Académique Documents

Professionnel Documents

Culture Documents

James ASR & Carbo Detect : Features and Benefits

Transféré par

Karim NazefTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

James ASR & Carbo Detect : Features and Benefits

Transféré par

Karim NazefDroits d'auteur :

Formats disponibles

Corrosion

James ASR & Carbo Features

and Benefits

Detect* • Test can be carried out completely on site.

Simple colored dye field test to • Utilizes only two environmentally safe dyes.

detect Alkali Silica reaction • Identifies ASR in concrete and differentiates

(ASR) Carbo Detect — simple ASR from other causes of degradation.

colored dye field test for • Results obtained in less than five minutes

carbonation are easy to interpret.

• Economic, fast and easy to use.

US Patent No. 5,739,035 and other patents pending.

*

Trademark of Los Alamos National Laboratory

www.ndtjames.com NDT JAMES INSTRUMENTS INC. 69

James ASR & Carbo

Detect ™

ASR Detect

Method imply apply each of the two reagents to the broken surface of a

S concrete core drilled in a suspect structure and rinse off the excess.

On ASR contaminated concrete, the resultant stains reveal the

presence of ASR.

The stain’s distribution shows the extent of ASR in the concrete, and

their proximity to different components of the aggregate gives clues to

the source of trouble. The two gels that are identified-one staining

yellow, the other pink - indicate the stage of ASR’s progression. Yellow

signals that degradation has begun. Pink warns that degradation is

advancing.

Typically, ASR occurs in cracks and these cracks often cut through

the aggregate and usually do not follow the aggregate-paste

boundaries. ASR tends to fill air voids.

SR Detect is both a practical and a scientific tool. It’s principal

Applications

A application is analyzing existing concrete structures. By identifying

ASR deterioration in its earliest stages, ASR Detect facilitates the

problem being identified when remediation techniques can be applied;

for example, treating the concrete with a lithium-bearing solution to

inhibit further deterioration. Where deterioration is advanced, ASR

Detect provides a clear picture of the extent and depth of the damage.

As a scientific tool, ASR Detect can be applied to improving the

understanding of where, how and why ASR occurs. That

understanding is basic to developing ASR preventatives that allow

high-alkali cements or poor-quality aggregates to be used in concrete

mixes without risking the development of ASR.

Untreated concrete. Concrete tested with Concrete tested with Concrete tested with

pink gel only showing yellow gel only showing pink and yellow gels

advanced ASR degrada- beginning stages of showing both beginning

tion. ASR degradation. and advanced stages

of ASR.

70 NDT JAMES INSTRUMENTS INC. www.ndtjames.com

Corrosion

Carbo Detect

Technical

arbonation is one of the two main causes of corrosion of steel

C in concrete, the other is chloride attack. The result of the

interaction of carbon dioxide gas in the atmosphere with the

alkaline hydroxides in the concrete, the carbonation process

effectively drops the pH of the concrete to a level where the

steel will corrode. The carbon dioxide dissolves in water to form

carbonic acid, which can migrate to the reinforcing steel if the

concrete cover is low or if the concrete is of poor quality (open

pore structure, low cement content, high water cement ratio, or

poor curing of the concrete). Carbonation is more common in old

structures, particularly buildings.

Concrete Core showing uncarbonat-

ed area at the left

Method

arbo Detect reagent is a type of pH indicator which will

C indicate the change of pH on a freshly exposed concrete

surface. The indicator is simply sprayed on the surface to be

checked. The indicator will change to pink in uncarbonated

concrete and remain colorless when sprayed on carbonated (low

pH) concrete. If the concrete test area is very dry, a light misting

with water will help show the color.

By spraying the indicator along a core drilled from the top

surface down to the reinforcement bar it can be readily seen

how far the carbonation has progressed and therefore the

outlook for corrosion, which will only occur after carbonation

reaches the reinforcement bar.

