Académique Documents

Professionnel Documents

Culture Documents

Design Calculation of Spherical MSM Free Sliding Bearing - 319 MT

Transféré par

Chandan VatsCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design Calculation of Spherical MSM Free Sliding Bearing - 319 MT

Transféré par

Chandan VatsDroits d'auteur :

Formats disponibles

AUTHOR :- Up-Gradation to two Lane with Paved Shoulder for Section CONSULTANT :- Accrete Consulting Engineers Pvt. Ltd.

from Km. 58.000 to Km. 91.600 Balotra to Sanderao via CONTRACTOR :- M/s H.G. Infra Engineering Ltd.

Jalore Section of NH 325 in the state of Rajasthan on EPC QUANTITY :- 4+16+8 = 28 Nos.

Mode REVISION :- 0

CLIENT :- CE (NH) PWD, Rajasthan PREPARED BY :- Prashant

SUBJECT :- Design Verification CHECKED BY :- Jaiprakash

Sanfield (India) Limited, Subsidiary of Maurer SE, Munich, Germany. This paper is strictly confidential. The disclosure to unauthorized third parties is

prohibited and may result in claims for damages.

General :- The design verification of the bearing is conducted in accordance with IRC:83 (Part- IV) and European Technical Approval ETA-06/0131

Location :- Bridge at C.A. Ch. 68+575, Ch. 90+880, Ch. 89+260

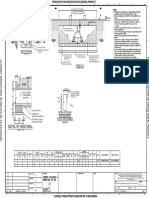

Type :- MSM SPHERICAL FREE SLIDING BEARING 319 MT (Type - B4)

ULS - Loads: Grade of Concrete (Pedestal) 50

max,Nsd = 3390.00 kN Grade of Concrete (Girder) 50

min,Nsd = 390.00 kN

Vx,sd = 101.70 kN Vy,sd = 101.70 kN

Vr,sd = 143.83

Vx,d = 100.00 mm i.e + 50.00 mm / - 50.00 mm

Vy,d = 50.00 mm i.e + 25.00 mm / - 25.00 mm

max,d = ± 0.010 rad

SLS - Loads:

max,Nsk = 3190.00 kN Nqd = 1914.00 kN

min,Nsk = 300.00 kN

perm,Nsk = 1276.00 kN

Vx,sk = 95.70 kN Vy,sk = 95.70 kN

max,k = ± 0.010 rad

maxNsd - Maximum vertical load in ULS Vx,sk - Horizontal Longitudinal Forces in SLS V,sd - Resultant Horizontal Force in ULS

minNsd - Minimum vertical load in ULS Vy,sk - Horizontal Transverse Forces in SLS Vx,d - Longitudinal Movement

maxNsk - Maximum vertical load in SLS Nqd - Variable Vertical Load in SLS Vy,d - Transverse Movement

minNsk - Minimum vertical load in SLS Vx,sd - Horizontal Longitudinal Force in ULS αdmax - Maximum of rotation

perm, Nsk - Permanent vertical load in SLS Vy,sd - Horizontal Transverse Force in ULS

Nomenclature :-

L = Diameter of the MSM® disc

R = Radius of the sphere part

fk = Characteristic strength acc. ETA

fy = Yield strength of the used steel grade

fu = Tensile strength of the used steel grade

k = Factor considering the ambient temperature higher than 35°C

m = Partial safety factor

A = Contact area

Ar = Reduced contact area

Aco = Area of the compressed concrete

Ed = Modulus of elasticity of steel (210000 N/mm²)

e = Eccentricity

µ = Sliding friction of MSM® to polished stainless steel

p = Centric pressure on MSM® in SLS

D,kal = Outer Diameter of the sphere part

D,druck = Diameter of the compressed concrete (conversion from the rectangular area)

