Académique Documents

Professionnel Documents

Culture Documents

AN1422EN00

Transféré par

xerxeshaka0 évaluation0% ont trouvé ce document utile (0 vote)

52 vues2 pagesMilli-pore bubble point

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentMilli-pore bubble point

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

52 vues2 pagesAN1422EN00

Transféré par

xerxeshakaMilli-pore bubble point

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

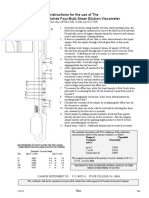

Bubble Point Test Method

Using Durapore 0.22 µm ®

Hydrophilic Membrane

with 60/40 IPA

The objective of these Materials Bubble Point Test Method

trials was to determine a • Durapore 0.22 µm modified PVDF 1. The membrane disc was thoroughly

hydrophilic membrane, 47 mm discs wetted with 70/30 IPA.

recommended Bubble Point

(Catalogue No. GVWP 047 00)

Ratio value for the Durapore 2. Thorough wetting was ensured

– Bubble point specification with by filtration of 5 mL of 70/30 IPA

0.22 µm hydrophilic membrane 70/30 Isopropyl Alcohol (IPA) = at ambient temperature.

wetted with 60% isopropyl 18.5 psi

3. The system was immediately

– Surface area = 13.8 cm2

N O T E

alcohol/40% water (v/v) connected to the Integritest II

• Integritest ® II automatic filter instrument and the bubble point

at ambient temperature. integrity test instrument program initiated.

(Catalogue No. XEIT 110 00); used

4. The bubble point measurement

to measure bubble point values.

was repeated after membrane

• Stainless steel holder (Catalogue

A P P L I C A T I O N

rewetting with an additional

No. XX44 047 00); used to hold the 5 mL of fresh 70/30 IPA.

47 mm membrane discs.

5. The membrane disc was dried

• Stainless steel 1.5 in. sanitary tee thoroughly for a minimum of

fitting; used between the Integritest II 2 hours.

instrument and the 47 mm holder to 6. The membrane disc was

provide expanded upstream volume. reinstalled in the holder.

• Millipore Milli-Q® Synthesis Water 7. The membrane wetting was

Purification System with A10™ TOC ensured by filtering 5 mL of the

Monitor; used to produce 18.2 60/40 IPA test product.

megohm-cm Type 1 water.

8. The system was immediately

• 60/40 IPA = 60% isopropyl connected to the Integritest II

alcohol/40% water (v/v). instrument and the bubble point

• 70/30 IPA = 70% isopropyl program initiated.

alcohol/30% water (v/v); alcohol 9. The bubble point measurement

standard for Durapore 0.22 µm was repeated after membrane

hydrophilic membrane. rewetting with 5 mL of fresh

• Compressed air. 60/40 IPA test product.

10. The bubble point measurement

was repeated until a stable result

was found (<1.0 psi variation

between 3 consecutive bubble

point readings).

11. Steps 1–10 were repeated

for disc samples 2 – 9.

Â

Results All of this depends, of course, • Trending bubble point results

The bubble point test results were on the uniformity of the non-standard for consistency.

obtained via a series of tests with 9 solution. Changes in formulation or • End-user determined process

different Durapore 47 mm membrane concentrations of the components, specific testing.

discs; 3 each for 3 different lab scale especially those with surface activity

compositions of 60/40 IPA test and effects on surface tension, can Remarks

product. The highest stable values of affect the Bubble Point Ratio.

It should be noted that 70/30 IPA

the tests performed on each membrane In PDA Technical Report No. 26,

reference bubble point standard

disc are considered to be the bubble “Sterilizing Filtration of Liquids,” it is

specifications for Millipore membranes

point. The results obtained with the suggested that a scale-down study

are based upon data developed from

70/30 IPA were in agreement with is only the first part of bubble point

extensive testing using 70/30 IPA

the specifications of the filter device validation; the second part is obtaining

under controlled testing conditions.

and confirm the integrity of the additional ongoing solution attribute

Bubble point and diffusion testing

different membranes tested. data. Millipore recommends that the

on specific test solutions are based

end-user verify the lab generated

upon limited testing and may not be

Conclusion minimum bubble point with on-site

statistically representative of all of the

verification or periodic process

Bubble Point Determination test products.

monitoring.

