Académique Documents

Professionnel Documents

Culture Documents

Conplast Ae316 PDF

Transféré par

dipinnediyaparambathTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Conplast Ae316 PDF

Transféré par

dipinnediyaparambathDroits d'auteur :

Formats disponibles

Conplast AE316* constructive solutions

High performance air entraining and plasticising admixture

Uses Standards compliance

To produce air entrained concrete for increased durability Conplast AE316 conforms with BS 5075 Part 2 and

and resistance to damage by frost and de-icing salts. ASTM C260.

Typical applications include concrete roads and bridge

decks, airport runways and taxiways and other concrete Typical dosage

exposed to potential frost damage.

The optimum dosage of Conplast AE316 to meet specific

To improve cohesion and workability of concrete mixes requirements must always be determined by trials using the

where poorly graded aggregates must be used and materials and conditions that will be experienced in use.

bleeding, segregation or sand runs occur. This allows the optimisation of admixture dosage and mix

Particularly suitable for use in situations where standard design and provides a complete assessment of the concrete

air entrainers are less reliable or less effective. Typical mix.

examples include where mixes containing PFA or

With air entrainers in particular, a large number of factors

aggregates with high dust contents are used.

affect the dosage required to obtain particular desired results.

This makes it impossible to predict the dosage required for

Advantages

a specific mix requirement. As a guide, the dosage will

Air entrainment increases the resistance of concrete to generally be in the range of 0.05 to 0.25 litres/100 kg of

attack by frost and de-icing salts, reducing problems of cement to obtain an air content of 5% ± 2% in a medium

surface scaling and concrete failure. workability concrete of 300-350 kg/m3 cement content.

Entrained air bubbles assist in the formation of a stable Where cement replacement materials are used they should

cohesive mix, reducing segregation and bleeding. be included in the cementitious content when calculating

Air entrainment improves workability and helps produce admixture dosage. Mixes containing only OPC will usually

a dense, uniform, close textured surface free from gravel require dosage in the lower half of the normal range. Mixes

nests and sand runs, further enhancing durability. containing PFA or microsilica are more likely to require

Excellent air bubble stability allows use with a wide range dosages in the higher part of the range. The use of lower

of aggregate qualities and mix conditions. quality PFA may increase the dosage required, possibly

Particularly effective with dusty aggregates and in mixes extending the normal maximum dosage up to 0.40 litres/100

containing PFA or microsilica. kg.

Particularly designed for less variability in performance Use at other dosages

at varying concrete temperatures than normal air

Dosages outside the typical ranges suggested on this sheet

entraining admixtures.

may be used if necessary and suitable to meet particular mix

requirements, provided that adequate supervision is

Description

available. Compliance with requirements must be assessed

Conplast AE316 air entraining admixture is chloride free and through trial mixes. Contact the Fosroc Technical Service

based on a synergystic blend of synthetic and naturally Department for advice in these cases.

occurring surfactants. It is supplied as a brown solution which

instantly disperses in water. Properties

Conplast AE316 acts at the interface between the mixing

Appearance : Brown liquid

water and cement/aggregate particles to produce

Specific gravity : Typically 1.01 at 20°C

microscopic air bubbles, which are evenly distributed

Chloride content : Nil to BS 5075

throughout the concrete.

Alkali content : Typically less than 15.0 g. Na 2O

The entrained air enhances durability by providing protection equivalent/litre of admixture. A fact

against the rapid temperature changes found in freezing and sheet on this subject is available.

Conplast AE316

thawing conditions and with the use of de-icing salts.

Conplast AE316*

Instructions for use Compatibility

Checking and control Conplast AE316 is compatible with other Fosroc admixtures

used in the same concrete mix. All admixtures should be

Once a suitable dosage has been selected, care should be

added to the concrete separately and must not be mixed

taken to ensure consistency of materials used and mixing and

together prior to addition. The resultant properties of

delivery procedures. Air content should be checked regularly by

concrete containing more than one admixture should be

such means as the pressure method described in BS 1881

assessed by the trial mix procedure recommended on this

and ASTM C231.

data sheet.