k = Rotation capacity with SLS

d = Rotation capacity with ULS

= Rotation safety from EN 1337

Index/Date :- Prepared by :- Checked by :- Sheet :-

Monday, July 23, 2018 Prashant Jaiprakash Sheet 1 of 6

Design Input :-

MSM Diameter (mm) = 220

MSM Thickness (mm) = 8

Radius of Curvature (mm) = 330

Concave Internal Diameter (mm) = 220

Bottom Effective Diameter (mm) = 300

Bottom Base Size L x W (mm) = 300 x 300

Bottom Base Thickness (mm) = 25

Bottom Base Total Thickness (mm) = 48.69

Bottom Wall Thickness (mm) = 40.00

Bottom Base wall Outer (mm) = 300.00

Callote Diameter (mm) = 250

Callote above Portion Thickness (mm) = 12

Callote Total Thickness (mm) = 37

Curved Surface Clearance (mm) = 8.90

Top Slide Plate Effective Diameter (mm) = 300.00

Top Slide Plate Size L x W (mm) = 400 x 350

Top Slide Plate Thickness (mm) = 34

S/S Sheet Size L x W (mm) = 400 x 350

S/S Sheet Thickness (mm) = 3

H.T.S. Bolts Diameter (mm) = 16 Grade 8.8

Length of H.T.S. Bolts (mm) = 35

Number of H.T.S. Bolts Per Component = 4 Nos.

Flange / Bolts Lug Thickness (mm) = 12

Dowels for Pedestal (Dia. x Length) = 40 x 120 mm

Dowels for Superstructure (Dia. x Length) = 40 x 120 mm

Bearing Total Height (mm) = 110

Design Output :-

MSM® Pressure according ETA-06/0131 (Annex C) & As per IRC :

3390 KN < 3495.37 KN Hence, Safe

83 (Part-IV), Clause 4.3 in ULS

Separation check acc. EN1337-7, section 6.2.2 & As per IRC : 83

26.36 mm < 27.50 mm Hence, Safe

(Part-IV), Clause 5.4.4

Diameter of Spherical Disc (Calotte) - (acc. EN-1337-1, Clause 5.4

246.60 mm < 250.00 mm Hence, Safe

a & IRC : 83 (Part-IV), Clause 5.2)

Pressure in Concrete Structure at Girder (Super-structure) - 3390.00 KN < 3499.46 KN Hence, Safe

(according to IRC: 83 (Part-IV), Annexure F ) 51.67 2

53.33 2

Hence, Safe

N/mm < N/mm

Pressure in Concrete Structure at Pedestal - (according to IRC: 83 3390.00 KN < 3468.49 KN Hence, Safe

(Part-IV), Annexure F ) 52.13 2

< 53.33 2

Hence, Safe

N/mm N/mm

Bearings backing plate in Bending (The verifications are conducted

0.63 mm < 0.65 mm Hence, Safe

to IRC : 83 (Part - IV), Clause 5.6)

Bearings Bottom plate in Bending (The verifications are conducted

0.59 mm < 0.65 mm Hence, Safe

to IRC : 83 (Part - IV), Clause 5.6)

Sliding Capacity of Top Plate 50.00 mm < 90.00 mm Hence, Safe

Total Resistance offered by Anchorage / Bolts (acc. IRC: 83 (Part-

143.83 KN < 436.15 KN Hence, Safe

IV), Annexure E)

Dowels / Sleeve Design Check for Pedestal 7.49 Mpa < 26.67 Mpa Hence, Safe

Dowels / Sleeve Design Check for Girder 7.49 Mpa < 26.67 Mpa Hence, Safe

Index/Date :- Prepared by :- Checked by :- Sheet :-

Monday, July 23, 2018 Prashant Jaiprakash Sheet 2 of 6

MSM® Pressure according ETA-06/0131 (Annex C) & As per IRC : 83 (Part-IV), Clause 4.3 (in ULS) :-

The permissible stress is reduced due to exceeding the category temperature above 35°.

Max. ambient temperate: 45 °C e

Reduction: 20 %

Assuming,

L = 220.00 mm

R = 330.00 mm

R/L = 1.50 Ar

fk = 180.00 N/mm²

m = 1.40

k = 0.80 L

max NSd ≤ Ar x k x fk / m

where,

Ar = xA

= (1 - 0.75 x x e / L)

e = e1+e3

e1 = µ,max x R

e3 = maxd x (R + b)

µ,max = 1.6 also 0.02 ≤ µ,max < 0.08

15 + MSM (As per IRC : 83 (Part-IV), Clause 5.4.3.1 (b))

