Académique Documents

Professionnel Documents

Culture Documents

To Study The Analysis, Design and Behavior of Corrugated Steel Silo

Transféré par

Mohammed AlnasharTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

To Study The Analysis, Design and Behavior of Corrugated Steel Silo

Transféré par

Mohammed AlnasharDroits d'auteur :

Formats disponibles

IJSRD - International Journal for Scientific Research & Development| Vol.

5, Issue 05, 2017 | ISSN (online): 2321-0613

To Study the Analysis, Design and Behavior of Corrugated Steel Silo

Kishor B Vaghela1 Hiten J Shah2

1

Assistant Professor 2Director

1,2

Department of Applied Mechanics

1,2

Government Engineering College-Rajkot, Gujarat

Abstract— The paper deals with Analysis and Design of

large cylindrical steel silos composed of horizontally

corrugated sheets with vertical stiffeners. The 3D FE

calculations were carried out with the commercial finite

element code ‘‘STAAD Pro. software ’’. Usually in India,

we are using IS and ACI codes for analysis and design of

steel silo, but in no one they have describe about corrugated

steel silo. It is important to know about the change in grain

pressure and wall thickness, when we are using corrugated

sheet instead of plain sheet during analyze and design the

silo. In this paper we have calculated grain pressures and

external load by using IS codes and other literature, then

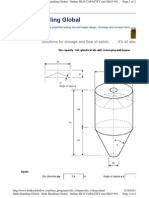

prepared geometry and analyzed it on STAAD Pro. Fig. 1: Common circular metal silo forms

Software to compare the result of hoop stress in vertical B. Structural forms of Metal silos with Corrugated

wall. Value of hoop stress in manual calculation and in Sheeting:

STAAD Pro. are almost matching, except in the case of top

Small and medium size silos are often built from corrugated

and bottom plate. It shows that our assumptions while

sheets. The commonest application involves corrugations

modeling the silos are correct.

running circumferentially around the silo. Unstjffened

Key words: "Steel Silo", "Corrugated Sheet", "Vertical

construction of this form is often used up to about 6m in

Storage System", “Grain Storage System", "Steel Silo with

height. Once vertical stiffeners are adopted, they must be

Stiffner”

assumed to carry the entire vertical load in the wall, as the

difference in stiffness between a compressible corrugation

I. INTRODUCTION

and a vertical stiffener is such that the stiffener will collapse

A. Definition & Classification: before the wall carries a significant part of the total load.

The terms "bin," "silo," and "bunker" have different

meanings in different parts of the world and may vary from

author to author. In India as per IS-4995 silo is a bin circular

or polygonal in plan. Bunker is a bin whose cross section in

plan would be square or rectangular. In the United State the

term "bin" generally includes both silos and bunkers, silos

being deep bins and bunkers shallow bins [10].

Metal silos are currently produced in a great variety

of forms: circular, square and rectangular in plan-form;

squat bunkers and tall cylinders; silos with smooth isotropic

walls, stiffened walls, built from horizontally or vertically

corrugated sheets with orthogonal stiffeners, or patented

special wall forms; silos supported on the ground and silos Fig. 2: Silos with corrugated sheet and vertical stiffener

elevated on skirts or columns. Some large and very squat silos have been built in

Steel silos and bunkers can be classified as an recent years from light corrugated sheets with the

either structural, made of structural steel plates, or the sheet corrugations running vertically. External bands are required

metal type, made of either plain or corrugated light-gauge to support the internal pressures in the silo, but the required

metal. Unless they are corrugated or have stiffeners buckling strength in axial compression is easily achieved.

attached, steel plates have little bending strength. Walls of For both forms of corrugated silo, the buckling resistance

circular units act horizontally as tension membranes. under wind is often critical, and should be determined from a

Vertically however, they may be subject to compressive calculation of the cylinder as an orthotropic eccentrically

stress and be prone to buckling. stiffened shell.

C. Standards and Codes of Practice:

The only codes of practice on bins and silos which give

guidance on structural design are the ACI code (ACI

313-77,1984) which relates only to concrete structures,

the British code for the design of farm silage silos (BS

5061, 1974) and the Japanese code for small aluminum

silos (JIS, 1987).

All rights reserved by www.ijsrd.com 198

To Study the Analysis, Design and Behavior of Corrugated Steel Silo

(IJSRD/Vol. 5/Issue 05/2017/047)

Neither of these latter codes is helpful to the designers of age of the material, degree of compaction, and changes of

large steel silos required at mines, railheads, power environment.

stations, port facilities and similar sites, for the storage For pressure computation, the properties considered

of grain, coal, mineral ores and industrial chemicals. most important are unit weight (γ), angle of internal friction

The best known tank design codes (AWWA D100- (Ф, approximately the same as angle of repose), and the

79,1979; API-620,1970) are relatively simple and appear coefficient of friction (µ) between the stored material and the

to be quite satisfactory for simple fluid storage tanks. bin wall. The coefficient of friction, µ, between stored

However, their provisions are less satisfactory for bulk material and the bin wall may also vary with age of the bin.

solids storage structures, for which the loadings are Whether the wall is metal or concrete, it will probably

much more complex, and the consequent structural become smoother with age, from abrasion by the sliding

behavior and failure criteria more involved. material.

