Académique Documents

Professionnel Documents

Culture Documents

Alcotech Alloy 4043tds

Transféré par

Juan Camaney XngonCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Alcotech Alloy 4043tds

Transféré par

Juan Camaney XngonDroits d'auteur :

Formats disponibles

ALLOY 4043 WELD DATA SHEET

TYPICAL APPLICATIONS

Welding Filler Wire

Spray and Flame Metallizing Wire

GENERAL INFORMATION

Trade Designation: Almigweld and Altigweld

Non-Heat treatable

Similar to AlSi5 (Germany), BS N21 (United Kingdom)

EN ISO 18273 designation AlSi5

Principle alloying element: Silicon

Applicable specifications: ANSI/AWS A5.10 (ER & R), AMS 4190 (Chemistry Only)

WELDING APPROVALS

Canadian Welding Bureau Lloyd’s Register

CE DB

TYPICAL PROPERTIES

Melting range: 1065 - 1170oF Resistance to corrosion: B (Gen) A (SCC)

Conductivity: 42 % IACS (-O) Anodize Color: Gray

Density: .097 lbs./cu. in.

CHEMISTRY

OTHERS

SILICON IRON COPPER MANGANESE MAGNESIUM CHROMIUM ZINC TITANIUM BERYLLIUM EACH TOTAL ALUM

4.5-6.0 0.8 0.30 0.05 0.05 ---- 0.10 0.20 0.0003 0.05 0.15 REM

NOTE: SINGLE VALUES ARE MAXIMUM UNLESS OTHERWISE NOTED.

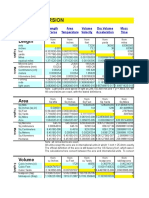

TYPICAL MECHANICAL PROPERTIES OF GTAW GROOVE JOINT WELDS

BASE ALLOY PROPERTIES AS WELDED POSTWELD HEAT-TREATED AND AGED1

BASE ALLOY UTS (KSI) UYS (KSI) ELONG (%) UTS (KSI) UYS (KSI) ELONG (%) UTS (KSI) UYS (KSI) ELONG (%)

2014-T6 70 60 13 34 28 4 50 ----- 2

6061-T4 35 21 22 27 18 8 352 ----- 82

6061-T6 45 40 12 27 18 8 44 40 5

6063-T4 25 22 22 20 10 12 30 ----- 13

(1) REQUIRES SUFFICIENT DILUTION OF BASE METAL INTO WELD POOL FOR HEAT TREAT AND/OR AGE RESPONSE. REFER TO

ALCOTECHNIC CONCERNING ALLOY 4643 FOR ADDITIONAL INFORMATION

(2) POSTWELD AGED ONLY.

AlcoTec Wire Corporation

2750 Aero Park Dr., Traverse City, MI 49686-9263 U.S.A. 1-800-228-0750 FAX: 231-941-9154

E-mail: sales@alcotec.com Website: www.alcotec.com

ALLOY CHARACTERISTICS

ALLOY 4043 IS ONE OF THE OLDEST AND MOST WIDELY USED WELDING AND BRAZING ALLOYS.

Almigweld AND Altigweld 4043 CAN BE CLASSED AS A GENERAL PURPOSE TYPE FILLER ALLOY. THE SILICON

ADDITIONS RESULT IN IMPROVED FLUIDITY (WETTING ACTION) TO MAKE THE ALLOY A PREFERRED CHOICE

BY WELDERS. THE ALLOY IS LESS SENSITIVE TO WELD CRACKING AND PRODUCES BRIGHTER, ALMOST

SMUT FREE WELDS.