µ,max = 0.015

e1 = 6.60 mm

e3 = 3.30 mm

e = 9.90 mm

= 0.89

Ar = 33982.77 mm²

thus,

max,Nsd ie 3390.00 kN ≤ Ar x k x fk / m = 3495.37 kN

Hence, Safe

Separation check acc. EN1337-7, section 6.2.2 & As per IRC : 83 (Part-IV), Clause 5.4.4 (in SLS) :-

Condition of separation of Sliding Surfaces is satisfied when, e t < L / 8

where,

et = e1+e3

e1 = µ,max x R

e3 = max,k x (R + b)

µ,max = 1.6 / (15 + (min,Nsk x 4 / ( x L²))) also 0.02 ≤ µmax < 0.08

µ,max = 0.0699

e1 = 23.06 mm

e3 = 3.30 mm

et = 26.36 mm < L/8 = 27.50 mm

Hence, Safe

Diameter of Spherical Disc (Calotte):

D,kal = L + 2 x R x (max,k + )

max,k = 0.010

= 0.030 (acc. EN-1337-1, Clause 5.4 a)

thus,

D,kal = 246.60 mm < 250.00 mm (Provided)

Hence, Safe

Pressure to structure ULS : (Eccentricity acc. ETA-06/0131, Annex D or as per IRC : 83 (Part - IV), Clause No. 5.4.3) :-

et = e1+e3

where,

e1 = µ,max x R

e3 = max,d x (R + b)

µ,max = 0.020 (As calculated in check (1) above)

Vr,sd = √(Vx,sd² + Vy,sd²) = 143.83 kN

b = 28.00 mm for bottom and - 76.59 mm for top

thus,

e1 = 6.60 mm

e3 = 3.58 mm for bottom and 2.53 mm for top

et = 10.18 mm for bottom and 9.13 mm for top

Index/Date :- Prepared by :- Checked by :- Sheet :-

Monday, July 23, 2018 Prashant Jaiprakash Sheet 3 of 6

Concrete Superstructure in ULS :-

max,Nsd ≤ Aco x c,zul or

c = max,Nsd/Aco ≤ c,zul

Aco = (1 - 0.75 x x e / D,druck) x D,druck² x / 4

c,zul = 53.33 N/mm²

D,druck = 300.00 mm

Top Dispersion = 600.00 x 600.00

Aco = 65614.90 mm²

max,Nsd i. e. 3390.00 kN ≤ 3499.46 kN

Hence, Safe

c = 51.67 N/mm² ≤ 53.33 N/mm²

Hence, Safe

Concrete Pedestal in ULS :-

max,Nsd ≤ Aco x c,zul or

c = max,Nsd/Aco ≤ c,zul

Aco = (1 - 0.75 x x e / D,druck) x D,druck² x / 4

c,zul = 53.33 N/mm²

D,druck = 300.00 mm

Pedestal = 600.00 x 600.00

Aco = 65034.25 mm²

max,Nsd i. e. 3390.00 kN ≤ 3468.49 kN

Hence, Safe

c = 52.13 N/mm² ≤ 53.33 N/mm²

Hence, Safe

Bearings backing plates :- (The verifications are conducted to IRC : 83 (Part - IV), Clause 5.6)

△w < △wzul

where,

△wzul = h x (0.45 - 2 x √h/L)

△w = (0.55 / L) x kc x c x kb x b (For details of kc, ac, kb & ab, refer IRC : 83 (Part - IV), Clause 5.6.1)

(i) Top plate:

h = 3.00 mm

tp = 34.00 mm tp,min req. = 21.17

σmax = 83.92

kc = 1.64 c = 162.41 mm²

kb = 1.05 b = 0.91

D,druck = 300.00 mm Lo = 300.00 mm

Nqd = 1914.00 KN Ecd = 35355.34 N/mm2 (5000 √fck)

perm,Nsk = 1276.00 KN Ecrd = 11785.11 N/mm2

△wzul = 0.65 mm

△w = 0.63 mm ≤ 0.65 mm

Hence, Safe

Index/Date :- Prepared by :- Checked by :- Sheet :-

Monday, July 23, 2018 Prashant Jaiprakash Sheet 4 of 6

(ii) Base plate:

h = 3.00 mm

t'b = tb,min + 0.6 x (tb,max - tb,min)