II. STORAGE FACILITIES III. CALCULATION OF PRESSURE DUE TO STORED

MATERIALS

Storing of bulk materials in silos and bunkers is essential to

agricultural, mining, mineral processing, chemical, shipping, Early silo designers, not recognizing the importance of

and other industries. Silos serve as long-term storage. It may vertical friction between the stored material and the silo wall,

serve as terminals for receiving and shipping. Such terminals assumed lateral pressures to vary hydrostatically. That

usually involve multiple transportation modes; for example, assumption (even when reduced material densities were

material arriving by truck may be stored in the terminal used) often gave wastefully conservative results.

temporarily and then discharged into train, barge, or ocean- Subsequently, analytical methods were developed that

going vessel for shipping elsewhere. Terminals usually have consider wall friction. These methods provide means for

sophisticated systems for weighing materials being received computing: (1) Pressure of the stored material against

and shipped. Methods of loading and unloading silos depend vertical walls, sloping surfaces, and flat bottoms; (2) Friction

largely on the type of material to be handled and on forces and wall compression forces; and (3) Vertical

economic and functional considerations. pressures at various depths in the stored material itself.

Some of these methods give static pressures

A. Various Types Of Grain Storage Systems: (pressures when material is at rest) only. During filling or

1) Plywood Bins emptying of the silo, pressures can be higher than static.

2) Hay Bales: Pressures may differ further if there is any lack of symmetry

3) Silage Bags: eccentrically located discharge openings, for example. The

4) Commercially Available: structural designer needs to know the final total pressure, or

5) Concrete Blocks or Road Barriers: "design pressure." This design pressure can be estimated by

6) Concrete Silos: modifying the computed static pressures to account for

material movement, eccentric discharge, and other pressure-

B. Advantages Of Vertical Storage Over The Horizontal

affecting conditions, or by using analytical methods intended

Storage System:

to give design pressures directly.

Simultaneous & continuous loading and unloading is

possible. A. Methods Of Computing Static Pressures Due To

Moisture free storage is possible. Granular Material:

Dust losses are reduced for powdery materials. These methods are based on equilibrium of the stored

Space is utilized more efficiently. material in a static condition. Elastic interaction with the bin

Very huge amount of cost is generally involved in structure is not considered, nor is strain energy in either the

construction of a single silo. So, it is required to concentrate stored material or the structure. These analytical methods

in selection of alternate solution to optimize the cost before correlate with test measurements with varying degrees of

going for the design. agreement.

Steel silos are wide spread around the world and are Various methods use for calculating horizontal pressure due

used for storing different materials, including Cement, to storage materials are,

Fertilizers, Grains and raw materials. 1) The JANSEEN method

It provides a fairly big storage capacity within a short 2) The AIRY method

period of time. 3) The REIMBERT method

IS code is follow JANSEEN method for calculating

C. Stored Materials: horizontal pressure. Derivation of this method describe

The physical properties of materials stored in silos and below.

bunkers influence the flowability of the material and the 1) The Janssen Method for Computing Static Pressure:

forces that the material applies to the silo walls and bottom. The major breakthrough in computation of stored material

Obviously those properties will vary from one material to pressures came in 1895 when H. A. Janssen developed

another, but they may also vary within a supposedly uniform equation for computing lateral and vertical pressures of

material. In materials of this latter type (coal is a good granular material in deep bins. Janssen’s method is based on

example) large variations of properties occur between equilibrium of a thin horizontal layer of stored material.

materials from different sources or even in materials from a Equating the vertical the vertical forces to zero gives:

common source. The physical properties may also very with

qA + yAdy = A [q + dyx(dq/dy) ] + µp(Udy)

All rights reserved by www.ijsrd.com 199

To Study the Analysis, Design and Behavior of Corrugated Steel Silo

(IJSRD/Vol. 5/Issue 05/2017/047)

In which: A rectangular silo with side lengths a and b will

q = static vertical pressure at depth Y have different pressures on short and long sides. A common

A = area of horizontal cross section through the silo procedure is to let R = a/4 when computing pressure on the

U = perimeter of horizontal cross section short side a, and for the long side to assume R = a'/4, where:

p = pressure of stored material against walls at a' = 2ab/(a + b) (2.4)

depth Y below surface of stored material An alternate value of a' suggested by Reimbert is to use

a' = (2ab-a2)/ b (2.5)

The silo wall designer needs to know the total

vertical force applied to the wall by friction from the stored

material. This force, from materials above any depth Y, is

equal to the weight of those materials minus the upward

force from vertical pressure q. Per unit length of wall, the

friction force from above is:

V = R(yY-q) (2.6)

B. Flow Patterns:

Flow of stored material from silos is of two main patterns,

funnel flow (core flow) and mass flow. In mass flow, all of

the stored material is in motion during discharge. In funnel

flow, movement occurs only in a channel within the stored

material, and this channel is surrounded by nonflowing

Fig. 5: Horizontal lamina for derivation of Janssen’s material.

equations 1) Mass-Flow Silos:

Substituting kq for p, and "hydraulic radius" R for In mass-flow silos the hopper is sufficiently steep and

A/U and rearranging, the differential equation of equilibrium smooth to cause flow of all the solids without stagnant

becomes: regions whenever any solid is withdrawn. Mass-flow silos

dq/dy = γ – (µkq/R) (2.1) are usually recommended for cohesive materials (coal, for

The solution to this differential equation is the example), materials that degrade with time, powders (unless

Janssen formula for vertical pressure at depth Y: means of withdrawal such as aeration are used), and

q = (yR/µk)[1-e-µkY/R] (2.2) materials in which segregation needs to be minimized. Mass

Koenen improved Janssen's method by introducing flow will occur if three conditions are met:

the term k = (1-sinФ)/(1+sinФ), or simply k = tan2(45° - 1) The outlet must be large enough for the material to flow

Ф/2), which is the Rankine coefficient for active earth without arching.