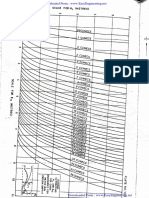

Factors affecting air entrainment

Conplast AE316 is suitable for use with all types of Portland

A number of factors can affect the air entrainment obtained for a cement. Contact the Fosroc Technical Service Department

particular dosage of air entraining admixture, some of which for advice on use with special cements and blends

are listed below. The examples given of changes that these containing cement replacement materials.

factors may make to a concrete mix should be taken as

Dispensing

guidelines only and the actual effects in any particular situation

confirmed in trials. The correct quantity of Conplast AE316 should be measured

by means of a recommended dispenser. The admixture

a) Sands of apparently the same grading may have

should then be added to the concrete with the mixing water

significantly different effects on the level of air entrainment,

to obtain the best results. Contact the Fosroc Technical

depending on factors such as silt content, particle size

Service Department for advice regarding suitable

distribution and particle shape. Where changes in sand

equipment and its installation.

source or content must be made, or where sand varies

within the same source, a careful check must be made on Effects of overdosing

the effects on air entrainment.

An overdose of double the intended amount of Conplast

b) Increased cement fineness or cement content will tend to

AE316 will result in a significant increase in air entrainment,

decrease air content. Changes in cement source and type

which will reduce strength. The degree of this effect will

may also lead to changes in the admixture dosage required

depend on the particular mix design and overdose level.

to obtain a particular air content.

c) The presence of carbon or organic impurities may reduce Increased air content from an overdose will tend to have an

the effectiveness of an air entrainer and require an increased increased plasticising effect. Some slight increase in setting

dosage. This will not usually be a problem but care may be time may also occur.

required when using PFA, certain pigments or lignite bearing

Curing

sands.

d) Increased concrete temperature will tend to reduce air As with all structural concrete, good curing practice should

entrainment. Typically a rise from 10°C to 32°C may halve be maintained. Water spray, wet hessian or a Concure*

the level of air. In normal mixing conditions daily fluctuations spray applied curing membrane should be used.

will not give significant variations.

e) Variations of mixer type and transit time may change the Limitations

level of air entrainment. Small losses may occur during

In some situations the powerful nature of Conplast AE316

pumping. These will generally be consistent for a given set

may result in very low dosages which can be difficult to

of conditions. High air contents may significantly reduce

dispense accurately. In such cases, the use of a less

pump efficiency over long pump distances.

powerful product such as Conplast AE300*† or a more dilute

f) Normal compacting procedures will not affect air

product such as Conplast AE313*† is recommended.

entrainment. Prolonged vibration should be avoided.

g) Increased dosages may be required at low workability levels

Technical support

to achieve the required air content.

Fosroc provides a technical advisory service for on-site

assistance and advice on admixture selection, evaluation

trials and dispensing equipment. Technical data and

guidance can be provided for admixtures and other products

for use with fresh and hardened concrete.

Conplast AE316 - Page 2 of 4

Conplast AE316*

Estimating

Supply

Conplast AE316 : 210 litre drums and in bulk

Dosage

Conplast AE316 : 0.05 to 0.25 ltrs/100 kg cement

Storage

Conplast AE316 has a minimum shelf life of 12 months provided

the temperature is kept within the range of 5°C to 50°C. Should

the temperature of the product fall outside this range then the

Fosroc Technical Service Department should be contacted for

advice.

Freezing point : Approximately 0°C

Precautions

Health and safety

Conplast AE316 is alkaline and an irritant and should not be

swallowed or allowed to come into contact with skin and eyes.

Suitable protective gloves and goggles should be worn.

Splashes on the skin should be removed with water. In case of

contact with eyes rinse immediately with plenty of water and

seek medical advice. If swallowed seek medical attention

immediately - do not induce vomiting.

For further information consult the Material Safety Data Sheet

available for this product.

Fire

Conplast AE316 is water based and non-flammable.

Cleaning and disposal

Spillages of Conplast AE316 should be absorbed onto sand,

earth or vermiculite and transferred to suitable containers.

Remnants should be hosed down with large quantities of water.

The disposal of excess or waste material should be carried out

in accordance with local legislation under the guidance of the

local waste regulatory authority.

