Académique Documents

Professionnel Documents

Culture Documents

1900 MTPD Ammonia Plant Venturi Flow Element Data Sheet

Transféré par

Jan Richardo GultomDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1900 MTPD Ammonia Plant Venturi Flow Element Data Sheet

Transféré par

Jan Richardo GultomDroits d'auteur :

Formats disponibles

PT PANCA AMARA UTAMA

1900 MTPD AMMONIA PLANT

CENTRAL SULAWESI, INDONESIA

PRELIMINARY DATA SHEET

FOR

VENTURI FLOW ELEMENT

F283-IC-DAS-IC0-0002

JOB NO. : F283

THIS DOCUMENT CONTAINS INFORMATION WHICH IS PROPRIETARY TO KELLOGG BROWN & ROOT

INTERNATIONAL, INC. (KBR). THIS INFORMATION IS TO BE HELD IN CONFIDENCE. NO DISCLOSURE,

REPRODUCTION OR OTHER USE OF THIS DOCUMENT IS TO BE MADE WITHOUT THE PRIOR WRITTEN CONSENT

OF KELLOGG BROWN & ROOT INTERNATIONAL, INC. (KBR).

THIS DOCUMENT CONTAINS INFORMATION THAT IS SUBJECTED TO U.S. CONTROL REGULATIONS, INCLUDING

RESTRICTIONS ON THE EXPORT, SALES OR TRANSFER OF U.S. ORGIN ITEMS (GOODS, TECHNOLOGY OR

SOFTWARE) TO SANCTIONED OR EMBARGOED COUNTRIES, ENTITIES EXCEPT AS AUTHORIZED UNDER U.S.

EXPORT CONTROL REQUIREMENTS.

P00 29-Jun-15 RE-ISSUED FOR DESIGN MM BBK RT

0 21-May-13 ISSUED FOR DESIGN PB NSB RT

REV. DATE DESCRIPTION PREP. CHKD. APVD.

Tag No. Service Rev.

FE-1003 PROCESS AIR TO COLD AIR COIL P00

FE-1004 PROCESS AIR TO COLD AIR COIL P00

FE-1072 BFW TO 103-C2 P00

FE-1007 103-J 1ST STAGE SUCTION P00

FE-1008 103-J 2ND STAGE SUCTION P00

FE-1059 103-J 3RD STAGE DISCHARGE P00

FE-1020 BFW TO 123-C1/C2 P00

FE-1257 SYN. GAS TO 102-B HEATER P00

FE-1012 REFRIGERANT FROM 120-CF1 TO 105-J 1ST STAGE P00

FE-1009 105-J 4TH STAGE DISCHARGE P00

FE-1010 105-J 3RD STAGE DISCHARGE TO 128-C P00

FE-1011 105-J 2ND STAGE DISCHARGE TO 167-C P00

FE-1002 PROCESS STEAM TO MIXED FEED P00

FE-1046 183-C REGEN TO 109-DA/DB P00

FE-1033 141-D H.P. STEAM 0UTLET P00

FE-1350 M.P. STEAM TO/FROM OFFSITES AND UREA P00

FE-1123 H.P. STEAM TO 103-JT P00

FE-1124 103-JT STEAM OUT TO MS HEADER P00

FE-1125 H.P. STEAM TO 105-JT P00

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 314 Sheet 1 of 39

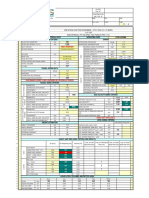

1 Tag Number FE-1003

2 Service PROCESS AIR TO COLD AIR COIL

3 Line No. / Equipment No. P & ID Number A1001 -16" (06CB1S01) 62-D101B

GENERAL 4 Line Size Line Sched. 16" 80

5 Line I.D. 14.312"

6

7

8 Fluid State PROCESS AIR VAPOR

9 Flow: Unit Min Nor Max kg/hr 80626 134377 147815

10 Pressure: Unit Min Nor Max kg/cm2 (a) 44.431

11 Temperature: Unit Min Nor Max °C 158.8

12 Density: Unit Min Nor Max kg/m3 34.453

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.025

CONDITIONS 14 Molecular Weight 28.88

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Cp/Cv 1.417

20

21 Tag Number Data Sheet Number FT-1003 / FT-1203 A / B / C BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material KILLED CARBON STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.65771

