Académique Documents

Professionnel Documents

Culture Documents

Welder Training Manual PDF

Transféré par

Lalit MohanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Welder Training Manual PDF

Transféré par

Lalit MohanDroits d'auteur :

Formats disponibles

WELDER MANUAL

1) What is welding?

Process of joining two materials Permanently by Heat and or Pressure.

2) Welder’s Safety – PPE :

1)Glasses 2)Shoes 3)Gloves 4)Shield 5)Respiratory Mask 6)Aprons

3) Welding Positions :

4) Types of Welding processes :

1)SAW 2)GMAW 3)GTAW 4)SMAW 5)FCAW

5) CONSUMABLES

i) GMAW (Process Code= 135)

ELECTRODE:

ER70S-6 ER 309-L

E- Electrode E- Electrode

R- Filler Rod

70 70,000psi (Tensile Strength) R- Rod

S- Solid Wire 309 Stainless Steel with Carbon Steel

6 Solid Wire Chemistry L- Low carbon

SHIELDING GAS:

1) ACM = Arogon + CO2 Mixture (Around 80% Argon and 20% CO2) 2) Pure CO2

ii)SAW (Process Code= 121)

F7A4 – EM12K

F Flux E Electrode

7 70,000 psi Tensile strength M Medium Mn

A As welded 12 0.12 % C

4 Impact Strength -40o C K Silicon Killed Wire (De Oxidized)

Flux baking temp=300 deg Flux holding temp=100 deg minimum

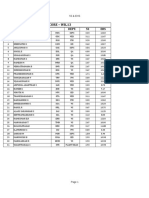

6) BASE MATERIAL: Other Materials

S355JO S355JR

S STRUCTURAL STEEL S275JR

355 Yield Strength 355 N/mm2 S355J2

J 27 Joules (Impact Strength) S355 NL

0 Impact Strength at 0o C S235 JR

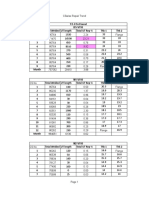

7) Heat Input(Q) Calculation

Q=(K x Voltage x Current ) For GMAW K=0.8 , For SAW K=1

Travel Speed

8) Modes of metal transfer in GMAW Process

1)Globular 2)Short circuit 3)Pulsed 4)Spray We use Globular and spray

9)Pre-Heating – To remove Moisture in work piece (Temperature- As per WPS) We use 100 degrees minimum

10)Inter-Pass Temperature = Maximum temperature between one pass to another pass (Temperature- As per

WPS) We use 350 degrees maximum

11)Polarity – Direct Current Electrode Positive (DCEP) for SAW and GMAW (Also called reverse polarity)

12)Stick Out – Distance between Electrode and Workpiece

GMAW = 10-15 mm SAW = 20-25 mm

13)Welding Symbols

Example:

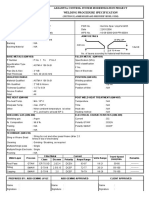

14) How to decide the welding parameters for a welding

Ans : Using WPS (Welding Procedure Specification)

15) Where do you find a WPS?

Ans : In chart diplayed in every booms. (WPS synopsis)

16) Which position you are qualified to weld?

Ans : Your position is given in the Approved Welder List displayed in each bay.

17) After completion of weld, at shift end what will you do?

Ans: Write the history card. Return the unused flux and coil to store.

18) If flux temperature is less than 100 degrees what will you do?

Ans: Inform supervisor. Then retuen the flux to store and take new baked flux and start welding.

Vous aimerez peut-être aussi

- WPS - EngineerDocument20 pagesWPS - Engineerhunghoanglong100% (1)

- Factors in Selection of Filler Metals in WeldingDocument2 pagesFactors in Selection of Filler Metals in WeldingBalakumarPas encore d'évaluation

- Welding Manual R01 Nov 2006Document184 pagesWelding Manual R01 Nov 2006SHIVAJI CHOUDHURY100% (5)

- Control Ferrite Content Stainless Steel WeldsDocument5 pagesControl Ferrite Content Stainless Steel Weldstedmer1Pas encore d'évaluation

- Murex Tig Poster 2008 PDFDocument1 pageMurex Tig Poster 2008 PDFPCPas encore d'évaluation

- BHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelDocument2 pagesBHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelpradhankruhsnaPas encore d'évaluation

- SS - Filler Wire SelectionDocument26 pagesSS - Filler Wire SelectionBaraa AzebPas encore d'évaluation

- GMAWDocument12 pagesGMAWsushant47Pas encore d'évaluation

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyPas encore d'évaluation

- Wps Sp14 Reva PDFDocument9 pagesWps Sp14 Reva PDFravi00098Pas encore d'évaluation

- P Q R - 005Document2 pagesP Q R - 005Courtney DukePas encore d'évaluation

- Heat Input CalculatorDocument2 pagesHeat Input Calculatormahi1437Pas encore d'évaluation

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenPas encore d'évaluation

- PQRDocument2 pagesPQRafqzfiePas encore d'évaluation

- Preparation and Control of WeldingDocument3 pagesPreparation and Control of Weldingbalakumar rajaramPas encore d'évaluation

- MEI - Aluminium MIG WeldDocument56 pagesMEI - Aluminium MIG WeldSaravana Kumar100% (1)

- Engineer CV Material Specialists Mechanical Piping NDT Coating Inspection Oil Gas AlgeriaDocument3 pagesEngineer CV Material Specialists Mechanical Piping NDT Coating Inspection Oil Gas Algeriaait.koufiPas encore d'évaluation

- Weld DefectsDocument45 pagesWeld Defectsanon_256154377Pas encore d'évaluation

- Welder CertificateDocument6 pagesWelder CertificateA. ΒρατσισταPas encore d'évaluation

- Testing of WeldsDocument44 pagesTesting of Weldspkn_pnt9950Pas encore d'évaluation

- Electrode Selection ChartDocument4 pagesElectrode Selection Chartsunitbhaumik100% (2)

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLEPas encore d'évaluation

- 254smo (Uns 31254)Document8 pages254smo (Uns 31254)Yang Gul LeePas encore d'évaluation

- All Materials DocumentsDocument1 pageAll Materials DocumentsHarnish BariaPas encore d'évaluation

- Miller Welding TitaniumDocument20 pagesMiller Welding TitaniumrcpretoriusPas encore d'évaluation

- JIMT Visual Inspection ReportDocument1 913 pagesJIMT Visual Inspection Reportgomathyselvi100% (1)

- Welding ReportDocument52 pagesWelding ReportalidadPas encore d'évaluation

- Weight Per Meter of WeldDocument1 pageWeight Per Meter of Weldreza329329Pas encore d'évaluation

- Heat TreatmentDocument5 pagesHeat TreatmentsheikmoinPas encore d'évaluation

- Interpass Temperature WeldingDocument2 pagesInterpass Temperature Weldinghareesh13hPas encore d'évaluation

- Material BehaviorDocument111 pagesMaterial BehaviorFajar LuqmanPas encore d'évaluation

- Tungsten ElectrodesDocument2 pagesTungsten ElectrodesSyed Furqan Rehmani0% (2)

- Defect IIWDocument3 pagesDefect IIWPPMPas encore d'évaluation

- Welding IiwDocument6 pagesWelding IiwletsmakeithappenPas encore d'évaluation

- Lecture 1-Fundamentals of Welding MetallurgyDocument46 pagesLecture 1-Fundamentals of Welding MetallurgyHamiduPas encore d'évaluation

- Gas Tungsten Arc Welding Practice:: Jobs 19-J1-J19 (Plate)Document8 pagesGas Tungsten Arc Welding Practice:: Jobs 19-J1-J19 (Plate)Willy UioPas encore d'évaluation

- A Study On Transverse Weld Cracks PDFDocument8 pagesA Study On Transverse Weld Cracks PDFRifani ImamPas encore d'évaluation

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Storing and Redrying Electrodes-Lincoln ElectricDocument3 pagesStoring and Redrying Electrodes-Lincoln ElectricjasminneePas encore d'évaluation

- Submerged Arc Welding: by L D PoyyaraDocument29 pagesSubmerged Arc Welding: by L D PoyyaraSapan KansaraPas encore d'évaluation

- Lesson 14 WelderQuals - New2Document80 pagesLesson 14 WelderQuals - New2Mohd Syafiq100% (1)