The data from the Durapore 47 mm Variability in customer prepared

There are several options for on-site

membrane discs are used to determine alcohol solutions, customer operating

verification including:

the Bubble Point Ratio (BPR) between conditions, and environmental

the 60/40 IPA and 70/30 IPA. The • Periodically monitoring the non- conditions may have some impact

Bubble Point Ratio can be used to standard solution Bubble Point Ratio on the bubble point values. For these

determine the bubble point value for by comparing pre-use bubble reasons, Millipore does not guarantee

Durapore hydrophilic membranes when points with post-use bubble points. that the results of these tests are

wetted with a non-standard solution. A Millipore protocol for on-site statistically relevant beyond the scope

The average of all the theoretical Bubble Point Ratio determination is of this report.

calculations of BPR are used to available; request Millipore For information on Durapore

determine the minimum BPR value: Application Note AN1505EN00. 0.1 µm hydrophilic membrane tested

• Periodically monitoring solution with alcohol solution, refer to Millipore

BPR = 60/40 IPA Bubble Point = 21.6 = 1.05 surface tension and comparing to Application Note AN1653EN00.

70/30 IPA Bubble Point 20.6

standard.

The minimum bubble point value of

the Durapore 0.22 µm hydrophilic

membrane disc wetted with 60/40 Bubble Point Data

IPA will be: Product 70/30 IPA 60/40 IPA BPR

PBPmin = 18.5 psi x 1.05 = 19.4 psi Disc No. Lot No. Bubble Point Bubble Point 60/40 IPA

1 1 20.6 21.6 1.05

The non-standard solution can be

used as a wetting agent to perform 2 1 20.5 21.6 1.05

the Bubble Point Integrity Test and the 3 1 20.6 21.6 1.05

recommended minimum bubble point 4 2 20.6 21.6 1.05

can be used as an initial specification

5 2 20.6 21.6 1.05

until the validation process is

completed, see discussion below. 6 2 20.6 21.6 1.05

7 3 20.6 21.6 1.05

Discussion

8 3 20.6 21.6 1.05

All Durapore 0.22 µm hydrophilic

9 3 20.6 21.6 1.05

membrane configurations (e.g. MPGL,

MCGL, LAGL, KVGL and CVGL) Overall Avg. 20.6 21.6 1.05

have the same Bubble Point Ratio Overall S.D. 0.0 0.0 0.00

(membrane consistency), when they Overall C.V. 0.0 0.0 0.00

are wetted with the same test solution.

Millipore, Durapore, Integritest, and Milli-Q are registered trademarks of Millipore Corporation.

A10 is a trademark of Millipore Corporation.

Lit. No. AN1422EN00 Rev.– 11/03 03-215

© 2003 Millipore Corporation, Billerica, MA 01821 U.S.A. All rights reserved.

Vous aimerez peut-être aussi

- Methods For Sampling & Analysis: Nitrogen Dioxide (NO) PrincipleDocument16 pagesMethods For Sampling & Analysis: Nitrogen Dioxide (NO) PrincipleMuhd ArifPas encore d'évaluation

- Monitoring Toxic Gases in the Atmosphere for Hygiene and Pollution Control: Pergamon International Library of Science, Technology, Engineering and Social StudiesD'EverandMonitoring Toxic Gases in the Atmosphere for Hygiene and Pollution Control: Pergamon International Library of Science, Technology, Engineering and Social StudiesÉvaluation : 3.5 sur 5 étoiles3.5/5 (17)

- Method SsDocument16 pagesMethod SsMuhd ArifPas encore d'évaluation

- Millipore Filter Integrity Test MethodsDocument12 pagesMillipore Filter Integrity Test Methodsmcarjona1100% (2)