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 239.092 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 16" 600# RF

40 Outlet Size, Rating & Preparation 16" 600# RF

41 Flow Full Scale 162596 kg/hr

42 Differential Pressure @ Full Scale 1250 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 2 of 39

Tag Number: FE-1003

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for venturi Tubes 26" & above

(Detail Engineering to confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 3 of 39

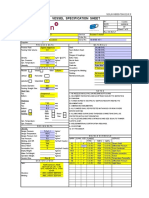

1 Tag Number FE-1004

2 Service PROCESS AIR TO COLD AIR COIL

3 Line No. / Equipment No. P & ID Number A1001 -16" (06CB1S01) 62-D101B

GENERAL 4 Line Size Line Sched. 16" 80

5 Line I.D. 14.312"

6

7

8 Fluid State PROCESS AIR VAPOR

9 Flow: Unit Min Nor Max kg/hr 80626 134377 147815

10 Pressure: Unit Min Nor Max kg/cm2 (a) 44.69

11 Temperature: Unit Min Nor Max °C 158.8

12 Density: Unit Min Nor Max kg/m3 34.481

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.025

CONDITIONS 14 Molecular Weight 28.88

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Cp/Cv 1.417

20

21 Tag Number Data Sheet Number FT-1004 BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material KILLED CARBON STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.65770

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 239.091 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 16" 600# RF

40 Outlet Size, Rating & Preparation 16" 600# RF

41 Flow Full Scale 162596 kg/hr

42 Differential Pressure @ Full Scale 1250 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 4 of 39

Tag Number: FE-1004

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 5 of 39

1 Tag Number FE-1072

2 Service BFW TO 103-C2

3 Line No. / Equipment No. P & ID Number BW1005-6" (15CB1S02) 62-D108

GENERAL 4 Line Size Line Sched. 6" 160

5 Line I.D. 5.187"

6

7

8 Fluid State BOILER FEED WATER LIQUID

9 Flow: Unit Min Nor Max kg/hr 61843 103071 113378

10 Pressure: Unit Min Nor Max kg/cm2 (a) 145.03

11 Temperature: Unit Min Nor Max °C 153.6

12 Density: Unit Min Nor Max kg/m3 921.31

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.181

CONDITIONS 14 Molecular Weight -

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Vapour Pressure 5.34 kg/cm2 (a)

20

21 Tag Number Data Sheet Number FT-1072 / 1106 BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material KILLED CARBON STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.68987

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 90.8904 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 6" 1500# RTJ

40 Outlet Size, Rating & Preparation 6" 1500# RTJ

41 Flow Full Scale 124715.8 kg/hr

42 Differential Pressure @ Full Scale 1250 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 6 of 39

Tag Number: FE-1072

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 7 of 39

1 Tag Number FE-1007

2 Service 103-J 1ST STAGE SUCTION

3 Line No. / Equipment No. P & ID Number SG1411 -20" (03CB1S01) 62-D113

GENERAL 4 Line Size Line Sched. 20" XS

5 Line I.D. 19"

6

7

8 Fluid State SYNTHESIS GAS VAPOR

9 Flow: Unit Min Nor Max kg/hr 51215 85359 93895

10 Pressure: Unit Min Nor Max kg/cm2 (a) 32.23

11 Temperature: Unit Min Nor Max °C 1.8

12 Density: Unit Min Nor Max kg/m3 11.722

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.014

CONDITIONS 14 Molecular Weight 8.617

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Cp/Cv 1.417

20

21 Tag Number Data Sheet Number FT-1007 BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material KILLED CARBON STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.53457

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 257.986 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 20" 300# RF

