Académique Documents

Professionnel Documents

Culture Documents

Model CB 15-100 HP Boilers: 1.04 Burner and Controls

Transféré par

sebaversaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Model CB 15-100 HP Boilers: 1.04 Burner and Controls

Transféré par

sebaversaDroits d'auteur :

Formats disponibles

Model CB 15-100 HP Boilers

1.04 Burner and Controls

A. Mode of Operation

Select one of the following:

• 15 and 20 hp. Burner operation shall be on-off principle.

• 30 and 40 hp. Burner operation shall be high-low-off principle. The burner

shall always return to low fire position for ignition.

• 50 - 100 hp. Burner operation shall be full modulation principle. The burner

shall always return to low fire position for ignition.

B. Blower

1. Air for combustion shall be supplied by a forced draft blower mounted in the front

boiler door, above the burner, to eliminate vibration and reduce noise level.

2. Maximum sound level of the boiler/burner package shall not exceed _____ dbA

(when measured in accordance with ABMA Sound Test Standards).

3. The impeller shall be cast aluminum, radial blade, carefully balanced, and directly

connected to the blower motor shaft.

C. Combustion Air Control

Select one of the following:

• 15 and 20 hp. Combustion air damper shall be manually set for proper air-

fuel ratios.

• 30 and 40 hp. Combustion air damper shall be linked to damper motor.

Auxiliary switch on the damper motor shall control high or low firing rate.

• 50 - 100 hp. Combustion air damper and cam operated fuel metering valves

shall be operated by a single damper control motor that regulates the fire

according to load demand. Potentiometer type position controls shall be

provided to regulate operation of the damper control motor.

D. Fuel Specification and Piping

Select one of the following fuel types:

• Fuel series 700 - Gas fired (4.4.1).

• Fuel series 100 - Light oil (No. 2) fired (4.4.2).

• Fuel series 200 - Light oil or gas fired (4.4.3).

• Fuel series 600 - No. 6 oil fired (4.4.4).

• Fuel series 400 - No. oil or gas fired (4.4.5).

1. Fuel Series 700 - Gas Fired

a. Burner Type - The burner shall be integral with the front head of the boiler

and of high radiant multi-port type for gas. The burner shall be approved for

operation on natural gas fuel.

b. Gas Pilot - The gas pilot shall be a premix type with automatic electric

ignition. An electronic detector shall monitor the pilot so that the primary gas

valve cannot open until pilot flame has been established. The pilot train shall

include two manual shut-off valves, solenoid valve, pressure regulator and

pressure gauge.

c. Gas Burner Piping - Gas burner piping on all units shall include pressure

regulator, primary gas shutoff valve, motor operated with proof of closure

switch and plugged leakage test connection. The main gas valve(s) shall be

wired to close automatically in the event of power failure, flame failure, low

Section A6-38 Rev. 07-10

Model CB 15-100 HP Boilers

water or any safety shutdown condition. A lubricating plug cock or butterfly

shutoff valve shall be provided as a means for a tightness check of the

primary shut off valve. An additional plug cock on butterfly valve shall be

furnished at entrance to gas train. Select one of the following:

1) 15-50 hp. Burners equipped as shown above.

2) 60-100 hp. High and low gas pressure switches shall be provided.

d. Burner Turndown - Select one of the following:

1) 15 and 20 hp. Burner shall operate on the on/off principle.

2) 30 and 40 hp. Burner shall operate on the high-low-off principle with a

turndown of 3:1 when firing natural gas.

3) 50-100 hp. Turndown range of burner shall be 4:1 when firing natural

gas.

2. Fuel Series 100 - Light Oil Fired

a. Burner Type - The burner shall be integral with the front head of the boiler,

and shall be a low pressure air atomizing type approved for operation with

CS12-48, Commercial No. 2 oil.

3. Oil Pilot - The oil pilot shall be air atomizing type with automatic electric ignition

and include oil solenoid valve. An electronic detector shall monitor the pilot so

that the primary oil valve cannot open until flame has been established.

