Académique Documents

Professionnel Documents

Culture Documents

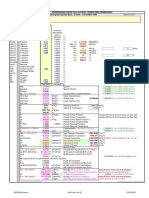

Centrifugal Pumps: Process Calculation / Data Sheet

Transféré par

Murali MuthuDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Centrifugal Pumps: Process Calculation / Data Sheet

Transféré par

Murali MuthuDroits d'auteur :

Formats disponibles

Client Contr. No Rev. Date By Chkd App.

Project

PROCESS CALCULATION / DATA SHEET

CENTRIFUGAL PUMPS

User's Note:

The equipment Tag No. to be

Calculation No. indicated in the title section.

TITLE

test

OBJECTIVE

METHOD

REFERENCES

DESIGN INPUT/ASSUMPTIONS CONFIRMATION

REQUIRED

ITEM YES NO

CONCLUSIONS CONFIRMATION

REQUIRED

PUMP RATED CAPACITY, m3/h ITEM YES NO

PUMP HEAD, kPa

PUMP BkW

C:\Users\sasmithakrishyanth\OneDrive\Technical\TECHNICAL\1. CALCULATION\Calculations1\Pump\[SNC_Centrif Pump Template.SI.xls]SNC Pump Calc. Data Sheet(Sh1)

Project

Client Project No.

PROCESS CALCULATION / DATA SHEET

CENTRIFUGAL PUMPS (SI Units)

Document No. Sheet 1 of 2

EQUIPMENT TAG NO. EQUIPMENT NAME: Service:

No. Required: No.Operating: No. Spare: Site Atm. Press.: 101.300 kPa abs

Pump Type: Motor Drive: Turbine Drive:

OPERATING CONDITIONS, EACH PUMP

Liquid: HC Flow at Normal T: m3/hr Norm. 113.90 Rated: 125.30 Min: 37.59

Normal Temp : 78.0 o

C ; Max: °C Disch Press: kPa(g) 302.95 Max: See below

S.G.@ Norm.T: 0.6975 ; @ Std 15oC: 0.7520 (2) Suct. Press: kPa(g) 94.42 Max: 441.28 kPa(g)

Vapor Press at NormT: 166.70 kPa abs Diff Press: kPa 208.52 Suction Vessel PSV Set@. : 392.30 kPa(g)

Viscosity at NormT: 0.33 cP Differential Head: m 30.5 Suction Vessel HLL : 7.16 m

Corrosion by: NPSH Available @ Rated flow : m 3.2 Suction Vessel HLL : 48.98 kPa

ALTERNATE CASES: NORMAL RATED MINIMUM TURBINE CONDITIONS

Discharge Line

Destination Pressure: kPa(g) 0.00 0.00 0.00 Inlet Steam Press: kPa(g)

Static Head: m 14.10 14.10 14.10 Temperature: °C

Static Head: (Note 3) kPa 96.45 96.45 96.45 Exhaust Steam Press: kPa(g)

Line Loss: kPa 22.50 27.23 2.45

Meter Loss: (Note 4) kPa 14.00 16.94 1.52 PUMP MATERIALS

Heat Exchanger: kPa 70.00 84.71 7.62

Item: kPa 0.00 0.00 0.00 Casing:

Item: kPa 0.00 0.00 0.00 Internal Parts:

Control Valve: kPa 100.00 77.62 194.91 API 610 Material Class:

Item: kPa 0.00 0.00 0.00

Item: kPa 0.00 0.00 0.00 POWER REQUIREMENT ESTIMATES

Item: kPa 0.00 0.00 0.00

Item: kPa 0.00 0.00 0.00 Hydraulic HP : 9.7 7.3 kW

Discharge Pressure: (Note 5) kPa(g) 302.94 302.95 302.95 Est. Pump Efficiency 67%

Suction Line: Brake Horse Power 14.5 BHP

Source Pressure: kPa(g) 68.65 68.65 68.65 Brake KW 10.8 kW

Static Head: m 6.05 6.05 6.05 API Factor 125% (Note 9)

Static Head: kPa 41.38 41.38 41.38 Calc. Motor 13.5 kW 18.2 HP

Line Loss: kPa 2.90 3.51 0.32 Std. Motor: 15.0 kW 20.1 HP

Heat Exchanger: kPa 0.00 0.00 0.00 Est. Motor Efficiency 86% (Note 10)