40 Outlet Size, Rating & Preparation 20" 300# RF

41 Flow Full Scale 103284 kg/hr

42 Differential Pressure @ Full Scale 1250 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 8 of 39

Tag Number: FE-1007

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 9 of 39

1 Tag Number FE-1008

2 Service 103-J 2ND STAGE SUCTION

3 Line No. / Equipment No. P & ID Number SG1039 -16" (15CB1S01) 62-D113

GENERAL 4 Line Size Line Sched. 16" 120

5 Line I.D. 13.562"

6

7

8 Fluid State SYNTHESIS GAS VAPOR

9 Flow: Unit Min Nor Max kg/hr 51215 85359 93895

10 Pressure: Unit Min Nor Max kg/cm2 (a) 80.25

11 Temperature: Unit Min Nor Max °C 41

12 Density: Unit Min Nor Max kg/m3 24.933

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.015

CONDITIONS 14 Molecular Weight 8.617

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Cp/Cv 1.423

20

21 Tag Number Data Sheet Number FT-1008 BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material KILLED CARBON STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.60972

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 210.035 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 16" 1500# RTJ

40 Outlet Size, Rating & Preparation 16" 1500# RTJ

41 Flow Full Scale 103284 kg/hr

42 Differential Pressure @ Full Scale 1250 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 10 of 39

Tag Number: FE-1008

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 11 of 39

1 Tag Number FE-1059

2 Service 103-J 3RD STAGE DISCHARGE

3 Line No. / Equipment No. P & ID Number SG1010 -24" (15CB1S01) 62-D113

GENERAL 4 Line Size Line Sched. 24" 120

5 Line I.D. 20.376"

6

7

8 Fluid State SYNTHESIS GAS VAPOR

9 Flow: Unit Min Nor Max kg/hr 182192 303654 334019

10 Pressure: Unit Min Nor Max kg/cm2 (a) 157.94

11 Temperature: Unit Min Nor Max °C 66.9

12 Density: Unit Min Nor Max kg/m3 49.698

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.017

CONDITIONS 14 Molecular Weight 9.771

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Cp/Cv 1.438

20

21 Tag Number Data Sheet Number FT-1059 BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material KILLED CARBON STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.63866

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 330.540 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 24" 1500# RTJ

40 Outlet Size, Rating & Preparation 24" 1500# RTJ

41 Flow Full Scale 367420 kg/hr

42 Differential Pressure @ Full Scale 1250 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 12 of 39

Tag Number: FE-1059

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 13 of 39

1 Tag Number FE-1020

2 Service BFW TO 123-C1/C2

3 Line No. / Equipment No. P & ID Number BW1004-10" (15CB1S02) 62-D114

GENERAL 4 Line Size Line Sched. 10" 140

5 Line I.D. 8.75"

6

7

8 Fluid State BOILER FEED WATER LIQUID

9 Flow: Unit Min Nor Max kg/hr 107678 179464 197410

10 Pressure: Unit Min Nor Max kg/cm2 (a) 145.03

11 Temperature: Unit Min Nor Max °C 153.6

12 Density: Unit Min Nor Max kg/m3 921.29

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.181

CONDITIONS 14 Molecular Weight -

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Vapour Pressure 5.34 kg/cm2 (a)

20

21 Tag Number Data Sheet Number FT-1020 BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material KILLED CARBON STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.56071

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 124.618 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 10" 1500# RTJ

40 Outlet Size, Rating & Preparation 10" 1500# RTJ

41 Flow Full Scale 217151 kg/hr

42 Differential Pressure @ Full Scale 1250 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 14 of 39

Tag Number: FE-1020

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 15 of 39

1 Tag Number FE-1257

2 Service SYN. GAS TO 102-B HEATER

3 Line No. / Equipment No. P & ID Number SG1026-12" (15CJ2S01) 62-D115

GENERAL 4 Line Size Line Sched. 12" 38.10 mm WALL

5 Line I.D. 9.750"

6

7

8 Fluid State SYNTHESIS GAS VAPOR

9 Flow: Unit Min Nor Max kg/hr 32500 65000 71500

10 Pressure: Unit Min Nor Max kg/cm2 (a) 103.32

11 Temperature: Unit Min Nor Max °C 220.0

12 Density: Unit Min Nor Max kg/m3 23.68

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.022

CONDITIONS 14 Molecular Weight 9.96

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Cp/Cv 1.405

20

21 Tag Number Data Sheet Number FT-1257 BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material 1-1/4 CR - 1/2 MO ALLOY STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.62573