Care should be taken to prevent drilling and coring dust from

contaminating the surface to be tested.

www.ndtjames.com NDT JAMES INSTRUMENTS INC. 71

James ASR & Carbo Detect ™

Technical Technical

Specifications One of the primary causes of premature concrete

deterioration is alkali-silica reaction (ASR). ASR causes

concrete to deteriorate when sodium and/or potassium

from the cement attacks silica rich components in the

aggregate, producing gels that expand and eventually

crack the structure.

ASR Detect was developed by Los Alamos National

Laboratory as part of its ongoing effort to characterize

concrete degradation mechanisms and to improve

concrete durability.

ASR Detect exploits the cation-exchange and

compositional properties of ASR gels to pinpoint ASR

degradation in a chemically specific way. Most gels

contain cations (positively charged atoms or

molecules) that readily exchange with other cations in

solution. ASR Detect’s two reagents react with cations

found in the two gels associated with ASR. The first

reagent exchanges sodium with the potassium found

in some ASR gels and then reacts to form a bright

yellow precipitate. The second reagent reacts with

calcium-rich ASR gel to form a bright pink stain. In

concrete containing ASR, the result is a brightly

colored surface showing the presence of the targeted

gels; concrete with no

ASR is unaffected.

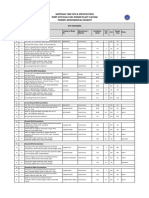

Sales Numbers

I-AS-3000 ASR-detect System

I-CB-6000 Carbo-detect System

200 ml of reagent —

sufficient for approximately

100 tests Sprayer Carrying Case

Concrete Core Showing Advanced ASR

3727 North Kedzie Avenue,

Chicago, Illinois 60618

1-800-426-6500 (773) 463-6565

FAX (773) 463-0009

e-mail: info@ndtjames.com

http://www.ndtjames.com

72 NDT JAMES INSTRUMENTS INC. www.ndtjames.com

Vous aimerez peut-être aussi

- Corrosion TestsDocument3 pagesCorrosion TestsbalakaleesPas encore d'évaluation

- Astm D1784-03Document4 pagesAstm D1784-03adanserranoPas encore d'évaluation

- Enhancing reliability of CRA piping welds with PAUTDocument10 pagesEnhancing reliability of CRA piping welds with PAUTMohsin IamPas encore d'évaluation

- Passivation Info For Laser Marked PartsDocument8 pagesPassivation Info For Laser Marked Partssaddleman100% (1)

- Surface Prep StandardsDocument25 pagesSurface Prep StandardsJahangir Khan100% (1)

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingD'EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingPas encore d'évaluation

- Preparation of Zinc (Hot-Dip Galvanized) Coated Iron and Steel Product and Hardware Surfaces For PaintingDocument5 pagesPreparation of Zinc (Hot-Dip Galvanized) Coated Iron and Steel Product and Hardware Surfaces For PaintingSyafiq RahimPas encore d'évaluation

- DTR VRD 2006Document51 pagesDTR VRD 2006Ahmed Lamine100% (5)

- Vents and Venting PDFDocument51 pagesVents and Venting PDFCamille MacatangayPas encore d'évaluation

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingD'EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghPas encore d'évaluation

- Challenges in Fabrication of 2.15Cr 1mo 0.25V ReactorsDocument56 pagesChallenges in Fabrication of 2.15Cr 1mo 0.25V Reactorsnikhileshkumar_mishr100% (1)

- Technology Guide 15: SSPC: The Society For Protective CoatingsDocument16 pagesTechnology Guide 15: SSPC: The Society For Protective CoatingsIris Carmen100% (1)

- Detect Concrete Corrosion CausesDocument4 pagesDetect Concrete Corrosion CausesApetsi AmpiahPas encore d'évaluation

- Alkali Aggregate ReactionDocument4 pagesAlkali Aggregate ReactionAbdelaziz AbdelhamidPas encore d'évaluation

- Raman Microscopy of Alkali-Silica Reaction (ASR) Products Formed in ConcreteDocument7 pagesRaman Microscopy of Alkali-Silica Reaction (ASR) Products Formed in ConcreteTao YangPas encore d'évaluation