4. Oil Pump - An oil pump with a capacity of approximately twice the maximum

burning rate shall be included. Select one of the following:

• 15 hp through 40 hp. The oil pump shall be integral with the burner and

belt driven from the blower motor.

• 50 hp through 100 hp. Separate motor driven pump set, shipped loose to

be installed in a location favorable to the oil storage tank, shall be

provided.

5. Oil Burner Piping - Fuel oil piping on the unit shall include oil pressure regulating

devices, oil metering controls, solenoid shutoff valves, pressure gauges and fuel

strainer, all integrally mounted on the unit. Select one of the following:

• 50 hp through 100 hp. A fuel oil controller shall be provided to combine all of

the fuel oil controls into a single casting which is mounted on the front door of

the unit. A single tip retractable nozzle shall be used for the low pressure air

atomizing burner.

• 70 hp through 100 hp. A low oil pressure switch shall be included in the oil

piping.

6. Low Pressure Air Atomizing - Select one of the following:

• 15 hp through 40 hp. Belt driven air compressor, lubricating oil tank, oil level

indicator, inlet air filter, air pressure gauge, and low atomizing air pressure

switch.

• 50 hp through 100 hp. Separate air compressor module mounted on boiler

base rail with low atomizing air pressure switch.

7. Burner Turndown - Select one of the following:

• 15 and 20 hp. Burner shall operate on the on/off principle.

• 30 and 40 hp. Burner shall operate on the high-low-off principle with a

turndown of 3:1 when firing No. 2 oil.

Section A6-39 Rev. 07-10

Model CB 15-100 HP Boilers

• 50 hp through 100 hp. Turndown range shall be 4:1 when firing No. 2 oil.

E. Fuel Series 200 - Light Oil or Gas Fired

1. Burner Type - The burner, integral with the front head of the boiler, shall be a

combination of the low pressure air atomizing type for oil and high radiant multi-

port type for gas. The burner shall be approved for operation with either CS12-48

Commercial No. 2 Oil or natural gas.

2. Gas Pilot - The gas pilot shall be premix type with automatic electric ignition. An

electronic detector shall monitor the pilot so that the primary fuel valve cannot

open until flame has been established. The pilot train shall include two manual

shut-off valves, solenoid valve, pressure regulator and pressure gauge.

3. Oil Burner

a. Oil Pump - An oil pump with a capacity of approximately twice the maximum

burning rate shall be included. Select one of the following:

1) 15 hp through 40 hp. The oil pump shall be integral with the burner and

belt driven from the blower motor.

2) 50 hp through 100 hp. Separate motor driven pump set, shipped loose,

to be installed in a location favorable to the oil storage tank, shall be

provided.

4. Oil Burner Piping - Fuel oil piping on the unit shall include oil pressure regulating

devices, oil metering controls, solenoid shutoff valves, pressure gauges and fuel

strainer, all integrally mounted on the unit. Select one of the following:

a. 50 hp through 100 hp. A fuel oil controller shall be provided to combine all of

the fuel oil controls into a single casting which is mounted on the front door of

the unit. A single tip retractable nozzle shall be used for the low pressure air

atomizing burner.

b. 70 hp through 100 hp. A low oil pressure switch shall be included in the oil

piping.

5. Low pressure air atomizing. Select one of the following:

a. 15 hp through 40 hp. Belt driven air compressor, lubricating oil tank, oil level

indicator, inlet air filter, air pressure gauge and low atomizing air pressure

switch.

b. 50 hp through 100 hp. Separate air compressor module mounted on boiler

base rail with low atomizing air pressure switch.

6. Gas Burner

a. Gas Burner Piping - gas burner piping on all units shall include pressure

regulator, primary gas shutoff valve, motor operated with proof of closure

switch and plugged leakage test connection. The main gas valve(s) shall be

wired to close automatically in the event of power failure, flame failure, low

water or any safety shutdown condition. A lubricating plug cock or butterfly

shutoff valve shall be provided as a means for a tightness check of the

primary shut off valve. An additional plug cock or butterfly valve shall be

furnished at entrance to gas train. Select one of the following:

1) 15-50 hp. Burners equipped as shown above.