Control Valve: kPa 0.00 0.00 0.00 Running Power Required 17.4 kW for Utility Summary

Suction Strainer: (Note 6) kPa 10.00 12.10 1.09 MAXIMUM DISCH. PRESS. ESTIMATES

Item: kPa 0.00 0.00 0.00

Vortex Breaker: kPa 0.00 0.00 0.00

Suction Pressure: kPa(g) 97.134 94.423 108.628 Maximum discharge pressure is the greater of:

NPSH AVAILABLE: 1) Maximum Suct. P. + Normal dP

Source Pressure: kPa abs 169.95 169.95 169.95 649.80 kPa(g)

-Vapor Pressure @ Norm T.:(Note 7) kPa abs 166.70 166.70 166.70 2a) Norm. Suct. P. + 1.25 x Norm. dP (for electric drive)

-Suction Losses: kPa 12.90 15.61 1.40 357.79 kPa(g)

Sub-Total: kPa -9.65 -12.36 1.85 2b) Norm. Suct. P. + 1.38 x Norm. dP (for turbine drive)

Sub-Total: m -1.4 -1.8 0.3 384.90 kPa(g)

Liquid Level @ bttmT/L or bttm horiz. drum: m 6.8 6.8 6.8 In the case of a blocked discharge that causes the suction

Elev. of Pump Center: (Note 8) m 0.9 0.9 0.9 pressure to rise to its maximum, use the following :

NPSH Calculated: m 4.5 4.1 6.2 3a) Max. Suct. P. + 1.25 x Norm. dP (for electric drive)

Safety Margin, as % of Calc. NPSH % 10.0% 10.0% 10.0% 701.93 kPa(g)

NPSH Margin: the greater of 0.9 m or 10%, m 0.9 0.9 0.9 3b) Max. Suct. P. + 1.38 x Norm. dP (for turbine drive)

NPSH Available m 3.6 3.2 5.3 729.04 kPa(g)

NOTES:

1) See next page for system sketch.

2) Specific gravity is calculated in reference to density of water at 4ºC. Density of water @ 4ºC = 1000 kg/m3.

3) Static Head in Pressure units = Static head in meter x gravitational constant x Specific gravity x Water Density@15ºC.

4) If the type of meter is unknown, assume an orifice plate meter with a dP of 14 kPa at Normal flow. This is based on 100 in. H 2O (24.8 kPa) dP with 60% recovery

5) Check that the dP allocated to the control valve to matches the pump discharge pressure at other flowrates. Confirm the actual pump discharge pressure when

is available.

6) dP through any permanent strainer shall be based on 50% clogging. Default value for strainer dP at normal flow is 10 kPa(1.5 psi). Use L/D = 250 for critical lin

7) Liquids containing dissolved gases must be treated as bubble point liquids.

8) Grade level for pump = 0.00 m.

9) As per "API Service Factor for Motors", API 610, Tenth Edition, October 2004.

10) Estimated Motor Efficiency is from referenced documents. Manufacturer data shall be used if applicable.

REVISION ISSUE STATUS DATE BY CHK'D APP'D

C:\Users\sasmithakrishyanth\OneDrive\Technical\TECHNICAL\1. CALCULATION\Calculations1\Pump\[SNC_Centrif Pump Template.SI.xls]SNC Pump Calc. Data Sheet(Sh1)

Project

Client Project No.

PROCESS CALCULATION / DATA SHEET

CENTRIFUGAL PUMPS (SI Units)

Document No. Sheet 2 of 2

Pump Sketch

REVISION ISSUE STATUS BY CHK'D APP'D

0 0 0 0 0

0 0 0 0 0

C:\Users\sasmithakrishyanth\OneDrive\Technical\TECHNICAL\1. CALCULATION\Calculations1\Pump\[SNC_Centrif Pump Template.SI.xls]SNC Pump Calc. Data Sheet(Sh1)

This document is the sole property of the SNC-Lavalin.Inc. The borrower promises and agrees that it shall not be reproduced, copied, lent or otherwise disposed nor used for any purpose other than that for which it has been provided.

By RAK Feb- 04.