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 154.973 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 12" 1500# RTJ

40 Outlet Size, Rating & Preparation 12" 1500# RTJ

41 Flow Full Scale 78650 kg/hr

42 Differential Pressure @ Full Scale 2500 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 16 of 39

Tag Number: FE-1257

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 17 of 39

1 Tag Number FE-1012

2 Service REFRIGERANT FROM 120-CF1 TO 105-J 1ST STAGE

3 Line No. / Equipment No. P & ID Number NH1013 -16" (01CA1S01) 62-D116A

GENERAL 4 Line Size Line Sched. 16" STD

5 Line I.D. 15.25"

6

7

8 Fluid State AMMONIA REFRIGERANT VAPOR

9 Flow: Unit Min Nor Max kg/hr 6052 10086 11095

10 Pressure: Unit Min Nor Max kg/cm2 (a) 1.035

11 Temperature: Unit Min Nor Max °C -33.3

12 Density: Unit Min Nor Max kg/m3 0.885

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.008

CONDITIONS 14 Molecular Weight 17.018

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Cp/Cv 1.381

20

21 Tag Number Data Sheet Number FT-1012 BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material LOW TEMPERATURE CARBON STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.45223

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 175.172 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 16" 300# RF

40 Outlet Size, Rating & Preparation 16" 300# RF

41 Flow Full Scale 12200 kg/hr

42 Differential Pressure @ Full Scale 1250 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 18 of 39

Tag Number: FE-1012

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 19 of 39

1 Tag Number FE-1009

2 Service 105-J 4TH STAGE DISCHARGE

3 Line No. / Equipment No. P & ID Number NH1007-20" (03CB1S01) 62-D117

GENERAL 4 Line Size Line Sched. 20" XS

5 Line I.D. 19"

6

7

8 Fluid State AMMONIA REFRIGERANT VAPOR

9 Flow: Unit Min Nor Max kg/hr 59451 99085 108994

10 Pressure: Unit Min Nor Max kg/cm2 (a) 16.153

11 Temperature: Unit Min Nor Max °C 97.8

12 Density: Unit Min Nor Max kg/m3 9.414

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.013

CONDITIONS 14 Molecular Weight 17.028

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Cp/Cv 1.367

20

21 Tag Number Data Sheet Number FT-1009 BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material KILLED CARBON STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.59991

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 289.516 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 20" 300# RF

40 Outlet Size, Rating & Preparation 20" 300# RF

41 Flow Full Scale 119893 kg/hr

42 Differential Pressure @ Full Scale 1250 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 20 of 39

Tag Number: FE-1009

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 21 of 39

1 Tag Number FE-1010

2 Service 105-J 3RD STAGE DISCHARGE TO 128-C

3 Line No. / Equipment No. P & ID Number NH1005-18" (01CB1S01) 62-D117

GENERAL 4 Line Size Line Sched. 18" STD

5 Line I.D. 17.25"

6

7

8 Fluid State AMMONIA REFRIGERANT VAPOR

9 Flow: Unit Min Nor Max kg/hr 33798 56330 61963

10 Pressure: Unit Min Nor Max kg/cm2 (a) 8.201

11 Temperature: Unit Min Nor Max °C 81.6

12 Density: Unit Min Nor Max kg/m3 4.843

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.012

CONDITIONS 14 Molecular Weight 17.028

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Cp/Cv 1.338

20

21 Tag Number Data Sheet Number FT-1010 BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material KILLED CARBON STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.59077

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 258.845 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 18" 300# RF

