Académique Documents

Professionnel Documents

Culture Documents

Turbinas A Gas para Propulsion Marina PDF

Transféré par

Cinthia Lidia Hidrogo PaulinoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Turbinas A Gas para Propulsion Marina PDF

Transféré par

Cinthia Lidia Hidrogo PaulinoDroits d'auteur :

Formats disponibles

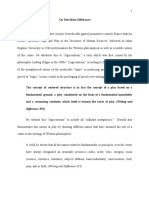

Development of High

Reheater Intermediate

pressure

Efficiency Marine Propulsion

Main boiler

High

pressure

turbine

Plant (Ultra Steam Turbine)

Reduction gears

turbine Shaft

Main burner generator

Super Low MAKOTO ITO* 1

heater Astern

turbine pressure KAZUYOSHI HIRAOKA* 1

turbine

Reheat burner SHOICHI MATSUMOTO* 1

Main turbine

KENJI TSUMURA* 1

Main

condenser

One environmental change for LNG carriers in recent years is the very rapid increase in propulsion plant energy

saving, which is attributed to the increase in the price of crude oil. In an effort to cope with this, in addition to

conventional steam turbine ships, the DFE (dual fuel engine) ship with an electric propulsion motor, with higher

plant efficiency and the DRL (diesel engine with re-liquefaction plant) ship fitted with a 2 cycle, low speed engine,

for propulsion have been introduced. The first DFE ship was built in a French shipyard and is already in service,

and a number of the LNG carriers with DFE and DRL plants are now being constructed in Korea. Although existing

steam turbine plants have good operational reliability, maintainability, and operability proven by past performance,

they are far behind the new plants in plant efficiency, which is an urgent issue. To address this issue, Mitsubishi

Heavy Industries, Ltd. (MHI) has developed the UST (ultra steam turbine) with 15% higher efficiency than a conven-

tional steam turbine plant, while retaining the high reliability, maintenance workability, and operability of a con-

ventional plant. This paper introduces this new UST plant.

market, it is no exaggeration to say that DFE and DRL

1. Introduction ships are becoming the mainstream.

Until a few years ago, steam turbines were used for However, as the new DFE and DRL plants use new

almost all LNG carriers for the propulsion plant because technology, it is naturally presumed that the crew will

of their operation profitability, reliability, operability, also need a level of technical knowledge as with turbine

maintainability and initial investment. Another reason ships. In other words, in selecting a propulsion plant

is that the steam turbine plant could safely treat boil-off for an LNG carrier today, plant efficiency is the most

gas (BOG) generated from the cargo tank and could also important issue. In these circumstances, MHI has de-

use heavy oil as fuel. veloped the UST (ultra steam turbine) plant whose

However, due to the following factors, new DFE and efficiency is equal to the new diesel plants while retain-

DRL plants using diesel engines began to attract at- ing the merits of conventional turbine plants.

tention and the use of alternative propulsion plants

accelerated rapidly. These factors include: (1) the in- 2. UST plant

troduction of gas-burning diesel engines, (2) 2.1 Plant configuration

energy-saving trends as a result of the rising price of The UST plant is a 2-stage feed water heating sys-

crude oil in recent years, and (3) a shortage of crew for tem based on the reheat cycle, ensuring a simple

steam turbine ships due to the LNG carrier construc- configuration considering improved efficiency, operabil-

tion boom caused by the rapid increase in worldwide ity, and maintainability. A comparison with the

demand for natural gas. In the current LNG carrier conventional plant is shown in Table 1

1.

Table 1 Comparison of conventional steam turbine plant and UST plant

CST (conventional plant) UST

o o

Boiler steam conditions 6 MPa X 515 C HP: 10 MPa X 560 C

Steam flow BLR HP LP BLR HP REHTR

IP LP

Flange standard ANSI 900 LB ANSI 2 500 LB

BLR: boiler, HP: high pressure turbine, LP: low pressure turbine

REHTR: reheater, IP: intermediate pressure turbine

*1 Nagasaki Shipyard & Machinery Works Mitsubishi Heavy Industries, Ltd.

