocument2 pagesMedium Voltage Copper/Aluminum XLPE Cables SpecsHafidz BandungPas encore d'évaluation

- IEC 60502 Single Core Copper/Aluminium XLPE Insulated MV CablesDocument2 pagesIEC 60502 Single Core Copper/Aluminium XLPE Insulated MV CablesAndrewPas encore d'évaluation

- BURNDY - Master - Catalog 2 Hole Long Barrel LugsDocument3 pagesBURNDY - Master - Catalog 2 Hole Long Barrel LugsSheaPas encore d'évaluation

- Tuf Strand BrochureDocument4 pagesTuf Strand BrochureIllarick Balarezo SalgadoPas encore d'évaluation

- Hke - 501 453 Univ (Upd260318)Document1 pageHke - 501 453 Univ (Upd260318)pneuma110Pas encore d'évaluation

- CML Type Examination Certificate for CMP Cable GlandsDocument7 pagesCML Type Examination Certificate for CMP Cable GlandsUmar FarooqPas encore d'évaluation

- Strip Cladding StripsDocument20 pagesStrip Cladding StripsMahesh DeshmukhPas encore d'évaluation

- 501 453 UnivDocument1 page501 453 UnivVishnu LalPas encore d'évaluation

- 40°C To + 100°C - 50°C To + 135°C: Product ApplicationDocument1 page40°C To + 100°C - 50°C To + 135°C: Product Applicationaleem ycPas encore d'évaluation

- Technical Specifications for Armoured Instrument CableDocument2 pagesTechnical Specifications for Armoured Instrument CableRijo RajanPas encore d'évaluation

- Sy LSZH Control Flexible CableDocument3 pagesSy LSZH Control Flexible Cableandy175Pas encore d'évaluation

- Piping Design Enginerring & Construction: Atul PatelDocument19 pagesPiping Design Enginerring & Construction: Atul Patelसरदार अतुल भाई पटेलPas encore d'évaluation

- HKE Cable Glands CatalogueDocument17 pagesHKE Cable Glands Cataloguesogetsu kazamaPas encore d'évaluation

- Soow H07RN-F Aj 24.02.2022Document4 pagesSoow H07RN-F Aj 24.02.2022Tamara TrejosPas encore d'évaluation

- Acsr Astm B Aluminium Conductor Steel ReinforcedDocument10 pagesAcsr Astm B Aluminium Conductor Steel ReinforcedAchint KumarPas encore d'évaluation

- Level SwitchesDocument94 pagesLevel SwitchesPremjith SudhakaranPas encore d'évaluation

- MAG-DS-00508-EN ModMAG M7600 Electromagnetic Flow Meters Product Data SheetDocument4 pagesMAG-DS-00508-EN ModMAG M7600 Electromagnetic Flow Meters Product Data SheetPhilippe jean-louisPas encore d'évaluation

- Fence ProductsDocument52 pagesFence ProductsWaleed MohamedPas encore d'évaluation

- 501-453 Universal Cable GalndsDocument1 page501-453 Universal Cable Galndsmeribout adelPas encore d'évaluation

- Installation and Maintenance Guidelines For Nibco Butterfly Valves With Rubber SeatsDocument16 pagesInstallation and Maintenance Guidelines For Nibco Butterfly Valves With Rubber SeatsJosé marinPas encore d'évaluation

- Standard Pipe Schedule 40 ASTM A 53 Grades A and BDocument2 pagesStandard Pipe Schedule 40 ASTM A 53 Grades A and BAngel PintoPas encore d'évaluation

- Hi Ex Gauge HangerDocument2 pagesHi Ex Gauge HangerWahiba EnergyPas encore d'évaluation

- Standard Pipe Schedule 40 ASTM A 53 Grades A and BDocument2 pagesStandard Pipe Schedule 40 ASTM A 53 Grades A and Btarek eidPas encore d'évaluation

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextD'EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextPas encore d'évaluation

- Battery-Powered, Reliable and Cost Efficient.: SITRANS F M MAG 8000 Water Meter For Long-Term AccuracyDocument8 pagesBattery-Powered, Reliable and Cost Efficient.: SITRANS F M MAG 8000 Water Meter For Long-Term AccuracyWidhi ImranovichPas encore d'évaluation

- Public Lighting - Standard Luminaires, Poles and Bracket ArmsDocument19 pagesPublic Lighting - Standard Luminaires, Poles and Bracket ArmsWidhi ImranovichPas encore d'évaluation

- Coefficients of Utilization For 20 Percent Effective Floor Cavity ReflectanceDocument1 pageCoefficients of Utilization For 20 Percent Effective Floor Cavity ReflectanceWidhi ImranovichPas encore d'évaluation

- Wiring DiagramDocument5 pagesWiring DiagramWidhi ImranovichPas encore d'évaluation