pressure the ratio of horizontal pressure to vertical. Hence, to 2) The flow-control device must permit material to flow

compute the horizontal pressure p, eq. (2-1) is multiplied by through the entire opening area.

k. Thus, the Janssen equation for horizontal pressure is: 3) The hopper walls must be smooth enough and steep

p = (yR/µ) x [1-e-µkY/R] 2.3) enough to allow the material to slide, thus expanding the

The term in brackets in eq. (2-2) may be easily flow channel upward until it meets the vertical walls of

calculated using a hand calculator. However, its values are the silo.

given by Table A-l (Appendix A) for various values of 2) Funnel-Flow Silos:

µkY/R. The wall friction force is µp per unit area of wall at Funnel flow occurs when the hopper is not sufficiently steep

depth Y. Vertical friction forces cause vertical force in the and smooth to force material to slide along the walls, or

wall: compression if the wall is supported from below, when the outlet of a mass-flow bin is not fully effective. In a

tension if suspended from above. Integrating from the top of funnel-flow silo, solid flows toward the outlet through a

the stored material to depth Y, the vertical force in the wall channel that forms within stagnant material. Usually, funnel-

(per unit of wall perimeter) at depth Y is: flow bins are suitable only for coarse, free-flowing or slightly

cohesive, nondegrading solids in which segregation is

unimportant. Yet, at the time of this writing, funnel-flow

silos are the more prevalent type.

3) Expanded Flow:

Besides the two main flow patterns, there is an intermediate

The above derivation makes no assumption as to type called "expanded flow." Expanded flow is a

shape of the silo cross section. If the cross section is circular, combination of mass flow and funnel flow. The lower

then the hydraulic radius is: portion of the hopper operates in mass flow and the upper in

R = area/perimeter = (πD2/4)/(πD) = D/4 funnel flow. To prevent ratholing in the upper, funnel-flow

In which D is the inside diameter. portion of the mass-flow hopper, the flow channel should

For a square silo of side length a, R = area/perimeter expand to a diagonal or diameter equal to or greater than the

= a/4. For regular polygonal silos a slightly conservative critical rathole diameter determined for the material to be

approximation is R = D/4, where De is the diameter of a stored.

circle whose area equals that of the polygon.

All rights reserved by www.ijsrd.com 200

To Study the Analysis, Design and Behavior of Corrugated Steel Silo

(IJSRD/Vol. 5/Issue 05/2017/047)

IV. ANALYSIS OF CORRUGATED STEEL SILO aw = bw / (bw + bi) = 0.25

µeff (During Filling) = 0.49

A. Problem Selection:

µeff (During Emptying) = 0.47

Name

of During Filling in During Emptying

Pressur kN/m2 kN/m2

e

Max 43.2

WxR = 43.20 WxR =

Pw 0

91.1

Max Ph WxR/µf = 87.37 WxR/µe =

4

(WxR)/(µfxλf 174.7 (WxR)/(µexλe 91.1

Max Pv

Fig. 6: Line sketch of corrugated steel silo )= 3 )= 4

Data: Table 1: Calculate max design pressures as per IS 4995 (Part

Internal Diameter of Silo = m23.0 I) 1974.

Type of Silo = FBS Variation of pressure along depth: Pi (z) = Pi max x (1-e-

Eave Height of Silo = 12.45 mtr. z/z0)

Peak Height of Silo = 19.35 Note: Where P stands for pressure & suffix i stand for w, h or

Angle of Roof with Vertical = 31.0° v corresponding to the pressure Pw, Ph or Pv respectively

Material to Be Stored = Wheat During filling Zof = R/ (µfxλf) = 23.30

B. Calculation Of All Design Parameters As Per Is: 4995 During emptying Zoe = R/ (µexλe) = 12.15

(Part-1) -1974 Table-1.2: Ht. of Pressure at the C.G. of

C.G. ring from level surface

Density of wheat W = 7.50 kN/m3 Shel Xf

of ring

Hydraulic radius R = 5.76 m l e- =

from z/z0 Ph x Pv x Pw x

Pressure ratio during filling λf = 0.50 Rin

Levele f

z/zo 1-e-

Xf Xf Xf

Pressure ratio during emptying λe = 1.00 g

d

f z/zo

kN/m kN/m kN/m

Angle of internal friction Ф = 28.0° No.

surfac

f

2 2 2

Angle of wall friction during filling δ = 21.0° e

Angle of wall friction during emptying δ = 16.8°

0.1 0.9 0.1

Co-efficient of wall friction during filling µf = 0.38 15 2.46 8.75 17.50 4.33

1 0 0

Co-efficient of wall friction during emptying µe = 0.30

0.1 0.8 0.1

14 3.29 11.50 23.00 5.69

C. Evaluation of the Effective Wall Friction Coefficient for 4 7 3

Corrugated Sheet: 0.1 0.8 0.1

13 4.12 14.15 28.31 7.00

8 4 6

0.2 0.8 0.1

12 4.95 16.72 33.43 8.27

1 1 9

0.2 0.7 0.2

11 5.78 19.19 38.38 9.49

5 8 2

0.2 0.7 0.2

10 6.61 21.57 43.14 10.67

8 5 5

0.3 0.7 0.2

9 7.44 23.87 47.75 11.81

2 3 7

0.3 0.7 0.3

8 8.27 26.10 52.20 12.91

5 0 0

0.3 0.6 0.3

7 9.10 28.24 56.49 13.97

9 8 2

0.4 0.6 0.3

6 9.93 30.31 60.63 14.99

3 5 5

Fig. 7: Corrugated Sheet Profile.