Technical Review Vol. 44 No. 3 (Sep. 2007)

1

The steam conditions of the UST plant were deter- main condenser and a reduction gear unit located in a

mined considering the actual performance and single casing and on a single shaft.

cost-effectiveness of land use natural circulation boilers 3.2 Adoption of the latest technology

as well as the scope of the ANSI2500LB flange. On the 3.2.1 Thermal shield

reheat cycle plant, steam flows through the reheater While HP and IP turbines are located in the same single

(REHTR) as shown in Fig. 1 1. casing, we should remember that the operation mode of

2.2 UST plant layout the UST turbine is different from land use turbine. That

An outline of the arrangement of the UST plant on a is, the UST turbine requires both start and stop opera-

Fig. 2

vessel is shown below (Fig. 2). The space required for tions within one voyage and the HP/IP turbine casing in

a UST plant is the same as a conventional steam tur- particular is subjected to repeated thermal loads.

bine plant. The severe difference between HP turbine inlet steam

temperature and LP turbine inlet steam temperature

3. UST turbine may cause uneven deformation of the casing and conse-

3.1 Components of UST turbine quent steam leakage from the horizontal flange of HP/

The UST turbine is an MHI high performance tur- IP casing. For that purpose, a thermal shield structure

bine based on the latest technology and which has a good has been applied, which has been proven in MHI land-

track record for land use. It consists of a high/interme- Fig. 4

use turbines (Fig. 4).

Fig. 3

diate pressure turbine (Fig. 3), a low pressure turbine, a

UST plant

2-stage feed water heating system + steam air heater

Economizer

Economizer

Reheater Intermediate

pressure

turbine

Reheater

Low

pressure

Deaerator turbine

Main boiler

Main

boiler

High Main turbine

Circulating Feed

pump pressure

water turbine

pump Shaft generator

Feed Distilling

water plant

heater Main

condenser

Drain tank

Fig. 1 Configuration of UST plant ELEVATION

Fig. 2 Layout of UST plant

Ahead nozzle valve

Thermal shield Thermal shield Shield steam

IP/T inlet

Dummy ring

Reheated steam inlet Dummy ring

Fig. 3 Cross-section of UST high/intermediate pressure turbine Fig. 4 Thermal shield and dummy ring

Mitsubishi Heavy Industries, Ltd.

Technical Review Vol. 44 No. 3 (Sep. 2007)

2

3.2.2 Technology to improve turbine performance term operation, because there are no moveable parts,

Figures 5 and 6 show the latest technologies that were gas damper etc., in the flow path of the combustion gas.

introduced for the UST to improve turbine performance. Also, in order to ensure the main steam conditions, we

have adopted the vertical twin header super heater sys-

4. UST boiler tem shown in Fig. 8 to secure the heat transfer area and

4.1 UST boiler also use 18 Cr stainless steel which is resistant to high-

The re-heater is designed to achieve a specified steam temperature corrosion.

temperature by using the reheat burner (Fig. Fig. 77). The 4.2 Boiler performance verification test

reheat burner stops automatically in low steam flow con- 4.2.1 Boiler cold model test

ditions (reduction of tube cooling effect), so that the tubes For the development of the UST boiler, a cold boiler

are not exposed to high temperature combustion gas. In model test (fluid dynamic simulation test) was carried

this situation, there is no damaging effect on the re- out using the 1/4 scale simulator at MHI Nagasaki's

heater tubes because the combustion gas temperature Fig. 9

R&D Center (Fig. 9). In this test the distribution of

from the main furnace will be low. Therefore, the re- the exhaust gas temperature at the boiler outlet could

heater is thoroughly protected, simply by stopping the be analyzed and optimized. As a result, we ensured a

reheat burner. uniform gas flow by using shielding material at the

In addition, high reliability is to be expected over long- exhaust gas outlet.