Additional information

Conplast AE316 was previously known as Conplast 316.

Conplast AE316 - Page 3 of 4

Conplast AE316*

Additional Information

Fosroc manufactures a wide range of complementary products

which include :

waterproofing membranes & waterstops

joint sealants & filler boards

cementitious & epoxy grouts

specialised flooring materials

Fosroc additionally offers a comprehensive package of

products specifically designed for the repair and refurbishment

of damaged concrete. Fosroc’s ‘Systematic Approach’ to

concrete repair features the following :

hand-placed repair mortars

spray grade repair mortars

fluid micro-concretes

chemically resistant epoxy mortars

anti-carbonation/anti-chloride protective coatings

chemical and abrasion resistant coatings

For further information on any of the above, please consult

your local Fosroc office - as below.

* Denotes the trademark of Fosroc International Limited

†

See separate data sheet

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard

Conditions for the Supply of Goods and Service. All Fosroc datasheets are updated on a regular basis. It is the user’s

responsibility to obtain the recent version. Refer to www.fosroc.com.

Head Office

Al Gurg Fosroc telephone: (+9714) 2039699 fax: (+9714) 2859649 email: agf@fosroc.com

LLC Regional offices

Abu Dhabi, Al Gurg Fosroc telephone: 673 1779 fax: 673 1449 email: abudhabi@fosroc.com

Post Box 657, Dubai Bahrain, YBA Kanoo telephone: 17735454 fax: 17732828 email: bahrain@fosroc.com

United Arab Emirates Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

Oman, Al Amana telephone: 24815080 fax: 24817554 email: oman@fosroc.com

Qatar, Tadmur telephone: 4500607 fax: 4500543 email: qatar@fosroc.com

www.fosroc.com

UAE/0348/01/B

Vous aimerez peut-être aussi

- Rabbi Shneur Zalman of Liadi - Lessons in Tanya Vol-1Document474 pagesRabbi Shneur Zalman of Liadi - Lessons in Tanya Vol-1Exequiel Medina83% (6)

- Autoridad Myles Munroe Poder de La El Proposito y PDF Autoridad Myles MunroeDocument5 pagesAutoridad Myles Munroe Poder de La El Proposito y PDF Autoridad Myles MunroeMaricarmen MorenoPas encore d'évaluation

- Ledger - Problems and SolutionsDocument1 pageLedger - Problems and SolutionsDjamal SalimPas encore d'évaluation

- Effortless by Greg McKeownDocument6 pagesEffortless by Greg McKeownNaison StanleyPas encore d'évaluation

- High performance air entraining admixtureDocument4 pagesHigh performance air entraining admixturemohab hakimPas encore d'évaluation

- Air entraining admixture improves concrete durabilityDocument3 pagesAir entraining admixture improves concrete durabilitytalatzahoorPas encore d'évaluation

- TDS Conplast AEA India3Document4 pagesTDS Conplast AEA India3Santosh MhetrePas encore d'évaluation

- Fosroc Conplast AEA: Constructive SolutionsDocument2 pagesFosroc Conplast AEA: Constructive SolutionsSeychellesPas encore d'évaluation

- Conplast AeaDocument2 pagesConplast AeaVincent JavatePas encore d'évaluation

- Conplast PA21: Constructive SolutionsDocument3 pagesConplast PA21: Constructive SolutionstalatzahoorPas encore d'évaluation

- Conplast AE300: Air Entraining AdmixtureDocument3 pagesConplast AE300: Air Entraining AdmixtureBalasubramanian AnanthPas encore d'évaluation

- Conplast AEA: Air Entraining AdmixtureDocument4 pagesConplast AEA: Air Entraining AdmixtureVenkata Raju KalidindiPas encore d'évaluation

- Conplast sp495Document2 pagesConplast sp495Vincent JavatePas encore d'évaluation

- Conplast X421 - DataSheetDocument2 pagesConplast X421 - DataSheetmido_20067581Pas encore d'évaluation

- Fosroc Conplast SP2000: Constructive SolutionsDocument2 pagesFosroc Conplast SP2000: Constructive SolutionsVincent JavatePas encore d'évaluation