For wall (corrugated or profile steel sheeting or 0.4 0.6 0.3

5 10.76 32.31 64.62 15.98

walls with horizontal ribs), the effective wall friction is a 6 3 7

function of the material's internal friction, friction against a 0.5 0.6 0.3

4 11.59 34.24 68.48 16.93

flat wall, and the profile of the sheeting. 0 1 9

The effective wall friction may be taken as: 0.5 0.5 0.4

3 12.42 36.10 72.19 17.85

µeff = (1-aw) tanФi+ aw µw 3 9 1

Where: 0.5 0.5 0.4

2 13.25 37.89 75.78 18.74

µeff is the effective wall friction coefficient; 7 7 3

tanФi is the internal friction coefficient; 0.6 0.5 0.4

1 14.08 39.62 79.25 19.59

µw is the wall friction coefficient (acting against a flat wall 0 5 5

surface); Table 2: During filling pressure at the C.G. of ring from

aw is the wall contact factor. level surface.

All rights reserved by www.ijsrd.com 201

To Study the Analysis, Design and Behavior of Corrugated Steel Silo

(IJSRD/Vol. 5/Issue 05/2017/047)

During Filling Horizontal Pressure Vs Height of During Emptying Horizontal Pressure Vs Height of

Silos

Silos

15.00

Height in Meter

15.00

Height in Meter

10.00

10.00

5.00

5.00

0.00

0.00

0.00 20.00 40.00 60.00 80.00

0.00 10.00 20.00 30.00 40.00 50.00

Pressure in kN/m2

Pressure in kN/m2

Chart 2: Horizontal pressure during emptying Vs height of

Chart 1: Horizontal pressure during filling Vs height of silo.

silo.

Ht. of Pressure at the C.G. of

C.G. ring from level surface D. Application Of Horizontal Pressure And Vertical

Shel Xf

of ring Friction Force On The Vertical Wall In Staad Pro.:

l e- =

from z/z0 Ph x Pv x Pw x Horizontal pressure is increase when height goes increase

Rin z/zo 1-e-

Levele f Xf Xf Xf from level surface. So, we have calculated horizontal

g f z/zo

d kN/m kN/m kN/m pressure at bottom of the plate and top of the plate. Then

No. f

surfac 2 2 2 apply this pressure as trapezoidal pressure on each plate at

e each level. Vertical friction forces apply on each plate by

0.2 0.8 0.1 using a uniform pressure option.

15 2.46 16.69 16.69 7.91

0 2 8

0.2 0.7 0.2

14 3.29 21.61 21.61 10.24

7 6 4

0.3 0.7 0.2

13 4.12 26.20 26.20 12.42

4 1 9

0.4 0.6 0.3

12 4.95 30.48 30.48 14.45

1 7 3

0.4 0.6 0.3

11 5.78 34.49 34.49 16.35

8 2 8

0.5 0.5 0.4

10 6.61 38.22 38.22 18.12

4 8 2

0.6 0.5 0.4

9 7.44 41.71 41.71 19.77

1 4 6

0.6 0.5 0.4 Fig. 8: Application of Horizontal Pressure in STAAD Pro.

8 8.27 44.98 44.98 21.32

8 1 9

0.7 0.4 0.5 V. RESULTS & CONCLUSION

7 9.10 48.03 48.03 22.77

5 7 3

0.8 0.4 0.5

6 9.93 50.88 50.88 24.12

2 4 6

0.8 0.4 0.5

5 10.76 53.54 53.54 25.38

9 1 9

0.9 0.3 0.6

4 11.59 56.03 56.03 26.56

5 9 1

1.0 0.3 0.6

3 12.42 58.34 58.34 27.65

2 6 4

1.0 0.3 0.6

2 13.25 60.50 60.50 28.68

9 4 6

1.1 0.3 0.6 Figure 9: Stress Sx in silo wall with stiffener due to

1 14.08 62.53 62.53 29.64 horizontal

6 1 9

Table 3: During emptying pressure at the C.G. of ring from

level surface

All rights reserved by www.ijsrd.com 202

To Study the Analysis, Design and Behavior of Corrugated Steel Silo

(IJSRD/Vol. 5/Issue 05/2017/047)

Figure 10: Stress Sx in silo wall without stiffener due to Because of this equivalent thickness of the corrugated

horizontal sheet it reduces the value of hoop stress and ultimately it

Ht. of reduces the thickness of the vertical wall.

C.G. Provide [2] Stiffness of vertical stiffener use in the modeling of silo

Equival Hoop

She of d Thk. wall is very small so, there is not considerable difference

Phx Hoop ent Stress

ll ring of in the value of Sx (Hoop Stress), when we are modeling

Xf in Tensi Thk. of Manua

Rin from Corruga silo with stiffener or without stiffener.

kN./ on In Rect. lly in

g Level ted [3] Where, Sx = Hoop tension force per unit length per unit

m2 kN. Plate In kN./m

No. ed Plate In thickness

mm 2

surfa mm [4] Stiffness of vertical stiffener is very small so, it can not

ce restraint the corrugated sheet from both the ends. Value

192.2 of hoop stress in manual calculation and in STAAD Pro.

15 2.46 16.69 2.00 6.72 28611 are almost matching, except in the case of top and

7

248.9 bottom plate. It shows that our assumptions while

14 3.29 21.61 2.00 6.72 37038 modeling the silos are correct.