- Lighting Lighting: Theta FBS110Document2 pagesLighting Lighting: Theta FBS110Widhi ImranovichPas encore d'évaluation

- QIPP-MPN012-J00-0101 Rev0 Instrument Hook Up DrawingDocument20 pagesQIPP-MPN012-J00-0101 Rev0 Instrument Hook Up DrawingWidhi ImranovichPas encore d'évaluation

- Lighting Lighting: Smart CFL-I Downlight FBS111/112/113/115/116 - A Reliable Way To Create Outstanding LightingDocument2 pagesLighting Lighting: Smart CFL-I Downlight FBS111/112/113/115/116 - A Reliable Way To Create Outstanding LightingWidhi ImranovichPas encore d'évaluation

- Requirements for CCTV InstallationDocument20 pagesRequirements for CCTV InstallationRaj RamachandranPas encore d'évaluation

- Power Quality Improvement With LV Capacitors and FiltersDocument20 pagesPower Quality Improvement With LV Capacitors and FiltershaunghiaPas encore d'évaluation

- How To Choose The Right EnclosureDocument32 pagesHow To Choose The Right EnclosureWidhi ImranovichPas encore d'évaluation

- Load Bank Testing ReportDocument1 pageLoad Bank Testing ReportWidhi ImranovichPas encore d'évaluation

- FAB Cable Float Level Switch - NewDocument16 pagesFAB Cable Float Level Switch - NewWidhi ImranovichPas encore d'évaluation

- Fibox Arca 2017 En-DeDocument50 pagesFibox Arca 2017 En-DeWidhi ImranovichPas encore d'évaluation

- DSE7320 Installation Instructions PDFDocument2 pagesDSE7320 Installation Instructions PDFRafael Fernando100% (1)

- Fibox Cabinets: Enclosing InnovationsDocument46 pagesFibox Cabinets: Enclosing InnovationsWidhi ImranovichPas encore d'évaluation

- Benefits of Stainless Steel Conduit Systems VS. PVC CoatedDocument2 pagesBenefits of Stainless Steel Conduit Systems VS. PVC CoatedWidhi ImranovichPas encore d'évaluation

- Magnetic Float Level Switch Specifications and ApplicationsDocument29 pagesMagnetic Float Level Switch Specifications and ApplicationsWidhi ImranovichPas encore d'évaluation

- Public Street - ROAD LIGHTING CALCDocument7 pagesPublic Street - ROAD LIGHTING CALCWidhi ImranovichPas encore d'évaluation

- Electrical Load EstimationDocument8 pagesElectrical Load EstimationWidhi ImranovichPas encore d'évaluation

- Lighting Design TipsDocument6 pagesLighting Design TipsWidhi ImranovichPas encore d'évaluation

- 12 Signet 2019Document66 pages12 Signet 2019Widhi ImranovichPas encore d'évaluation

- 1 Introduction PDFDocument4 pages1 Introduction PDFWidhi ImranovichPas encore d'évaluation

- Nayy CableDocument5 pagesNayy CableWidhi ImranovichPas encore d'évaluation

- GF Planning FundamentalDocument74 pagesGF Planning FundamentalWidhi ImranovichPas encore d'évaluation

- ANSI Codes PDFDocument3 pagesANSI Codes PDFelectrical_1012000100% (2)

- Power Cable H05VV-F 2 × 0.5mmsq Description: ConductorDocument4 pagesPower Cable H05VV-F 2 × 0.5mmsq Description: ConductorWidhi ImranovichPas encore d'évaluation

- Electrical Load Calculations for Building ConstructionDocument16 pagesElectrical Load Calculations for Building ConstructionKitz DerechoPas encore d'évaluation

- 09 Technical TablesDocument8 pages09 Technical TablesRuban Vijaya SinghPas encore d'évaluation

- As/nz: 4024.3610-2015Document8 pagesAs/nz: 4024.3610-2015Widhi Imranovich20% (5)

- FMS 1Document27 pagesFMS 1bishal dattaPas encore d'évaluation

- 4 5994641624901094407Document20 pages4 5994641624901094407Success100% (1)

- HazopDocument4 pagesHazopbaaziz2015Pas encore d'évaluation

- Turning Frequency in Adult Bedridden Patients To Prevent Hospital-Acquired Pressure Ulcer: A Scoping ReviewDocument12 pagesTurning Frequency in Adult Bedridden Patients To Prevent Hospital-Acquired Pressure Ulcer: A Scoping ReviewfajaqaPas encore d'évaluation

- Optimize Your Portfolio With Modern TheoriesDocument65 pagesOptimize Your Portfolio With Modern Theoriesastro9jyotish9asim9mPas encore d'évaluation