- Fosroc Conplast WP200: Appearance: Specific Gravity: Chloride Content: Nil To BS 5075 / BS:EN934Document2 pagesFosroc Conplast WP200: Appearance: Specific Gravity: Chloride Content: Nil To BS 5075 / BS:EN934Vincent JavatePas encore d'évaluation

- TDS Conplast SP435 Saudi ArabiaDocument3 pagesTDS Conplast SP435 Saudi ArabiaEng. Renjith SarmaPas encore d'évaluation

- Conplast SP431R TDSDocument2 pagesConplast SP431R TDSBiruckPas encore d'évaluation

- Fosroc Conplast SP491 high range water reducerDocument2 pagesFosroc Conplast SP491 high range water reducerVincent JavatePas encore d'évaluation

- Fosroc Conplast WP200: Constructive SolutionsDocument2 pagesFosroc Conplast WP200: Constructive SolutionsVincent JavatePas encore d'évaluation

- Conplast SP431R: Constructive SolutionsDocument2 pagesConplast SP431R: Constructive SolutionsAmr RagabPas encore d'évaluation

- Fosroc Conplast SP335 Multi-Range Water Reducing AdmixtureDocument2 pagesFosroc Conplast SP335 Multi-Range Water Reducing AdmixtureVincent JavatePas encore d'évaluation

- 5 Conplast SP 335Document2 pages5 Conplast SP 335racingspirit80Pas encore d'évaluation

- 4 Conplast RP 264Document4 pages4 Conplast RP 264racingspirit80Pas encore d'évaluation

- 3 Conplast RP 244Document3 pages3 Conplast RP 244racingspirit80Pas encore d'évaluation

- Fosroc Conplast NC: Chloride Free Accelerating AdmixtureDocument4 pagesFosroc Conplast NC: Chloride Free Accelerating AdmixtureVincent JavatePas encore d'évaluation

- 1 Conplast P211Document3 pages1 Conplast P211racingspirit80Pas encore d'évaluation

- Pds Conplast Wp500Document3 pagesPds Conplast Wp500ilhamPas encore d'évaluation

- 6 Conplast SP 431Document2 pages6 Conplast SP 431racingspirit80Pas encore d'évaluation

- Cebex 305: Retarding Admixture For Mortar Uses Technical SupportDocument4 pagesCebex 305: Retarding Admixture For Mortar Uses Technical SupportSyed HassaanPas encore d'évaluation

- Fosroc Conplast SP335: Multi-Range Water Reducing AdmixtureDocument2 pagesFosroc Conplast SP335: Multi-Range Water Reducing AdmixtureVincent JavatePas encore d'évaluation

- Fosroc Conplast SP470: Constructive SolutionsDocument2 pagesFosroc Conplast SP470: Constructive SolutionsVincent JavatePas encore d'évaluation

- Fosroc Conplast NC: Constructive SolutionsDocument4 pagesFosroc Conplast NC: Constructive SolutionsVincent JavatePas encore d'évaluation

- Fosroc Conplast SP333: Constructive SolutionsDocument2 pagesFosroc Conplast SP333: Constructive SolutionsVincent JavatePas encore d'évaluation

- Fosroc Conplast SP495: Constructive SolutionsDocument2 pagesFosroc Conplast SP495: Constructive SolutionsVincent JavatePas encore d'évaluation

- Conplast SD100Document3 pagesConplast SD100talatzahoorPas encore d'évaluation

- Fosroc Conplast SP491: Constructive SolutionsDocument2 pagesFosroc Conplast SP491: Constructive SolutionsVincent JavatePas encore d'évaluation

- Fosroc Conplast WP400: Constructive SolutionsDocument2 pagesFosroc Conplast WP400: Constructive SolutionsVincent JavatePas encore d'évaluation

- Conplast SP337Document4 pagesConplast SP337Anonymous VJUVtmVusPas encore d'évaluation

- Fosroc Conplast SP430PC: Constructive SolutionsDocument2 pagesFosroc Conplast SP430PC: Constructive SolutionsVincent JavatePas encore d'évaluation

