Académique Documents

Professionnel Documents

Culture Documents

Masterflex 3000

Transféré par

Doby YuniardiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Masterflex 3000

Transféré par

Doby YuniardiDroits d'auteur :

Formats disponibles

MASTERFLEX® 611

Gun grade, hydroswelling waterbar

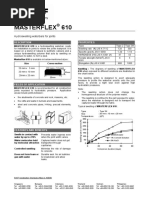

DESCRIPTION Swelling: Typical swelling behaviour of MASTERFLEX

611 in distilled water is illustrated below. The swelling

Masterflex 611 is a single component, urethane action depends on the solution to which it is exposed.

modified, gun grade, hydroswelling waterbar for

120

application in situations where pre-formed waterbars 20x10x50mm

cannot be used. 100

Swelling rate in volume

FIELDS OF APPLICATION 80

(%)

MASTERFLEX 611 is recommended for sealing all 60

narrow joints, cavities or gaps exposed to hydrostatic 40

pressure. Applications include :

20

• insitu casting of ‘gaskets’ for sealing joints in piping

and between precast elements. 0

• sealing of construction joints. 0 2 4 7 10 14 21 28 35

Immersion duration (days)

• use as a smoothing and adhesive paste over

uneven joint surfaces before laying MASTERFLEX

610. PROPERTIES

• repair works and sealing of gaps.

Note : If MASTERFLEX 611 is used on exposed Appearance : Paste

surfaces, the swelling effect from continuous rain may

cause the unprotected part of the waterbar to bulge Specific Gravity (JIS A 1439) : 1.29 +/-0.05

slightly.

Extrusion (JIS A 1439) : max 5 sec

FEATURES AND BENEFITS

Slump (JIS A 1439) : max 5 mm

Swells in contact with Seals gaps effectively.

water by over 90%

Tack-free time (JIS A 1439) : within 5 hr

Water molecules held No wicking effect that

by molecular could cause leaks.

attraction APPLICATION

Excellent adhesion No leakage through bond Surface Preparation

interface. Correct preparation is critical for optimum performance.

Highly elastic Prevents damage from Surfaces should be structurally sound, clean, and free

swelling and shrinking from loose particles and sharp protrusion, oil, grease, or

cycles caused by wetting any other contaminant.

and drying. Repair any honeycombs and such other defects with a

Controlled swelling Minimise the risk of suitable repair mortar (consult BASF Construction

damage to substrate. Chemicals). Clear any standing water from the surface.

Insert the cartridge filled with MASTERFLEX 611 into

Bonds to moist Benefit in humid areas.

the frame of a standard sealant gun. Cut off the nozzle

surfaces

at a suitable distance from the end in diagonal to obtain

an opening that best matches the width of the gap to be

TYPICAL PERFORMANCE sealed or of the waterbar (MASTERFLEX 610) to be

laid.

Tensile strength (JIS A 6251) : min 3.9 N/mm2

Elongation (JIS K 6251) : min 1000 % Placing

With the nozzle just above the substrate surface, gently

Tear strength (JIS K 6252) : min12 N/mm and repeatedly squeeze the trigger depositing a

Swelling ratio (JIS K 6258) : min 85% continuous bead of MASTERFLEX 611 into the gap or

o

Distilled water at 23 C where the waterbar is to be laid. Avoid entrapment of air

in the gunned material by matching the rate of advance

of the gun nozzle with the rate of deposition.

BASF Construction Chemicals offices in ASEAN

Singapore Malaysia Indonesia Thailand Vietnam Philippines

Tel :+65-6861-6766 Tel :+60-3-3344-3388 Tel :+62-21-893-4339 Tel :+66-3845-3020 Tel :+84-650-743-100 Tel : +63-2-632-9995

Fax :+65-6861-3186 Fax :+60-3-3344-2288 Fax : +62-21-893-4342 Fax :+66-3845-3029 Fax :+84-650-743-200 Fax : +63-2-632-9996

MASTERFLEX® 611

If using as a smoothing or adhesive paste for PRECAUTIONS

MASTERFLEX 610 (pre-formed waterbar), place the

waterbar over the adhesive paste while it is still tacky Health : Some people may be sensitive to certain resin

and gently press to ensure bonding. systems. Wear impervious gloves and use hand barrier

cream while handling the product. Prevent eye contact.

