Académique Documents

Professionnel Documents

Culture Documents

WG-2 Welding Gage

Transféré par

LucioCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

WG-2 Welding Gage

Transféré par

LucioDroits d'auteur :

Formats disponibles

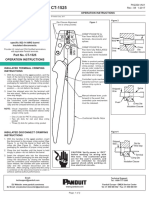

WG-2 1/32 or Zero Line

Internal HI-LO Gauge

ECONOMY

4 quick steps check internal alignment

You can check the internal alignment of your

fit-up quickly with the G.A.L. HI-LO gauge.

1. Unlock the retaining screw. Press the gauge legs

Single Purpose HI-LO beyond the barrel.

Welding Gage

2. Insert the legs (wires) into the root gap space or

the two pieces of pipe to be fitted. Turn the gauge

90°, being careful to apply a constant back pressure

to the barrel.

3. Hold the gauge as square as possible with the

fitting to obtain an accurate reading. Lock the

Available in retaining screw. Reverse the 90° turn and remove the

gauge. You're now ready to read the increment

Standard or Metric opposite the red line.

4. When the red line aligns with the 1/32 increment

line you have a good internal alignment and fit-up.

Misalignment can be determined from the zero line

by increment markings of 1/16 inch.

Eliminates rejects,

improves

productivity

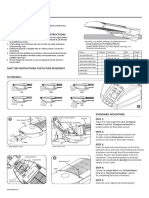

Rootweld Spacing Gauge

Easy operation determines rootweld spacing.

1. Unlock the retaining screw and insert

the gauge interior alignment stops

between the two pieces of pipe to be

fitted.

2. Insert the leg with the longer taper into

the root gap until it makes contact with

both sides of the gap.

3. Re-lock the retaining screw, remove

the gauge and read it.

4. The scale is calibrated in fractional

Internal dimensions from 1/32 to 3/16 in 1/16 inch

increments. The read-out you receive

misalignment

represents the amount of rootweld gap.

Rootweld space

Retainer Lock Screw

Part No. Description

WG-2 Standard Econo HI-LO Gauge

WG-2M Metric Econo HI-LO Gauge

© June 2000

www.newmantools.com tel 1-800-465-1384 fax 1-800-605-2442 page 2

Vous aimerez peut-être aussi

- 9211B Installation Kistler PDFDocument2 pages9211B Installation Kistler PDFCristian MaldonadoPas encore d'évaluation

- Como Interpretas Las Galgas de SoldadurasDocument3 pagesComo Interpretas Las Galgas de SoldadurasFreddy Sanjuan SalcedoPas encore d'évaluation

- MFL40322181Sapience 23inch CSA - Service Manual - 131014Document58 pagesMFL40322181Sapience 23inch CSA - Service Manual - 131014Cesar Calderon Gr100% (1)

- KSG 5K DM3 Installation Manual PDFDocument2 pagesKSG 5K DM3 Installation Manual PDFMIchelle SmithPas encore d'évaluation

- Manual Servicio LG T1607Document58 pagesManual Servicio LG T1607Jaime VelazquezPas encore d'évaluation

- Washing Machine: Service ManualDocument59 pagesWashing Machine: Service ManualHama AieaPas encore d'évaluation

- Car Speedo SensorDocument1 pageCar Speedo Sensorkelumpj8479Pas encore d'évaluation

- Internal Cutters: Manual E535Document23 pagesInternal Cutters: Manual E535Wagner AmaralPas encore d'évaluation

- Weld CheckDocument6 pagesWeld CheckArnold c ElverPas encore d'évaluation

- Installation Instructions Speedometer / Hourmeter / ClockDocument6 pagesInstallation Instructions Speedometer / Hourmeter / ClockJavier Machuca SánchezPas encore d'évaluation

- IM&OM - PC-AR - enDocument12 pagesIM&OM - PC-AR - enzodenapePas encore d'évaluation

- Hose AssemblyDocument1 pageHose AssemblyScott SepperPas encore d'évaluation

- To Decrease Arc:: Gear Driven SprinklersDocument2 pagesTo Decrease Arc:: Gear Driven SprinklersBernianuNicoletaPas encore d'évaluation

- Material de Inspección VisualDocument27 pagesMaterial de Inspección VisualGuillermo BarragánPas encore d'évaluation

- DX68 Hose Crimping Machine User Manual (Introductions)Document4 pagesDX68 Hose Crimping Machine User Manual (Introductions)Leanne GeermanPas encore d'évaluation

- ASS2005002801 D Roxtec RS Ex Seal Installation Instruction enDocument4 pagesASS2005002801 D Roxtec RS Ex Seal Installation Instruction enRicardo RbPas encore d'évaluation