40 Outlet Size, Rating & Preparation 18" 300# RF

41 Flow Full Scale 68160 kg/hr

42 Differential Pressure @ Full Scale 1250 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 22 of 39

Tag Number: FE-1010

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 23 of 39

1 Tag Number FE-1011

2 Service 105-J 2ND STAGE DISCHARGE TO 167-C

3 Line No. / Equipment No. P & ID Number NH1003 -16" (01CB1S01) 62-D117

GENERAL 4 Line Size Line Sched. 16" STD

5 Line I.D. 15.25"

6

7

8 Fluid State AMMONIA REFRIGERANT VAPOR

9 Flow: Unit Min Nor Max kg/hr 15434 25724 28296

10 Pressure: Unit Min Nor Max kg/cm2 (a) 4.375

11 Temperature: Unit Min Nor Max °C 66.4

12 Density: Unit Min Nor Max kg/m3 2.655

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.0122

CONDITIONS 14 Molecular Weight 17.026

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Cp/Cv 1.328

20

21 Tag Number Data Sheet Number FT-1011 BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material KILLED CARBON STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.53248

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 206.257 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 16" 300# RF

40 Outlet Size, Rating & Preparation 16" 300# RF

41 Flow Full Scale 31125 kg/hr

42 Differential Pressure @ Full Scale 1250 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 24 of 39

Tag Number: FE-1011

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 25 of 39

1 Tag Number FE-1002

2 Service PROCESS STEAM TO MIXED FEED

3 Line No. / Equipment No. P & ID Number MS1006-16" (06CB1S02) 62-D120

GENERAL 4 Line Size Line Sched. 16" 80

5 Line I.D. 14.312"

6

7

8 Fluid State MP STEAM VAPOR

9 Flow: Unit Min Nor Max kg/hr 63483 105805 116386

10 Pressure: Unit Min Nor Max kg/cm2 (a) 47.69

11 Temperature: Unit Min Nor Max °C 383.8

12 Density: Unit Min Nor Max kg/m3 16.621

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.06

CONDITIONS 14 Molecular Weight 18.015

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Cp/Cv 1.385

20

21 Tag Number Data Sheet Number FT-1002/1202A/B/C BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material KILLED CARBON STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.68905

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 250.485 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 16" 600# RF

40 Outlet Size, Rating & Preparation 16" 600# RF

41 Flow Full Scale 128024.6 kg/hr

42 Differential Pressure @ Full Scale 1250 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 26 of 39

Tag Number: FE-1002

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 27 of 39

1 Tag Number FE-1046

2 Service 183-C REGEN TO 109-DA/DB

3 Line No. / Equipment No. P & ID Number SG1412-14" (03CJ1S01) 62-D130

GENERAL 4 Line Size Line Sched. 14" XS

5 Line I.D. 13"

6

7

8 Fluid State WASTE GAS VAPOR

9 Flow: Unit Alt Max Nor Max kg/hr 6535 0 14178 20874

10 Pressure: Unit Alt Max Nor Max kg/cm2 (a) 2.085 2.31

11 Temperature: Unit Alt Max Nor Max °C 245.0 245.0

12 Density: Unit Alt Max Nor Max kg/m3 0.52 1.311

PROCESS 13 Viscosity: Unit Alt Max Nor Max cP 0.022 0.025

CONDITIONS 14 Molecular Weight 24.953

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Cp/Cv 1.346

20

21 Tag Number Data Sheet Number FT-1046 BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material 1-1/4 CR - 1/2 MO ALLOY STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.62555

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 206.558 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 14" 300# RF

40 Outlet Size, Rating & Preparation 14" 300# RF

41 Flow Full Scale 22961.4 kg/hr

42 Differential Pressure @ Full Scale 1250 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 28 of 39

Tag Number: FE-1046

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

9 Two Meter factors are required for FV-1046.

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 29 of 39

1 Tag Number FE-1033

2 Service 141-D H.P. STEAM 0UTLET

3 Line No. / Equipment No. P & ID Number HS1001-18" (15CB1S02) 64-D101

GENERAL 4 Line Size Line Sched. 18" 140

5 Line I.D. 14.876"

6

7

8 Fluid State HP STEAM VAPOR

9 Flow: Unit Min Nor Max kg/hr 167829 279715 307687

10 Pressure: Unit Min Nor Max kg/cm2 (a) 127.53

11 Temperature: Unit Min Nor Max °C 327.8

12 Density: Unit Min Nor Max kg/m3 74.051

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.021

CONDITIONS 14 Molecular Weight 18.015

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Cp/Cv 2.791

20

21 Tag Number Data Sheet Number FT-1033 BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material KILLED CARBON STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.63631