- 7625-300 Vitamin B12 AccuBind ELISA Rev 6Document2 pages7625-300 Vitamin B12 AccuBind ELISA Rev 6carlosalfredorivasPas encore d'évaluation

- Labchip® GX Touch/Gxii: Genomic Dna Assay Quick GuideDocument2 pagesLabchip® GX Touch/Gxii: Genomic Dna Assay Quick Guideyujuncheng12Pas encore d'évaluation

- IPC-TM-650 Test Methods Manual: Association Connecting Electronics IndustriesDocument4 pagesIPC-TM-650 Test Methods Manual: Association Connecting Electronics IndustriesAngus CHUPas encore d'évaluation

- Continuous Separation of Fermentation Broth Using A CEPA LE Laboratory Centrifuge SystemDocument2 pagesContinuous Separation of Fermentation Broth Using A CEPA LE Laboratory Centrifuge SystemjdPas encore d'évaluation

- Development and Validation of High Performance Thin Layer Chromatographic Method For Determination of Rebamipide From Its Tablet Dosage FormDocument5 pagesDevelopment and Validation of High Performance Thin Layer Chromatographic Method For Determination of Rebamipide From Its Tablet Dosage FormPinak PatelPas encore d'évaluation

- IPC-TM-650 Test Methods Manual: 3000 Lakeside Drive, Suite 309S Bannockburn, IL 60015-1249Document3 pagesIPC-TM-650 Test Methods Manual: 3000 Lakeside Drive, Suite 309S Bannockburn, IL 60015-1249LoisirsPas encore d'évaluation

- TP-430-I Brookfield Viscosity Carbopol-PHDocument5 pagesTP-430-I Brookfield Viscosity Carbopol-PHqmlaboratorioPas encore d'évaluation

- CLAROX-Membranes 04 2018 E PDFDocument3 pagesCLAROX-Membranes 04 2018 E PDFjpsingh75Pas encore d'évaluation

- Productbrochure Spark INTEGRITYDocument5 pagesProductbrochure Spark INTEGRITYKhunnalak KhitmohPas encore d'évaluation

- Suspended Solids Removal Mechanism Comparisonin Tube SettlerDocument5 pagesSuspended Solids Removal Mechanism Comparisonin Tube SettlerjcbobedaPas encore d'évaluation

- EPA HQ OW 2014 0408 0021 - ContentDocument8 pagesEPA HQ OW 2014 0408 0021 - ContentAugustine Gabriel YapPas encore d'évaluation

- Lab Manual For Drilling FluidDocument13 pagesLab Manual For Drilling FluidLemony Snickit100% (1)

- Specification For Microbiology Lab EquipmentsDocument65 pagesSpecification For Microbiology Lab Equipmentsgreen solutionPas encore d'évaluation

- C1. Brochure Biossays 240 Plus 180827Document2 pagesC1. Brochure Biossays 240 Plus 180827Francisca ValenzuelaPas encore d'évaluation

- 2-Amino-Acid-Analyzer BrochureDocument16 pages2-Amino-Acid-Analyzer BrochureGlobal TominentPas encore d'évaluation

- Qubit - 4 - Assays - Anexo 2Document2 pagesQubit - 4 - Assays - Anexo 2pdf2006Pas encore d'évaluation

- CC2 LabDocument18 pagesCC2 LabMACOB, ETHELHYN JHANEPas encore d'évaluation

- CE6611 Environmental Engineering Lab ManualDocument44 pagesCE6611 Environmental Engineering Lab ManualArun Pugal100% (3)

- eDocument1 pageeMuhammad ZinedinePas encore d'évaluation

- En Apam1Document1 pageEn Apam1Nghi NguyenPas encore d'évaluation

- Good Akta PracticesDocument14 pagesGood Akta PracticesKatie MickoPas encore d'évaluation

- BIONEWS1Document2 pagesBIONEWS1Nisreen MohamedPas encore d'évaluation

- Materials and MethodsDocument3 pagesMaterials and Methodsakib patelPas encore d'évaluation

