Académique Documents

Professionnel Documents

Culture Documents

MTEBS04

Transféré par

d_abdosDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MTEBS04

Transféré par

d_abdosDroits d'auteur :

Formats disponibles

TECHNICAL AND INSTALLATION MANUAL

Cod. MTEBS04

APPARECCHI RADIOLOGICI ELETTROMEDICALI

VIA DEL PARLAMENTO EUROPEO 9D - 50010 SCANDICCI (FI) - TEL. ++39-0557228511 - FAX ++39-0557228512

www.italray.it info@italray.it

BS 45 MTEBS04

MANUAL DATA

REVISIONE RELEASE MTEBS03 - VALIDITY FROM S/N 14-288-04

PREPARATO PREPARED RICCARDO SARTI

VERIFICATO CHECKED RICCARDO SARTI

APPROVATO APPROVED STEFANO BALDINI

DATA DI EMISSIONE DATE OF EMISSION 14/09/2004

REVISION RECORD

MTEBS01

24/04/2003 MTEBS02 - New Italray’s telephone number

13/10/2003 MTEBS03 - General device revision.

14/09/04 MTEBS04 - New braking system

THIS DOCUMENT ACCOMPANIES THE FOLLOWING PRODUCT

Part Number:

S/N.

ENCLOSED DOCUMENTATION

CODE / PART NUMBER REVISION

Cassette Tray

Potter Bucky manual

TECHNICAL AND INSTALLATION MANUAL Pag. 1 di 15

BS 45 MTEBS04

WARNING!

Read carefully this manual before performing the setting up and calibration of the

equipment.

Although this equipment is designed and manufactured in compliance with the latest

safety regulations, the X-Ray source is still a danger whenever the operator is not qualified

or not informed. Excessive exposure to X-Rays causes damages to the organism.

Therefore, all precautions must be taken to prevent unauthorised or unqualified personnel

from using this equipment, which would be dangerous for themselves and for other

persons.

Before they carry out any operation, the personnel qualified and authorised to use this

equipment must be informed of the protection measure issued by the International

Committee on Radiological Protection and of the related national rules.

The ray passage must be controlled from a radiation shielded area.

When stopping near the equipment, during an exposure, wear anti-X Ray protective

garments.

The diagnosis system must be provided with audio and visual means for the

communications between the operator, who works in the shielded area, and the patient.

The Company disclaims all responsibility in case of interventions of unauthorised

personnel.

The equipment must not be used for purposes other than those provided for.

The Company disclaims all responsibility if the authorised personnel do not comply with

the requirements set forth in this manual.

Should any anomaly or failure occur which cannot be solved with the instructions given in

this manual, the authorised personnel must consult the manufacturer to get the relevant

necessary instructions.

ITALRAY s.r.l.

Via del Parlamento Europeo 9/D – 50010 - Scandicci – Firenze - ITALY

Telefono +39 055 7228511 Fax +39 055 7228512

Email info@italray.it

Web www.italray.it

TECHNICAL AND INSTALLATION MANUAL Pag. 2 di 15

BS 45 MTEBS04

Index

1 INTRODUCTION .............................................................................................................................................3

2 DESCRIPTION ................................................................................................................................................3

3 TECHNICAL DATA .........................................................................................................................................3

4 PACKAGING AND TRANSPORT ...................................................................................................................5

5 DEVICE DIMENSION ......................................................................................................................................6

6 INSTALLATION...............................................................................................................................................7

6.1 CASSETTE TRAY INSERTION SIDE.......................................................................................................9

7 ELECTRIC CONNECTIONS .........................................................................................................................10

7.1 IONISATION CHAMBER CONNECTION ...............................................................................................11

8 DEVICE MAINTENANCE .............................................................................................................................13

8.1 PERIODICAL MAINTENANCE (every 12 month ) .................................................................................13

8.2 ROPE REPLACEMENT .........................................................................................................................13

8 SPARE PART LIST .......................................................................................................................................15

1 INTRODUCTION

This manual is meant to provide the technical staff of the Manufacturer, or authorised

technical personnel, with the instructions for a proper installation and maintenance of the

equipment. The device must not be used for different purposes from those expectations.