- Washing Machine: Service ManualDocument57 pagesWashing Machine: Service ManualSantacruzmateo SantacruzmateoPas encore d'évaluation

- CraftyCNC Probe Manual Rev 4Document9 pagesCraftyCNC Probe Manual Rev 4lynnwardlePas encore d'évaluation

- Regulator General Specification: RGS10B001Document7 pagesRegulator General Specification: RGS10B001RaúlPas encore d'évaluation

- TRANZX INSTALL MANUAL 2x INTERNAL v0Document5 pagesTRANZX INSTALL MANUAL 2x INTERNAL v0dan nadPas encore d'évaluation

- Laser CuttingDocument39 pagesLaser CuttingAndré TrevizanPas encore d'évaluation

- Measure Make Trouble-Free Measure Interior Socket Welds Using Fillet Weld Size Misalignment The G.A.L. Method Two (2) WaysDocument1 pageMeasure Make Trouble-Free Measure Interior Socket Welds Using Fillet Weld Size Misalignment The G.A.L. Method Two (2) WaysMiguel Angel Zavala RiosPas encore d'évaluation

- Installation CAB300Document2 pagesInstallation CAB300Yuri OliveiraPas encore d'évaluation

- WT-H750, WT-H755 Service ManualDocument60 pagesWT-H750, WT-H755 Service ManualRoberto Augusto Aristizabal MorenoPas encore d'évaluation

- How To Read Welding GaugesDocument6 pagesHow To Read Welding GaugesSaira ShahPas encore d'évaluation

- Lavadora LG Wfs1338etd Wfs1358etdDocument59 pagesLavadora LG Wfs1338etd Wfs1358etdJohn SalsaPas encore d'évaluation

- How To V-Mod Your ExhaustDocument10 pagesHow To V-Mod Your ExhaustBren MERAKPas encore d'évaluation

- GAS IMU Reference BookletDocument29 pagesGAS IMU Reference BookletRelentless 0063Pas encore d'évaluation

- Pi Tape Calibration ProcedureDocument11 pagesPi Tape Calibration ProcedureAaron QuinnPas encore d'évaluation

- How To Read Welding Gauges PDFDocument5 pagesHow To Read Welding Gauges PDFjimbox88Pas encore d'évaluation

- RAI S ManualDocument2 pagesRAI S ManualNesil Abiera0% (1)

- (Susana) NAME AND PART OF TOOLS PDFDocument6 pages(Susana) NAME AND PART OF TOOLS PDFSusana KhrPas encore d'évaluation

- Cvaau G600Document8 pagesCvaau G600homebase750Pas encore d'évaluation

- AM 201 Fully Automatic Terminal Crimping MachineDocument16 pagesAM 201 Fully Automatic Terminal Crimping MachineademirffPas encore d'évaluation

- A New Approach To Shop-Floor Gear InspectionDocument4 pagesA New Approach To Shop-Floor Gear InspectionvijaykumarnPas encore d'évaluation

- Error Code Tyt 8fd-G-15Document549 pagesError Code Tyt 8fd-G-15aleksandar.stamenkovskiPas encore d'évaluation

- U-Joint SKF Cross ReferenceDocument162 pagesU-Joint SKF Cross ReferenceCHEE SENG LEEPas encore d'évaluation

- Large WM Live Tap InstructionsDocument2 pagesLarge WM Live Tap InstructionswaleeedPas encore d'évaluation

- Letlok Tube Fitting Catalog 2017Document94 pagesLetlok Tube Fitting Catalog 2017chipulinoPas encore d'évaluation

- Tools Install PDFDocument20 pagesTools Install PDFmfj79607555Pas encore d'évaluation

- CT-1525 ManualDocument2 pagesCT-1525 ManualTrần Long VũPas encore d'évaluation

- PART NO. 8200: Tune Up Kit For GM Hei V8 DistributorsDocument2 pagesPART NO. 8200: Tune Up Kit For GM Hei V8 DistributorschrispyPas encore d'évaluation

- 626 e 3 CCB 56164Document2 pages626 e 3 CCB 56164MohamedHussein MohamedHusseinPas encore d'évaluation

- FISHER Mscope M-96manualDocument18 pagesFISHER Mscope M-96manualDrew AlbanesePas encore d'évaluation

- Tle 4th QuarterDocument3 pagesTle 4th QuarteryushinzhiPas encore d'évaluation

- Maxxum 6 Bin and 10 Bin Vertical Collators: "When You Need More Than Staples."Document10 pagesMaxxum 6 Bin and 10 Bin Vertical Collators: "When You Need More Than Staples."LaurentEunicePas encore d'évaluation

- WT 16 WSBDocument55 pagesWT 16 WSBJuan ChávezPas encore d'évaluation

- DODGE® GRIP TIGHT Adapter Mount Ball BearingsDocument4 pagesDODGE® GRIP TIGHT Adapter Mount Ball BearingsDaNnIe09Pas encore d'évaluation