2) 60-100 hp. High and low gas pressure switches shall be provided.

7. Burner Turndown

Select one of the following:

Section A6-40 Rev. 07-10

Model CB 15-100 HP Boilers

• 15 and 20 hp. Burner shall operate on the on/off principle.

• 30 and 40 hp. Burner shall operate on the high-low-off principle with a

turndown of 3:1

• 50-100 hp. Turndown range of the burner shall be 4:1.

F. Fuel Series 600 - No. 6 Oil Fired

1. Burner Type - The burner shall be integral with the front head of the boiler and

low pressure air atomizing type approved for operation with CS12-48,

Commercial No. 6 Oil.

2. Gas Pilot - The gas pilot shall be a premix type with automatic electric ignition.

An electronic detector shall monitor the pilot so that the primary oil valve cannot

open until pilot flame has been established. The pilot train shall include two

manual shut-off valves, solenoid valve, pressure regulator and pressure gauge.

3. Oil Pump - An oil pump set with a capacity of approximately twice the maximum

burning rate shall be included.

A separate motor driven pump set shall be included shipped loose for location

favorable to the oil storage tank.

4. Oil Burner Piping - A fuel oil controller combining all of the fuel oil controls into a

single casing shall be provided. Oil pressure regulating devices, oil metering

controls, solenoid shutoff valves, high and low oil temperature switches and

necessary pressure and temperature gauges shall be included in this packaged

assembly mounted on the front door of the boiler. A fuel strainer shall also be

provided, mounted to the boiler. A single tip retractable nozzle shall be used for

the low pressure air atomizing burner. Flexible hoses shall be provided to allow

easy removal of the nozzle for inspection when it is placed in the vice jaws

located on the front door of the boiler.

The metering valve shall permit circulation of hot oil to the burner at all times.

The burner drawer oil piping and nozzle shall be purged of oil on each shutdown.

For 70 through 100 hp, a low oil pressure switch shall be included in the oil

piping.

5. Low Pressure Air Atomizing - Select one of the following:

a. 50 through 100 hp. Separate air compressor module mounted on boiler base

rail with low atomizing air pressure switch.

6. Oil Preheat

The oil shall be preheated by a steam heater and electric heater, each with

thermostatic control. Both heaters shall be installed in a single compact shell

mounted, piped, and wired on the boiler. The thermostatic controls shall be set to

cut-out the electric heater when steam is available. Select one of the following:

a. 50 through 100 hp. Electric preheater size shall be 5 kW.

G. Fuel Series 400 - No. 6 Oil or Gas Fired

1. Burner Type - The burner shall be integral with the front head of the boiler and

shall be a combination of the low pressure atomizing type for oil and high radiant

multi-port type for gas. The burner shall be approved for operation with either

CS12-48 Commercial No. 6 oil or natural gas.

2. Gas Pilot - The gas pilot shall be a premix type with automatic electric ignition.

An electronic detector shall monitor the pilot so that the primary oil valve cannot

open until pilot flame has been established. The pilot train shall include two

manual shut-off valves, solenoid valve, pressure regulator and pressure gauge.

Section A6-41 Rev. 07-10

Model CB 15-100 HP Boilers

3. Oil Burner

a. Oil Pump - An oil pump set with a capacity of approximately twice the

maximum burning rate shall be included.

b. Oil Burner Piping - A fuel oil controller combining all of the fuel oil controls

into a single casing shall be provided. Oil pressure regulating devices, oil

metering controls, solenoid shutoff valves, high and low oil temperature

switches, and the necessary pressure and temperature gauges shall be

included in this packaged assembly mounted on the front door of the boiler.

A fuel strainer shall also be provided, mounted to the boiler. A single tip

retractable nozzle shall be used for the low pressure air atomizing burner.

Flexible hoses shall be provided to allow easy removal of the nozzle for

inspection when it is placed in the vice jaws located on the front door of the

boiler. The metering valve shall permit circulation of hot oil to the burner at all

times. The burner drawer oil piping and nozzle shall be purged of oil at each

shutdown.

