Académique Documents

Professionnel Documents

Culture Documents

Summary Are We Ready For An Automotive Plantt

Transféré par

harrypputraTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Summary Are We Ready For An Automotive Plantt

Transféré par

harrypputraDroits d'auteur :

Formats disponibles

Case Summary : Are We Ready for Automotive Plant

At the end of 2008, McAllen had a lower unemployment rate compared to other cities in the US, but

their economic not as good as the unemployment rate. The city of McAllen, Texas wanted to boost

their economic activity by attract automotive companies to build manufacturing/ assembly plant in

McAllen. They knew the need of automakers such as access to top-tier auto parts suppliers, lower

wages, a higher education system with automative programs and a convenient transportation system,

and they established the MEDC with the ultimate goal to prepare the Edinburg-McAllen-Misssion,

Texas MSA as a ready site for automakers. They have the advantage from the proximity to Reynosa,

Mexico with the NAFTA provisions, high availability of workforce, the low labour cost, strategic

geographic location with timely access to national and international markets, and proposed incentives

included the economic development grant and property tax reimbusement. But they also have the

disadvantage with the lack of skilled labour as a handicap in attracting the auto manufacturers. The

other potential sites Detroit, Michigan is equipped with abundant suppliers, offered a large financial

incentive and reduction of personal income taxes, had highly educated workers available, accessibility

to strategic transportation infrastructure, abundant and affordable energy and its proximity to Canada.

Norfolk, Virginia has the experience with Ford automotive assembly plant, strong labour pool with

good labour-management relations, sufficient infrastructure, had the availability of skilled workers and

inclusive logistic, offered worker training and site preparation. Louisville, Kentucky lying in the centreof

America’s “Automotive Alley” which enabled the JIT delivery, had an logistical advantage with the

UPS hub for the US, utilized the lowest industrial power rates and possessed abundant coal reserves,

the workforce productivity had surpassed the national average, the fourth lowest cost of operating

business in the nation, provided tax credits and incentives : a sales tax refund on construction

materials and building equioments, lower housing, land and living cost than the national average, very

cooperative people.

The key factors for an automotive company to choosing a site : Labour cost, union activity, financial

incentive, workforce availability, supplier availability, and living cost.

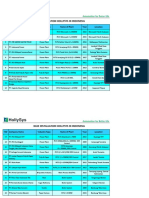

Compared to the other potential sites, McAllen has the lowest cost of labour cost (exhibit 3). Their

union activity about 4 to 5% of total workers (exhibit 4). McAllen had the second biggest financial

incentinve about 166 million from the other potential sites (exhibit 5). Had the lowest workforce

availability from the other potential sites (exhibit 6). The supplier in McAllen are limited compared to

the other potential sites (exhibit 7). For living cost, almost the cost of living in McAllen below the US

except for the healthcare and miscellaneous (exhibit 8).

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Indonesia HollySys Base-Installation. 11.03.2019Document3 pagesIndonesia HollySys Base-Installation. 11.03.2019Aerox neoPas encore d'évaluation

- The Employment Cost Index: What Is It?Document14 pagesThe Employment Cost Index: What Is It?AdminAliPas encore d'évaluation

- Tradingfxhub Com Blog How To Identify Supply and Demand CurveDocument15 pagesTradingfxhub Com Blog How To Identify Supply and Demand CurveKrunal ParabPas encore d'évaluation

- Joint Affidavit Ejectment SampleDocument3 pagesJoint Affidavit Ejectment SamplemessageforjasonPas encore d'évaluation

- ICBC Presentation 09Document24 pagesICBC Presentation 09AhmadPas encore d'évaluation

- Accounting Adjustments Chapter 3Document4 pagesAccounting Adjustments Chapter 3Alyssa LexPas encore d'évaluation

- Potentials, Applications & Challenges Challenges of Geothermal in IndonesiaDocument30 pagesPotentials, Applications & Challenges Challenges of Geothermal in IndonesiaMartin TambunPas encore d'évaluation

- Yeh Dil Maange More!!: Presenters: Ashwani Sangwan Pawan Dahiya Ajay NayakDocument43 pagesYeh Dil Maange More!!: Presenters: Ashwani Sangwan Pawan Dahiya Ajay NayakAshwani SangwanPas encore d'évaluation

- Philippine corporate law case digest summariesDocument42 pagesPhilippine corporate law case digest summariesAlarm GuardiansPas encore d'évaluation

- Cir Vs Mindanao GeothermalDocument2 pagesCir Vs Mindanao GeothermalAerwin AbesamisPas encore d'évaluation

- Sri Lankas Economic Crisis ABrief OverviewDocument12 pagesSri Lankas Economic Crisis ABrief OverviewSadhika MathurPas encore d'évaluation

- Capitalist and Socialist Economic Systems - GeeksforGeeksDocument8 pagesCapitalist and Socialist Economic Systems - GeeksforGeeksVI OrchidPas encore d'évaluation

- 6 PakistanDocument62 pages6 PakistanKhalil Ur Rehman YousafzaiPas encore d'évaluation

- Hosier y Dowd (1987) - Household Fuel Choice in Zimbabwe - An Empirical Test of The Energy Ladder HypothesisDocument15 pagesHosier y Dowd (1987) - Household Fuel Choice in Zimbabwe - An Empirical Test of The Energy Ladder HypothesisrEnato_sk8Pas encore d'évaluation

- A. Name and General LocationDocument11 pagesA. Name and General LocationJims Leñar CezarPas encore d'évaluation

- Builder NOC Format 1Document3 pagesBuilder NOC Format 1zaraiftu100% (4)

- Cardinal Utility AnalysisDocument27 pagesCardinal Utility AnalysisGETinTOthE SySteMPas encore d'évaluation

- 32 Resolution (20% DEVELOPMENT FUND 2020)Document3 pages32 Resolution (20% DEVELOPMENT FUND 2020)anabel100% (2)

- HersheyDocument9 pagesHersheyPew DUckPas encore d'évaluation

- St. Michael's College cost concepts and behaviorDocument5 pagesSt. Michael's College cost concepts and behaviorEmma Mariz GarciaPas encore d'évaluation

- gr6 Social Studies StandardsDocument11 pagesgr6 Social Studies Standardsapi-325184613Pas encore d'évaluation

- International Trade TheoryDocument28 pagesInternational Trade TheoryArpita ArtaniPas encore d'évaluation

- Girish KSDocument3 pagesGirish KSSudha PrintersPas encore d'évaluation

- Cecchetti 6e Chapter 23Document50 pagesCecchetti 6e Chapter 23Karthik LakshminarayanPas encore d'évaluation

- India's Coastal Regulation Zone Notification: A Critical AnalysisDocument69 pagesIndia's Coastal Regulation Zone Notification: A Critical Analysisajaythakur11Pas encore d'évaluation

- Black Soldier Fly larvae reduce vegetable waste up to 74Document11 pagesBlack Soldier Fly larvae reduce vegetable waste up to 74Firman Nugraha100% (1)

- List of Delegates - Aug 07Document30 pagesList of Delegates - Aug 07Pankaj BamalwaPas encore d'évaluation

- Forex Card RatesDocument2 pagesForex Card RatesKrishnan JayaramanPas encore d'évaluation

- GlobalDocument373 pagesGlobalMiguel RuizPas encore d'évaluation

- Foundations That Provide Small Grants To NgosDocument4 pagesFoundations That Provide Small Grants To NgosDevan BhallaPas encore d'évaluation