Vous aimerez peut-être aussi

- Line Sizing For Liquid, (DO IT OWN)Document11 pagesLine Sizing For Liquid, (DO IT OWN)sumitPas encore d'évaluation

- Calculation Cover Sheet: ClientDocument9 pagesCalculation Cover Sheet: Clientanamaria ursuPas encore d'évaluation

- Objective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpDocument5 pagesObjective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpAJAY1381Pas encore d'évaluation

- Equipment Name Sheet No. 1 of 3 Tag No.: Hydraulic Power CalcDocument2 pagesEquipment Name Sheet No. 1 of 3 Tag No.: Hydraulic Power Calcbagus handoko0% (1)

- Vertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFDocument4 pagesVertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFJhonnatan Fredy Gomez DominguezPas encore d'évaluation

- Pump (English) TemplateDocument1 pagePump (English) TemplateMichael HaisePas encore d'évaluation

- Process Engineer - PSV SizingDocument3 pagesProcess Engineer - PSV SizingLaorenciaPas encore d'évaluation

- 2002 Foster Wheeler Energy Limited. All Rights ReservedDocument4 pages2002 Foster Wheeler Energy Limited. All Rights Reservedhwang2Pas encore d'évaluation

- Specification Sheet For Separator: Operating Conditions SketchDocument12 pagesSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- RT PDFDocument2 pagesRT PDFsri9987Pas encore d'évaluation

- Power CalculationDocument4 pagesPower CalculationGunasekaranPas encore d'évaluation

- Vertical Separator SizingDocument4 pagesVertical Separator SizingnemprrPas encore d'évaluation

- Sizing Calculation - AC214312UJ - R0 PDFDocument1 pageSizing Calculation - AC214312UJ - R0 PDFPavendhan PavPas encore d'évaluation

- Maz - Design - Separator Capacity EvaluationDocument5 pagesMaz - Design - Separator Capacity EvaluationNaeem HussainPas encore d'évaluation

- 3Ph Vert Sep 2010 Weir VerA FPS PDFDocument5 pages3Ph Vert Sep 2010 Weir VerA FPS PDFhaiderPas encore d'évaluation

- Gas-Gas Exchanger DatasheetDocument3 pagesGas-Gas Exchanger DatasheetidilfitriPas encore d'évaluation

- PIPE-100: Variabel Satuan Sumur HCE 29 Pad 7Document55 pagesPIPE-100: Variabel Satuan Sumur HCE 29 Pad 7Hesti Fuzi LestariPas encore d'évaluation

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Document26 pagesSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801Pas encore d'évaluation

- PTM-68-P3-CS-002 - Fuel Gas Filter - Rev.0Document1 pagePTM-68-P3-CS-002 - Fuel Gas Filter - Rev.0Indraharja FerryPas encore d'évaluation

- Salt Water CalculationsDocument13 pagesSalt Water CalculationsHsein WangPas encore d'évaluation

- Compressor Settle Out PressureDocument1 pageCompressor Settle Out PressureAhmed GattoufiPas encore d'évaluation

- Memoria de Calculo Separadores BifasicosDocument1 pageMemoria de Calculo Separadores BifasicosJhonnatan Fredy Gomez DominguezPas encore d'évaluation

- Pump & Pressure Drop CalculationDocument42 pagesPump & Pressure Drop CalculationMuhammad RizkyPas encore d'évaluation

- Calculation Cover SheetDocument6 pagesCalculation Cover SheetAnonymous a4Jwz14WPas encore d'évaluation

- PDM-P-CS-002 - HP Prod SeparatorDocument5 pagesPDM-P-CS-002 - HP Prod Separatorfirman adiyantoPas encore d'évaluation

- Values Highlighted in GREEN Are Calculated Values: Suction Fittings & ValvesDocument7 pagesValues Highlighted in GREEN Are Calculated Values: Suction Fittings & ValvesaltruismPas encore d'évaluation

- Cooling Water Line HydDocument7 pagesCooling Water Line HydpavanPas encore d'évaluation

- Line Sizing Design Basis - General Specification PDFDocument11 pagesLine Sizing Design Basis - General Specification PDFSaiKumarPas encore d'évaluation

- API 12j SizingDocument1 pageAPI 12j SizingAdewunmi OlufemiPas encore d'évaluation

- Pump Calculation SheetDocument4 pagesPump Calculation SheetMuhammad BilalPas encore d'évaluation