- TELECOMMANDE FILAIRE IOM 042021 DX Control KJR-120X 14LDocument646 pagesTELECOMMANDE FILAIRE IOM 042021 DX Control KJR-120X 14LEL KEHELPas encore d'évaluation

- Precaution and Sources of ErrorDocument3 pagesPrecaution and Sources of ErrorSuresh KumarPas encore d'évaluation

- RG6 Cable Mounting InstructionsDocument2 pagesRG6 Cable Mounting InstructionsStaffan FogelbergPas encore d'évaluation

- Ridgid Precision Flaring Tools ManualDocument1 pageRidgid Precision Flaring Tools ManualmaftmutoPas encore d'évaluation

- IsolatorDocument35 pagesIsolatoranmol maharanaPas encore d'évaluation

- 65R-C & 65R-TC Manual Pipe Threader Instructions: ThreadingDocument8 pages65R-C & 65R-TC Manual Pipe Threader Instructions: ThreadingJohnfromFresnoPas encore d'évaluation

- Pag.45-64 GE INSTRUCTIONS DRILLING MOTOR-GENERATOR TYPE GE752Document10 pagesPag.45-64 GE INSTRUCTIONS DRILLING MOTOR-GENERATOR TYPE GE752sertecs polPas encore d'évaluation

- Semi Atomatic Die HeadDocument4 pagesSemi Atomatic Die HeadCesar Carito ValenciaPas encore d'évaluation

- Apc BG AcDocument19 pagesApc BG AcIgnatius Albert Shan HandokoPas encore d'évaluation

- Installation Manual PTFE SNSDocument4 pagesInstallation Manual PTFE SNSDANDE VENKATA RAJESH100% (1)

- Connectors: For 75-Ohm HELIAX and Radiax Coaxial Cable of Nominal Diameter 7/8" (22 MM)Document2 pagesConnectors: For 75-Ohm HELIAX and Radiax Coaxial Cable of Nominal Diameter 7/8" (22 MM)ruizinho 1Pas encore d'évaluation

- Mag Torches PDFDocument1 pageMag Torches PDFLucioPas encore d'évaluation

- Mig Mag Torches - 19Document1 pageMig Mag Torches - 19LucioPas encore d'évaluation

- ID 250 Welding MachinesDocument1 pageID 250 Welding MachinesLucioPas encore d'évaluation

- 400A Mag TorchesDocument1 page400A Mag TorchesLucioPas encore d'évaluation

- Mig Mag Torches - 19 PDFDocument1 pageMig Mag Torches - 19 PDFLucioPas encore d'évaluation

- Welding Machines Monomig 200ikDocument1 pageWelding Machines Monomig 200ikLucioPas encore d'évaluation

- RS 350 MK Welding MachineDocument1 pageRS 350 MK Welding MachineLucioPas encore d'évaluation

- ID 350 Welding MachineDocument1 pageID 350 Welding MachineLucioPas encore d'évaluation

- ID 250 T DC PulseDocument1 pageID 250 T DC PulseLucioPas encore d'évaluation

- RS 200 MK Welding MachineDocument1 pageRS 200 MK Welding MachineLucioPas encore d'évaluation

- Mini Sub Gauge: Sliding Pointer For Different Pipe SchedulesDocument1 pageMini Sub Gauge: Sliding Pointer For Different Pipe SchedulesLucioPas encore d'évaluation

- RS 250 M Welding MachineDocument1 pageRS 250 M Welding MachineLucioPas encore d'évaluation

- Tig ConsumablesDocument1 pageTig ConsumablesLucioPas encore d'évaluation

- Welding Machine RD 500EDocument1 pageWelding Machine RD 500ELucioPas encore d'évaluation

- ID 250 Welding MachinesDocument1 pageID 250 Welding MachinesLucioPas encore d'évaluation

- Welding Machines Monomig 200ikDocument1 pageWelding Machines Monomig 200ikLucioPas encore d'évaluation

- Welding Generators MPMDocument1 pageWelding Generators MPMLucioPas encore d'évaluation

- 09 Welding Machine TD 355Document1 page09 Welding Machine TD 355LucioPas encore d'évaluation

- Welding Machines RD500EDocument1 pageWelding Machines RD500ELucioPas encore d'évaluation

- Special Gauge SectionDocument1 pageSpecial Gauge SectionLucioPas encore d'évaluation

- G.A.L. Weld Gauge / Calculator: Newl Y RedesignedDocument1 pageG.A.L. Weld Gauge / Calculator: Newl Y RedesignedLucioPas encore d'évaluation