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 240.432 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 18" 1500# RTJ

40 Outlet Size, Rating & Preparation 18" 1500# RTJ

41 Flow Full Scale 338455.7 kg/hr

42 Differential Pressure @ Full Scale 2500 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 30 of 39

Tag Number: FE-1033

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 31 of 39

1 Tag Number FE-1350

2 Service M.P. STEAM TO/FROM OFFSITES AND UREA

3 Line No. / Equipment No. P & ID Number MS1010 -10" (06CB1S02) 64-D103

GENERAL 4 Line Size Line Sched. 10" 80

5 Line I.D. 9.562"

6

7

8 Fluid State MP STEAM VAPOR

9 Flow: Unit Min Nor Max kg/hr 15000 25000 27500

10 Pressure: Unit Min Nor Max kg/cm2 (a) 47.88

11 Temperature: Unit Min Nor Max °C 384.0

12 Density: Unit Min Nor Max kg/m3 16.687

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.024

CONDITIONS 14 Molecular Weight 18.015

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Cp/Cv 1.387

20

21 Tag Number Data Sheet Number FT-1350A/B BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material KILLED CARBON STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.52432

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 127.344 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 10" 600# RF

40 Outlet Size, Rating & Preparation 10" 600# RF

41 Flow Full Scale 30250 kg/hr

42 Differential Pressure @ Full Scale 1250 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 32 of 39

Tag Number: FE-1350

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 33 of 39

1 Tag Number FE-1123

2 Service H.P. STEAM TO 103-JT

3 Line No. / Equipment No. P & ID Number HS1103-16" (25CK1S02) 64-D107

GENERAL 4 Line Size Line Sched. 16" 57.15mm WALL

5 Line I.D. 11.500"

6

7

8 Fluid State HP STEAM VAPOR

9 Flow: Unit Min Nor Max kg/hr 95491 159152 192574

10 Pressure: Unit Min Nor Max kg/cm2 (a) 123.63

11 Temperature: Unit Min Nor Max °C 509.8

12 Density: Unit Min Nor Max kg/m3 37.077

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.029

CONDITIONS 14 Molecular Weight 18.015

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Cp/Cv 1.426

20

21 Tag Number Data Sheet Number FT-1123 BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material 2-1/4 CR - 1 MO ALLOY STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.64703

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 188.998 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 16" 2500# RTJ

40 Outlet Size, Rating & Preparation 16" 2500# RTJ

41 Flow Full Scale 211831.4 kg/hr

42 Differential Pressure @ Full Scale 5000 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 34 of 39

Tag Number: FE-1123

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 35 of 39

1 Tag Number FE-1124

2 Service 103-JT STEAM OUT TO MS HEADER

3 Line No. / Equipment No. P & ID Number MS1013-18" (06CB1S02) 64-D107

GENERAL 4 Line Size Line Sched. 18" 80

5 Line I.D. 16.124"

6

7

8 Fluid State MP STEAM VAPOR

9 Flow: Unit Min Nor Max kg/hr 72125 120209 145453

10 Pressure: Unit Min Nor Max kg/cm2 (a) 48.18

11 Temperature: Unit Min Nor Max °C 384.2

12 Density: Unit Min Nor Max kg/m3 16.794

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.024

CONDITIONS 14 Molecular Weight 18.015

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Cp/Cv 1.387

20

21 Tag Number Data Sheet Number FT-1124 BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material KILLED CARBON STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.68347

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 279.913 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 18" 600# RF

40 Outlet Size, Rating & Preparation 18" 600# RF

41 Flow Full Scale 159998.3 kg/hr

42 Differential Pressure @ Full Scale 1250 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 36 of 39

Tag Number: FE-1124

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements

8 The following information shall be stamped on the Element:

- Venturi Throat Diameter, d (mm)