- Calculation Title: Seagas Pipeline Design - MinervaDocument1 pageCalculation Title: Seagas Pipeline Design - Minerva秦东旺Pas encore d'évaluation

- Vessel - Vertical Sizing - IPunitsDocument25 pagesVessel - Vertical Sizing - IPunitsAnders FTPas encore d'évaluation

- Calculation For Steam Blow Rev03Document6 pagesCalculation For Steam Blow Rev03tauqeerPas encore d'évaluation

- Aspen Exchanger Design and Rating Shell & Tube V8.8Document3 pagesAspen Exchanger Design and Rating Shell & Tube V8.8Camila Florencia ScarlatoPas encore d'évaluation

- PSV D-103Document24 pagesPSV D-103DIANTOROPas encore d'évaluation

- ParalDocument9 pagesParalTahirJabbarPas encore d'évaluation

- Line Losses (Fittings) ΔP (ft) ΔP (ft)Document3 pagesLine Losses (Fittings) ΔP (ft) ΔP (ft)ahmadliePas encore d'évaluation

- Open TankDocument27 pagesOpen Tankhgagselim2012Pas encore d'évaluation

- Pump NPSH Calculation-0801Document1 pagePump NPSH Calculation-0801Vlanic StudioPas encore d'évaluation

- Thermosyphon Reboiler (Horizontal) GPSADocument6 pagesThermosyphon Reboiler (Horizontal) GPSAsyamsudin2006Pas encore d'évaluation

- Hyd. Calc of 43p17 Ab - As Per P&idDocument7 pagesHyd. Calc of 43p17 Ab - As Per P&idAnindyaPas encore d'évaluation

- Heat Transfer Coeficient in ReactorDocument2 pagesHeat Transfer Coeficient in ReactorDavid LambertPas encore d'évaluation

- Tube Side Velocity CalculationDocument20 pagesTube Side Velocity CalculationNitin KurupPas encore d'évaluation

- 325 - Sparger DesignDocument3 pages325 - Sparger DesignInggit Prillasari100% (1)

- Packed Column DesignDocument6 pagesPacked Column Designyamen-691904Pas encore d'évaluation

- Filter Vessel Shell VelocityDocument12 pagesFilter Vessel Shell VelocityAye KywePas encore d'évaluation

- Distillation Column: Major Equipment DesignDocument45 pagesDistillation Column: Major Equipment Designrubesh_rajaPas encore d'évaluation

- Heat Exchanger Design Calculation EOR Condition Design InputsDocument4 pagesHeat Exchanger Design Calculation EOR Condition Design InputsSiva baalanPas encore d'évaluation

- Gas Pressure Drop Calculation Using SCFM: Pipe ValvesDocument3 pagesGas Pressure Drop Calculation Using SCFM: Pipe ValvesDavid Muñoz CastroPas encore d'évaluation

- Calculation Sheet For Pump Hydraulic (Fps Unit)Document1 pageCalculation Sheet For Pump Hydraulic (Fps Unit)chemical todiPas encore d'évaluation

- Centrif Pumps1 SpreadsheetDocument2 pagesCentrif Pumps1 SpreadsheetCast Ed Iv0% (1)

- Shell Tube Heat Exchanger DesignDocument7 pagesShell Tube Heat Exchanger DesignAbhijeet JhaPas encore d'évaluation

- VSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)Document7 pagesVSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)rudi 010% (1)

- Boiling Up Rate For Batch DistillationDocument4 pagesBoiling Up Rate For Batch DistillationKanhaiyalal PatilPas encore d'évaluation

- ΔP criteria ΔP criteria ρV ρVDocument3 pagesΔP criteria ΔP criteria ρV ρVjenish parekhPas encore d'évaluation

- TC 2212921 - Washtech Industries - 20.02 PDFDocument1 pageTC 2212921 - Washtech Industries - 20.02 PDFDevesh PathakPas encore d'évaluation

- Technical Bid Evaluation FormDocument2 pagesTechnical Bid Evaluation Formshyam100% (3)

- Technical Bid Evaluation FormDocument2 pagesTechnical Bid Evaluation Formanon_213471744Pas encore d'évaluation

- Generator Exhaust Pipe Diameter Calculations: Marina Towers L9959Document4 pagesGenerator Exhaust Pipe Diameter Calculations: Marina Towers L9959febousPas encore d'évaluation