The customer is responsible for how much pertains to legal fulfilment, of the installation

and the operation of this apparatus. If the apparatus is not done installed from technical

specialised entrusted by the factory (Italray), or a suitable maintenance is not operated,

the manufacturer cannot be considered responsible of possible break-ups or lesions.

The original of this manual is in ITALIAN language.

2 DESCRIPTION

BS 45 is a vertical column bucky stand complete with potter bucky and mobile grid with a

wide vertical excursion. Designed for radiographic examinations especially in vertical

position and for stretched patients.

3 TECHNICAL DATA

The equipment complies with the following rules:

EEC 89/336 directive and further modifications

EEC 93/42 directive (Class I)

and in particular with the following technical rules:

CEI EN 60601-1 (Class I Type B) CEI EN 60601-1-2

CEI EN 60601-1-3 CEI EN 60601-2-32

TECHNICAL AND INSTALLATION MANUAL Pag. 3 di 15

BS 45 MTEBS04

OPTIMAL CONDITIONS FOR TRANSPORT AND STORAGE

Temperature: -10 + 70°

Humidity: 20 - 80%

OPTIMAL ENVIRONMENTAL CONDITIONS

temperature: +10 ÷ 40° C

Humidity: 30 - 75%

ELECTRICAL FEATURES

Supply: 24V DC

POTTER BUCKY

- Motorised grid movement.

- Standar Grid specification ratio 1:10 D.F.F. 150. L/inc 103 (other grid on request)

- Manual, autocentering cassette-tray.

- Get ready for Ionisation chamber.

IDENTIFICATION

The identification label is on the back side, at the column base (fig.1). It shows Code of

the unit, Serial Number (with number and year of manufacture) and Voltage and Current.

ITALRAY s.r.l. Via del Parlamento Europeo 9/D 50010 SCANDICCI (FI) - ITALY Fig. n°1

Tel +39 0557228511 fax + 39 055 7228512 info@italray.it

For Servicing and Spare Parts Request always refer to the serial number of this label.

OPTIONAL ON REQUEST

- Ionisation chamber for automatic exposure.

- No standard grid, customer specification.

- Potentiometer kit, for automatic centring of the Bucky with x-ray source.

- Patient arm support.

- Special plate support for weight distribution

TECHNICAL AND INSTALLATION MANUAL Pag. 4 di 15

BS 45 MTEBS04

MATERIAL AND PACKAGING ELIMINATION

- Packing:

Wood and Ball in Ball Film: 100% recyclable

- Direct Materials:

Carbon Iron: 100% recyclable.

Elastomers and plastic materials: 100% recyclable.

Electric wire and other electrical material

Toxic and noxious substances are not used.

The waste disposal will have to happen in conformity to the local laws.

4 PACKAGING AND TRANSPORT

The BS45 is packed in a wood case with dimensions of 220x85x60 cm, total weight 250

Kg, (with singularly packing)

The box can be moved by crane or transpallet (fig. 2)

UNPACKING

• Open the box in this sequence 1→ 2→ 3→ 4 → 5

• Remove the fixed support.

• Remove from the box the device.

• Remove the “Ball in Ball Film”.

TECHNICAL AND INSTALLATION MANUAL Pag. 5 di 15

BS 45 MTEBS04

FIG. 2

P = 200 kg 1

A

4

2

I

5 3

B

5 DEVICE DIMENSION

Fig. 3

weight: 200 kg

TECHNICAL AND INSTALLATION MANUAL Pag. 6 di 15

BS 45 MTEBS04

6 INSTALLATION

1) Put the BS 45 in vertical position.

2) Remove all cover carters: the upper cover, the lateral covers pos. c fig. 4 and the

back cover pos. f. For the wood packing; all cover are removed for transport in

Italray.

3) Find out the rope in to the center of the two pulley

4) Remove the red screw and the lock (see the following photo) situated on the right

side of the column, use the no red marked screw to fix the guide, after, remove the

pivot of counterweight (see fig.2 Pos. d)

Remove the red

screw and the lock,

after use the no red

marker screw to

block the guide

1

2

FIG. 4

5) Remove the back side cover (fig.10 - pos. 6), introduce the enclose weight to balance

the potter bucky panel, block the weight with the special cover (fig.5), reassemble the

back side cover.