For 70 through 100 hp, a low oil pressure switch shall be included in the oil

piping.

1. Low Pressure Air Atomizing - Select one of the following:

a. 50 through 100 hp. Separate air compressor module mounted on boiler base

rail with low atomizing air pressure switch.

2. Oil Preheat

The oil shall be preheated by a steam heater and electric heater, each with

thermostatic control. Both heaters shall be installed in a single compact shell

mounted, piped, and wired on the boiler. The thermostatic controls shall be set to

cut-out the electric heater when steam is available.

a. 50 through 100 hp. Electric preheater size shall be 5 kW.

3. Gas Burner

a. Gas Burner Piping - Gas burner piping on all units shall include pressure

regulator, primary gas shutoff valve, motor operated with proof of closure

switch and plugged leakage test connection. The main gas valve(s) shall be

wired to close automatically in the event of power failure, flame failure, low

water or any safety shutdown condition. A lubricating plug cock or butterfly

shutoff valve shall be provided as means for a tightness check of the primary

shutoff valve. An additional plug cock or butterfly valve shall be furnished at

entrance to gas train. Select one of the following:

1) 50 hp. Burner equipped as shown above.

2) 60 through 100 hp. High and low gas pressure switches shall be

provided.

b. Burner Turndown - Turndown shall be 4:1.

H. Boiler Flame Safeguard Controller and Control Panel

1. CB780E Flame Safeguard

a. Boilers with CB780E Control - Each boiler shall be factory equipped with

flame safeguard controller providing technology and functions equal to the

Cleaver-Brooks Model CB780E.

Controller shall be computerized solid state having sequence and flame-on

lights and alpha- numeric “first out” fault indications of flame safeguard trip

functions. It shall include dynamic self-check logic. The controller shall have

a fixed operating sequence incapable of being manually altered. The

Section A6-42 Rev. 07-10

Vous aimerez peut-être aussi

- Model CBR 125-800 HP BoilersDocument5 pagesModel CBR 125-800 HP BoilerssebaversaPas encore d'évaluation

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaPas encore d'évaluation

- Model CBLE 100-800 HP BoilersDocument4 pagesModel CBLE 100-800 HP BoilerssebaversaPas encore d'évaluation

- 60 PPM Nox Operation Natural Gas: CBEX Elite 100-800 HPDocument4 pages60 PPM Nox Operation Natural Gas: CBEX Elite 100-800 HPsebaversaPas encore d'évaluation

- CBEX Elite 100-800 HPDocument4 pagesCBEX Elite 100-800 HPsebaversaPas encore d'évaluation

- CBEX Elite 100-800 HPDocument4 pagesCBEX Elite 100-800 HPsebaversaPas encore d'évaluation

- CBEX 350 To 800 HorsepowerDocument4 pagesCBEX 350 To 800 HorsepowersebaversaPas encore d'évaluation

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaPas encore d'évaluation

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaPas encore d'évaluation

- High-efficiency boiler specifications for 100-800 HP modelsDocument4 pagesHigh-efficiency boiler specifications for 100-800 HP modelssebaversaPas encore d'évaluation

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaPas encore d'évaluation

- 900-1800 HP Boiler SpecsDocument5 pages900-1800 HP Boiler SpecssebaversaPas encore d'évaluation

- Series 4vt Steam SpecificationsDocument5 pagesSeries 4vt Steam Specificationsagusti24Pas encore d'évaluation

- Boiler SpecificationsDocument25 pagesBoiler Specificationspaul kioiPas encore d'évaluation

- Hurst Boiler & Welding Co., IncDocument4 pagesHurst Boiler & Welding Co., IncChristian Veliz CamargoPas encore d'évaluation

- Series 500 Water SpecDocument5 pagesSeries 500 Water SpecChristhofer Arroyo ChacónPas encore d'évaluation

- Details Mentioned in DPR For BoilerDocument3 pagesDetails Mentioned in DPR For BoilershivendupadtePas encore d'évaluation