- 2005 PDFDocument5 pages2005 PDFMihai-Eugen PopaPas encore d'évaluation

- Process Engineering Equipment Handbook: Claire SoaresDocument9 pagesProcess Engineering Equipment Handbook: Claire SoaresMurali MuthuPas encore d'évaluation

- Design and Implement A Totally Enclosed Ground FlareDocument3 pagesDesign and Implement A Totally Enclosed Ground FlareMurali MuthuPas encore d'évaluation

- 0 Exercise Instruction Heating ValueDocument7 pages0 Exercise Instruction Heating ValueMurali MuthuPas encore d'évaluation

- Fulltext PDFDocument221 pagesFulltext PDFMurali MuthuPas encore d'évaluation

- Sengupta and Staats Method PSVDocument6 pagesSengupta and Staats Method PSVMurali MuthuPas encore d'évaluation

- Select Optimal Schemes For Gas Processing PlantsDocument4 pagesSelect Optimal Schemes For Gas Processing PlantsMurali MuthuPas encore d'évaluation

- Relief Valve and Flare Action Items - What Plant Engineers Should KnowDocument6 pagesRelief Valve and Flare Action Items - What Plant Engineers Should KnowMurali MuthuPas encore d'évaluation

- ACFrOgALH7tI4bGAHoY RBTNzPHzMIyHy7FK3 - NLfBCnaIFG6 NJq3Ec8m HIQzGzsRrhL - EaKBKBfiHbz8J4GJN6MjbtxKXVhWqDR 2HbQRcF HAQ5 - xgrqTpvP2io PDFDocument6 pagesACFrOgALH7tI4bGAHoY RBTNzPHzMIyHy7FK3 - NLfBCnaIFG6 NJq3Ec8m HIQzGzsRrhL - EaKBKBfiHbz8J4GJN6MjbtxKXVhWqDR 2HbQRcF HAQ5 - xgrqTpvP2io PDFMurali MuthuPas encore d'évaluation

- Fulltext PDFDocument221 pagesFulltext PDFMurali MuthuPas encore d'évaluation

- 7997-Article Text PDF-16627-3-10-20151223 PDFDocument5 pages7997-Article Text PDF-16627-3-10-20151223 PDFMurali MuthuPas encore d'évaluation

- Calculation Cover SheetDocument10 pagesCalculation Cover SheetMurali MuthuPas encore d'évaluation

- W4 Lesson 2 and 3Document15 pagesW4 Lesson 2 and 3Murali MuthuPas encore d'évaluation

- A Comparative Study of Propane Recovery ProcessesDocument15 pagesA Comparative Study of Propane Recovery ProcessesMurali MuthuPas encore d'évaluation

- Grade 3 - Shapes - Revision Work Sheet PDFDocument1 pageGrade 3 - Shapes - Revision Work Sheet PDFMurali MuthuPas encore d'évaluation

- 50 Years of Innovations: in Solar TechnologyDocument12 pages50 Years of Innovations: in Solar TechnologyMurali MuthuPas encore d'évaluation

- Process Diagrams: 11 4:3 Easy To EditDocument16 pagesProcess Diagrams: 11 4:3 Easy To EditMurali MuthuPas encore d'évaluation

- Grade To Year Equivalency Chart Grade System Year System: ST STDocument1 pageGrade To Year Equivalency Chart Grade System Year System: ST STMurali MuthuPas encore d'évaluation

- Simulation: Gautham S Process EngineerDocument25 pagesSimulation: Gautham S Process EngineerMurali MuthuPas encore d'évaluation

- Vickers Cartridge Kits Catalogue PDFDocument5 pagesVickers Cartridge Kits Catalogue PDFSamuel Frank VejarPas encore d'évaluation

- Gate Valves: Ips Carbon Steel Pipe - Fire Protection ValvesDocument8 pagesGate Valves: Ips Carbon Steel Pipe - Fire Protection ValvesAndi IrawanPas encore d'évaluation

- Omni - Series - dc2 - dc6 - Manual de Instalación PDFDocument46 pagesOmni - Series - dc2 - dc6 - Manual de Instalación PDFmazzingerzPas encore d'évaluation