- Heat Treatment of SteelsDocument9 pagesHeat Treatment of SteelsEhsan KhanPas encore d'évaluation

- 131.4.1-1 Temperaturas de PreaquecimentoDocument1 page131.4.1-1 Temperaturas de PreaquecimentoRodrigo CarneiroPas encore d'évaluation

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDocument3 pagesTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanPas encore d'évaluation

- Cordon Off - 4 (00000003)Document1 pageCordon Off - 4 (00000003)Anonymous PlyxbQ3tPas encore d'évaluation

- Welding Interview Questions and Answers PDFDocument11 pagesWelding Interview Questions and Answers PDFMOHANPas encore d'évaluation

- Welding Checklist For Field WeldingDocument1 pageWelding Checklist For Field Weldingnapster386Pas encore d'évaluation

- BOC IPRM S08-ConsumablesDocument187 pagesBOC IPRM S08-ConsumablesEduard Lupus Lobo100% (1)

- Tacom Weld Code SteelDocument165 pagesTacom Weld Code SteelAles Kubat0% (1)

- 05-Welder Certification PDFDocument11 pages05-Welder Certification PDFAnonymous bfxeE1zvY100% (1)

- Introduction to Gas Shielded Arc WeldingDocument157 pagesIntroduction to Gas Shielded Arc Weldingrohit mathankerPas encore d'évaluation

- WeldingDocument19 pagesWeldingAlexander Muñoz SánchezPas encore d'évaluation

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpPas encore d'évaluation

- BOC 216295 GeneralGasesBrochure AUS v12Document28 pagesBOC 216295 GeneralGasesBrochure AUS v12idontlikeebooksPas encore d'évaluation

- Industrial radiography A Complete Guide - 2019 EditionD'EverandIndustrial radiography A Complete Guide - 2019 EditionPas encore d'évaluation

- Ni base flux cored wireDocument1 pageNi base flux cored wireBBalopesabbPas encore d'évaluation

- CuZr0,15 alloy properties guideDocument17 pagesCuZr0,15 alloy properties guidekristechnikPas encore d'évaluation

- M El p0.2 2Document3 pagesM El p0.2 2Gopal RamalingamPas encore d'évaluation

- CSWIP Module Re-ExamDocument2 pagesCSWIP Module Re-ExamAhmad Khalimi Ilmawan100% (1)

- Metrode ER110S-G FillerDocument6 pagesMetrode ER110S-G FillerBernie SimcsPas encore d'évaluation

- Item Approx Price ActualDocument2 pagesItem Approx Price ActualAnilkumarGopinathanNairPas encore d'évaluation

- Trading Book - DSDocument9 pagesTrading Book - DSAnilkumarGopinathanNairPas encore d'évaluation

- SL No Date Stock Long/Short Buy Price Sell Price Qty Leverage Profit/LossDocument27 pagesSL No Date Stock Long/Short Buy Price Sell Price Qty Leverage Profit/LossAnilkumarGopinathanNairPas encore d'évaluation

- Address To ApplyDocument1 pageAddress To ApplyAnilkumarGopinathanNairPas encore d'évaluation

- WeldDocument22 pagesWeldAnilkumarGopinathanNairPas encore d'évaluation

- EuclidDocument15 pagesEuclidAnilkumarGopinathanNairPas encore d'évaluation

- Trading Book - AGDocument7 pagesTrading Book - AGAnilkumarGopinathanNairPas encore d'évaluation

- Weld 1Document18 pagesWeld 1AnilkumarGopinathanNairPas encore d'évaluation

- Supplier Kpi From Vs - Fab, NDT & QCDocument4 pagesSupplier Kpi From Vs - Fab, NDT & QCAnilkumarGopinathanNairPas encore d'évaluation

- Supplier Kpi From Ved - Purc, Stores & LogDocument18 pagesSupplier Kpi From Ved - Purc, Stores & LogAnilkumarGopinathanNairPas encore d'évaluation

- Daily ExpenseDocument33 pagesDaily ExpenseAnilkumarGopinathanNairPas encore d'évaluation

- Daily Attendance Report July 2018Document9 pagesDaily Attendance Report July 2018AnilkumarGopinathanNairPas encore d'évaluation