- Cebex 311 PDFDocument4 pagesCebex 311 PDFSriraamPas encore d'évaluation

- Fosroc Conplast SP430PCDocument2 pagesFosroc Conplast SP430PCVincent JavatePas encore d'évaluation

- Conplast PA21 Air Entraining AdmixtureDocument3 pagesConplast PA21 Air Entraining AdmixtureTori SmallPas encore d'évaluation

- Conplast RP200Document2 pagesConplast RP200thoryamaraghyPas encore d'évaluation

- Fosroc Conplast WP400 waterproofing admixtureDocument2 pagesFosroc Conplast WP400 waterproofing admixtureVincent JavatePas encore d'évaluation

- Conplast SP335Document2 pagesConplast SP335m.elsanee.cubicPas encore d'évaluation

- Fosroc Conplast RP264: Retarding Water Reducing AdmixtureDocument2 pagesFosroc Conplast RP264: Retarding Water Reducing AdmixtureShaik QutubuddinPas encore d'évaluation

- Fosroc Conplast SP333: Constructive SolutionsDocument2 pagesFosroc Conplast SP333: Constructive SolutionsVincent JavatePas encore d'évaluation

- Conplast Sp430saDocument3 pagesConplast Sp430sathoryamaraghyPas encore d'évaluation

- Fosroc Conplast RP264: Constructive SolutionsDocument2 pagesFosroc Conplast RP264: Constructive SolutionsVincent JavatePas encore d'évaluation

- Fosroc Conplast SP472: Constructive SolutionsDocument2 pagesFosroc Conplast SP472: Constructive SolutionsVincent JavatePas encore d'évaluation

- Conplast R Retarding Concrete AdmixtureDocument2 pagesConplast R Retarding Concrete AdmixtureHemaPas encore d'évaluation

- Fosroc Conplast P211: Water Reducing Admixture Uses Technical SupportDocument2 pagesFosroc Conplast P211: Water Reducing Admixture Uses Technical SupportVincent JavatePas encore d'évaluation

- Conplast P211Document2 pagesConplast P211mohab hakimPas encore d'évaluation

- 2 Conplast P509Document2 pages2 Conplast P509racingspirit80Pas encore d'évaluation

- Fosroc Conplast SP472 High Range Water ReducerDocument2 pagesFosroc Conplast SP472 High Range Water ReducerVincent JavatePas encore d'évaluation

- 7 Conplast SP 1000Document2 pages7 Conplast SP 1000racingspirit80Pas encore d'évaluation

- Fosroc Conplast P505: High Performance, Slump Retaining and Water Reducing AdmixtureDocument2 pagesFosroc Conplast P505: High Performance, Slump Retaining and Water Reducing AdmixtureVincent JavatePas encore d'évaluation

- Pds Conplast RDocument4 pagesPds Conplast RilhamPas encore d'évaluation

- Cebex 305: Retarding Admixture For MortarDocument4 pagesCebex 305: Retarding Admixture For MortartrickyggPas encore d'évaluation

- Fosroc Conplast SP561: Constructive SolutionsDocument2 pagesFosroc Conplast SP561: Constructive SolutionsVincent JavatePas encore d'évaluation

- CAPENTRAINDocument2 pagesCAPENTRAINMedrar TareqPas encore d'évaluation

- Waterproof Mortar AdmixtureDocument4 pagesWaterproof Mortar AdmixtureMoatz HamedPas encore d'évaluation

- TechBrief Air Entraining AdmixturesDocument2 pagesTechBrief Air Entraining AdmixturesgayathriPas encore d'évaluation

- 04 CET 416 PROJECT PHASE II SLOT U S8Document9 pages04 CET 416 PROJECT PHASE II SLOT U S8dipinnediyaparambathPas encore d'évaluation

- Project About Construction of Medical CollegeDocument4 pagesProject About Construction of Medical CollegedipinnediyaparambathPas encore d'évaluation

- 03 CET 404 COMPREHENSIVE COURSE VIVA SLOT E S8Document1 page03 CET 404 COMPREHENSIVE COURSE VIVA SLOT E S8dipinnediyaparambathPas encore d'évaluation