- Alkali-Aggregate Reaction (AAR) : Lecture # 8Document20 pagesAlkali-Aggregate Reaction (AAR) : Lecture # 8ashar khanPas encore d'évaluation

- Detailed Non-Destructive Investigation Guidelines For Concrete and Steel BridgesDocument13 pagesDetailed Non-Destructive Investigation Guidelines For Concrete and Steel BridgessahilkaushikPas encore d'évaluation

- 3 Testing For Alkali-Silica ReactionDocument42 pages3 Testing For Alkali-Silica ReactionLuca BrandiPas encore d'évaluation

- A Study of Deterioration of Cement Paste Due To Acid Attack Using X-Ray ComputedDocument16 pagesA Study of Deterioration of Cement Paste Due To Acid Attack Using X-Ray ComputedFARZI ACCOUNTPas encore d'évaluation

- 2015 - Kassu Et Al. - Effect of Pore Size and Film Thickness On Gold-Coated Nanoporous Anodic Aluminum Oxide Substrates For Surface-EnhaDocument14 pages2015 - Kassu Et Al. - Effect of Pore Size and Film Thickness On Gold-Coated Nanoporous Anodic Aluminum Oxide Substrates For Surface-EnhaClaudio BiaginiPas encore d'évaluation

- Surface-Preparation Chemicals For Salt Decontamination or Flash Rust InhibitionDocument3 pagesSurface-Preparation Chemicals For Salt Decontamination or Flash Rust InhibitionDaniel Benegas100% (1)

- 2011 - Salerno Et Al. - Large-Scale Lithography-Free Fabrication of SERS Substrates by Gold Coating of Anodic Porous Alumina - 13th FotoDocument5 pages2011 - Salerno Et Al. - Large-Scale Lithography-Free Fabrication of SERS Substrates by Gold Coating of Anodic Porous Alumina - 13th FotoClaudio BiaginiPas encore d'évaluation

- Inspecting For Galvanization-Related Cracking in Steel StructuresDocument3 pagesInspecting For Galvanization-Related Cracking in Steel Structuress.mladinPas encore d'évaluation

- Analytical MetallographyDocument20 pagesAnalytical MetallographyAnthony AbelPas encore d'évaluation

- What Is Pitting Corrosion - How To Detect and Treat Pitting CorrosionDocument11 pagesWhat Is Pitting Corrosion - How To Detect and Treat Pitting CorrosionTahir AbbasPas encore d'évaluation

- Macr1300282 OffprintDocument11 pagesMacr1300282 OffprintASMAMAW GEDEFAWPas encore d'évaluation

- Alkali Aggregate ReactionDocument2 pagesAlkali Aggregate ReactionBatepola BacPas encore d'évaluation

- Handbook For The Identification of Alkali-Silica Re Activity in Highway Structures, Revised EditionDocument25 pagesHandbook For The Identification of Alkali-Silica Re Activity in Highway Structures, Revised EditionTooma DavidPas encore d'évaluation

- En Solutions-overview Steel Metals Overview Low Res Rel-1.3Document11 pagesEn Solutions-overview Steel Metals Overview Low Res Rel-1.3yifei.shao97Pas encore d'évaluation

- ASR in Concrete Harms Nuclear Plant SafetyDocument10 pagesASR in Concrete Harms Nuclear Plant SafetyChris BuckPas encore d'évaluation

- Control of CorrosionDocument12 pagesControl of CorrosionSyed ShahbazPas encore d'évaluation

- Effect of Soribing Modes On Corrosion Test ResultsDocument6 pagesEffect of Soribing Modes On Corrosion Test ResultsINRO IngeníeriaPas encore d'évaluation

- Lecture 06 Durability (ASR)Document36 pagesLecture 06 Durability (ASR)Danyal SafdarPas encore d'évaluation

- Effectiveness of Portland Pozolana Cement (PPC) in Mitigation of ASRDocument3 pagesEffectiveness of Portland Pozolana Cement (PPC) in Mitigation of ASRerpublicationPas encore d'évaluation

- Corrosion Inhibiting AdmixturesDocument2 pagesCorrosion Inhibiting AdmixturesDS20CE017Bhaskar WabhitkarPas encore d'évaluation