- Aquinity P35/70: Product InformationDocument12 pagesAquinity P35/70: Product InformationAfzalur AlfanPas encore d'évaluation

- 4925-300 E2 AccuBind ELISA Rev 4Document2 pages4925-300 E2 AccuBind ELISA Rev 4Roxana RoxPas encore d'évaluation

- Cortisol AccuBind ELISA Rev 4Document2 pagesCortisol AccuBind ELISA Rev 4bukharaendobukhPas encore d'évaluation

- Elisa Instrument DR Mirja LiliDocument21 pagesElisa Instrument DR Mirja Lilidrunken monkeyPas encore d'évaluation

- Ais-1 Spec Muestrador Aire MicrobianoDocument1 pageAis-1 Spec Muestrador Aire MicrobianojmatallanaPas encore d'évaluation

- E 715 Â " 80 R96 - RTCXNS04MFI5NKUXDocument2 pagesE 715 Â " 80 R96 - RTCXNS04MFI5NKUXhans ccPas encore d'évaluation

- 04 - SupaSpun IIDocument2 pages04 - SupaSpun IIlilianaPas encore d'évaluation

- EZ-Pak Dispenser Curve Data Sheet MSIG Web High ResDocument8 pagesEZ-Pak Dispenser Curve Data Sheet MSIG Web High RescatabacteymicrobioloPas encore d'évaluation

- Carbofil Test KitDocument2 pagesCarbofil Test KitChristian EscobarPas encore d'évaluation

- Ethanol Extraction Membrane During Supported Liquid Ferment at IonDocument8 pagesEthanol Extraction Membrane During Supported Liquid Ferment at Ionapi-26678889Pas encore d'évaluation

- Bionet Engineering - m1 - Benchtop - Tangential-Flow-Filtration - SystemDocument2 pagesBionet Engineering - m1 - Benchtop - Tangential-Flow-Filtration - SystemElena Rojo de BenitoPas encore d'évaluation

- Rancangan Obat InjeksiDocument5 pagesRancangan Obat InjeksiYona Vista VianaPas encore d'évaluation

- Rancangan Obat InjeksiDocument5 pagesRancangan Obat InjeksiPERMATASARI BKUPas encore d'évaluation

- PH Iso & AatccDocument8 pagesPH Iso & AatccrasheudlPas encore d'évaluation

- Sphera Duo Data SheetDocument2 pagesSphera Duo Data SheetHohoPas encore d'évaluation

- BS 400 MindrayDocument1 pageBS 400 MindraytantoPas encore d'évaluation

- Cortisol ElisaDocument2 pagesCortisol ElisaCha GuingabPas encore d'évaluation

- Biossays 240 Series: Automatic Biochemistry AnalyzerDocument3 pagesBiossays 240 Series: Automatic Biochemistry AnalyzerKarim Karimou100% (1)

- M1062E01-Biossays 240 Series-181207-1Document2 pagesM1062E01-Biossays 240 Series-181207-1Luana ZuffoPas encore d'évaluation

- MiniCapt Mobile Microbial Air SamplerDocument2 pagesMiniCapt Mobile Microbial Air SamplerĐặng HoàngPas encore d'évaluation

- Instructiuni de Lucru Cu UbbelohdeDocument1 pageInstructiuni de Lucru Cu UbbelohdeCorina StanculescuPas encore d'évaluation

- Denison Filterability TP-02100 PDFDocument2 pagesDenison Filterability TP-02100 PDFRIZKY FIQRIPas encore d'évaluation

- AATCC - 15 - 2002 - CF To PerspirationDocument3 pagesAATCC - 15 - 2002 - CF To PerspirationNguyễn Công ThoạiPas encore d'évaluation

- Qualisa Dengue NS1 IFUDocument4 pagesQualisa Dengue NS1 IFUshanmicroPas encore d'évaluation

- Phosphorus, Reactive, PhosVer 3 Method 8048, 02-2009, 9th EdDocument7 pagesPhosphorus, Reactive, PhosVer 3 Method 8048, 02-2009, 9th EdSun lrPas encore d'évaluation