- Unit-1 5S & EHS ScoreDocument1 pageUnit-1 5S & EHS ScoreAnilkumarGopinathanNairPas encore d'évaluation

- Weld 1Document18 pagesWeld 1AnilkumarGopinathanNairPas encore d'évaluation

- Daily Attendance Report July 2018Document9 pagesDaily Attendance Report July 2018AnilkumarGopinathanNairPas encore d'évaluation

- WEEK 22 LS Repair TrendDocument2 pagesWEEK 22 LS Repair TrendAnilkumarGopinathanNairPas encore d'évaluation

- Img 412114601Document1 pageImg 412114601AnilkumarGopinathanNairPas encore d'évaluation

- Deputy Manager - Ied SGM - IedDocument2 pagesDeputy Manager - Ied SGM - IedAnilkumarGopinathanNairPas encore d'évaluation

- WEEK 22 LS Repair TrendDocument2 pagesWEEK 22 LS Repair TrendAnilkumarGopinathanNairPas encore d'évaluation

- UT Performance 8-05-2018Document13 pagesUT Performance 8-05-2018AnilkumarGopinathanNairPas encore d'évaluation

- Copy of Copy of Copy of Copy of WEEK 29 COMPLETEDDocument58 pagesCopy of Copy of Copy of Copy of WEEK 29 COMPLETEDAnilkumarGopinathanNairPas encore d'évaluation

- UT Performance March 2018 GraphDocument12 pagesUT Performance March 2018 GraphAnilkumarGopinathanNairPas encore d'évaluation

- UT Performance 24-04-2018Document13 pagesUT Performance 24-04-2018AnilkumarGopinathanNairPas encore d'évaluation

- Requirement For LS SAW ProcessDocument1 pageRequirement For LS SAW ProcessAnilkumarGopinathanNairPas encore d'évaluation

- UT Performance 5-05-2018Document13 pagesUT Performance 5-05-2018AnilkumarGopinathanNairPas encore d'évaluation

- UT Performance 13-04-2018.odsDocument151 pagesUT Performance 13-04-2018.odsAnilkumarGopinathanNairPas encore d'évaluation

- ISO 15614-1 2012 190 ISO 15609-1 2004 98 ISO 9606-1 2013 190 ISO 14732 2013 164 ISO 4063 2010 190 Total 832Document1 pageISO 15614-1 2012 190 ISO 15609-1 2004 98 ISO 9606-1 2013 190 ISO 14732 2013 164 ISO 4063 2010 190 Total 832AnilkumarGopinathanNairPas encore d'évaluation

- Bay: Section No: Date: Cs No O/S Amps Voltage Welder Id M/C No Remarks Bevel Width Bevel Depth No of Pass Travel Speed Welding MonitorDocument1 pageBay: Section No: Date: Cs No O/S Amps Voltage Welder Id M/C No Remarks Bevel Width Bevel Depth No of Pass Travel Speed Welding MonitorAnilkumarGopinathanNairPas encore d'évaluation

- UT Performance 13-04-2018.odsDocument151 pagesUT Performance 13-04-2018.odsAnilkumarGopinathanNairPas encore d'évaluation

- Unit-1 5S & EHS ScoreDocument2 pagesUnit-1 5S & EHS ScoreAnilkumarGopinathanNairPas encore d'évaluation

- Cooling Methods for Electronic EquipmentDocument31 pagesCooling Methods for Electronic EquipmentShashank PansariPas encore d'évaluation

- TCS3400 DS000411 4-00Document34 pagesTCS3400 DS000411 4-00Miguel_Angel92Pas encore d'évaluation

- Through Silicon Via Ts V 3Document2 pagesThrough Silicon Via Ts V 3Shriram ShastriPas encore d'évaluation

- Adafruit Motor Shield PDFDocument54 pagesAdafruit Motor Shield PDFRax ReyPas encore d'évaluation

- Lab Manual - Mech 1051 Ay 2021-2022 EvenDocument10 pagesLab Manual - Mech 1051 Ay 2021-2022 EvenKoushik DebnathPas encore d'évaluation