0

301.7

13 4.12 26.20 2.00 6.72 44908 REFERENCES

8

12 4.95 30.48

351.1

2.00 6.72 52258 [1] John W. Carson, Ph.D., M.ASCE1 “Limits of Silo

8 Design Codes” 2014 American Society of Civil

397.3 Engineers.

11 5.78 34.49 3.20 8.00 49664

1 [2] M. Esther Magdalene Sharon, C.V.Kavitha Abirami and

10 6.61 38.22

440.3

3.20 8.00 55037 K.Alagusundaram “Grain Storage Management in

0 India” Journal of Postharvest Technology 02 (01): 012-

480.5 024, January’ 2014

9 7.44 41.71 3.20 8.00 60068

5 [3] M.Wojcik, P.Iwicki, J.Tejchman “3D buckling analysis

518.2 of a cylindrical metal bin composed of corrugated

8 8.27 44.98 3.20 8.00 64778

3 sheets strengthened by vertical stiffeners” Science

553.3 Direct/Thin-Walled Structures 49 (2011) 947–963.

7 9.10 48.03 3.20 8.00 69166

3 [4] E.Gallego, C.González-Montellano, A.Ramírez,

586.1 F.Ayuga, E.Gallego et al. “A simplified analytical

6 9.93 50.88 3.20 8.00 73265 procedure for assessing the worst patch load location on

2

616.7 circular steel silos with corrugated walls” Science

5 10.76 53.54 3.20 8.00 77093 Direct / Engineering Structures 33 (2011) 1940–1954.

4

645.4 [5] P.Iwicki, M.Wójcik, J.Tejchman “Failure of cylindrical

4 11.59 56.03 4.00 8.63 74787 steel silos composed of corrugated sheets and columns

1

672.0 and repair methods using a sensitivity analysis” Science

3 12.42 58.34 4.00 8.63 77874 Direct/Engineering Failure Analysis 18 (2011) 2064–

6

697.0 2083.

2 13.25 60.50 4.00 8.63 80765 [6] Rotter J.M. “Guide for the economic design of circular

0

720.3 metal silos” Spon Press; 2001.

1 14.08 62.53 4.00 8.63 83470 [7] Adem Dogangun1; Zeki Karaca2; Ahmet Durmus3; and

5

Table 4: Hoop stress applied on plate due to horizontal Halil Sezen, M.ASCE4. “Cause of Damage and Failures

pressure during emptying in Silo Structures” Journal Of Performance Of

Constructed Facilities © ASCE / March /April 2009 /

65

[8] Adam J. Sadowski1 and J. Michael Rotter, F.ASCE2.

“Buckling in Eccentrically Discharged Silos and the

Assumed Pressure Distribution” 858 / Journal Of

Engineering Mechanics © ASCE/July 2013

[9] Y.M. Cheng1; K. T. Chau2; L. J. Xiao3; and N. Li4.

“Flow Pattern for a Silo with Two Layers of Materials

with Single or Double Openings” 1278/Journal Of

Geotechnical and Geoenvironmental Engineering ©

ASCE / September 2010

Chart. 3: Comparison of hoop stress results from STAAD [10] IS-4995(Part-1&2) – 1974 “Code of practice for RCC

Pro. and Manual calculation bins”, Bureau of Indian Standards, New Delhi.

[11] IS-875 (Part-1,2&3) – 1987 “Indian code of practice for

A. Following observation can be made from the above loads for buildings and structures”, Bureau of Indian

stress diagrams due to Horizontal pressure during filling Standards, New Delhi.

and emptying condition. [12] IS-1893 (Part-1) 2002 “Indian standard criteria for

[1] We have use equivalent thickness of the corrugated earthquake resistant design of structure”, Bureau of

sheet while modeling of the silo in STAAD Pro. Indian Standards, New Delhi.

All rights reserved by www.ijsrd.com 203

To Study the Analysis, Design and Behavior of Corrugated Steel Silo

(IJSRD/Vol. 5/Issue 05/2017/047)

[13] IS-9178 (Part-1) – 1979 “Criteria for design of steel

bins for storage of bulk materials”, Bureau of Indian

Standards, New Delhi.

[14] ACI – 313R91 “Commentary on standard practice for

design and construction of concrete silos and stacking

tubes for storing granular materials”, American

Concrete Institute

[15] IS-277 – 2003 “Galvanized steel sheet (plain and

corrugated) specification”, Bureau of Indian Standards,

New Delhi.

[16] IS-800 – 2007 “Code of practice for general

construction in steel”, Bureau of Indian Standards, New

Delhi.

All rights reserved by www.ijsrd.com 204

Vous aimerez peut-être aussi

- Stresses in SiloDocument12 pagesStresses in SiloENAENA187Pas encore d'évaluation

- Design of Silo: Presented by Shyamala.C M.Tech (Storage Engg.) 2015604605Document26 pagesDesign of Silo: Presented by Shyamala.C M.Tech (Storage Engg.) 2015604605Darshan PanchalPas encore d'évaluation

- Examples Modern Silo DesignDocument7 pagesExamples Modern Silo DesignRui TerrasPas encore d'évaluation

- Construction Sequence of SilosDocument44 pagesConstruction Sequence of SilosIshratPas encore d'évaluation

- Silo PDFDocument6 pagesSilo PDFCalPas encore d'évaluation

- Presentation Construction Sequence of Silos 1503761554 305716Document44 pagesPresentation Construction Sequence of Silos 1503761554 305716MOHAMMED MOHSINPas encore d'évaluation

- BHEL Panki VOL III (Mechanical)Document116 pagesBHEL Panki VOL III (Mechanical)anishgirmePas encore d'évaluation

- Bins & Feeders in Cement IndustryDocument29 pagesBins & Feeders in Cement IndustryNaelPas encore d'évaluation