TECHNICAL AND INSTALLATION MANUAL Pag. 7 di 15

BS 45 MTEBS04

Block weight

cover

counterweight to put in

for balance, for transport

all weight are removed, to

avoid possible damage.

Fig 5

6) Place the device to find the right alignment with the x-ray source, pay attention in

maintaining a perpendicular position of the device.

7) Mark the position of the fixing holes on the floor, drill the floor and introduce the

expansion metal wedges (at least 4 with 10 mm screw) never use plastic wedges.

8) Fix the BS 45 to the floor, use 2 screws for the frontal side and 2 or more for the back

side.

9) Connect the BS 45 with the x-ray generator, following the instruction on the

paragraph 7: electric connection.

10) Connect the ground protection conductor of the room to the ground marked screw of

BS45 base (fig.6)

ground knot

Fig. 6

Fig. 6 B

11) Reassemble all device covers, for the left column cover pay attention, the right

procedure is to push down the bucky panel (Fig. 6 B) and introduce the cover from

the tall one to the lower part.

TECHNICAL AND INSTALLATION MANUAL Pag. 8 di 15

BS 45 MTEBS04

12) Make a radiographic check for x-ray alignment, make sure to obtain the same grey

level on the right and on the left of the film

13) On request the device can be provided with a special plate for not linear floor.

6.1 CASSETTE TRAY INSERTION SIDE

BS 45 can be provided with cassette tray insertion from the left or from the right side, this

predisposition is done in Italray on customer indication, it is possible to change insertion

side following those instructions:

1) Remove the manual cassette tray , pressing the metal tongue on the final part of

cassette tray.

2) Remove the potter bucky plastic cover (fig. 7)

3) Cut along the incision pos. d fig. 7 with sharp utensil.

4) Change the stop position of cassette tray on the potter (for more details see the bucky

technical manual enclosed).

5) Remove the handle pos. c fig. 7 and reassemble it on the other side

6) Reassemble the potter bucky plastic cover.

2 Fig. 7

1

7) Perform a general mechanic, electrical and radiographic check.

TECHNICAL AND INSTALLATION MANUAL Pag. 9 di 15

BS 45 MTEBS04

7 ELECTRIC CONNECTIONS

The BS 45 vertical bucky power supply MUST BE 24 V ac

BS45 has a x-ray generator connection

clamp (MS1) in the middle of the right side

MS1 of column.

This connection are replicated on MS2 on

the left of the sliding part. Inside the bucky

panel cover is placed TB1 clamp, in the

lower part of potter bucky.

The vertical movement brake is in the upper

part of column, it is always on. By the

pressure of handle button the

MS2 electromagnetic unblock the pulley and

allow the vertical movement

Fig.8

Fig 9

Fig 10

MS3 is the connection clamp of electromagnetic, thanks to this solution the device remain

braked without power supply too.

DON’T MOVE THE BUCKY WITHOUT PUSH THE UNBLOCK BUTTON TO DAMEGE

THE BRAKING SYSTEM.

TECHNICAL AND INSTALLATION MANUAL Pag. 10 di 15

BS 45 MTEBS04

The x-ray generator must be connected to MS1 with this indications:

MS1

1 X-ray contact

2 X-ray contact

3 Grid start

4 Grid start

5 0 Vdc

6 + 24 Vdc

7 Gnd

7.1 IONISATION CHAMBER CONNECTION

It is possible on after market connection of an ionisation chamber:

1) Remove the potter bucky plastic cover (see fig. 7) and the right column cover (fig. 4).

2) Perform the mechanical installation of an ultra thin ionisation chamber (for more details

see the bucky technical manual enclosed) between the scatter grid and the cassette

tray. After the introduction check the free movement of the grid and cassette, the

chamber must not to touch the grid during the exposure or the cassette during the film

charging.

3) The ionisation chamber cable must come out from bucky near to the TB1 clamp.

4) The cable from the generator must go together the power supply cable up to MS1 (see

fig. 9) inside the “plastic stocking” up to MS2, then has to follow the existing cable up to

the potter bucky. Block the cable with the fixing clamp.

5) Connect the two cables (from ionisation chamber and from generator) and check the

correct working of the chamber.

6) Reassemble all removed covers.

Note:

The lenght of the cable from the entrance in the BS 45 nearly the floor and the ionizatio

chamber is around 2 meters.