Typical Semiautomatic GMA Procedures for Fillet and Lap Welding Aluminum

DC(EP)3 Base1 DC(EP) Wire Argon Approximate

Wire Dia Range Thickness Suggested Feed Gas Flow Consumption2

Inches Amps Volts Inches Amps Volts IPM CFH Lbs/100Ft

.030 100-130 18-22 .094 100 22 500 30 0.75

125-150 20-24 .125 120 22 600 30 1

.035 85-120 20-23 .094 110 22 480 30 0.75

125-150 20-24 .125 130 22 566 30 1

170-190 21-26 .250 170 23 740 35 4

.047 125-150 20-24 .125 150 23 360 30 1

180-210 22026 .187 180 23 410 30 2.3

170-240 24-28 .250 190 24 470 40 4

.062 190-260 21-26 .250 200 23 265 50 4

240-300 22-27 .375 230 24 300 50 9

260-310 22-27 .500 260 26 340 60 16

280-320 24-28 .750 280 27 385 65 36

290-340 26-30 1.000 300 28 420 70 64

.094 280-360 26-30 .750 320 29 170 60 36

300-400 26-32 1.000 330 30 180 80 64

1. Metal thickness of ¾” or greater for fillet welds sometimes employs a double vee bevel of 50 deg

or greater included vee with 3/32 to 1/8 inch land thickness on the abutting member.

2. Electrode consumption given for weld on one side only and based on leg length equal to plate

thickness.

3. For 5XXX series electrodes use a welding current in the high side of the range given and an arc

voltage in the lower portion of the range. 1XXX, 2XXX, and 4XXX series electrodes would use

the lower currents and higher arc voltages.

THIS INFORMATION IS BASED ON DATA DEVELOPED UNDER LABORATORY CONDITIONS AND IS DESIGNED AS

A GUIDELINE ONLY. INDIVIDUAL CONDITIONS, WELDING EQUIPMENT AND ENVIRONMENT CAN AFFECT

SUGGESTED SETTINGS.

AlcoTec Wire Corporation

2750 Aero Park Dr., Traverse City, MI 49686-9263 U.S.A. 1-800-228-0750 FAX: 231-941-9154

E-mail: sales@alcotec.com Website: www.alcotec.com

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- 100 Great War Movies-Robert Niemi PDFDocument394 pages100 Great War Movies-Robert Niemi PDFJuan Camaney Xngon100% (1)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Laminated Composite Stiffened Panels Application and BehaviourDocument46 pagesLaminated Composite Stiffened Panels Application and BehaviourHemendra Jain100% (1)

- Ship Corrosion - Cathodic Protection and Sacrificial AnodesDocument17 pagesShip Corrosion - Cathodic Protection and Sacrificial Anodese. barajas100% (1)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- SSP421 Body BasicsDocument76 pagesSSP421 Body Basicsmamuko100% (3)

- Basic Metatrader 5 GuideDocument22 pagesBasic Metatrader 5 GuideDavid Al100% (1)

- ASME B31.8 Wall Thickness CalculationDocument23 pagesASME B31.8 Wall Thickness Calculationisrar khan100% (2)

- Non Destructive Testing MethodsDocument186 pagesNon Destructive Testing Methodspatil_nana805567% (3)

- Ms-Mech-10, Ms Fabrication of PipingDocument13 pagesMs-Mech-10, Ms Fabrication of PipingBabar Manzoor GhauriPas encore d'évaluation

- FV 623 CatalogDocument50 pagesFV 623 CatalogOmar Coronado50% (2)

- A Guide To Ship Repair Estimates in Man-Hours-2nd Edition-2012 PDFDocument125 pagesA Guide To Ship Repair Estimates in Man-Hours-2nd Edition-2012 PDFJuan Camaney XngonPas encore d'évaluation

- Anchoring Practice (T.idzikovski 2001)Document98 pagesAnchoring Practice (T.idzikovski 2001)Mikhail Buyankin100% (1)

- ASME B31.3 wall thickness calcDocument11 pagesASME B31.3 wall thickness calcAnonymous wIPMQ5rhPas encore d'évaluation

- Design DocumentDocument10 pagesDesign DocumentLiza WoodsPas encore d'évaluation

- Aisc Shapes Database v15.0Document14 pagesAisc Shapes Database v15.0ErickSimonPas encore d'évaluation