- Bahan Metlit1Document9 pagesBahan Metlit1valentinenorsPas encore d'évaluation

- nrcc22703 PDFDocument11 pagesnrcc22703 PDFDan MatPas encore d'évaluation

- Astm B0537Document8 pagesAstm B0537juniorferrari06Pas encore d'évaluation

- A Comparative Study Between ASTM C1567 and ASTM C227 To Mitigate Alkali-Silica ReactionDocument8 pagesA Comparative Study Between ASTM C1567 and ASTM C227 To Mitigate Alkali-Silica ReactionMARLON ESPINOZAPas encore d'évaluation

- Paint Specification No.: SSPC: The Society For Protective CoatingsDocument5 pagesPaint Specification No.: SSPC: The Society For Protective CoatingsanoopkumarPas encore d'évaluation

- Residual Strength of Reinforced Concrete Beams Damaged by Alkali-Silica Reaction-Examination of Rating Index MethodDocument9 pagesResidual Strength of Reinforced Concrete Beams Damaged by Alkali-Silica Reaction-Examination of Rating Index MethodMyat NoePas encore d'évaluation

- What Are Rust Converters?: So Why Mechanically Clean When You Can Convert Rust Easily?Document2 pagesWhat Are Rust Converters?: So Why Mechanically Clean When You Can Convert Rust Easily?Ian PerdanaPas encore d'évaluation

- Alkali-Aggregate Reaction: Prevention of Alkali-Silica Reaction in New ConcreteDocument2 pagesAlkali-Aggregate Reaction: Prevention of Alkali-Silica Reaction in New ConcretePritha DasPas encore d'évaluation

- 10 1016@j Conbuildmat 2008 02 020 PDFDocument8 pages10 1016@j Conbuildmat 2008 02 020 PDFJorge Iván Rivera DelgadoPas encore d'évaluation

- Anokap Stainless Steel SolutionsDocument2 pagesAnokap Stainless Steel SolutionsReadersmoPas encore d'évaluation

- Appleman - SalzeinflussDocument6 pagesAppleman - SalzeinflussyugandharPas encore d'évaluation

- Fernandez2018 Article EvaluationOfCorrosionLevelOfNaDocument13 pagesFernandez2018 Article EvaluationOfCorrosionLevelOfNaodongo johnPas encore d'évaluation

- Detect flaws and measure corrosion in concrete structuresDocument2 pagesDetect flaws and measure corrosion in concrete structuresWajira Sanjaya PereraPas encore d'évaluation

- Evaluation of Edge Detection Filters Applied To Corroded Steel SheetsDocument5 pagesEvaluation of Edge Detection Filters Applied To Corroded Steel SheetsInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- D610.Degree of RustingDocument6 pagesD610.Degree of RustingHector Aldair Valle RiveraPas encore d'évaluation

- Evaluating Degree of Rust on Prestressed Concrete StrandDocument6 pagesEvaluating Degree of Rust on Prestressed Concrete StrandrmqkrdPas encore d'évaluation

- Evaluation of Degree of Rusting On Prestressed Concrete StrandDocument6 pagesEvaluation of Degree of Rusting On Prestressed Concrete StrandEfrain SueldoPas encore d'évaluation

- Corrosion Failure From Water-Soluble Contaminants On AbrasivesDocument6 pagesCorrosion Failure From Water-Soluble Contaminants On Abrasivesyo_lobehotmailcom100% (1)

- Aspects of Salt Concentration On Prepared Steel SubstratesDocument6 pagesAspects of Salt Concentration On Prepared Steel Substratesmuthukumar100% (1)

- Cases from the F-Files: Shop Painting Going to WasteDocument5 pagesCases from the F-Files: Shop Painting Going to WasteEduard Gonzalo Rojas CervantesPas encore d'évaluation

- T-03 - TP-04 - Data Gathering Non Destructive Testing and Destructive Testing Procedures For Structural EngineersDocument57 pagesT-03 - TP-04 - Data Gathering Non Destructive Testing and Destructive Testing Procedures For Structural EngineersLimar SetstraPas encore d'évaluation