Ventilate application area. Wash thoroughly after

CURING handling. Persons who are sensitive to the vapours

MASTERFLEX 611 is self curing. It achieves tack-free must wear approved respirators.

state within 5 hr. at 25°C. Should skin contact occur, wash immediately with soap

and water, or an effective hand cleaner.

Note : It is important to protect the waterbar from In case of accidental eye contact wash with copious

exposure to water until it is fully cured. quantities of water and seek medical help immediately.

If ingested, do not induce vomiting. Consult doctor

ESTIMATING DATA

immediately.

The coverage in running metres of a 320 ml cartridge If the inhalation of vapours is causing discomfort,

for common widths and thicknesses of application is remove to fresh air.

given below. Fire : Product is flammable. Avoid exposure to naked

flame or other ignition sources. Do not smoke while

Application Application width in mm handling the product.

Depth in mm 5 10 20 25 30 Flash point : 44°C

5 3.2 2.6 2.1 For Health, Safety and Environmental

recommendations, please consult and follow all

10 6.4 3.2 1.6 1.3 1.1 instructions on the product Material Safety Data Sheet.

20 3.2 1.6 0.8 0.6 0.5

25 2.6 1.3 0.6 0.5 0.4

1-1-1-106

PACKAGING

Masterflex 611 is packaged in 320 ml (400 g)

cartridges. 24 cartridges are packed per carton.

SHELF LIFE

Masterflex 611 can be stored in a well enclosed dry

place for 6 months in unopened original packing away

from heat and direct sunlight.

The technical information and application advice given in this BASF Construction Chemicals publication are

STATEMENT OF based on the present state of our best scientific and practical knowledge. As the information herein is of a

general nature, no assumption can be made as to a product's suitability for a particular use or application and

RESPONSIBILITY no warranty as to its accuracy, reliability or completeness either expressed or implied is given other than

those required by law. The user is responsible for checking the suitability of products for their intended use.

NOTE Field service where provided does not constitute supervisory responsibility. Suggestions made by BASF

Construction Chemicals either orally or in writing may be followed, modified or rejected by the owner,

engineer or contractor since they, and not BASF Construction Chemicals, are responsible for carrying out

procedures appropriate to a specific application.

Vous aimerez peut-être aussi

- Geotextiles and Geomembranes HandbookD'EverandGeotextiles and Geomembranes HandbookT.S. IngoldÉvaluation : 5 sur 5 étoiles5/5 (1)

- Masterseal 555S: Flexible, Polymer Cement Waterproofing SlurryDocument2 pagesMasterseal 555S: Flexible, Polymer Cement Waterproofing SlurryshashiPas encore d'évaluation

- Basf Masterflow 980 TdsDocument4 pagesBasf Masterflow 980 Tdschopdekar1969_890124Pas encore d'évaluation

- MasterSeal 530Document2 pagesMasterSeal 530dewipuspa0503Pas encore d'évaluation

- NITOPROOFDocument4 pagesNITOPROOFTejinder KumarPas encore d'évaluation

- Masterflow 980 TdsDocument4 pagesMasterflow 980 Tdszhangjinlin132Pas encore d'évaluation

- BASF Masterseal 530Document2 pagesBASF Masterseal 530JM SubionPas encore d'évaluation

- Non-shrink underwater groutDocument4 pagesNon-shrink underwater grouttin aungtunPas encore d'évaluation

- MasterFlow 526Document3 pagesMasterFlow 526ashraf komiPas encore d'évaluation

- Masterflow 559: Versatile High Strength, Non Shrink Cementitious Construction GroutDocument3 pagesMasterflow 559: Versatile High Strength, Non Shrink Cementitious Construction GroutGavriel NgPas encore d'évaluation

- MasterSeal 726 - TDSDocument2 pagesMasterSeal 726 - TDSKhin Sandi KoPas encore d'évaluation