- Welding Machine Monotig 160iDocument1 pageWelding Machine Monotig 160iLucioPas encore d'évaluation

- Automatic Weld Size GaugeDocument1 pageAutomatic Weld Size GaugeLucioPas encore d'évaluation

- W.T.P.S. Gauge WithDocument1 pageW.T.P.S. Gauge WithLucio100% (1)

- CC 62 - EPIA Capital Improvement PlanDocument26 pagesCC 62 - EPIA Capital Improvement PlanErika EsquivelPas encore d'évaluation

- DxdiagDocument26 pagesDxdiagvalkirion shadowPas encore d'évaluation

- Insight Link 1 - Dictation - PDFDocument16 pagesInsight Link 1 - Dictation - PDFHeejin LeePas encore d'évaluation

- Film Adaptation: Five AnalysesDocument7 pagesFilm Adaptation: Five Analysesprpr_rina6095Pas encore d'évaluation

- Lost StarsDocument3 pagesLost StarsRodrigo Massayuki SadakanePas encore d'évaluation

- 750G HDDDocument9 pages750G HDDMoses AbdulkassPas encore d'évaluation

- L3 31BTRS06Document41 pagesL3 31BTRS06Tirumalarao PechettyPas encore d'évaluation

- U27 Alice in Wonderland Episode 7Document5 pagesU27 Alice in Wonderland Episode 7jksalmPas encore d'évaluation

- You're My EverythingDocument7 pagesYou're My EverythingErik TelfordPas encore d'évaluation

- Caribbean Dance From Abakuá To Zouk How Movement Shapes Identity (Susanna Sloat) (Z-Library)Document440 pagesCaribbean Dance From Abakuá To Zouk How Movement Shapes Identity (Susanna Sloat) (Z-Library)Guilherme ResendePas encore d'évaluation

- Heroes & Villains of GreyhawkDocument6 pagesHeroes & Villains of GreyhawkScott W. Nelson100% (2)

- Ken Holt 02 The Riddle of The Stone ElephantDocument251 pagesKen Holt 02 The Riddle of The Stone ElephantPastPresentFuture100% (2)

- 1819187-Kobold TrapsDocument4 pages1819187-Kobold Trapsjustin.callPas encore d'évaluation

- House of The Rising Sun ChordsDocument2 pagesHouse of The Rising Sun ChordsTeacherPas encore d'évaluation

- SRG 2150 2250DN BrochureDocument2 pagesSRG 2150 2250DN BrochureRizqi FirmansyahPas encore d'évaluation

- PD2-PaperGang Dozer A4Document3 pagesPD2-PaperGang Dozer A4Bot 2Pas encore d'évaluation

- LG lhb625 Manual de UsuarioDocument73 pagesLG lhb625 Manual de UsuarioAlberto Jim Quijano TaleroPas encore d'évaluation

- Barc India AppDocument11 pagesBarc India AppAnto GeorgePas encore d'évaluation

- Pedestrian Safety in Road TrafficDocument9 pagesPedestrian Safety in Road TrafficMaxamed YusufPas encore d'évaluation

- Ceviche FloraDocument50 pagesCeviche FloraqflornayumiPas encore d'évaluation

- A Winters Eve - LyricsDocument13 pagesA Winters Eve - LyricsmaryleesunseriPas encore d'évaluation

- My Little Panda BearDocument8 pagesMy Little Panda Bearkarla faces100% (4)

- Seac Sub AssoDocument6 pagesSeac Sub Assobeard007Pas encore d'évaluation

- Listening and Speaking Intro Q: Skills For Success Unit 1 Student Book Answer KeyDocument2 pagesListening and Speaking Intro Q: Skills For Success Unit 1 Student Book Answer KeySamet Kaya71% (7)

- Talk About Tricks Last IssueDocument10 pagesTalk About Tricks Last IssueDylan TayPas encore d'évaluation

- Solo and Ensemble Musical LiteratureDocument3 pagesSolo and Ensemble Musical Literatureapi-535311838Pas encore d'évaluation

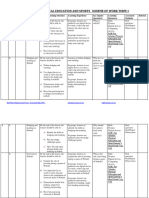

- 2024 Grade 7 Physical Education and Sports Schemes of Work Term 1 KLB Top SchoDocument10 pages2024 Grade 7 Physical Education and Sports Schemes of Work Term 1 KLB Top SchokevinsamuelnewversionPas encore d'évaluation

- Service Level Agreement (SLA) : Network ManagementDocument7 pagesService Level Agreement (SLA) : Network ManagementJAANUJAN RaviPas encore d'évaluation

- Peter Pan MonologuesDocument2 pagesPeter Pan MonologuesLenaPas encore d'évaluation

- Mariam ChincharauliDocument8 pagesMariam ChincharauliMa RiPas encore d'évaluation