TECHNICAL AND INSTALLATION MANUAL Pag. 11 di 15

BS 45 MTEBS04

7.2 Potentiometer kit, for Bucky automatic centring

By customer request, BS45 can be equipped with a special kit for the automatic following

of the X-Ray source during the vertical movement of the potter bucky.

The potentiometer is an 10 K ohm 10 round (PR2, fig 11), it is connect to the opposite

pulley of the braking system.

This optional function is available only with

PR2 ceiling tube stand and vertical tube stand with

safety and precise motorised movement like

our STATIX and Ceilstand Syncro.

Fig. 11

CALIBRATION:

with ceiling or floor tube stand not Italray production see the respective technical manual

for right potentiometer and calibration.

Common activity:

1) remove the potentiometer PR2 from the gear (fi.11)

2) turn on the automatic centring on the tube stand, turn the x-ray tube in teleradiographic

position, turn on the collimator light and adjust the potentiometer until reach the

centering.

3) Repositioning the potentiometer on the gear.

4) Cover again the device, attention to connect all ground contact.

5) Check the following function

6) Test of all function, clean, mechanical, electrical and radiographic test.

TECHNICAL AND INSTALLATION MANUAL Pag. 12 di 15

BS 45 MTEBS04

8 DEVICE MAINTENANCE

8.1 PERIODICAL MAINTENANCE (every 12 month )

1) Check usury of the two metal ropes, if only one metal wire of the ropes is damaged

change the rope (for instruction see the following paragraph).

2) Check all cables, all cables exit and all connections. Inspect and check the ground

connections

3) Remove the plastic bucky cover and clean internal component, remove dust, and all

extraneous thing (like metal number, letter ..)

4) Lubricate all movement parts (internal rail with brown grease, for ropes use white

grease like type zeta2)

5) Remove the lateral column covers and lubricate the sliding guides

6) Performance a generals cleaning of the device.

7) Performance a generals mechanical, electrical and radiographic test

8.2 ROPE REPLACEMENT

1) Remove the upper cover pos. e fig 10, the lateral covers Pos. c fig. 10.

2) Push the bucky panel in the lower position and introduce the counterweight pivot into

the hole Pos. f fig. 10, lift lightly the bucky panel (the counterweight will rest on

pivot), push up the bucky panel (3/5 cm) and stop the panel in this position with a

“step” (or something to support the panel), the two ropes now are free.

3) Remove the back side cover Pos. h.

4) Stand out the damaged rope from the sliding part Pos. g removing the pivot.

5) Stand out the other rope side from the counterweight fig. RIC 4 pos. e

6) Change the rope, reassemble the pivots removed before from the sliding part and

from the counterweight.

7) Put in to the two pulley’s slot (fig RIC 2 pos g) pay attention into the column the ropes

do not cross together.

8) Release the bucky panel, be careful the two ropes have to remain into the pulley’s

slot

9) The counterweight will balance automatically the two ropes

10) Reassemble all covers, pay attention to connect all ground contacts

11) Performance general check, mechanical, electrical and radiographic check

TECHNICAL AND INSTALLATION MANUAL Pag. 13 di 15

BS 45 MTEBS04

FIG. 12

TECHNICAL AND INSTALLATION MANUAL Pag. 14 di 15

BS 45 MTEBS04

8 SPARE PART LIST

Enclose

Ö Drawing from RIC-1, 3, 4, 5, 16, 17, 19, 20, 21

Ö Connection diagram BS45Z01B

The following spare parts can be required to:

Via del Parlamento Europeo 9/D – 50010 - Scandicci – Firenze - ITALY

Telefono +39 055 7228511 Fax +39 055 7228512

Email info@italray.it

Web www.italray.it

TECHNICAL AND INSTALLATION MANUAL Pag. 15 di 15

ITALRAY s.r.l. SCAND ICCI (FI) ITALY

DISTINTA RICAMBI TAV O LA N.

SPAR ES PART LIST D RAW N.

RIC-1

ITALRAY s.r.l. SCANDICCI (FI) ITALY

DISTINTA RICAMBI TAVOLA N.

SPARES PART LIST DRAW N.

RIC-3

ITALRAY s.r.l. SCANDICCI (FI) ITALY

DISTINTA RICAMBI TAVO LA N.