- Bucket ElevatorDocument6 pagesBucket ElevatorbetojulioPas encore d'évaluation

- SiloDocument7 pagesSiloMayr - GeroldingerPas encore d'évaluation

- FEECO Complete OfferingsDocument8 pagesFEECO Complete OfferingsawfahPas encore d'évaluation

- Silo Design: Mech D (4'2) Roll No: 16311A03M4 16311A03M7 16311A03P7Document44 pagesSilo Design: Mech D (4'2) Roll No: 16311A03M4 16311A03M7 16311A03P7Akhilprasad SadigePas encore d'évaluation

- Hopper WordDocument15 pagesHopper WordJani MisterioPas encore d'évaluation

- Storage Silos: General CatalogueDocument32 pagesStorage Silos: General CatalogueNatarajan RavisankarPas encore d'évaluation

- Storage of Bulk Solids - 3Document31 pagesStorage of Bulk Solids - 3Naman GoelPas encore d'évaluation

- IS 9178 - Part 3 PDFDocument75 pagesIS 9178 - Part 3 PDFSOURAVPas encore d'évaluation

- Silo GuideDocument14 pagesSilo GuideMd. Mynul Hossain100% (2)

- IS 4995 (Part 1) 1974Document20 pagesIS 4995 (Part 1) 1974Sumit Narayan0% (1)

- Statik Silo PresentationDocument13 pagesStatik Silo PresentationsajsigalomaPas encore d'évaluation

- MASE 5510 Finite Element AnalysisDocument3 pagesMASE 5510 Finite Element AnalysisdarkrusePas encore d'évaluation

- Design of BinsDocument37 pagesDesign of BinsAgarry Emmanuel100% (1)

- Indian Standard: Criteria For Design of Steel Bins For Storage of Bulk MaterialsDocument27 pagesIndian Standard: Criteria For Design of Steel Bins For Storage of Bulk MaterialsajayaghimirePas encore d'évaluation

- CEMA Elevador de CangilonesDocument20 pagesCEMA Elevador de CangilonesCORDOVA DAVILA HECTOR ALONSOPas encore d'évaluation

- Dynamic Analysis of Steel Silo Using Wind Load As Per Indian Standard IJERTV8IS110206Document4 pagesDynamic Analysis of Steel Silo Using Wind Load As Per Indian Standard IJERTV8IS110206AliPas encore d'évaluation

- Central Cone Silos StructuralDocument28 pagesCentral Cone Silos Structuraldox4use100% (1)

- Silo VoDocument2 pagesSilo Vosuntoshsalvi4859Pas encore d'évaluation

- PDFDocument244 pagesPDFRené Mella CidPas encore d'évaluation

- Silos Design With Different Aspect RatiosDocument9 pagesSilos Design With Different Aspect Ratiosmrnaeem100% (1)

- Westeel Commercial Storage 2016 - WebDocument15 pagesWesteel Commercial Storage 2016 - Webmelgarcia829Pas encore d'évaluation

- 9178 2 PDFDocument39 pages9178 2 PDFvivekPas encore d'évaluation

- Solids Notes 10 Hopper DesignDocument26 pagesSolids Notes 10 Hopper DesignCss GaneshPas encore d'évaluation

- Brochure Tubular DragDocument2 pagesBrochure Tubular DragIvo KovachevPas encore d'évaluation

- Rotary ScrubberDocument14 pagesRotary Scrubberkejriwal_itPas encore d'évaluation

- SILODocument44 pagesSILOClezel MesaPas encore d'évaluation

- Steel Silo With Corrugated WallsDocument8 pagesSteel Silo With Corrugated WallsMaria TnsPas encore d'évaluation

- Hopper DesignDocument49 pagesHopper Designmhd badhrul bin baharPas encore d'évaluation

- FEECO Handbook Section4Document62 pagesFEECO Handbook Section4hashem62100% (2)

- Silo Capacity CalculationDocument1 pageSilo Capacity Calculationlbc123Pas encore d'évaluation

- Silo BucklingDocument14 pagesSilo BucklingrahilmlPas encore d'évaluation

- Bin and Hopper Design LectureDocument73 pagesBin and Hopper Design Lecturejigarshah21Pas encore d'évaluation

- 9178 3Document72 pages9178 3govimanoPas encore d'évaluation

- Storage Silo, Bolting Silo, Mild Steel Silo, Lime Storage Silo, Manufacturers, Ahmedabad, Gujarat, IndiaDocument2 pagesStorage Silo, Bolting Silo, Mild Steel Silo, Lime Storage Silo, Manufacturers, Ahmedabad, Gujarat, Indiaaarticleseansmo50% (2)

- Silo CountyT1 DS Rev02-562791007ebe3Document2 pagesSilo CountyT1 DS Rev02-562791007ebe3Andor MolitoriszPas encore d'évaluation

- Modern Technological Developments in The Storage and Handling of Bulk Solids - EditDocument26 pagesModern Technological Developments in The Storage and Handling of Bulk Solids - Editpavan317Pas encore d'évaluation

- CEMA 6 Belt Conveyors Belt AlignmentDocument2 pagesCEMA 6 Belt Conveyors Belt Alignmentali kajbafPas encore d'évaluation

- Grain Silo Storage SizesDocument8 pagesGrain Silo Storage SizesTyler HallPas encore d'évaluation

- Bucket Elevators, Bucket Conveyors and MoreDocument22 pagesBucket Elevators, Bucket Conveyors and MoreDilnesa EjiguPas encore d'évaluation