- Instrument Tag Number

- Flange Size and Rating

- Material of Construction

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 37 of 39

1 Tag Number FE-1125

2 Service H.P. STEAM TO 105-JT

3 Line No. / Equipment No. P & ID Number HS1105-14" (25CK1S02) 64-D108

GENERAL 4 Line Size Line Sched. 14" 50.80 mm WALL

5 Line I.D. 10.000"

6

7

8 Fluid State HP STEAM VAPOR

9 Flow: Unit Min Nor Max kg/hr 71848 119746 143695

10 Pressure: Unit Min Nor Max kg/cm2 (a) 123.63

11 Temperature: Unit Min Nor Max °C 509.8

12 Density: Unit Min Nor Max kg/m3 37.077

PROCESS 13 Viscosity: Unit Min Nor Max cP 0.029

CONDITIONS 14 Molecular Weight 18.015

15 Quality Superheat

16 Super Compressibility Factor

17 Base Pressure Base Temperature 1.013 kg/cm2 (a) 15.56 °C

18 Max Allowed Delta P

19 Cp/Cv 1.426

20

21 Tag Number Data Sheet Number FT-1125 BY DETAIL ENGG.

SECONDARY 22 Manufacturer BY DETAIL ENGG.

INSTRUMENTS 23 Model Number BY DETAIL ENGG.

24

25 Type CLASSICAL - ROUGH CAST INLET

26 Material 2-1/4 CR - 1 MO ALLOY STEEL

27 Thickness BY SUPPLIER

28 Conform To ISO 5167

29 Beta Ratio 0.64171

30 Cylinder Entrance Section Length BY SUPPLIER

31 Conical Convert Length BY SUPPLIER

32 Throat Length BY SUPPLIER

33 Throat Diameter (Bore) 162.994 mm

34 Conical Diverge Length BY SUPPLIER

VENTURI 35 Conical Diverge Angle 15 Degree

TUBE 36 Taps Type SOCKET WELD

37 Taps Size 1/2"

38 Taps Orientation VERTICAL

39 Inlet Size, Rating & Preparation 14" 2500# RTJ

40 Outlet Size, Rating & Preparation 14" 2500# RTJ

41 Flow Full Scale 157000 kg/hr

42 Differential Pressure @ Full Scale 5000 mm WC

43 Permanent DP Loss @ Normal Flow BY SUPPLIER mm WC

44

45 Supplier BY DETAIL ENGG.

46 Manufacturer BY DETAIL ENGG.

PURCHASE 47 Model Number BY DETAIL ENGG.

48 Purchase Order Number BY DETAIL ENGG.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

FLOW METER - VENTURI TUBE

Client: PT PANCA AMARA UTAMA

Project: 1900 MTPD AMMONIA PLANT

Location: CENTRAL SULAWESI, INDONESIA

P00 MM BBK RT 29-Jun-15 RE-ISSUED FOR DESIGN Unit: AMMONIA

0 PB NSB RT 21-May-13 ISSUED FOR DESIGN Drawing No.: F283-IC-DAS-IC0-0002

Rev By Chk Appr Date Revision Description Spec Form No. 318 Sheet 38 of 39

Tag Number: FE-1125

NOTES:

1 Supplier shall verify suitability of design and all materials for the temperatures and pressures specified on data sheet.

2 Supplier shall be responsible for proper and optimum sizing, selection and supply of the flow element for the application specified in the data sheets.

3 Detail Engineering Contractor shall confirm final Pipe Inner Diameter (ID), and shall revise flow element calculation(s) as required.

4 Supplier to confirm Beta ratio and Throat Diameter.

5 Supplier to provide certified Flow Curves.

6 Raised Face flanged shall be as per ASME B 16.5 for Venturi Tubes 24" & below, and as per ASME B16.47 Series B for Venturi Tubes 26" & above

(Detail Engineering to Confirm).

7 Detail Engineering contractor shall confirm that final upstream and downstream straight pipe runs meet minimum ASME MFC-3M / ISO5167 requirements