Reduction in

leak steam

Steam

Flow

Tenon blade Integrated shroud blade (ISB)

Conventional type UST type

(conventional type) (UST type)

2D stationary blade 3D stationary blade

Fig. 5 3D stationary blade (low pressure turbine reaction stage) Fig. 6 Conventional tenon blade and UST type integral shroud

Adoption of the 3D stationary blade which improves blade performance blade (ISB)

by optimizing the blade form three-dimensionally. The use of ISB reduces steam leaks at the blade periphery by improving

the steam seal section as in the above drawing.

Exhaust gas economizer

Reheater

Main boiler

Main burner

Reheat burner

Fig. 7 Outline drawing of UST boiler Fig. 8 Outline drawing of super heater Fig. 9 Gas flow test model

Mitsubishi Heavy Industries, Ltd.

Technical Review Vol. 44 No. 3 (Sep. 2007)

3

4.2.2 Combustion test of reheat burner

The reheat burner of the UST boiler is installed in 5. Shaft generator

the path of the boiler exhaust gas flow. Therefore it was One shaft generator motor (SGM) is located on the

necessary to check the influence of the exhaust gas flow intermediate shaft. Under normal operation, the SGM

when burning the reheat burner, so an ignition test and is used as a generator to improve the plant efficiency

a low load firing test were carried out using the test fur- (SG mode). If the operator wants 100% MCR power

nace of the burner manufacturer. As a result, an excellent when one re-heater is out of service, the SGM can be

state of combustion and ignition performance were con- changed to assist motor mode (PAM mode). By this op-

Fig. 10

firmed in an extreme gas flow (Fig. 10). eration, the propulsion power will be recovered to 100%

4.2.3 Plant simulator Fig. 12

MCR (Fig. 12).

In order to understand the dynamic behavior of the

UST plant, we built a plant model and developed a simu- 6. Influence on environment

lator which can deal with all kinds of load fluctuations. 6.1 Comparison of exhaust gas components during

As shown in Fig. 1 1 , the simulator has a function

11 navigation (gas single fuel combustion mode)

which displays the changes taking place in each part of Under normal sea going conditions in gas burning

the plant as the trend data and the dynamic behavior of mode, SOx is not emitted at all from the propulsion plant,

each part become analyzable, thus contributing to the and the emission of NOx and CO 2 from the steam tur-

automation and instrumentation of the UST plant. bine plant is the smallest of all propulsion plants. The

A dynamic condition analysis in all operations was UST's emissions are smaller than conventional steam

necessary to analyze the dynamic behavior of the UST Fig. 13

turbine plants due to fuel saving (Fig. 13).

plant. This plant simulator can simulate all loads and

operations.

The dynamic behavior of each parameter (for example,

the steam temperature and pressure, fuel flow and M/T

output) can be identified and they are displayed as trend

data in the table below (Fig. 11).

It is very important to verify the dynamic condition

of each parameter and this simulation is also useful for

the development of the control and automation system

for the UST plant (both turbine and boiler).

Fig. 12 Shaft generator

3

: CO2

: NOx

Fig. 10 Combustion of reheat burner at low load

(Standard)

1

0

CST UST DFE GTCC

CST : Conventional steam turbine (standard)

UST : Ultra steam turbine

DFE : Dual fuel engine + electric propulsion motor

GTCC: Gas turbine combined cycle + electric propulsion motor

Fig. 11 Example simulator screen Fig. 13 Composition of exhaust gas components during

navigation

Mitsubishi Heavy Industries, Ltd.

Technical Review Vol. 44 No. 3 (Sep. 2007)

4

8

7. Conclusion

7 : NOx This paper has introduced the UST plant which can

: SOx

achieve an efficiency equivalent to that of other diesel

6 : CO2

propulsion engines, while maintaining high reliability,

5 which is the primary advantage of conventional tur-

bine ships. Its major characteristics are summarized

4

as follows:

3 (1) Higher plant efficiency: about 15% improvement in

fuel consumption.