- Hygropin ProceqDocument4 pagesHygropin Proceqmohammad loai sabbaghPas encore d'évaluation

- Optimized PAH Analysis Using The Agilent Self Cleaning Ion SourceDocument8 pagesOptimized PAH Analysis Using The Agilent Self Cleaning Ion Sourcemagdalena.marques3141Pas encore d'évaluation

- H8 Operation Flow ChartDocument1 pageH8 Operation Flow Chartgerente soportecPas encore d'évaluation

- Edexcel International A Levels Biology Unit 3 Wbi13Document7 pagesEdexcel International A Levels Biology Unit 3 Wbi13Bara' Hammadeh100% (1)

- Laboratory Instruments & ProtocolsDocument32 pagesLaboratory Instruments & ProtocolsLingesswari NagarajanPas encore d'évaluation

- Activity #3Document9 pagesActivity #3PrincessPas encore d'évaluation

- Experiment 1 Introduction To Biology LaboratoryDocument11 pagesExperiment 1 Introduction To Biology LaboratorySuria Seri SulyanaPas encore d'évaluation

- Sterilizing-grade Durapore® 0.22 μm Hydrophobic FiltersDocument8 pagesSterilizing-grade Durapore® 0.22 μm Hydrophobic FiltersxerxeshakaPas encore d'évaluation

- Capsules PDFDocument30 pagesCapsules PDFxerxeshakaPas encore d'évaluation

- 2695 SpecificationDocument3 pages2695 SpecificationxerxeshakaPas encore d'évaluation

- Determination of Hydrochloric and Nitric Acid in Etching Baths by Thermometric Titration PDFDocument3 pagesDetermination of Hydrochloric and Nitric Acid in Etching Baths by Thermometric Titration PDFxerxeshakaPas encore d'évaluation

- The 58th Annual Meeting International Society of ElectrochemistryDocument102 pagesThe 58th Annual Meeting International Society of ElectrochemistryxerxeshakaPas encore d'évaluation

- Durapore Hydrophilic Filter Cartridges User Guide L PDFDocument52 pagesDurapore Hydrophilic Filter Cartridges User Guide L PDFxerxeshakaPas encore d'évaluation

- Surface Engineering Industry GermanyDocument27 pagesSurface Engineering Industry GermanyxerxeshakaPas encore d'évaluation

- Determination of Hydrochloric and Nitric Acid in Etching Baths by Thermometric TitrationDocument3 pagesDetermination of Hydrochloric and Nitric Acid in Etching Baths by Thermometric TitrationxerxeshakaPas encore d'évaluation

- F838 15a Standard Test Method ForDocument6 pagesF838 15a Standard Test Method Forxerxeshaka100% (2)

- Understanding BARCDocument24 pagesUnderstanding BARCxerxeshakaPas encore d'évaluation

- 5205Document1 page5205xerxeshakaPas encore d'évaluation

- 1992-New Kinetic Model For Resist DissolutionDocument3 pages1992-New Kinetic Model For Resist DissolutionxerxeshakaPas encore d'évaluation

- Corrosion - Aqueous GRCGRSDocument18 pagesCorrosion - Aqueous GRCGRSxerxeshakaPas encore d'évaluation

- E Prep 280 NCZDocument4 pagesE Prep 280 NCZxerxeshakaPas encore d'évaluation

- Filter Systems: Out-Tank Models In-Tank ModelsDocument1 pageFilter Systems: Out-Tank Models In-Tank ModelsxerxeshakaPas encore d'évaluation

- E Brite 50 Cu SdsDocument8 pagesE Brite 50 Cu SdsxerxeshakaPas encore d'évaluation

- HPLC Metal ComplexDocument15 pagesHPLC Metal Complexxerxeshaka100% (1)

- CHEM A 14B COMP Qual - Anions PDFDocument6 pagesCHEM A 14B COMP Qual - Anions PDFxerxeshakaPas encore d'évaluation