- DesignDocument4 pagesDesignJigneshkumar PatelPas encore d'évaluation

- 3100 CV 0001Document11 pages3100 CV 0001tranceinttPas encore d'évaluation

- CasoEstudio PervaporaciónDocument17 pagesCasoEstudio PervaporaciónValentina SánchezPas encore d'évaluation

- Bucket ConveyorsDocument9 pagesBucket ConveyorsAirom Lee PenuliarPas encore d'évaluation

- Review On Thin Shell Cylindrical Steel SilosDocument5 pagesReview On Thin Shell Cylindrical Steel SilosMaurizio FalconieriPas encore d'évaluation

- Contributions of Different Standards and Codes For The Design of Silo: A ReviewDocument7 pagesContributions of Different Standards and Codes For The Design of Silo: A ReviewFreddie KooPas encore d'évaluation

- IJSDR190491Document21 pagesIJSDR190491RohimPas encore d'évaluation

- MODULE 1 - Intro To Structural Steel DesignDocument10 pagesMODULE 1 - Intro To Structural Steel DesignGail Nathalie LiraPas encore d'évaluation

- Tel: (978) 649-3300 Fax: (978) 649-3399 Tel: (805) 541-0901 Fax: (805) 541-4680Document48 pagesTel: (978) 649-3300 Fax: (978) 649-3399 Tel: (805) 541-0901 Fax: (805) 541-4680gkdora57489% (9)

- CFSEI Tech Note X Bracing L001-09Document8 pagesCFSEI Tech Note X Bracing L001-09Jane EyrePas encore d'évaluation

- Ijfeat: Comparative Analysis of Cold Form Steel and Hot Rolled Steel Structure For Static Shed Type Steel StructureDocument7 pagesIjfeat: Comparative Analysis of Cold Form Steel and Hot Rolled Steel Structure For Static Shed Type Steel StructureMITHUN BDMLPas encore d'évaluation

- Module 1 - Intro To Design of Steel StructuresDocument10 pagesModule 1 - Intro To Design of Steel StructuresJuan Paulo DiazPas encore d'évaluation

- (IJETA-V11I1P1) :gaurav Singh Raghav, Mohsin Khan AgwanDocument10 pages(IJETA-V11I1P1) :gaurav Singh Raghav, Mohsin Khan AgwanIJETA - EighthSenseGroupPas encore d'évaluation

- Outline: Spring Functions & Types Helical SpringsDocument46 pagesOutline: Spring Functions & Types Helical SpringsMohammed AlnasharPas encore d'évaluation

- Project Planning: Jesper LarsenDocument19 pagesProject Planning: Jesper LarsenMohammed AlnasharPas encore d'évaluation

- Steel Silos With Different Aspect Ratios: I - Behaviour Under Concentric DischargeDocument25 pagesSteel Silos With Different Aspect Ratios: I - Behaviour Under Concentric DischargeBayari ArPas encore d'évaluation

- Routine Press Maintenance Routine Press Maintenance Routine Press Maintenance Routine Press MaintenanceDocument42 pagesRoutine Press Maintenance Routine Press Maintenance Routine Press Maintenance Routine Press MaintenanceMorshedPas encore d'évaluation

- FT0511 1192 AbsDocument1 pageFT0511 1192 AbsMohammed AlnasharPas encore d'évaluation

- Silo - Tips Table of ContentDocument18 pagesSilo - Tips Table of ContentMohammed AlnasharPas encore d'évaluation

- Feeds and SpeedsDocument1 pageFeeds and SpeedsMohammed AlnasharPas encore d'évaluation

- Problem Analysis TechniquesDocument10 pagesProblem Analysis TechniquesIRMTraining100% (5)

- Programme Specification (Master) : A-GeneralDocument33 pagesProgramme Specification (Master) : A-GeneralMohammed AlnasharPas encore d'évaluation

- 174-175 Technical A Boring Calculation of Cutting Forces PDFDocument2 pages174-175 Technical A Boring Calculation of Cutting Forces PDFMohammed AlnasharPas encore d'évaluation

- FintoriaDocument1 pageFintoriaMohammed AlnasharPas encore d'évaluation

- Thompson - Comparativa Entre Sist. de GuiadoDocument10 pagesThompson - Comparativa Entre Sist. de GuiadoalexPas encore d'évaluation

- تقرير برنامج ماجستيرDocument6 pagesتقرير برنامج ماجستيرMohammed AlnasharPas encore d'évaluation

- ScreeningDocument16 pagesScreeningMohammed AlnasharPas encore d'évaluation

- The Discrete Element Method For The Simulation of Ball MillsDocument7 pagesThe Discrete Element Method For The Simulation of Ball MillsMohammed AlnasharPas encore d'évaluation

- DR A CombinedDocument14 pagesDR A CombinedArief SaladdinPas encore d'évaluation

- 174-175 Technical A Boring Calculation of Cutting Forces PDFDocument2 pages174-175 Technical A Boring Calculation of Cutting Forces PDFMohammed AlnasharPas encore d'évaluation

- Obram Cheese LineDocument16 pagesObram Cheese LineMohammed AlnasharPas encore d'évaluation

- v1 AB4013 DillonDocument12 pagesv1 AB4013 DillonMohammed AlnasharPas encore d'évaluation

- Content in Revit - Families: Bill KnittleDocument12 pagesContent in Revit - Families: Bill KnittleMohammed AlnasharPas encore d'évaluation

- Numerical Analysis of Impact Events in A Centrifugal Impact Pin MillDocument5 pagesNumerical Analysis of Impact Events in A Centrifugal Impact Pin MillMohammed AlnasharPas encore d'évaluation