SPARES PART LIST DRAW N.

RIC-4

ITALRAY s.r.l. SCANDICCI (FI) ITALY

DISTINTA RICAMBI TAVOLA N.

SPARES PART LIST DRAW N.

RIC-5

5 4 3 2 1

D D

TB1 MS2 MS1

1 1 1 X R A Y C ONTACT

2 2 2 X R A Y C ONTACT F ROM

3 3 3 0 V c c G R ID START

4 4 4 2 4 V c c G R ID START X -RAY

5 5 5 2 4 Vcc

6 6 6 0 V cc G ENERATOR

7 7 7 G ND

8

C C

POTTER

ET2

MS3

U NBRAKE PUSH BOTTON

1

2 B RAKES

3

O N THE

C OLUMN-TOP

B B

a t e r m i n i d i l e g g e è s e v e r a m e n t e v i e t a t o r i p r o d u r r e o comunicare a terzi il contenuto

d e l p r e s e n t e disegno

A A

T itle

2 WIRE DIAGRAM

1 S ize D o c u m e n t N u m ber Rev

A4 B S 4 5 Z 03A 0

0 - P R I M A E M I S SIONE F .B. F .F. S.B. 1 5 . 0 9.04

R E V. Z ONA D E S C R I Z I O N E V A R I ANTI Disegnato C o n t roll. A p p r o v. Data S h eet 1 of 1

5 4 3 2 1

Vous aimerez peut-être aussi

- Energy Storage Unit Service - Manual PDFDocument28 pagesEnergy Storage Unit Service - Manual PDFathinabeba100% (2)

- TankTech UTIDocument16 pagesTankTech UTIetchegarayf100% (2)

- Manual 800 KvaDocument87 pagesManual 800 Kvavicvarg100% (3)

- CM 21 002 RevCDocument113 pagesCM 21 002 RevCYolanda PeñaPas encore d'évaluation

- Flat E Operator'S ManualDocument110 pagesFlat E Operator'S ManualPeter Yli100% (1)

- BKM-Z24B (III) Maintenance ManualDocument36 pagesBKM-Z24B (III) Maintenance ManualJosselyn Stephanie Ayala SolísPas encore d'évaluation

- Transistor 2N4401NPNDocument7 pagesTransistor 2N4401NPNSwisela Oktavia Tumembow IIPas encore d'évaluation

- Manual Service Tektronix 2712Document692 pagesManual Service Tektronix 2712TECSISCOM100% (1)

- DKDP - Manual Eng 12 - 2018Document12 pagesDKDP - Manual Eng 12 - 2018Lý Chính ĐạoPas encore d'évaluation

- Spare Part List 7700 - SM - DOC2042197 - 1 PDFDocument139 pagesSpare Part List 7700 - SM - DOC2042197 - 1 PDFd_abdosPas encore d'évaluation

- Alpha RTDocument8 pagesAlpha RTd_abdosPas encore d'évaluation

- JMO Solutions 2008Document4 pagesJMO Solutions 2008ichkhuyPas encore d'évaluation

- Bio-Rad D-10 Dual ProgramDocument15 pagesBio-Rad D-10 Dual ProgramMeesam AliPas encore d'évaluation

- 667 HB 32900 000Document260 pages667 HB 32900 000Rodrigo Francisco León BarríaPas encore d'évaluation

- Pub109 141 00 0220Document4 pagesPub109 141 00 0220Auk ah PusingPas encore d'évaluation

- ATEX Certfificate SKF QuickCollect CMDT 391 Ex TCM 12 577416Document3 pagesATEX Certfificate SKF QuickCollect CMDT 391 Ex TCM 12 577416Moises Minotti GilPas encore d'évaluation

- 9.9 Differential Pressure TransmittersDocument99 pages9.9 Differential Pressure TransmittersorazioconiglioPas encore d'évaluation

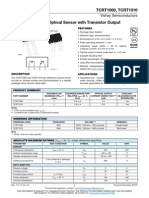

- TCRT 1000Document10 pagesTCRT 1000Boppudi Sasi BinduPas encore d'évaluation

- 002 - ManualC - G - 47-50 - ING Rev.2 20.10.11Document13 pages002 - ManualC - G - 47-50 - ING Rev.2 20.10.11aiabbasi9615Pas encore d'évaluation