- Nanocrystalline PBS Thin Films: Synthesis, Microstructural and PDFDocument6 pagesNanocrystalline PBS Thin Films: Synthesis, Microstructural and PDFxerxeshakaPas encore d'évaluation

- Tin Electrolytes - Schloetter - deDocument2 pagesTin Electrolytes - Schloetter - dexerxeshakaPas encore d'évaluation

- Chemical Reaction The Us Response ToREACHDocument4 pagesChemical Reaction The Us Response ToREACHxerxeshakaPas encore d'évaluation

- Colsid ApDocument6 pagesColsid ApxerxeshakaPas encore d'évaluation

- The Root Cause of Black PadDocument5 pagesThe Root Cause of Black PadxerxeshakaPas encore d'évaluation

- Colloid Chemistry and Phase Rule 4022146-1: (Essentials of Physical Chemistry - Arun Bahl & B.S. Bahl) Chapter 19 and 22Document51 pagesColloid Chemistry and Phase Rule 4022146-1: (Essentials of Physical Chemistry - Arun Bahl & B.S. Bahl) Chapter 19 and 22Razan khalidPas encore d'évaluation

- Gas Cylider Technical Regulation PDFDocument37 pagesGas Cylider Technical Regulation PDFVinod Varadan SPas encore d'évaluation

- Multiple Choice LachingDocument3 pagesMultiple Choice Lachingraghu_iict100% (1)

- Chapter-6 Tissues-Full NotesDocument12 pagesChapter-6 Tissues-Full NotesAdithya VinodPas encore d'évaluation

- Aerospace Material Specification: (R) Gas Nitriding of Low-Alloy Steel PartsDocument10 pagesAerospace Material Specification: (R) Gas Nitriding of Low-Alloy Steel PartsVIJAY YADAVPas encore d'évaluation

- Purestab Md1024: Technical Data SheetDocument2 pagesPurestab Md1024: Technical Data SheetHadyan AdliPas encore d'évaluation

- 6.1 Chemical Reactions and EquationsDocument23 pages6.1 Chemical Reactions and EquationsShadow MartinPas encore d'évaluation

- Mec 9000Document40 pagesMec 9000Dark Cenobite100% (1)

- JPSP0123 Source FileDocument23 pagesJPSP0123 Source FileYusuf AndrianaPas encore d'évaluation

- 118 Worm Gear LubesDocument4 pages118 Worm Gear LubesWajahat RasoolPas encore d'évaluation

- Ver 3.0 - Test Series - NEET - Schedule (XII & RM) - Code-A - BDocument3 pagesVer 3.0 - Test Series - NEET - Schedule (XII & RM) - Code-A - BCorona virusPas encore d'évaluation

- Epn008msds N1250 - en - SDSDocument9 pagesEpn008msds N1250 - en - SDSSANI RIZKIPas encore d'évaluation

- Surface Water Treatment Operator Certification Manual - Tratamiento de Aguas ResidualesDocument311 pagesSurface Water Treatment Operator Certification Manual - Tratamiento de Aguas ResidualesJhon Jairo Mazuera GuzmanPas encore d'évaluation

- Hydrogen Fracturing Process Section 6Document8 pagesHydrogen Fracturing Process Section 6BillPas encore d'évaluation

- ULO TempDocument7 pagesULO TempcnacevedoPas encore d'évaluation

- Alemu BelayDocument132 pagesAlemu BelayZolaPas encore d'évaluation

- Test Farma En-Ro, Ro-EnDocument3 pagesTest Farma En-Ro, Ro-EnIuliaUngurPas encore d'évaluation

- Transformer Oil: Bangladesh Power Management Institute (BPMI) 2019Document34 pagesTransformer Oil: Bangladesh Power Management Institute (BPMI) 2019Farhan AhmedPas encore d'évaluation

- NW6Document10 pagesNW6Mamidala HarithaPas encore d'évaluation

- Advantages and Disadvantages of A CSTRDocument3 pagesAdvantages and Disadvantages of A CSTRszulkipeli50% (8)