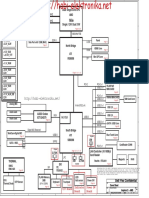

- Schematics Laptop Dell Inspiron Amd m301z Dell Flex 2Document37 pagesSchematics Laptop Dell Inspiron Amd m301z Dell Flex 2Krista TranPas encore d'évaluation

- 9702 p1 Current Electricity AllDocument35 pages9702 p1 Current Electricity AllMCHPas encore d'évaluation

- Applied Energy: Hubert Hug, Michael Bader, Peter Mair, Thilo GlatzelDocument10 pagesApplied Energy: Hubert Hug, Michael Bader, Peter Mair, Thilo Glatzel蒲俊雄Pas encore d'évaluation

- Digital Over-current Relay ProtectionDocument4 pagesDigital Over-current Relay Protectionpanji gustyPas encore d'évaluation

- 06ESL37 Analog Electronics Lab MANUALDocument70 pages06ESL37 Analog Electronics Lab MANUALSan AngadiPas encore d'évaluation

- Automatic NiCd Battery Charger CircuitDocument2 pagesAutomatic NiCd Battery Charger CircuitdewasuryantoPas encore d'évaluation

- Physics Project On Optical Fiber and Its ApplicationsDocument12 pagesPhysics Project On Optical Fiber and Its ApplicationsShlok Sah60% (5)

- Atlas DCA Pro (Model DCA75) Software Package Revisions: Latest Version at The TopDocument2 pagesAtlas DCA Pro (Model DCA75) Software Package Revisions: Latest Version at The TopAirkid Discomovil JesusPas encore d'évaluation

- EDA Open Source Tools WikiDocument13 pagesEDA Open Source Tools WikiNitin PatelPas encore d'évaluation

- Computer Memory TypesDocument9 pagesComputer Memory TypesJEETENDRAPas encore d'évaluation

- enDocument91 pagesenMoPas encore d'évaluation

- Motor Protection and Control - Catalogue - 2012Document392 pagesMotor Protection and Control - Catalogue - 2012Jigyesh SharmaPas encore d'évaluation

- Title Page, Toc, and PrefaceoldDocument12 pagesTitle Page, Toc, and Prefaceoldarehanliaqat8125Pas encore d'évaluation

- RESISTOR COLORDocument29 pagesRESISTOR COLORJomer JuanPas encore d'évaluation

- CED CH 1 Introduction v1 03042018 095851AMDocument7 pagesCED CH 1 Introduction v1 03042018 095851AMRizwan AhemadPas encore d'évaluation

- Elect Questions For Paper IIDocument49 pagesElect Questions For Paper IIavijayakumar_1964Pas encore d'évaluation

- 04 - Second-Order Effects On MOSFET Small Signal ModelDocument27 pages04 - Second-Order Effects On MOSFET Small Signal ModelWinnie LahPas encore d'évaluation

- RecloserDocument12 pagesRecloserJuan Alberto Amaya HurtadoPas encore d'évaluation

- Sanwa-Cd800a + - Datasheet PDFDocument2 pagesSanwa-Cd800a + - Datasheet PDFcpt_yahoo.esPas encore d'évaluation

- Waveguide Arc Detector: Passive ComponentsDocument3 pagesWaveguide Arc Detector: Passive ComponentsAmine EminePas encore d'évaluation

- Trench Angle: A Key Design Factor For A Deep Trench Superjunction MOSFETDocument6 pagesTrench Angle: A Key Design Factor For A Deep Trench Superjunction MOSFETCazimir BostanPas encore d'évaluation

- General Description Features: Ezbuck™ 3A Simple Buck RegulatorDocument18 pagesGeneral Description Features: Ezbuck™ 3A Simple Buck RegulatorNielsen KaezerPas encore d'évaluation

- 2SMPP-03 Sensor PresionDocument10 pages2SMPP-03 Sensor PresionGerman GodiPas encore d'évaluation

- LX3V Programmable Logic Controller I/O and SpecsDocument4 pagesLX3V Programmable Logic Controller I/O and SpecsElgin GinetePas encore d'évaluation

- Sinamics Sm150 Gm150 Igbt enDocument12 pagesSinamics Sm150 Gm150 Igbt ensykimk8921Pas encore d'évaluation