2

(2) High reliability and safety: the same high reliability

(Standard) and safety as conventional turbine plants.

1

(3) Low maintenance costs: similar low maintenance

0

CST UST DFE GTCC costs to conventional turbine plants.

(Diesel mode) (4) Environmentally friendly: about 15% decrease in

emissions (NOx, SOx, CO2)

Fig. 14 Comparison of exhaust gas components during

loading and unloading (5) Flexibility of fuel selection: flexible burning of any

fuel combination, oil only, gas only and dual.

6.2 Comparison of exhaust gas components during (6) Extremely long plant life: operational for more than

loading and unloading 40 years.

During loading and unloading, steam turbine plants Finally, while hoping that the UST plant developed

(CST and UST) have dual fuel burning modes. However, through the collective efforts of MHI will be actually

a DFE plant is restricted to diesel mode only, because realized in the near future, we would like to express

gas mode cannot be used in low load conditions. There- our sincere appreciation to all parties concerned for

fore the NOx and SOx emissions from a DFE plant are the wide-ranging guidance and cooperation extended

Fig. 14

higher than other plants (Fig. 14). to us during the development period of about a year

The majority of emission regulations for current en- and a half.

vironmental measures are targeted at coastal zones and

Reference

port areas including those of Europe and the west coast

of the US. The introduction of stricter regulation is (1) Ito, M., Development of Mitsubishi High Efficiency Marine

Propulsion Plant (Ultra Steam Turbine), KANRIN (Bulletin

expected in the near future especially concerning exhaust

of The Japan Society of Naval Architects and Ocean Engi-

gas components during loading and unloading. In this neers) Vol. 12 (2007) p.43

regard, the UST plant is the most outstanding compared

with other plants.

Makoto Ito Kazuyoshi Hiraoka Shoichi Matsumoto Kenji Tsumura

Mitsubishi Heavy Industries, Ltd.

Technical Review Vol. 44 No. 3 (Sep. 2007)

5

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- 02 Listening HandoutDocument8 pages02 Listening HandoutCinthia Lidia Hidrogo PaulinoPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- IACS Rec.96Document6 pagesIACS Rec.96Cinthia Lidia Hidrogo PaulinoPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- ISO 5488 Accomm LaddersDocument8 pagesISO 5488 Accomm LaddersCinthia Lidia Hidrogo Paulino0% (1)

- URL - StabilityDocument14 pagesURL - StabilityCinthia Lidia Hidrogo PaulinoPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Electrical InstallationsDocument51 pagesElectrical InstallationsCinthia Lidia Hidrogo Paulino100% (1)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- 09-7220 UT 728 S R1 - Design PresentationDocument22 pages09-7220 UT 728 S R1 - Design PresentationCinthia Lidia Hidrogo PaulinoPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Brief Presentation of Ut-Design UT 739 L: Multifunctional, Deep Water Anchor Handling, Tug, Supply and Service VesselDocument32 pagesBrief Presentation of Ut-Design UT 739 L: Multifunctional, Deep Water Anchor Handling, Tug, Supply and Service VesselCinthia Lidia Hidrogo PaulinoPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- SESAMDocument2 pagesSESAMCinthia Lidia Hidrogo PaulinoPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Drewry Publications IDocument126 pagesDrewry Publications ICinthia Lidia Hidrogo PaulinoPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- MotorDocument17 pagesMotorCinthia Lidia Hidrogo PaulinoPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Variables GuideDocument103 pagesVariables GuideCinthia Lidia Hidrogo PaulinoPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Proceeding of Rasce 2015Document245 pagesProceeding of Rasce 2015Alex ChristopherPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Financial Accounting 2 SummaryDocument10 pagesFinancial Accounting 2 SummaryChoong Xin WeiPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- E0 UoE Unit 7Document16 pagesE0 UoE Unit 7Patrick GutierrezPas encore d'évaluation