- Starproof WF MB 602Document2 pagesStarproof WF MB 602dhivahar158Pas encore d'évaluation

- Masterseal 480 Asean 0709Document2 pagesMasterseal 480 Asean 0709jessicaPas encore d'évaluation

- Masterflow 980 Tds PDFDocument4 pagesMasterflow 980 Tds PDFAdamo Absalome MulochePas encore d'évaluation

- Masterseal 910: Hydroswelling Waterbar For Construction JointsDocument4 pagesMasterseal 910: Hydroswelling Waterbar For Construction JointsHJPas encore d'évaluation

- 07 - TDS - Masterflow 520Document3 pages07 - TDS - Masterflow 520Alexi ALfred H. TagoPas encore d'évaluation

- Emaco s188 AseanDocument2 pagesEmaco s188 AseanDoby YuniardiPas encore d'évaluation

- Nullifire SC601 PDSDocument4 pagesNullifire SC601 PDSPeter ThomsonPas encore d'évaluation

- Masterseal 540 TdsDocument2 pagesMasterseal 540 TdsRhinzy CajuraoPas encore d'évaluation

- Product Submittal - MasterSeal 730 UVSDocument66 pagesProduct Submittal - MasterSeal 730 UVSTrầnDuyPas encore d'évaluation

- MasterSeal 902 Hydro-swelling WaterstopDocument2 pagesMasterSeal 902 Hydro-swelling WaterstopHJPas encore d'évaluation

- Masterflex 610 AseanDocument2 pagesMasterflex 610 AseanDoby YuniardiPas encore d'évaluation

- Garlock Torque Torques en InglesDocument6 pagesGarlock Torque Torques en InglesGustavo MardonesPas encore d'évaluation

- Masterseal 540 - Map v1-0716Document3 pagesMasterseal 540 - Map v1-0716Mcr KumaraPas encore d'évaluation

- MasterSeal 555Document2 pagesMasterSeal 555dewipuspa0503Pas encore d'évaluation

- Masterflow 626: Heavy Duty, Epoxy Resin Based GroutDocument2 pagesMasterflow 626: Heavy Duty, Epoxy Resin Based GroutAndri AjaPas encore d'évaluation

- Masterflow 980 TdsDocument5 pagesMasterflow 980 Tdsrobin rezkPas encore d'évaluation

- Masterseal 588: Description Packaging and ColorsDocument2 pagesMasterseal 588: Description Packaging and ColorsmariaPas encore d'évaluation

- Dow Corning 991 Product InfoDocument4 pagesDow Corning 991 Product InfocurlyjockeyPas encore d'évaluation

- Fosroc Conbextra EP10: Constructive SolutionsDocument2 pagesFosroc Conbextra EP10: Constructive SolutionsVincent JavatePas encore d'évaluation

- Masterseal 930/masterseal 933Document4 pagesMasterseal 930/masterseal 933Paladi Ravi100% (1)

- MasterSeal 730 UVS v4Document2 pagesMasterSeal 730 UVS v4Chaitanya MehtaPas encore d'évaluation

- Non-shrink cement grout for foundation platesDocument4 pagesNon-shrink cement grout for foundation platesLftea AdiPas encore d'évaluation

- Galvit EZ P40.01: Previous Suitable CoatDocument2 pagesGalvit EZ P40.01: Previous Suitable CoatDamian RowePas encore d'évaluation

- Nitoseal MS600Document3 pagesNitoseal MS600talatzahoorPas encore d'évaluation

- Non-Sag Epoxy Adhesive 617NS Technical Data SheetDocument4 pagesNon-Sag Epoxy Adhesive 617NS Technical Data SheetAmar Babu ChPas encore d'évaluation

- Masterseal 345 TdsDocument2 pagesMasterseal 345 TdsMarko BlagojevicPas encore d'évaluation

- 09 - TDS - Masterflow 928T PDFDocument5 pages09 - TDS - Masterflow 928T PDFGibbs PerPas encore d'évaluation