- Operator & Installation Manual Tr-810 857645Document50 pagesOperator & Installation Manual Tr-810 857645बासुदेव अर्यालPas encore d'évaluation

- 1004Document13 pages1004Edie VaLenzPas encore d'évaluation

- 1VLG100520 - Installation Guide of IR Temperature Sensors - RevbDocument46 pages1VLG100520 - Installation Guide of IR Temperature Sensors - RevbtuanvuttPas encore d'évaluation

- Tfg710 Infrared Sensor Technical GuideDocument155 pagesTfg710 Infrared Sensor Technical Guidert.polymer.afraPas encore d'évaluation

- 181-SSRS AM AlphaSSRS MED-B Cert 5-7-2021Document2 pages181-SSRS AM AlphaSSRS MED-B Cert 5-7-2021Costin CaraimanPas encore d'évaluation

- PM5519-PHilips TV Signal GenDocument82 pagesPM5519-PHilips TV Signal GenstwebsterPas encore d'évaluation

- Model 810-N1-24VDC: Panel Mount Control EnclosureDocument10 pagesModel 810-N1-24VDC: Panel Mount Control EnclosureWERMERMPas encore d'évaluation

- Detectronic - Ec-Declaration-Of-Conformity-22-Detectronic-Ec-D-Of-C-Ec-DeclarationDocument9 pagesDetectronic - Ec-Declaration-Of-Conformity-22-Detectronic-Ec-D-Of-C-Ec-DeclarationAfumatoare VanbetPas encore d'évaluation

- st1510fx Salida HorizontalDocument10 pagesst1510fx Salida HorizontalAdan ChavezPas encore d'évaluation

- Data Sheet Transistor 2n3906Document7 pagesData Sheet Transistor 2n3906Raul EsparzaPas encore d'évaluation

- 22-23-4 Iec60598 - NovalitingDocument61 pages22-23-4 Iec60598 - NovalitingLuis Fernando ValenciaPas encore d'évaluation

- VBN Vib 13 062 e C Ac3mo 038Document28 pagesVBN Vib 13 062 e C Ac3mo 038roberto_monguzziPas encore d'évaluation

- CB CU Conveyor Belt Control Unit Safety CertificateDocument54 pagesCB CU Conveyor Belt Control Unit Safety CertificateBala Sasanka MadabhushiPas encore d'évaluation

- Lci TX / Lci Tx-440: User GuideDocument42 pagesLci TX / Lci Tx-440: User GuideIqball ArdiyanPas encore d'évaluation

- CB Test CertificateDocument2 pagesCB Test CertificateTILAK RAJ KambojPas encore d'évaluation

- Newtec Mod 2080Document120 pagesNewtec Mod 2080jean27000100% (2)

- 2N3442 DDocument4 pages2N3442 DIonut SimaPas encore d'évaluation

- Installation and Operation Manual: Omslagma00834.Fm Page 1 Friday, March 17, 2006 1:49 PMDocument29 pagesInstallation and Operation Manual: Omslagma00834.Fm Page 1 Friday, March 17, 2006 1:49 PMMuhammet GulbahcePas encore d'évaluation

- Variable Frequency Vibrators Controlled Through Rotary Switches With Connection ExtractableDocument16 pagesVariable Frequency Vibrators Controlled Through Rotary Switches With Connection ExtractableLucy HernandezPas encore d'évaluation

- H4A71110 Vol-1 AllDocument134 pagesH4A71110 Vol-1 AllDwijaputra Templorer100% (1)

- RL34 MZ TC - 2916230-8Document80 pagesRL34 MZ TC - 2916230-8Sergio MandelliPas encore d'évaluation

- Ese 00528 enDocument36 pagesEse 00528 enHoàng Minh ÁiPas encore d'évaluation

- IECEx BAS 10.0045X 005Document6 pagesIECEx BAS 10.0045X 005Marcos SiqueiraPas encore d'évaluation

- ATEXDocument9 pagesATEXBanan PajamPas encore d'évaluation

- Transitor NPN Q324 Datasheet BookDocument7 pagesTransitor NPN Q324 Datasheet BookCandra SetyaPas encore d'évaluation