where, tb,min, req. = 10.61

tb,max = 48.69 mm tb,min = 25.00 mm

σmax = 83.92

t'b = 39.2156952 mm

kc = 1.64 c = 162.41 mm²

kb = 1.05 b = 0.84

D,druck = 300.00 mm Lo = 300.00 mm

Nqd = 1914.00 KN Ecd= = 35355.34 N/mm2 (5000 √fck)

perm,Nsk = 1276.00 KN Ecrd= = 11785.11 N/mm2

△wzul = 0.65 mm

△w = 0.59 mm ≤ 0.65 mm

Hence, Safe

Sliding Capacity of Top Plate :-

Slide Plate Dimension used = 400.00 mm length x 350.00 mm wide

MSM Diameter = 220.00 mm dia.

Preset in Long. Dir = 0.00 mm

Longitudinal Movement = 400.00 - 220.00 = 180.00 mm

M'ment possible in one direction = 180 / 2 + 0

90.00 mm > 50.00 mm

Hence, Safe

M'ment possible in other direction = 180 / 2 - 0 =

90.00 mm > 50.00 mm

Hence, Safe

Transverse Movement = 350.00 - 220.00 = 130.00 mm

= + 65.00 > + 25.00 mm

Hence, Safe

Index/Date :- Prepared by :- Checked by :- Sheet :-

Monday, July 23, 2018 Prashant Jaiprakash Sheet 5 of 6

Calculation of Anchorage (Acc. IRC: 83 (Part-IV, Annexure E) :-

i Bolts

Bolt design shall be deemed satisfactory when

Vr,sd < µk x min,Nsd + Vpd

ms

where,

µk = 0.6 (Friction Factor Steel to Concrete Surface)

ms = 1.2 (Safety Factor against Sliding)

Vpd = Total Shear Resistance offered by the Bolts calculated as below:

= n x 0.6 x Fy x A

m

No of bolts used, n = 4 Nos. Bolt Diameter = 16 mm

C. Sec. Area of one Bolt (A) = 157 mm2 Total C. Sec. Area of Bolts (n x A) = 628.00 mm2

Grade of Bolts = 8.8 m = 1.25

Spec. min. Yield Strength (Fy) = 800.00 MPa (IS 1367)

(Vpd) = 4 x 0.6 x 800 x 157

1.25

= 241152.00 N or 241.15 kN

Thus, putting in the equation,

Vr,sd < µk x min,Nsd + Vpd

ms

143.83 < 0.6 x 390.00 + 241.15

1.2

= 143.83 < 436.15 kN

Hence, Safe

ii Dowels Dia. ( Dld ) = 40 mm

For Pedestal

Length ( Dll ) = 120 mm

Pressure in Concrete < 26.67 Mpa

Vr,sd x 1000

Dld x Dll x n

= 7.49 < 26.67 MPa

Hence, Safe

iii Dowels Dia. ( Dld ) = 40 mm

For Girder

Length ( Dll ) = 120 mm

Pressure in Concrete < 26.67 Mpa

Vr,sd x 1000

Dld x Dll x n

= 7.49 < 26.67 MPa

Hence, Safe

Index/Date :- Prepared by :- Checked by :- Sheet :-

Monday, July 23, 2018 Prashant Jaiprakash Sheet 6 of 6

Vous aimerez peut-être aussi

- Online LRC login details for Bihar judgesDocument2 pagesOnline LRC login details for Bihar judgesChandan VatsPas encore d'évaluation

- Design of Thrust Block for Transmission PipelineDocument56 pagesDesign of Thrust Block for Transmission PipelineChandan VatsPas encore d'évaluation

- B.O.Q. (BUILT-UP) : S.No. Partmark Description Qty. Unit Weight WeightDocument1 pageB.O.Q. (BUILT-UP) : S.No. Partmark Description Qty. Unit Weight WeightChandan VatsPas encore d'évaluation

- Chapter 10Document14 pagesChapter 10Chandan VatsPas encore d'évaluation

- Estimation Goyal GDocument9 pagesEstimation Goyal GChandan VatsPas encore d'évaluation

- Lec-1@introduction Review of Basic Concepts in MechanicsDocument4 pagesLec-1@introduction Review of Basic Concepts in MechanicsBharath BhushanPas encore d'évaluation