- Nitoproof 600 UAEDocument4 pagesNitoproof 600 UAECharles FernandesPas encore d'évaluation

- Masterseal 590 - PDS - ASEAN - 160512Document2 pagesMasterseal 590 - PDS - ASEAN - 160512Andri AjaPas encore d'évaluation

- Product Data Sheets VU27G PDFDocument1 pageProduct Data Sheets VU27G PDFSai KatikalaPas encore d'évaluation

- Nitoproof 600: Liquid Applied Single Component Elastomeric Waterproofi NG MembraneDocument4 pagesNitoproof 600: Liquid Applied Single Component Elastomeric Waterproofi NG MembraneKunal MandalaywalaPas encore d'évaluation

- High strength epoxy grout for heavy duty applicationsDocument4 pagesHigh strength epoxy grout for heavy duty applicationsVikas Singh ChandelPas encore d'évaluation

- Masterpren Masterpren Masterpren Masterpren 1000 1000 1000 1000Document2 pagesMasterpren Masterpren Masterpren Masterpren 1000 1000 1000 1000Lemark R.Pas encore d'évaluation

- Masterkure 100WBDocument2 pagesMasterkure 100WBDoby YuniardiPas encore d'évaluation

- Multi-Purpose Acrylic Joint SealantDocument2 pagesMulti-Purpose Acrylic Joint Sealantmuhammad aliPas encore d'évaluation

- Conbextra EP10Document2 pagesConbextra EP10m.elsanee.cubicPas encore d'évaluation

- High Strength Non-Shrink Micro Concrete GroutDocument4 pagesHigh Strength Non-Shrink Micro Concrete GroutJoshua EkoPas encore d'évaluation

- Masterflow 928 TdsDocument5 pagesMasterflow 928 Tdsrobin rezkPas encore d'évaluation

- Basf Masterseal 640 TdsDocument2 pagesBasf Masterseal 640 TdsJassi Singh0% (1)

- iKOTE CM 40X (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 40X (TDS) 02-APRIL-2024nguyen hoang AnhPas encore d'évaluation

- Fosroc Conbextra EP75: Constructive SolutionsDocument2 pagesFosroc Conbextra EP75: Constructive SolutionsmangjitPas encore d'évaluation

- MasterSeal® 610Document2 pagesMasterSeal® 610awad.aslamhouriPas encore d'évaluation

- High strength epoxy resin grout for heavy duty applicationsDocument4 pagesHigh strength epoxy resin grout for heavy duty applicationsHamkarPas encore d'évaluation

- TDS - Masterflow 885Document4 pagesTDS - Masterflow 885aahtagoPas encore d'évaluation

- MASTERKURE 106i v5Document2 pagesMASTERKURE 106i v5bollavaram sivaramireddyPas encore d'évaluation

- Masterseal - NP 474 - TdsDocument4 pagesMasterseal - NP 474 - Tdscahyo hutomoPas encore d'évaluation

- TagoProof StrongDocument2 pagesTagoProof StrongShaikh Nadim Akhtar0% (1)

- High Strength Non-Shrink Micro Concrete GroutDocument4 pagesHigh Strength Non-Shrink Micro Concrete GroutilhamPas encore d'évaluation

- HIT Rebar Fatigue enDocument7 pagesHIT Rebar Fatigue enWalter CastilloPas encore d'évaluation

- Renderoc HB25: Constructive SolutionsDocument4 pagesRenderoc HB25: Constructive SolutionsDoby YuniardiPas encore d'évaluation

- Tabel Konversi SatuanDocument1 pageTabel Konversi SatuanSutopo AhmadPas encore d'évaluation

- Intercure 99Document4 pagesIntercure 99Doby YuniardiPas encore d'évaluation

- FOR DOCUMENTDocument2 pagesFOR DOCUMENTDoby YuniardiPas encore d'évaluation

- Preco EAC-SDocument2 pagesPreco EAC-SDoby YuniardiPas encore d'évaluation

- HIT Rebar Fatigue enDocument7 pagesHIT Rebar Fatigue enWalter CastilloPas encore d'évaluation