- Destructive FlyerDocument2 pagesDestructive Flyertomperrett100% (2)

- 2019 - Synthesis, Characterization, and Water Uptake Property of Alkali-Silica Reaction ProductsDocument14 pages2019 - Synthesis, Characterization, and Water Uptake Property of Alkali-Silica Reaction ProductsDomingos FerreiraPas encore d'évaluation

- Research ArticleDocument9 pagesResearch Articlekairu2506Pas encore d'évaluation

- SEM Analysis Reveals Failure MechanismDocument1 pageSEM Analysis Reveals Failure Mechanismanush srinivasPas encore d'évaluation

- Testing of ConcreteDocument24 pagesTesting of ConcreteNur IffahPas encore d'évaluation

- Corrosion Rate Calculation PDFDocument10 pagesCorrosion Rate Calculation PDFcometPas encore d'évaluation

- Field Guide For Rust On Reinforcing BarsDocument4 pagesField Guide For Rust On Reinforcing Barsragunas tatyaPas encore d'évaluation

- TMB 1580Document4 pagesTMB 1580Karim NazefPas encore d'évaluation

- TMB 1580Document4 pagesTMB 1580Karim NazefPas encore d'évaluation

- Automatic Evaluation of Traffic Sign Visibility Using SVM Recognition MethodsDocument6 pagesAutomatic Evaluation of Traffic Sign Visibility Using SVM Recognition MethodsKarim NazefPas encore d'évaluation

- Walking Pofiler 3 ARRB - PB - WPG3Document2 pagesWalking Pofiler 3 ARRB - PB - WPG3Karim NazefPas encore d'évaluation

- TMB 1548Document4 pagesTMB 1548Karim NazefPas encore d'évaluation

- PT Export 2018 NewDocument2 pagesPT Export 2018 NewKarim NazefPas encore d'évaluation

- Examen Anglais 2010 1AM T3Document2 pagesExamen Anglais 2010 1AM T3Karim NazefPas encore d'évaluation

- Examen Maths2011 1AP T2Document2 pagesExamen Maths2011 1AP T2Karim NazefPas encore d'évaluation

- English Test N2: Activity One: Let's Count Use There Is There AreDocument2 pagesEnglish Test N2: Activity One: Let's Count Use There Is There AreKarim NazefPas encore d'évaluation

- Examen Anglais 2011 1AM T3Document2 pagesExamen Anglais 2011 1AM T3Karim NazefPas encore d'évaluation

- Examen Arabe2012 1AP T2Document2 pagesExamen Arabe2012 1AP T2Karim NazefPas encore d'évaluation

- Examen Maths 2011 1AP T2Document2 pagesExamen Maths 2011 1AP T2Karim NazefPas encore d'évaluation

- Examen Arabe 2011 1AP T2Document2 pagesExamen Arabe 2011 1AP T2Karim NazefPas encore d'évaluation

- Examen Arabe 2011 1AP T2Document2 pagesExamen Arabe 2011 1AP T2Karim NazefPas encore d'évaluation

- Examen Maths2011 1AP T2Document2 pagesExamen Maths2011 1AP T2Karim NazefPas encore d'évaluation

- Evaluation Maths 2010 1AP T2Document2 pagesEvaluation Maths 2010 1AP T2Karim NazefPas encore d'évaluation

- Evaluation Arabe 2010 1AP T2Document2 pagesEvaluation Arabe 2010 1AP T2Karim NazefPas encore d'évaluation

- Resea Um SilaDocument1 pageResea Um SilaKarim NazefPas encore d'évaluation

- Devoir n02 Maths2012 1AP T2Document2 pagesDevoir n02 Maths2012 1AP T2Karim NazefPas encore d'évaluation

- SEMINAR REPORT RCC RoadDocument25 pagesSEMINAR REPORT RCC RoadAkshay GhorpadePas encore d'évaluation

- SOR 2023-24 JunagadhDocument284 pagesSOR 2023-24 JunagadhChander SenPas encore d'évaluation