- HPLP Bypass SystemDocument16 pagesHPLP Bypass SystemRakesh Kiran100% (1)

- Efficient 15-100 HP Boilers for BuildingsDocument5 pagesEfficient 15-100 HP Boilers for BuildingssebaversaPas encore d'évaluation

- Flagro Fvo 400 Heater Operations and TroubleshootingDocument30 pagesFlagro Fvo 400 Heater Operations and TroubleshootingJocelyn DuteauPas encore d'évaluation

- Eca Day Tank SpecDocument3 pagesEca Day Tank Specenlightened1718Pas encore d'évaluation

- Model 4WI Boiler Warranty, Tests and StartupDocument4 pagesModel 4WI Boiler Warranty, Tests and StartupsebaversaPas encore d'évaluation

- Fire Pump PropertiesDocument62 pagesFire Pump Propertiesyamaha100% (2)

- Oil Burner ManualDocument42 pagesOil Burner Manualguru22100% (1)

- Warm StartupDocument3 pagesWarm StartupRahul KurmiPas encore d'évaluation

- HP - LP Bypass and Aprds SystemDocument47 pagesHP - LP Bypass and Aprds SystemSanjay Dadel100% (4)

- Asme6 5Document6 pagesAsme6 5daburto2Pas encore d'évaluation

- Hurst Boiler & Welding Company, Inc.: SERIES 500 STEAM BOILER (100-1500 HP, STEAM 15-300 Psig) Sample SpecificationsDocument5 pagesHurst Boiler & Welding Company, Inc.: SERIES 500 STEAM BOILER (100-1500 HP, STEAM 15-300 Psig) Sample SpecificationsDaniel GonzalezPas encore d'évaluation

- Fairbanks Nijhuis Fire Pumps Brochure PDFDocument8 pagesFairbanks Nijhuis Fire Pumps Brochure PDFEko ParjonoPas encore d'évaluation

- Series 1: Forced Draft Dual Fuel BurnersDocument4 pagesSeries 1: Forced Draft Dual Fuel Burnersdiogenes torresPas encore d'évaluation

- Diesel Pump Check ListDocument3 pagesDiesel Pump Check Listபிரபாகரன் மீண்டும் வருவான்Pas encore d'évaluation

- BARC Develops Fire Resistant Hydraulic Fluid Test FacilityDocument28 pagesBARC Develops Fire Resistant Hydraulic Fluid Test Facilityrkp17Pas encore d'évaluation

- Turbine Shutting Down From Full LoadDocument7 pagesTurbine Shutting Down From Full Loadrohit_0123100% (1)

- Emergency GeneratorDocument19 pagesEmergency GeneratorSathish Khanna100% (1)

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaPas encore d'évaluation

- Section 1520 Data (Diesel Fire Pump)Document8 pagesSection 1520 Data (Diesel Fire Pump)Shoukat Ali ShaikhPas encore d'évaluation

- Fire Pump, Motor and ControllerDocument3 pagesFire Pump, Motor and Controllerعامر شیخPas encore d'évaluation

- SD5560 08 Kbo BurnerDocument2 pagesSD5560 08 Kbo BurnercherryatomicryanPas encore d'évaluation

- Paxman SpecsDocument9 pagesPaxman Specsbastech100% (2)

- Electric/Diesel Fire Pump Check List: InstallationDocument6 pagesElectric/Diesel Fire Pump Check List: InstallationSeptian Citra KusumaPas encore d'évaluation

- Turbine Fuel SystemDocument66 pagesTurbine Fuel SystemDamon Leong100% (1)

- 43-4002 - Fuel Oil SupplyDocument4 pages43-4002 - Fuel Oil Supplydebu1985Pas encore d'évaluation

- Model 59503 C L Regulator InstructionsDocument4 pagesModel 59503 C L Regulator InstructionsmasPas encore d'évaluation

- Gas Oven InstructionsDocument12 pagesGas Oven InstructionsJonathan Hernandez100% (1)