- Concrete Mix Design: Strength (Psi) 4000 Slump (In) : 3 To 4 Max. Aggregate (In) : 0.750 Cement: Coarse AggregateDocument2 pagesConcrete Mix Design: Strength (Psi) 4000 Slump (In) : 3 To 4 Max. Aggregate (In) : 0.750 Cement: Coarse AggregateAnonymous PeFQLw19Pas encore d'évaluation

- Essay #01 (First Draft)Document2 pagesEssay #01 (First Draft)thanhtam3819Pas encore d'évaluation

- The 5th Edition of The World Health Organization Classification - of Haematolymphoid Tumours Myeloid and Histiocytic - Dendritic NeoplasmsDocument17 pagesThe 5th Edition of The World Health Organization Classification - of Haematolymphoid Tumours Myeloid and Histiocytic - Dendritic NeoplasmsADMINISTRACION LABORATORIO INTERMEDICAPas encore d'évaluation

- Best Practice Guidelines For Cardiac Rehabilitation and Secondary Prevention: A SynopsisDocument16 pagesBest Practice Guidelines For Cardiac Rehabilitation and Secondary Prevention: A SynopsisErdy VincentPas encore d'évaluation

- 8th Edition of The AJCC - TNM Staging System of Thyroid Cancer - What To Expect (ITCO#2)Document5 pages8th Edition of The AJCC - TNM Staging System of Thyroid Cancer - What To Expect (ITCO#2)Valentina IndahPas encore d'évaluation

- D5092 - Design and Installation of Ground Water Monitoring Wells in AquifersDocument14 pagesD5092 - Design and Installation of Ground Water Monitoring Wells in Aquifersmaxuelbestete100% (1)

- An Evaluation of Maglev Technology and Its Comparison With High Speed Rail PDFDocument20 pagesAn Evaluation of Maglev Technology and Its Comparison With High Speed Rail PDFJohanFaqar ZainPas encore d'évaluation

- Shakuntala and Other Works, by KåalidåasaDocument255 pagesShakuntala and Other Works, by KåalidåasaMohamed Sayed AbdelrehimPas encore d'évaluation

- Visvesvaraya Technological University BelagaviDocument148 pagesVisvesvaraya Technological University BelagavichetanbvPas encore d'évaluation

- TLC Treatment and Marketing ProposalDocument19 pagesTLC Treatment and Marketing Proposalbearteddy17193Pas encore d'évaluation

- EC604(A) Microcontrollers and Embedded Systems Unit 2 SummaryDocument38 pagesEC604(A) Microcontrollers and Embedded Systems Unit 2 SummaryAbhay AmbulePas encore d'évaluation

- Gee1-Lp1 2022-2023Document18 pagesGee1-Lp1 2022-2023Sherrizah AlidoPas encore d'évaluation

- The Photoconductive CellDocument4 pagesThe Photoconductive Cellfasdasd123Pas encore d'évaluation

- Data Sheet 6EP1457-3BA00: InputDocument4 pagesData Sheet 6EP1457-3BA00: InputSeyyed Amir MohmmadiPas encore d'évaluation

- Axial and Appendicular Muscles GuideDocument10 pagesAxial and Appendicular Muscles GuideYasmeen AlnajjarPas encore d'évaluation

- Nutritional Deficiency Disorder Edit OneDocument23 pagesNutritional Deficiency Disorder Edit One01 HifzaPas encore d'évaluation

- The Message Development Tool - A Case For Effective Operationalization of Messaging in Social Marketing PracticeDocument17 pagesThe Message Development Tool - A Case For Effective Operationalization of Messaging in Social Marketing PracticesanjayamalakasenevirathnePas encore d'évaluation

- Deepali Bhartiya: TCI Express Limited Gurgaon Assistant Manager Prateek Group Noida Senior ExecutiveDocument3 pagesDeepali Bhartiya: TCI Express Limited Gurgaon Assistant Manager Prateek Group Noida Senior ExecutiveThe Cultural CommitteePas encore d'évaluation

- BV14 Butterfly ValveDocument6 pagesBV14 Butterfly ValveFAIYAZ AHMEDPas encore d'évaluation

- 3: Batteries: I Ne NR+RDocument3 pages3: Batteries: I Ne NR+RIsrael EdeaghePas encore d'évaluation

- A P1qneer 1n Neuroscience: Rita Levi-MontalciniDocument43 pagesA P1qneer 1n Neuroscience: Rita Levi-MontalciniAntPas encore d'évaluation

- Lab ReportDocument11 pagesLab Reportkelvinkiplaa845Pas encore d'évaluation

- Differential Scanning CalorimetryDocument60 pagesDifferential Scanning CalorimetryMariyam100% (2)

- Deepa CVDocument3 pagesDeepa CVDeepa M PPas encore d'évaluation

- Educational PlanningDocument20 pagesEducational PlanningedelynPas encore d'évaluation