- Buveco Datasheet Uk St450ecDocument5 pagesBuveco Datasheet Uk St450ecAmitPas encore d'évaluation

- N59e Le46a856s PDFDocument346 pagesN59e Le46a856s PDFToni Argudo DuchPas encore d'évaluation

- 1SVR405611R1100 CR m024dc2lDocument3 pages1SVR405611R1100 CR m024dc2lalvinkertPas encore d'évaluation

- CB Test CertificateDocument3 pagesCB Test Certificatemarino palmaresPas encore d'évaluation

- 08-Instruction Manual Fan UnitDocument20 pages08-Instruction Manual Fan Unitvodoley634Pas encore d'évaluation

- Uc 2710Document6 pagesUc 2710pic18f4550Pas encore d'évaluation

- IECEx BAS 10.0045X 004Document6 pagesIECEx BAS 10.0045X 004ESTEBAN DUARTE VIDESPas encore d'évaluation

- Rev-CDocument39 pagesRev-CEduardo EspinetPas encore d'évaluation

- 2SD1266, 2SD1266A: Silicon NPN Triple Diffusion Planar TypeDocument4 pages2SD1266, 2SD1266A: Silicon NPN Triple Diffusion Planar TypevdăduicăPas encore d'évaluation

- Com.5257 Manuale MR-B 8K Igbt EngDocument50 pagesCom.5257 Manuale MR-B 8K Igbt Engjesse.carvalhoPas encore d'évaluation

- Fpb1a3030s13w CCT Led Panels ManualDocument16 pagesFpb1a3030s13w CCT Led Panels Manualnosas4gPas encore d'évaluation

- TIP31C: General FeaturesDocument10 pagesTIP31C: General Featuressarantapodarusa4009Pas encore d'évaluation

- TBoxLT2 Uk 1.09Document197 pagesTBoxLT2 Uk 1.09nddbd8jhrsPas encore d'évaluation

- Vigilance 4.0 Installation Manual - V1.31Document23 pagesVigilance 4.0 Installation Manual - V1.31onlywork35Pas encore d'évaluation

- Base de Rele Phoenix Contact 2900958 PDFDocument13 pagesBase de Rele Phoenix Contact 2900958 PDFFlavioPas encore d'évaluation

- 50 20-RP1Document10 pages50 20-RP1h1234bPas encore d'évaluation

- Esa - PBC & PBST (E3280e)Document28 pagesEsa - PBC & PBST (E3280e)crvitor1Pas encore d'évaluation

- 500V / 7A Switching Regulator Applications: Data SheetDocument4 pages500V / 7A Switching Regulator Applications: Data SheetFlorin RaduPas encore d'évaluation

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7D'EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7Pas encore d'évaluation

- Electrical Energy Efficiency: Technologies and ApplicationsD'EverandElectrical Energy Efficiency: Technologies and ApplicationsPas encore d'évaluation

- Installation Guide & User's Manual: 27 November 2013Document251 pagesInstallation Guide & User's Manual: 27 November 2013d_abdosPas encore d'évaluation

- Quad SPST CMOS Analog Switches: General Description FeaturesDocument12 pagesQuad SPST CMOS Analog Switches: General Description Featuresd_abdosPas encore d'évaluation

- FORM 10-K: Securities and Exchange CommissionDocument265 pagesFORM 10-K: Securities and Exchange Commissiond_abdosPas encore d'évaluation

- Konica Xpress CR PDFDocument6 pagesKonica Xpress CR PDFd_abdosPas encore d'évaluation

- DRGEMDocument2 pagesDRGEMd_abdosPas encore d'évaluation

- SUPiA Animal FinalDocument2 pagesSUPiA Animal Finald_abdosPas encore d'évaluation

- Mm12 v-004 BrochureDocument3 pagesMm12 v-004 Brochured_abdosPas encore d'évaluation

- Common X Ray Tube Failure ModesDocument15 pagesCommon X Ray Tube Failure Modesd_abdosPas encore d'évaluation

- CLINOMATDocument1 pageCLINOMATd_abdosPas encore d'évaluation

- Unit Test 7 (PDF)Document1 pageUnit Test 7 (PDF)emirelliucPas encore d'évaluation