- 2MW Turbine EnquiryDocument7 pages2MW Turbine EnquiryRamu MaddiPas encore d'évaluation

- HP LPDocument36 pagesHP LPSam100% (1)

- Boiler Normal Shut DownDocument13 pagesBoiler Normal Shut DownRajat SharmaPas encore d'évaluation

- Burner Principle and StructureDocument30 pagesBurner Principle and StructureChesya Sera De ClaresyaPas encore d'évaluation

- Section A1 Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)Document4 pagesSection A1 Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)sebaversaPas encore d'évaluation

- Module 9 - Fuel Systems PDFDocument73 pagesModule 9 - Fuel Systems PDFOresteHernandezPas encore d'évaluation

- Boiler Normal Shut DownDocument13 pagesBoiler Normal Shut Downgaurav tiwari100% (1)

- Axial Reaction Fan - Double Stage: Operation & Maintenance ManualDocument44 pagesAxial Reaction Fan - Double Stage: Operation & Maintenance ManualNidhiPas encore d'évaluation

- 9W - 02 - Weishaupt - 6lip6letid - L - RL - M - 1-3 - ENGDocument16 pages9W - 02 - Weishaupt - 6lip6letid - L - RL - M - 1-3 - ENGMurari LalPas encore d'évaluation

- SPEC Model CB Steam Jan11Document12 pagesSPEC Model CB Steam Jan11Stanford BrownPas encore d'évaluation

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SD'EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SPas encore d'évaluation

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGD'EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGPas encore d'évaluation

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaPas encore d'évaluation

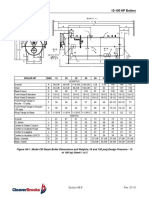

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocument5 pagesModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaPas encore d'évaluation

- Efficient 15-100 HP Boilers for BuildingsDocument5 pagesEfficient 15-100 HP Boilers for BuildingssebaversaPas encore d'évaluation

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 pagesModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaPas encore d'évaluation

- 900-1800 HP Boiler SpecsDocument5 pages900-1800 HP Boiler SpecssebaversaPas encore d'évaluation

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaPas encore d'évaluation

- 15-100 HP Boilers Dimensions SpecsDocument5 pages15-100 HP Boilers Dimensions SpecssebaversaPas encore d'évaluation

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaPas encore d'évaluation

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaPas encore d'évaluation

- Model CB 15-100 HP Boilers: Sound LevelDocument5 pagesModel CB 15-100 HP Boilers: Sound LevelsebaversaPas encore d'évaluation

- Features and Benefits: Model CB 15-100 HP BoilersDocument5 pagesFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaPas encore d'évaluation

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaPas encore d'évaluation

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocument5 pagesModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaPas encore d'évaluation

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaPas encore d'évaluation

- 81Document5 pages81sebaversaPas encore d'évaluation

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaPas encore d'évaluation

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaPas encore d'évaluation

- 900-1800 HP Steam Boilers: Features, Dimensions and Engineering DataDocument5 pages900-1800 HP Steam Boilers: Features, Dimensions and Engineering DatasebaversaPas encore d'évaluation

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocument5 pagesModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaPas encore d'évaluation

- 78Document5 pages78sebaversaPas encore d'évaluation

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Document6 pagesModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaPas encore d'évaluation

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocument5 pages125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaPas encore d'évaluation

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocument5 pages125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaPas encore d'évaluation

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaPas encore d'évaluation

- High-efficiency boiler specifications for 100-800 HP modelsDocument4 pagesHigh-efficiency boiler specifications for 100-800 HP modelssebaversaPas encore d'évaluation

- 75Document5 pages75sebaversaPas encore d'évaluation

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaPas encore d'évaluation

- Importance of Orientation of BuildingDocument45 pagesImportance of Orientation of Buildingrgrid100% (1)

- PDFDocument100 pagesPDFharshkumar patelPas encore d'évaluation

- Elektrogas VMRDocument8 pagesElektrogas VMRthiago_juliao1984Pas encore d'évaluation