- Masterflex 828: Hot Pour Joint Sealant, ASTM D1190Document2 pagesMasterflex 828: Hot Pour Joint Sealant, ASTM D1190Doby YuniardiPas encore d'évaluation

- HIT Rebar Fatigue enDocument7 pagesHIT Rebar Fatigue enWalter CastilloPas encore d'évaluation

- MBrace Putty ASEANDocument2 pagesMBrace Putty ASEANDoby YuniardiPas encore d'évaluation

- Mastertop Primer 9Document3 pagesMastertop Primer 9Doby YuniardiPas encore d'évaluation

- Nitoplate FRC: Constructive SolutionsDocument2 pagesNitoplate FRC: Constructive SolutionsDoby YuniardiPas encore d'évaluation

- ProdukDocument3 pagesProdukDoby YuniardiPas encore d'évaluation

- Intercryl 520Document4 pagesIntercryl 520Doby YuniardiPas encore d'évaluation

- Intergard 774Document4 pagesIntergard 774Doby YuniardiPas encore d'évaluation

- Interlac 826Document4 pagesInterlac 826Doby YuniardiPas encore d'évaluation

- Masterflex 3000: Masterflex Sealing System For Irregular and Unconventional JointsDocument3 pagesMasterflex 3000: Masterflex Sealing System For Irregular and Unconventional JointsDoby YuniardiPas encore d'évaluation

- Mastertop 102: Natural Aggregate Concrete Surface HardenerDocument2 pagesMastertop 102: Natural Aggregate Concrete Surface HardenerDoby YuniardiPas encore d'évaluation

- Conbextra EUW: Water Insensitive Epoxy MaterialDocument2 pagesConbextra EUW: Water Insensitive Epoxy MaterialDoby YuniardiPas encore d'évaluation

- Backer RodDocument2 pagesBacker RodDoby YuniardiPas encore d'évaluation

- Preco EAC-SDocument2 pagesPreco EAC-SDoby YuniardiPas encore d'évaluation

- Mastertop 566: Self Smoothing Cementitious Based Floor LevellerDocument2 pagesMastertop 566: Self Smoothing Cementitious Based Floor LevellerDoby YuniardiPas encore d'évaluation

- Masterflex 3000: Masterflex Sealing System For Irregular and Unconventional JointsDocument3 pagesMasterflex 3000: Masterflex Sealing System For Irregular and Unconventional JointsDoby YuniardiPas encore d'évaluation

- Mastertop 1240 AseanDocument2 pagesMastertop 1240 AseanDoby YuniardiPas encore d'évaluation

- Ucrete Ud200 AseanDocument2 pagesUcrete Ud200 AseanDoby YuniardiPas encore d'évaluation

- Mastertop 1220 AseanDocument3 pagesMastertop 1220 AseanDoby YuniardiPas encore d'évaluation

- Mastertop 1240 AseanDocument2 pagesMastertop 1240 AseanDoby YuniardiPas encore d'évaluation

- Intergard 774Document4 pagesIntergard 774Doby YuniardiPas encore d'évaluation

- Intergard 774Document4 pagesIntergard 774Doby YuniardiPas encore d'évaluation

- Piper J-3 CubDocument15 pagesPiper J-3 CubAviation/Space History Library100% (8)

- Bonding To Enamel Using Alternative Enamel Conditioner/etchantsDocument15 pagesBonding To Enamel Using Alternative Enamel Conditioner/etchantsRahul PPas encore d'évaluation

- Loctite - Automotive CatalogDocument60 pagesLoctite - Automotive CataloglimalizadoPas encore d'évaluation

- Magne Resing Coating 2021Document11 pagesMagne Resing Coating 2021jotapintor100% (2)

- Additional Works: Elma V. Arda 2 Storey Residence Pook, Kalibo, AklanDocument6 pagesAdditional Works: Elma V. Arda 2 Storey Residence Pook, Kalibo, AklanJohn Remmel RogaPas encore d'évaluation

- Wa5000 3hDocument986 pagesWa5000 3hEdinson Javier Guevara Garcia100% (1)