- KTUMTechconstructionengineeringmanagement (2015)Document68 pagesKTUMTechconstructionengineeringmanagement (2015)dipinnediyaparambathPas encore d'évaluation

- Blench Curve ADocument1 pageBlench Curve Adipinnediyaparambath50% (2)

- Civil Engineering Airport, Seaport and Harbour CourseDocument8 pagesCivil Engineering Airport, Seaport and Harbour CourseSAKHI U 20MLCE11Pas encore d'évaluation

- Montague CurveDocument1 pageMontague Curvedipinnediyaparambath100% (2)

- Cet402 Quantity Surveying and ValuationDocument13 pagesCet402 Quantity Surveying and ValuationdipinnediyaparambathPas encore d'évaluation

- PARTIAL DIFFERENTIAL EQUATIONS AND COMPLEX ANALYSISDocument8 pagesPARTIAL DIFFERENTIAL EQUATIONS AND COMPLEX ANALYSISdipinnediyaparambathPas encore d'évaluation

- CEL 203 SyllabusDocument4 pagesCEL 203 SyllabusdipinnediyaparambathPas encore d'évaluation

- Cet306 Design of Hydraulic Structures SyllabusDocument7 pagesCet306 Design of Hydraulic Structures SyllabusdipinnediyaparambathPas encore d'évaluation

- CET201 SyllabusDocument13 pagesCET201 SyllabusdipinnediyaparambathPas encore d'évaluation

- CE233 Surveying LabDocument1 pageCE233 Surveying LabdipinnediyaparambathPas encore d'évaluation

- CE233 Surveying LabDocument1 pageCE233 Surveying LabdipinnediyaparambathPas encore d'évaluation

- CET205 SyllabusDocument10 pagesCET205 SyllabusdipinnediyaparambathPas encore d'évaluation

- Civil Engineering: Geotechnical Engineering LAB Category L T P Credit Year of PCC 0 0 3 2 2019Document3 pagesCivil Engineering: Geotechnical Engineering LAB Category L T P Credit Year of PCC 0 0 3 2 2019dipinnediyaparambathPas encore d'évaluation

- CET 203 SyllabusDocument12 pagesCET 203 SyllabusdipinnediyaparambathPas encore d'évaluation

- Semester 5Document1 pageSemester 5dipinnediyaparambathPas encore d'évaluation

- Amie Exam FormDocument1 pageAmie Exam FormmukeshhPas encore d'évaluation

- 6.disaster ManagementDocument12 pages6.disaster Managementram jrpsPas encore d'évaluation

- CET309Document12 pagesCET309dipinnediyaparambathPas encore d'évaluation

- SYLLUBUSDocument2 pagesSYLLUBUSdipinnediyaparambathPas encore d'évaluation

- Allotment of Proj Guide Lab ExpDocument376 pagesAllotment of Proj Guide Lab ExpdipinnediyaparambathPas encore d'évaluation

- Civil Engineering: Category L T P Credit Year ofDocument8 pagesCivil Engineering: Category L T P Credit Year ofdipinnediyaparambathPas encore d'évaluation

- The Institution of Engineers (India) : (For Member Technologist Applicants)Document8 pagesThe Institution of Engineers (India) : (For Member Technologist Applicants)dipinnediyaparambathPas encore d'évaluation

- Privileges of Institutional MembersDocument3 pagesPrivileges of Institutional MembersdipinnediyaparambathPas encore d'évaluation

- Amie Section B SyllabusDocument1 pageAmie Section B SyllabusdipinnediyaparambathPas encore d'évaluation

- 05 10 21 Engineering Geology CET 202 SyllabusDocument7 pages05 10 21 Engineering Geology CET 202 SyllabusdipinnediyaparambathPas encore d'évaluation

- SYLLABUSDocument6 pagesSYLLABUSdipinnediyaparambathPas encore d'évaluation

- CET 307 SyllabusDocument12 pagesCET 307 SyllabusdipinnediyaparambathPas encore d'évaluation

- ADTHEORENT SOTI Programmatic 102722Document20 pagesADTHEORENT SOTI Programmatic 102722chinmayPas encore d'évaluation