- Drasta C 5022: UtilisationsDocument1 pageDrasta C 5022: UtilisationsAnya PamungkasPas encore d'évaluation

- Polyolefin ElastomerDocument6 pagesPolyolefin ElastomerHari SuthanPas encore d'évaluation

- Manual Recip Package Mar 09 PDFDocument29 pagesManual Recip Package Mar 09 PDFanita shindePas encore d'évaluation

- Service Manual: Room Air ConditionerDocument148 pagesService Manual: Room Air ConditionerQuasistatico PolitropicoPas encore d'évaluation

- CIVE #302 Lab #2: Wheatstone Bridge For Strain Measurement: 1. PurposeDocument3 pagesCIVE #302 Lab #2: Wheatstone Bridge For Strain Measurement: 1. PurposeAhmadAliAKbarPhambraPas encore d'évaluation

- Exercises V1 Part2Document8 pagesExercises V1 Part2Ahmed AlgadriPas encore d'évaluation

- Bearing Steel 52100Document10 pagesBearing Steel 52100Dan PascuPas encore d'évaluation

- NEW PARÉ Vertica Soffit Panels - 2022Document12 pagesNEW PARÉ Vertica Soffit Panels - 2022abhichidPas encore d'évaluation

- Translated Doors and Windows Construction MethodologyDocument12 pagesTranslated Doors and Windows Construction MethodologyOlan PrincePas encore d'évaluation

- Report On ViscosityDocument8 pagesReport On ViscosityYogesh GargPas encore d'évaluation

- Datasheet - T94N01GDocument2 pagesDatasheet - T94N01GMarcelMinotelliPas encore d'évaluation

- EFD Dispensing TipsDocument3 pagesEFD Dispensing TipsEduardo Lopez RomeroPas encore d'évaluation

- Energy Core Ventilators: Model Minicore and EcvDocument8 pagesEnergy Core Ventilators: Model Minicore and EcvTrần Thị Thanh TuyềnPas encore d'évaluation

- Construction of Dibrugarh Bypass New ProjDocument26 pagesConstruction of Dibrugarh Bypass New ProjUday DeyPas encore d'évaluation

- Refrigerants and Alternatives: Service Engineers' Section Datasheet 14Document4 pagesRefrigerants and Alternatives: Service Engineers' Section Datasheet 14rituneshmPas encore d'évaluation

- LK65CZ1Document9 pagesLK65CZ1hobolghaniPas encore d'évaluation

- A Methodology To Determine in Situ Rock Mass FailureDocument8 pagesA Methodology To Determine in Situ Rock Mass FailurerannscribdPas encore d'évaluation

- Kashino House Tadao AndoDocument7 pagesKashino House Tadao AndoShubham Patidar0% (1)

- ASTM A 197 - A 197M - 00Document4 pagesASTM A 197 - A 197M - 00Er Widodo100% (2)

- Hydraulics Refersher ModuleDocument4 pagesHydraulics Refersher ModuleJunar Amaro100% (2)

- hs3100 Parts List Issue 9Document9 pageshs3100 Parts List Issue 9Александр ЩербаковPas encore d'évaluation

- GMCC air conditioner specifications comparisonDocument1 pageGMCC air conditioner specifications comparisonJose Enrique Sanchez Thompson100% (1)

- PSC Single SpanDocument99 pagesPSC Single SpanRaden Budi HermawanPas encore d'évaluation

- Concrete Fundamental: Bfs 40603 Concrete Technology Semester Ii Session 2015/2016Document25 pagesConcrete Fundamental: Bfs 40603 Concrete Technology Semester Ii Session 2015/2016Qayyum Uzear UsinPas encore d'évaluation

- Thermodynamics Lab ManualDocument100 pagesThermodynamics Lab ManualNottaAmandeepSingh80% (5)

- Drawing Seimens BRKRDocument14 pagesDrawing Seimens BRKRrajeshPas encore d'évaluation

- SECTION 15110 Valves Rev 0Document43 pagesSECTION 15110 Valves Rev 0Munir Rasheed100% (1)