- Armaflex Application INTMODocument36 pagesArmaflex Application INTMODavid O. AlmeidaPas encore d'évaluation

- MasterTile® 700 PDFDocument7 pagesMasterTile® 700 PDFJong Dollente Jr.Pas encore d'évaluation

- Bridge FittingDocument15 pagesBridge FittingpauPas encore d'évaluation

- Berger Fosroc: Waterproofing SolutionsDocument15 pagesBerger Fosroc: Waterproofing SolutionsGraha NusaPas encore d'évaluation

- Wood Finger-Joint StrengthDocument11 pagesWood Finger-Joint StrengthDritan AjdinajPas encore d'évaluation

- Structural Integrity - Theory and Experiment - 1989Document260 pagesStructural Integrity - Theory and Experiment - 1989abo029Pas encore d'évaluation

- Dash Kits Installation InstructionsDocument8 pagesDash Kits Installation InstructionsGeze QcoPas encore d'évaluation

- AAC Block AdhesiveDocument3 pagesAAC Block AdhesiveBiswajit SahooPas encore d'évaluation

- The Construction of The Crystal Houses Façade: Challenges and InnovationsDocument22 pagesThe Construction of The Crystal Houses Façade: Challenges and InnovationsMaxabe HerreraPas encore d'évaluation

- Adhesive Strength of Pitch Glue Group 4Document13 pagesAdhesive Strength of Pitch Glue Group 4Annalie LobianoPas encore d'évaluation

- Dai Gil Lee (2004) Design and Manufacture of An Automotive Hybrid Aluminum-Composite Drive ShaftDocument13 pagesDai Gil Lee (2004) Design and Manufacture of An Automotive Hybrid Aluminum-Composite Drive Shaftmc_ensPas encore d'évaluation

- Spec Book 6Document72 pagesSpec Book 6Vincze RobertPas encore d'évaluation

- Sikadur 31, Hi-Mod Gel 1 1 Mix Ratio-UsDocument2 pagesSikadur 31, Hi-Mod Gel 1 1 Mix Ratio-Usgrats_singcoPas encore d'évaluation

- 2013-Influence of Adhesive Thickness On High Velocity Impact Performance of Ceramicmetal Composite TargetsDocument12 pages2013-Influence of Adhesive Thickness On High Velocity Impact Performance of Ceramicmetal Composite TargetsvenkatesanjsPas encore d'évaluation

- Operation On LJT-4D HLC Paper Tube Winder MachineDocument15 pagesOperation On LJT-4D HLC Paper Tube Winder MachineYonas MuluPas encore d'évaluation

- Bituproof 50RDocument2 pagesBituproof 50RYousef HalasehPas encore d'évaluation

- Labels Vol36 Issue5 2014Document168 pagesLabels Vol36 Issue5 2014fivehours5Pas encore d'évaluation

- Journal of Dental Research: Meta-Analytical Review of Parameters Involved in Dentin BondingDocument8 pagesJournal of Dental Research: Meta-Analytical Review of Parameters Involved in Dentin BondingTeresa BeltranPas encore d'évaluation

- Technical Data Sheet Chemitac 23: DescriptionDocument3 pagesTechnical Data Sheet Chemitac 23: DescriptionPhuong The NguyenPas encore d'évaluation

- Double Road Engine Shed v2Document13 pagesDouble Road Engine Shed v2ruedanton131100% (1)

- 4b-Engineering Applications of BotanyDocument60 pages4b-Engineering Applications of BotanyAshok NenePas encore d'évaluation

- Tile Adhesive Heavy-Duty - Allgemeine Bau-Chemie Phil., IncDocument4 pagesTile Adhesive Heavy-Duty - Allgemeine Bau-Chemie Phil., IncRoland CepedaPas encore d'évaluation

- ACCU Therm Plate Heat ExchangerDocument37 pagesACCU Therm Plate Heat ExchangerMihai MateiPas encore d'évaluation

- Service Manual: Tissue ProcessorDocument42 pagesService Manual: Tissue Processordarka EisenkolbPas encore d'évaluation