- The Art of Logical ThinkingDocument210 pagesThe Art of Logical ThinkingAndyAyam100% (1)

- Drainage BasinsDocument4 pagesDrainage BasinsDannySP10100% (1)

- L23 - Axial Flow CompressorDocument17 pagesL23 - Axial Flow CompressorRohan GuptaPas encore d'évaluation

- Fermat Contest: Canadian Mathematics CompetitionDocument4 pagesFermat Contest: Canadian Mathematics Competitionสฮาบูดีน สาและPas encore d'évaluation

- 19 Free Amigurumi Crochet Patterns: MaterialsDocument4 pages19 Free Amigurumi Crochet Patterns: MaterialsLucica Diaconu100% (1)

- Atlantis Is Discovered - Atlantis in Middle Danubian Depression (Pannonian Basin) A New Location of Atlantis IslandDocument31 pagesAtlantis Is Discovered - Atlantis in Middle Danubian Depression (Pannonian Basin) A New Location of Atlantis Islandpaulct2004721260% (10)

- Practice Exam 3 KEY (Solutions)Document13 pagesPractice Exam 3 KEY (Solutions)josePas encore d'évaluation

- Surface & Subsurface Geotechnical InvestigationDocument5 pagesSurface & Subsurface Geotechnical InvestigationAshok Kumar SahaPas encore d'évaluation

- Contactor - SchniderDocument28 pagesContactor - SchniderPramod DixitPas encore d'évaluation

- National Railway Museum Annual Review 04-05Document40 pagesNational Railway Museum Annual Review 04-05sol.loredo1705530Pas encore d'évaluation

- Digital Logic DesignDocument38 pagesDigital Logic DesignAri BaderPas encore d'évaluation

- Linear Predictor: Nature of Linear PredictionDocument9 pagesLinear Predictor: Nature of Linear PredictionkvPas encore d'évaluation

- Attacks On Cryptosystems PDFDocument18 pagesAttacks On Cryptosystems PDFUjjayanta BhaumikPas encore d'évaluation

- Barilla SpaDocument11 pagesBarilla Spavariapratik100% (1)

- Eureka Forbes ReportDocument75 pagesEureka Forbes ReportUjjval Jain0% (1)

- Integration of Phodi Process With Mutation in Bhoomi (Simultaneous Approval of Phodi and The Mutation)Document19 pagesIntegration of Phodi Process With Mutation in Bhoomi (Simultaneous Approval of Phodi and The Mutation)seshadrimn seshadrimnPas encore d'évaluation

- Text 5Document7 pagesText 5santoshkumarray490Pas encore d'évaluation

- Multilicative ABC IndexDocument6 pagesMultilicative ABC IndexBalachandranPas encore d'évaluation

- Driver DST-4812 For 7.2 KG CMDocument5 pagesDriver DST-4812 For 7.2 KG CMWWW.150775.BUGME.PWPas encore d'évaluation

- 8v92ta DetroitDocument554 pages8v92ta Detroit10000389% (9)

- 31. (NÂNG CAO) Đề soạn theo cấu trúc minh họa 2021 - Tiếng Anh - Đề 31 - DươngDocument15 pages31. (NÂNG CAO) Đề soạn theo cấu trúc minh họa 2021 - Tiếng Anh - Đề 31 - DươngNguyễn Quế Anh100% (1)

- Energy Thesis StatementDocument6 pagesEnergy Thesis Statementnicoledixonmobile100% (2)

- Toda People in IndiaDocument9 pagesToda People in IndiaAmoona KopiKoPas encore d'évaluation

- Safety Data Sheet: Section 1. Identification Jotun Essence Easy CleanDocument11 pagesSafety Data Sheet: Section 1. Identification Jotun Essence Easy CleanHồng PhongPas encore d'évaluation

- MicrosoftDynamicsNAVAdd OnsDocument620 pagesMicrosoftDynamicsNAVAdd OnsSadiq QuddusePas encore d'évaluation

- Electron Withdrawing and Electron Donating GroupsDocument2 pagesElectron Withdrawing and Electron Donating GroupsOmar Abd ElsalamPas encore d'évaluation

- L15 - Parallel Magnetic CircuitsDocument6 pagesL15 - Parallel Magnetic CircuitsParikshit MishraPas encore d'évaluation