- 4.3 Well Stimulation PDFDocument60 pages4.3 Well Stimulation PDFJohn CooperPas encore d'évaluation

- Pollutants and Its MeasurementDocument70 pagesPollutants and Its MeasurementECRDPas encore d'évaluation

- Types of Dosage Forms Lecture2,2Document34 pagesTypes of Dosage Forms Lecture2,2Bhuvana TejaPas encore d'évaluation

- Research Article Removal of 3-MCPD Esters and Related Substances After Refining by Adsorbent MaterialDocument6 pagesResearch Article Removal of 3-MCPD Esters and Related Substances After Refining by Adsorbent MaterialAlexPas encore d'évaluation

- Dhulian FinalDocument50 pagesDhulian FinalShams Sardar100% (1)

- EagleBurgmann DMS SSE E5 Brochure Seal Supply Systems en 22.06.2017Document84 pagesEagleBurgmann DMS SSE E5 Brochure Seal Supply Systems en 22.06.2017Billal Al-ankarPas encore d'évaluation

- Orgo Naming RulesDocument7 pagesOrgo Naming Ruleskirtmartinreyes14Pas encore d'évaluation

- Mahogany Tree Fruit Husk CharcoalDocument38 pagesMahogany Tree Fruit Husk CharcoalScholar AccountPas encore d'évaluation

- IMO55 2021 T2 Problems EngDocument15 pagesIMO55 2021 T2 Problems EngTrần Phạm Gia BảoPas encore d'évaluation

- Valorizacion Del Desecho de Aguas Residuales Del Prosamiento de AceitunasDocument11 pagesValorizacion Del Desecho de Aguas Residuales Del Prosamiento de AceitunasJalcamPas encore d'évaluation

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincD'EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincÉvaluation : 3.5 sur 5 étoiles3.5/5 (137)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseD'EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseÉvaluation : 3.5 sur 5 étoiles3.5/5 (69)

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldD'EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldÉvaluation : 4 sur 5 étoiles4/5 (596)

- Fire Season: Field Notes from a Wilderness LookoutD'EverandFire Season: Field Notes from a Wilderness LookoutÉvaluation : 4 sur 5 étoiles4/5 (142)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessD'EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessPas encore d'évaluation

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingD'EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingÉvaluation : 5 sur 5 étoiles5/5 (5)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsD'EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsÉvaluation : 3.5 sur 5 étoiles3.5/5 (13)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingD'EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (35)

- The Best American Science And Nature Writing 2021D'EverandThe Best American Science And Nature Writing 2021Évaluation : 4 sur 5 étoiles4/5 (8)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionD'EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionÉvaluation : 4 sur 5 étoiles4/5 (812)

- Come Back, Como: Winning the Heart of a Reluctant DogD'EverandCome Back, Como: Winning the Heart of a Reluctant DogÉvaluation : 3.5 sur 5 étoiles3.5/5 (10)

- Spoiled Rotten America: Outrages of Everyday LifeD'EverandSpoiled Rotten America: Outrages of Everyday LifeÉvaluation : 3 sur 5 étoiles3/5 (19)

- When the Sahara Was Green: How Our Greatest Desert Came to BeD'EverandWhen the Sahara Was Green: How Our Greatest Desert Came to BeÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorD'EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorÉvaluation : 4.5 sur 5 étoiles4.5/5 (137)

- The Other End of the Leash: Why We Do What We Do Around DogsD'EverandThe Other End of the Leash: Why We Do What We Do Around DogsÉvaluation : 5 sur 5 étoiles5/5 (65)

- The Mind of Plants: Narratives of Vegetal IntelligenceD'EverandThe Mind of Plants: Narratives of Vegetal IntelligenceÉvaluation : 4.5 sur 5 étoiles4.5/5 (11)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildD'EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildÉvaluation : 4.5 sur 5 étoiles4.5/5 (44)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldD'EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (18)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsD'EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsÉvaluation : 4 sur 5 étoiles4/5 (223)