- Canon D420 - Windows 8 Notice - ENGDocument1 pageCanon D420 - Windows 8 Notice - ENGSaulPas encore d'évaluation

- Section at A-A' Raft Detail Rf1: As/Plan As/PlanDocument1 pageSection at A-A' Raft Detail Rf1: As/Plan As/PlanChandan VatsPas encore d'évaluation

- Kusum Shaw Bridge Design Engineer: Personal DetailsDocument5 pagesKusum Shaw Bridge Design Engineer: Personal DetailsChandan VatsPas encore d'évaluation

- PIPE CULVERT WITH CUSHION (1X1.2m) - (1x900) - 13+140-2Document1 pagePIPE CULVERT WITH CUSHION (1X1.2m) - (1x900) - 13+140-2Chandan VatsPas encore d'évaluation

- Lec-1@introduction Review of Basic Concepts in MechanicsDocument4 pagesLec-1@introduction Review of Basic Concepts in MechanicsBharath BhushanPas encore d'évaluation

- Clear Cover To Main Reinf.: Width Depth D' Eff DepthDocument6 pagesClear Cover To Main Reinf.: Width Depth D' Eff DepthChandan VatsPas encore d'évaluation

- Lec 10 PDFDocument2 pagesLec 10 PDFChandan VatsPas encore d'évaluation

- Lec 7 PDFDocument2 pagesLec 7 PDFChandan VatsPas encore d'évaluation

- Indian Army: 10+2 Technical Entry Scheme Course - 42 Commencing From Jan 2020Document10 pagesIndian Army: 10+2 Technical Entry Scheme Course - 42 Commencing From Jan 2020Chandan VatsPas encore d'évaluation

- Aayush Sangal CVDocument2 pagesAayush Sangal CVChandan VatsPas encore d'évaluation

- 1 PDFDocument1 page1 PDFChandan VatsPas encore d'évaluation

- 02 - Bearing - 32m (Spherical) - Type of Bearing Revised PDFDocument18 pages02 - Bearing - 32m (Spherical) - Type of Bearing Revised PDFChandan VatsPas encore d'évaluation

- Design Calculation of Spherical MSM Fixed Bearing - 319 MTDocument7 pagesDesign Calculation of Spherical MSM Fixed Bearing - 319 MTChandan VatsPas encore d'évaluation

- STR Upto DateDocument7 pagesSTR Upto DateChandan VatsPas encore d'évaluation

- Scope of Work For Design of BridgesDocument1 pageScope of Work For Design of BridgesChandan VatsPas encore d'évaluation

- STR Upto DateDocument7 pagesSTR Upto DateChandan VatsPas encore d'évaluation

- Box Culvert@ Ca CH.-89+750Document3 pagesBox Culvert@ Ca CH.-89+750Chandan VatsPas encore d'évaluation

- Location Map of AM2 ProjectDocument2 pagesLocation Map of AM2 ProjectChandan VatsPas encore d'évaluation

- Free Bearing (CH 0+000)Document1 pageFree Bearing (CH 0+000)Chandan VatsPas encore d'évaluation

- MOM:-MR. Chetan Bhandale, MR - Kulkarni, MR Bhargava, MR JhaffarDocument1 pageMOM:-MR. Chetan Bhandale, MR - Kulkarni, MR Bhargava, MR JhaffarChandan VatsPas encore d'évaluation

- Design of Top SlabDocument2 pagesDesign of Top SlabChandan VatsPas encore d'évaluation

- Finalreport 170308170043Document177 pagesFinalreport 170308170043Chandan VatsPas encore d'évaluation

- Design of Top SlabDocument2 pagesDesign of Top SlabChandan VatsPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Df15a - 20a PDFDocument66 pagesDf15a - 20a PDFJonathan Alexander Rojas BlancoPas encore d'évaluation

- Cobra & Vaal Medical Catalogue IntroductionDocument24 pagesCobra & Vaal Medical Catalogue IntroductionKamlesh Kamlesh EtwaroPas encore d'évaluation

- Assembly Modeling TechniquesDocument29 pagesAssembly Modeling TechniquesChristian JorgensenPas encore d'évaluation