- Technical Guidance Notes: Level 2, No. 13Document4 pagesTechnical Guidance Notes: Level 2, No. 13Τε ΧνηPas encore d'évaluation

- Fire Load CalculationDocument6 pagesFire Load CalculationGunvant Patel91% (11)

- 20K DWT Bulk Carrier Tech SpecDocument97 pages20K DWT Bulk Carrier Tech Specİbrahim Aydın100% (4)

- IONE-VP-02-H-001-075 - Rv11 - C - INSTRUMENT ALARM AND TRIP LIST - R11Document3 pagesIONE-VP-02-H-001-075 - Rv11 - C - INSTRUMENT ALARM AND TRIP LIST - R11dhiaa mohammedPas encore d'évaluation

- ASME B31.4 Riser CalcDocument14 pagesASME B31.4 Riser CalcCastorNoroñoPas encore d'évaluation

- #Div/0! #Div/0! #Div/0! #Div/0! #Div/0! #Div/0! #Div/0! #Div/0! #Div/0! #Div/0! #Div/0! #Div/0! #Div/0!Document7 pages#Div/0! #Div/0! #Div/0! #Div/0! #Div/0! #Div/0! #Div/0! #Div/0! #Div/0! #Div/0! #Div/0! #Div/0! #Div/0!Sefa CetinkayaPas encore d'évaluation

- Draft Survey - Specimen of Calculation - Marine and Cargo SurveyorsDocument15 pagesDraft Survey - Specimen of Calculation - Marine and Cargo SurveyorsJuan Camaney XngonPas encore d'évaluation

- GL 10Document99 pagesGL 10juanPas encore d'évaluation

- Draft Survey - The Accuracy and Factors Effecting Marine Surveyor InformationDocument5 pagesDraft Survey - The Accuracy and Factors Effecting Marine Surveyor InformationJuan Camaney XngonPas encore d'évaluation

- Paper OBM FinalDocument10 pagesPaper OBM FinalJuan Camaney XngonPas encore d'évaluation

- Brochure A0-A15 Internal Door DatasheetDocument1 pageBrochure A0-A15 Internal Door DatasheetJuan Camaney XngonPas encore d'évaluation

- The Construction of An A60 Fire Rated Door PDFDocument2 pagesThe Construction of An A60 Fire Rated Door PDFJuan Camaney XngonPas encore d'évaluation

- Unit Conversion: LengthDocument35 pagesUnit Conversion: LengthAnonymous 8aj9gk7GCLPas encore d'évaluation

- Boskalis Installation BrochureDocument11 pagesBoskalis Installation BrochureJuan Camaney XngonPas encore d'évaluation

- The Temperature Scales On Thermometers: How Are They Related?Document7 pagesThe Temperature Scales On Thermometers: How Are They Related?Juan Camaney XngonPas encore d'évaluation

- 10 5923 J Mechanics 20140403 02Document12 pages10 5923 J Mechanics 20140403 02Juan Camaney XngonPas encore d'évaluation

- TALAT Lecture 4201: Arc Welding Processes: TIG, Plasma Arc, MIGDocument36 pagesTALAT Lecture 4201: Arc Welding Processes: TIG, Plasma Arc, MIGCORE Materials100% (1)

- The Temperature Scales On Thermometers: How Are They Related?Document7 pagesThe Temperature Scales On Thermometers: How Are They Related?Juan Camaney XngonPas encore d'évaluation

- Unit Conversion: LengthDocument35 pagesUnit Conversion: LengthAnonymous 8aj9gk7GCLPas encore d'évaluation

- Temperature ScalesDocument3 pagesTemperature ScalesJuan Camaney XngonPas encore d'évaluation

- Galvanic Anode Selection and Design ConsiderationsDocument58 pagesGalvanic Anode Selection and Design ConsiderationsJuan Camaney XngonPas encore d'évaluation

- RtosDocument78 pagesRtossekinPas encore d'évaluation

- MESL - Differential Equation 2Document9 pagesMESL - Differential Equation 2Mark-Lorie Duculan NonesPas encore d'évaluation