- FAI Services Overview (Compressed Pictures)Document293 pagesFAI Services Overview (Compressed Pictures)Mariela CarrilloPas encore d'évaluation

- Paramount 2012Document10 pagesParamount 2012Naga SayanPas encore d'évaluation

- Tolerances and Resultant Fits - SKF PDFDocument3 pagesTolerances and Resultant Fits - SKF PDFOfic MecanicaPas encore d'évaluation

- Unit 2 - Toilet MonitoringDocument54 pagesUnit 2 - Toilet MonitoringJhecy RodriguezPas encore d'évaluation

- Bridge Project FINALDocument45 pagesBridge Project FINALteweldePas encore d'évaluation

- Audi A8/A8L 2004-2008 Body Interior 70 - Removal and InstallationDocument33 pagesAudi A8/A8L 2004-2008 Body Interior 70 - Removal and InstallationやめぴPas encore d'évaluation

- NSCR-ROW-Elevated-StructuresDocument1 pageNSCR-ROW-Elevated-Structuresftma borjaPas encore d'évaluation

- Datasheet Zetamix AluminaDocument2 pagesDatasheet Zetamix Aluminaamandapoly0123Pas encore d'évaluation

- SMA Technical NoteDocument2 pagesSMA Technical NoteLutfi TofiqPas encore d'évaluation

- Veneer and Laminates in Residential Construction PresentationDocument36 pagesVeneer and Laminates in Residential Construction PresentationVishakhaBhardwajPas encore d'évaluation

- REX Silica TapeDocument4 pagesREX Silica TapeREX Sealing and Packing Industries Pvt. Ltd.Pas encore d'évaluation

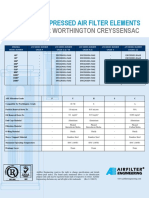

- Compatible Compressed Air Filter Elements for Worthington Creyssensac ModelsDocument1 pageCompatible Compressed Air Filter Elements for Worthington Creyssensac ModelsАнтон ЕмельяновPas encore d'évaluation

- MPSHD Hi Ar DWG A 6004Document1 pageMPSHD Hi Ar DWG A 6004Emon RayPas encore d'évaluation

- Structural Steel Fabrication Process ControlDocument1 pageStructural Steel Fabrication Process ControlMrk KhanPas encore d'évaluation

- Standard Specifications Roll and Cut Groove For Steel Pipe Technical Data General DescriptionDocument4 pagesStandard Specifications Roll and Cut Groove For Steel Pipe Technical Data General DescriptionMohammad SaleemPas encore d'évaluation

- MTO & Specification - Grounding & ConduitDocument6 pagesMTO & Specification - Grounding & ConduitMikailPas encore d'évaluation

- Duralatex, Mortar and Screed Improver and AdhesiveDocument2 pagesDuralatex, Mortar and Screed Improver and AdhesiveM HAFEEZ RAJAPas encore d'évaluation

- Estonia JobsDocument8 pagesEstonia JobsMd JonayedPas encore d'évaluation

- FSI FiltersDocument91 pagesFSI FiltersEduardo RodriguesPas encore d'évaluation

- ReviewDocument40 pagesReviewRossana VerdidaPas encore d'évaluation

- Online 1 PREFABRICATION LOW COST Affordable HousingDocument16 pagesOnline 1 PREFABRICATION LOW COST Affordable HousingSadiya SharminPas encore d'évaluation

- Cleaning MasterplanDocument28 pagesCleaning MasterplanJoseph James QuichoPas encore d'évaluation

- Effect of heat treatment on hardness and microstructure of manganese steelDocument8 pagesEffect of heat treatment on hardness and microstructure of manganese steelndeminPas encore d'évaluation

- Corrosion Repair Works in ICF Coaches and LHB Coach Maintenance at C&W PeramburDocument28 pagesCorrosion Repair Works in ICF Coaches and LHB Coach Maintenance at C&W PeramburVishnu GopiPas encore d'évaluation

- 1 Metallography Lab SheetDocument5 pages1 Metallography Lab SheetAlexPas encore d'évaluation