- EarthingDocument19 pagesEarthingraoPas encore d'évaluation

- (381611313) BOQ EarthworkDocument39 pages(381611313) BOQ EarthworkAshish SadaPas encore d'évaluation

- Perenco PCP-2 PL2019-BR-PCP-C2-KPE-MT-Q-001 Macaé-RJ 10070-3000-T29-4-0002Document8 pagesPerenco PCP-2 PL2019-BR-PCP-C2-KPE-MT-Q-001 Macaé-RJ 10070-3000-T29-4-0002Marcos AndréPas encore d'évaluation

- GE-H302-Parts ManualDocument85 pagesGE-H302-Parts ManualJeff LPas encore d'évaluation

- Dentis - OneQ CatalogueDocument52 pagesDentis - OneQ CatalogueAnonymous GMHivr50% (2)

- Mercury - Mariner 25 Service ManualDocument471 pagesMercury - Mariner 25 Service Manualjoao linhanPas encore d'évaluation

- ResultsDocument75 pagesResultsTATATAHERPas encore d'évaluation

- Thomson Glide ScrewDocument12 pagesThomson Glide ScrewRuben PauwelsPas encore d'évaluation

- Pipe Fittings CatalogueDocument0 pagePipe Fittings CatalogueDara AmeliaPas encore d'évaluation

- Volvo Penta 2002 WorkshDocument35 pagesVolvo Penta 2002 WorkshCristian OrdoñezPas encore d'évaluation

- Parts List for Digital Minilab Frontier 355/375, SP-3000, LP1500SC/LP2000SCDocument185 pagesParts List for Digital Minilab Frontier 355/375, SP-3000, LP1500SC/LP2000SCЮрий ДмитриевPas encore d'évaluation

- W169 Rear Door ModuleDocument3 pagesW169 Rear Door ModuleAlex100% (1)

- 16759910-Triumph 2012-2015 Tiger Explorer 1200 Service Repair ManualDocument557 pages16759910-Triumph 2012-2015 Tiger Explorer 1200 Service Repair Manualpaulo cunha75% (4)

- Bugle Hex Drive Roofix Type 17 Wood Tec (Class 2, 3 & 4) : Part NumberDocument18 pagesBugle Hex Drive Roofix Type 17 Wood Tec (Class 2, 3 & 4) : Part NumbersdewssPas encore d'évaluation

- User Manual TFP SeriesDocument24 pagesUser Manual TFP SeriesJaekeun Sung0% (1)

- Determining Decarburization and Carburization F2328Document2 pagesDetermining Decarburization and Carburization F2328Ali MohsinPas encore d'évaluation

- Replacement of fm1 Mill, Trunions, and LinersDocument1 pageReplacement of fm1 Mill, Trunions, and Linerspinion gearPas encore d'évaluation

- Bantog - Finals HW 1Document4 pagesBantog - Finals HW 1Penuel G. BantogPas encore d'évaluation

- BMT 5011E - EnglishDocument28 pagesBMT 5011E - EnglishIng Tino TecorralPas encore d'évaluation

- D10056019 E1Document33 pagesD10056019 E1rcpretoriusPas encore d'évaluation

- Service Manual: Powershift Transmission T16000Document138 pagesService Manual: Powershift Transmission T16000Marcos Aldana VillaldaPas encore d'évaluation

- 12.12.4 Bolt Pre-LoadDocument25 pages12.12.4 Bolt Pre-Loadjingyong123Pas encore d'évaluation

- Drum Motor Manual - All Motors Operation & Parts J102516 R32Document19 pagesDrum Motor Manual - All Motors Operation & Parts J102516 R32Pkk Siam Rayong co-salePas encore d'évaluation

- ShopNotes Issue 12Document32 pagesShopNotes Issue 12benignoPas encore d'évaluation

- Maintaining Resilient Wedge Gate ValvesDocument16 pagesMaintaining Resilient Wedge Gate ValvesAriel DimacaliPas encore d'évaluation

- ELECTRONIC KILOWATT-HOUR METER SPECIFICATIONSDocument30 pagesELECTRONIC KILOWATT-HOUR METER SPECIFICATIONSnatsclimbersPas encore d'évaluation

- Bezares Part List 1000 BZDocument19 pagesBezares Part List 1000 BZreincidentesk8Pas encore d'évaluation