- Min PDFDocument1 pageMin PDFMohammed AlnasharPas encore d'évaluation

- CC-S1 SaleCNC ManualDocument44 pagesCC-S1 SaleCNC ManualMohammed AlnasharPas encore d'évaluation

- Module ListDocument24 pagesModule ListMohammed AlnasharPas encore d'évaluation

- Ch3 Steps in FEMDocument39 pagesCh3 Steps in FEMMohammed AlnasharPas encore d'évaluation

- Portfolio Management Professional Reference ListDocument1 pagePortfolio Management Professional Reference ListMohammed AlnasharPas encore d'évaluation

- 4977 96eeDocument3 pages4977 96eeMohammed AlnasharPas encore d'évaluation

- Fire Water Tank ModelDocument1 pageFire Water Tank ModelMohammed AlnasharPas encore d'évaluation

- TS A Plant FinalDocument10 pagesTS A Plant FinalSaurabh TyagiPas encore d'évaluation

- Cleats CatalogueDocument73 pagesCleats Cataloguefire123123Pas encore d'évaluation

- 16620YDocument17 pages16620YbalajivangaruPas encore d'évaluation

- PassivityDocument15 pagesPassivitySmarties AcademyPas encore d'évaluation

- RRB JE CBT-2 Electronics Tech Paper With Key 31-8-2019 1st ShiftDocument55 pagesRRB JE CBT-2 Electronics Tech Paper With Key 31-8-2019 1st ShiftKuldeep SinghPas encore d'évaluation

- Coek - Info The Fabric of RealityDocument5 pagesCoek - Info The Fabric of RealityFredioGemparAnarqiPas encore d'évaluation

- Sqluser v11r1Document199 pagesSqluser v11r1samnolenPas encore d'évaluation

- Thermocouple: Seeback EffectDocument8 pagesThermocouple: Seeback EffectMuhammadHadiPas encore d'évaluation

- Three - Dimensional Viscous Confinement and Cooling of Atoms by Resonance Radiation PressureDocument6 pagesThree - Dimensional Viscous Confinement and Cooling of Atoms by Resonance Radiation PressureWenjun ZhangPas encore d'évaluation

- MathDocument2 pagesMathWessam ElmongyPas encore d'évaluation

- Notes For Class 11 Maths Chapter 8 Binomial Theorem Download PDFDocument9 pagesNotes For Class 11 Maths Chapter 8 Binomial Theorem Download PDFRahul ChauhanPas encore d'évaluation

- Chord Tone Improvisation Part IDocument38 pagesChord Tone Improvisation Part I2018 01097Pas encore d'évaluation

- DA Savitz - Interpreting Epidemiologic Evidence - Strategies For Study Design and Analysis 2003 PDFDocument329 pagesDA Savitz - Interpreting Epidemiologic Evidence - Strategies For Study Design and Analysis 2003 PDFrindy_bilhaniPas encore d'évaluation

- Orthographic Views in Multiview Drawings: Autocad 2015 Tutorial: 2D Fundamentals 5-1Document30 pagesOrthographic Views in Multiview Drawings: Autocad 2015 Tutorial: 2D Fundamentals 5-1Uma MageshwariPas encore d'évaluation

- Driver LCI 150W 500-850ma FlexC NF h28 EXC3 enDocument7 pagesDriver LCI 150W 500-850ma FlexC NF h28 EXC3 enMoustafa HelalyPas encore d'évaluation

- C191HM Powermeter and Harmonic Manager CommunicationsDocument30 pagesC191HM Powermeter and Harmonic Manager CommunicationsRoberto GarridoPas encore d'évaluation

- 1 Tail & 2 Tail TestDocument3 pages1 Tail & 2 Tail TestNisha AggarwalPas encore d'évaluation

- NumpyDocument23 pagesNumpymuzammil jawedPas encore d'évaluation

- 3yr-Astro-Properies of StarsDocument35 pages3yr-Astro-Properies of StarsBharath V YPas encore d'évaluation

- Food Preparation, Terms and DefinitiosDocument2 pagesFood Preparation, Terms and DefinitiosLacsi, Erica Joy V.Pas encore d'évaluation

- Ampla's Technology ArchitectureDocument4 pagesAmpla's Technology ArchitecturesyeadtalhaaliPas encore d'évaluation

- Pile Test LoadingDocument10 pagesPile Test LoadingFeyisayo Ayomide OgunladePas encore d'évaluation

- KD-131 Asme Viii Div3Document2 pagesKD-131 Asme Viii Div3comar85Pas encore d'évaluation

- Same Virtus: Alarm ListDocument23 pagesSame Virtus: Alarm ListLacatusu Mircea100% (1)

- VT300 User ManualDocument21 pagesVT300 User ManualLuvPas encore d'évaluation

- Practical Report Guideline EEE250Document8 pagesPractical Report Guideline EEE250MOHD ASYRAAF BIN SAIDINPas encore d'évaluation

- PDC NitDocument6 pagesPDC NitrpshvjuPas encore d'évaluation

- Hitachi HDDs Repair Scheme Based On MRT ProDocument21 pagesHitachi HDDs Repair Scheme Based On MRT ProvicvpPas encore d'évaluation

- Microporous and Mesoporous Materials: SciencedirectDocument8 pagesMicroporous and Mesoporous Materials: SciencedirectAssyakurPas encore d'évaluation

- 02 Survey Calculations - PpsDocument96 pages02 Survey Calculations - PpsLeo Ivan Aviles RicaldiPas encore d'évaluation

- N5X Tuning SpreadsheetDocument79 pagesN5X Tuning SpreadsheetWhyAnN20Pas encore d'évaluation