- On Derridean Différance - UsiefDocument16 pagesOn Derridean Différance - UsiefS JEROME 2070505Pas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Corrosion Fatigue Phenomena Learned From Failure AnalysisDocument10 pagesCorrosion Fatigue Phenomena Learned From Failure AnalysisDavid Jose Velandia MunozPas encore d'évaluation

- Dynamics of Machinery PDFDocument18 pagesDynamics of Machinery PDFThomas VictorPas encore d'évaluation

- Ito Na Talaga Yung FinalDocument22 pagesIto Na Talaga Yung FinalJonas Gian Miguel MadarangPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- CT SizingDocument62 pagesCT SizingMohamed TalebPas encore d'évaluation

- German Atv-Dvwk Rules and StandardsDocument25 pagesGerman Atv-Dvwk Rules and StandardsMehmet Emre Bastopcu100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Chronic Kidney DiseaseDocument15 pagesChronic Kidney Diseaseapi-270623039Pas encore d'évaluation

- Ron Kangas - IoanDocument11 pagesRon Kangas - IoanBogdan SoptereanPas encore d'évaluation

- Parliament of India: Rajya SabhaDocument64 pagesParliament of India: Rajya SabhaSivapothuraju KonathalaPas encore d'évaluation

- Soosan Crane Training: (Principles)Document119 pagesSoosan Crane Training: (Principles)Boumediene CHIKHAOUIPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Excon2019 ShowPreview02122019 PDFDocument492 pagesExcon2019 ShowPreview02122019 PDFSanjay KherPas encore d'évaluation

- Decision Making and The Role of Manageme PDFDocument20 pagesDecision Making and The Role of Manageme PDFRaadmaan RadPas encore d'évaluation

- Working With Difficult People Online WorksheetDocument4 pagesWorking With Difficult People Online WorksheetHugh Fox IIIPas encore d'évaluation

- Science7 - q1 - Mod3 - Distinguishing Mixtures From Substances - v5Document25 pagesScience7 - q1 - Mod3 - Distinguishing Mixtures From Substances - v5Bella BalendresPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Kahneman & Tversky Origin of Behavioural EconomicsDocument25 pagesKahneman & Tversky Origin of Behavioural EconomicsIan Hughes100% (1)

- Theory GraphDocument23 pagesTheory GraphArthur CarabioPas encore d'évaluation

- Appendix - Pcmc2Document8 pagesAppendix - Pcmc2Siva PPas encore d'évaluation

- 3 Carbohydrates' StructureDocument33 pages3 Carbohydrates' StructureDilan TeodoroPas encore d'évaluation

- 05 x05 Standard Costing & Variance AnalysisDocument27 pages05 x05 Standard Costing & Variance AnalysisMary April MasbangPas encore d'évaluation

- Azimuth Steueung - EngDocument13 pagesAzimuth Steueung - EnglacothPas encore d'évaluation

- Famous Russian PianoDocument10 pagesFamous Russian PianoClara-Schumann-198550% (2)

- Sam Media Recruitment QuestionnaireDocument17 pagesSam Media Recruitment Questionnairechek taiPas encore d'évaluation

- Waterstop TechnologyDocument69 pagesWaterstop TechnologygertjaniPas encore d'évaluation

- Acute Coronary SyndromeDocument30 pagesAcute Coronary SyndromeEndar EszterPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Fusion Implementing Offerings Using Functional Setup Manager PDFDocument51 pagesFusion Implementing Offerings Using Functional Setup Manager PDFSrinivasa Rao Asuru0% (1)

- (500eboard) Version Coding Model 140 As of MY 1995Document1 page(500eboard) Version Coding Model 140 As of MY 1995Saimir SaliajPas encore d'évaluation

- Cisco SDWAN Case Study Large Global WANDocument174 pagesCisco SDWAN Case Study Large Global WANroniegrokPas encore d'évaluation