- 8 p1517 1550 FH - en PDFDocument34 pages8 p1517 1550 FH - en PDFfarid kerrouchePas encore d'évaluation

- Nose Cone & Fin OptimizationDocument48 pagesNose Cone & Fin Optimizationnhung_33Pas encore d'évaluation

- Property - Mq.edu - Au - Inspection and Test Plans (ITP) - MUM-08 - Valves FORM - 2pDocument2 pagesProperty - Mq.edu - Au - Inspection and Test Plans (ITP) - MUM-08 - Valves FORM - 2pHarumPas encore d'évaluation

- Module 3Document28 pagesModule 3Carms GamePas encore d'évaluation

- Artificial Supercavitation. Physics and CalculationDocument34 pagesArtificial Supercavitation. Physics and Calculationmohsen123Pas encore d'évaluation

- 3 Circulation Vorticity PVDocument12 pages3 Circulation Vorticity PVNura GuyoPas encore d'évaluation

- Aerodynamic Optimization of A Morphing Winglet DesignDocument5 pagesAerodynamic Optimization of A Morphing Winglet DesignPreetham PreethuPas encore d'évaluation

- BSB Rupture Disk With Safety Relief ValvesDocument8 pagesBSB Rupture Disk With Safety Relief ValvesChitikala RajeshPas encore d'évaluation

- Ne Batch2Document108 pagesNe Batch2Hannah MartinezPas encore d'évaluation

- FMDocument78 pagesFMindumathijayakaranPas encore d'évaluation

- Ra 1 020 Ep242 11001 Piping Material Specification 1Document363 pagesRa 1 020 Ep242 11001 Piping Material Specification 1Hugo RuizPas encore d'évaluation

- TM 90 21 PDFDocument22 pagesTM 90 21 PDFJuan MatePas encore d'évaluation

- Chapter 24 - Intro To Turbulence Modeling in CFDDocument23 pagesChapter 24 - Intro To Turbulence Modeling in CFDprashanthreddyhPas encore d'évaluation

- Mechanical Engineering Important MCQ PDF-Fluid Mechanics 3Document25 pagesMechanical Engineering Important MCQ PDF-Fluid Mechanics 3Bala MetturPas encore d'évaluation

- Three-Dimensional CFD Rotordynamic Analysis of Gas Labyrinth SealsDocument7 pagesThree-Dimensional CFD Rotordynamic Analysis of Gas Labyrinth SealsTapanVaishnavPas encore d'évaluation

- Schem SPI Sizing EquationsDocument62 pagesSchem SPI Sizing EquationsRAJAVIGNESH SPas encore d'évaluation

- Calculation of Orifice DiameterDocument4 pagesCalculation of Orifice DiameterNaseer HydenPas encore d'évaluation

- Control Valve PDFDocument26 pagesControl Valve PDFRoona Thankam VarghesePas encore d'évaluation

- Lab ManualDocument40 pagesLab ManualHimanshu TripathiPas encore d'évaluation

- Vlvula2020Web de Conferencias E3SDocument8 pagesVlvula2020Web de Conferencias E3SJesus Juica HuamaniPas encore d'évaluation

- CVE 372 HYDROMECHANICS - 2 Flow in Closed Conduits 2 PDFDocument54 pagesCVE 372 HYDROMECHANICS - 2 Flow in Closed Conduits 2 PDFabhilibra14Pas encore d'évaluation

- Chapter 2 Fanning EquationDocument9 pagesChapter 2 Fanning EquationFaisal AyyazPas encore d'évaluation

- ASWC2013 Aero 4 ANSYS Germany FrankDocument41 pagesASWC2013 Aero 4 ANSYS Germany Frankbecool_bcn75100% (1)

- 2006 - Lattice Boltzmann Method For Incompressible Flows With Large Pressure Gradients PDFDocument12 pages2006 - Lattice Boltzmann Method For Incompressible Flows With Large Pressure Gradients PDFzebrazerozeroPas encore d'évaluation

- Bernoulli ExperimentDocument6 pagesBernoulli ExperimentKiki AkiraPas encore d'évaluation

- Ductulator May 2010Document8 pagesDuctulator May 2010haroub_nasPas encore d'évaluation

- Analysis of CORRUGATED AirfoilDocument17 pagesAnalysis of CORRUGATED AirfoilJash BhagatPas encore d'évaluation