- AA Practice Problems on Amino Acids and Peptides (less than 40 charsDocument20 pagesAA Practice Problems on Amino Acids and Peptides (less than 40 charsNurlaeli NaelulmunaMajdiyahPas encore d'évaluation

- SPXDocument6 pagesSPXapi-3700460Pas encore d'évaluation

- 1 - Introducing Your SelfDocument31 pages1 - Introducing Your SelfAbdurrahmanPas encore d'évaluation

- Phlebotomy Blood, Micro-OrganismDocument4 pagesPhlebotomy Blood, Micro-Organismapi-372107867% (3)

- Parameter Pengelasan SMAW: No Bahan Diameter Ampere Polaritas Penetrasi Rekomendasi Posisi PengguanaanDocument2 pagesParameter Pengelasan SMAW: No Bahan Diameter Ampere Polaritas Penetrasi Rekomendasi Posisi PengguanaanKhamdi AfandiPas encore d'évaluation

- Heat Exchangers: Thermal Activity and Fluid MotionDocument14 pagesHeat Exchangers: Thermal Activity and Fluid Motionishu vohraPas encore d'évaluation

- ICT Backup Procedure PolicyDocument8 pagesICT Backup Procedure PolicySultan BatoorPas encore d'évaluation

- Nestle CompanyDocument5 pagesNestle CompanymehakPas encore d'évaluation

- Nutritional Deficiency Disorder Edit OneDocument23 pagesNutritional Deficiency Disorder Edit One01 HifzaPas encore d'évaluation

- Adele Lyrics Play the Adele QuizDocument2 pagesAdele Lyrics Play the Adele QuizkomangPas encore d'évaluation

- 1 (Speaking of A Letter) I Made This One Longer, Only Because I Had Not Enough Time To Make It ShorterDocument10 pages1 (Speaking of A Letter) I Made This One Longer, Only Because I Had Not Enough Time To Make It ShorterJhancarlos Carrasco MPas encore d'évaluation

- Sense Organs Lesson PlanDocument16 pagesSense Organs Lesson PlanBernard DayotPas encore d'évaluation

- Tectonics, Vol. 8, NO. 5, PAGES 1015-1036, October 1989Document22 pagesTectonics, Vol. 8, NO. 5, PAGES 1015-1036, October 1989atoinsepePas encore d'évaluation

- Plumbing Layout and SpecificationsDocument1 pagePlumbing Layout and SpecificationsLiza P. PaculanangPas encore d'évaluation

- Academic StyleDocument4 pagesAcademic StyleHa ToPas encore d'évaluation

- Visvesvaraya Technological University BelagaviDocument148 pagesVisvesvaraya Technological University BelagavichetanbvPas encore d'évaluation

- Lali The Sun Also Rises Final PaperDocument4 pagesLali The Sun Also Rises Final PaperDaniel AdamsPas encore d'évaluation

- Configuring Cisco Easy VPN and Easy VPN Server Using SDM: Ipsec VpnsDocument56 pagesConfiguring Cisco Easy VPN and Easy VPN Server Using SDM: Ipsec VpnsrajkumarlodhPas encore d'évaluation

- Batangas State University - Testing and Admission OfficeDocument2 pagesBatangas State University - Testing and Admission OfficeDolly Manalo100% (1)

- Land, Soil, Water, Natural Vegetation& Wildlife ResourcesDocument26 pagesLand, Soil, Water, Natural Vegetation& Wildlife ResourcesKritika VermaPas encore d'évaluation

- MA Music Education FDocument4 pagesMA Music Education FSu YimonPas encore d'évaluation

- And Others - ScriptDocument32 pagesAnd Others - ScriptLisaPas encore d'évaluation

- MR - Abhishek JiDocument4 pagesMR - Abhishek Jimalikgaurav01Pas encore d'évaluation

- Right to Personal Liberty and Judicial Process in IndiaDocument636 pagesRight to Personal Liberty and Judicial Process in IndiaDrDiana PremPas encore d'évaluation

- English NotesDocument39 pagesEnglish NotesNorAini MohamadPas encore d'évaluation