- RGD AccessAbility Handbook 2015 ForWebFINAL-s PDFDocument32 pagesRGD AccessAbility Handbook 2015 ForWebFINAL-s PDFtiago87pintoPas encore d'évaluation

- GaAs solar cell modeling improves efficiencyDocument4 pagesGaAs solar cell modeling improves efficiencyTarak BenslimanePas encore d'évaluation

- Static Analysis of VMC Spindle For Maximum Cutting Force: Mahesh M. Ghadage Prof. Anurag V. KarandeDocument5 pagesStatic Analysis of VMC Spindle For Maximum Cutting Force: Mahesh M. Ghadage Prof. Anurag V. Karandefujy fujyPas encore d'évaluation

- Design of Foundations On Sensitive Champlain Clay Subjected To Cyclic LoadingDocument9 pagesDesign of Foundations On Sensitive Champlain Clay Subjected To Cyclic LoadingRamiro ChairezPas encore d'évaluation

- JT85 Vertical to Horizontal Drive Shaft Gearbox, 90 Deg Bevel Gear Box, 4 to 1 Gearbox, 2-Way Gearbox, Right Angle Gearbox Speed Increaser,Speed Increaser Gearbox Micro, 90 Degree Power Transfer 1 to 1 RatioDocument7 pagesJT85 Vertical to Horizontal Drive Shaft Gearbox, 90 Deg Bevel Gear Box, 4 to 1 Gearbox, 2-Way Gearbox, Right Angle Gearbox Speed Increaser,Speed Increaser Gearbox Micro, 90 Degree Power Transfer 1 to 1 RatioWarren LeePas encore d'évaluation

- Environmental Engineering - Civil Engineering - McGill UniversityDocument4 pagesEnvironmental Engineering - Civil Engineering - McGill Universityamrin jannatPas encore d'évaluation

- OpenDSS Level 1 TrainingDocument85 pagesOpenDSS Level 1 Trainingraul_bsu100% (1)

- High-Efficiency Controllers for Notebook ComputersDocument28 pagesHigh-Efficiency Controllers for Notebook ComputerscPas encore d'évaluation

- Net Positive Suction HeadDocument4 pagesNet Positive Suction Headjorge alarconPas encore d'évaluation

- Killexams HPE0 S46 Real Exam Questions Answers PDFDocument6 pagesKillexams HPE0 S46 Real Exam Questions Answers PDFopen_666Pas encore d'évaluation

- Charge AmpsDocument5 pagesCharge AmpsKrishnamurthy AnantharamakrishnanPas encore d'évaluation

- Effects of Cryogenic Cooling on Grinding Forces, Temperature and Residual StressesDocument9 pagesEffects of Cryogenic Cooling on Grinding Forces, Temperature and Residual StressesChirag JainPas encore d'évaluation

- TBR Wipro LeanDocument8 pagesTBR Wipro LeanAnonymous fVnV07HPas encore d'évaluation

- Database Normalization Is The Process of Organizing The Fields and Tables of A Relational Database To Minimize RedundancyDocument2 pagesDatabase Normalization Is The Process of Organizing The Fields and Tables of A Relational Database To Minimize RedundancyStan DitonaPas encore d'évaluation

- Carcass Chilling Systems and Their Impact On Meat Quality - Pig Articles From The Pig SiteDocument3 pagesCarcass Chilling Systems and Their Impact On Meat Quality - Pig Articles From The Pig SiteJose Romanillos VelascoPas encore d'évaluation

- Projection Achievement ReportDocument8 pagesProjection Achievement ReportPskaruppiah KarupsPas encore d'évaluation

- Radiography 2 ProcedureDocument9 pagesRadiography 2 ProceduresheikmoinPas encore d'évaluation

- Topaz HTC English Manual PDFDocument232 pagesTopaz HTC English Manual PDFRafael AdrianPas encore d'évaluation

- Heat Exchangers: T T T TDocument11 pagesHeat Exchangers: T T T Tcjc0706Pas encore d'évaluation