Académique Documents

Professionnel Documents

Culture Documents

Round: Spiral Duct & Fittings

Transféré par

NaniTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Round: Spiral Duct & Fittings

Transféré par

NaniDroits d'auteur :

Formats disponibles

Single-Wall

Eastern Sheet Metal

ROUND

SPIRAL DUCT & FITTINGS

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

Rev.#4 7/16

2

Single-Wall

Eastern Sheet Metal ROUND

SINGLE-WALL ROUND SPIRAL DUCT AND FITTINGS CONSTRUCTION STANDARDS

Positive Pressure

Gauge selection for galvanized steel (ASTM A 653), paint grip steel, type 304 and 316 stainless steel,

and Eastern Polyvinyl Chloride Coated Steel (PCS).*

Fittings are spot welded and/or gorelocked through 40” diameter. All larger fittings are continuously welded except for

PCS fittings. All fittings can be provided as continuously welded if required. All galvanized and PCS spiral duct 6” and

larger is corrugated unless ordered without corrugations. Smaller sizes may also be corrugated. Check with the plant

when ordering. All spiral duct from other materials will not be corrugated.

2005 SMACNA 10” WG 1995 SMACNA 2” WG 1995 SMACNA 10” WG

DUCT SPIRAL SPIRAL SPIRAL

DIAMETER DUCT FITTINGS DUCT FITTINGS DUCT FITTINGS

3”-6” 26 26 26 26 26 26

7”-8” 26 26 26 26 26 26

9”-10” 26 26 26 26 26 26

11”-12” 26 26 26 26 26 24

13”-14” 26 26 26 26 26 24

15”-16” 26 26 24 24 24 22

17”-18” 26 26 24 24 24 22

19”-24” 26 24 24 24 24 22

25”-26” 24 22 24 24 24 22

27”-36” 24 22 24 22 22 20

37”-42” 24 22 22 20 22 20

43”-48” 22 20 22 20 20 20

49”-50” 22 20 22 20 20 20

51”-60” 22 20 20 18 18 18

61”-66” 22 18 18 16 18 16

67”-84” 20 18 18 16 18 16

1985 SMACNA 2” WG 1985 SMACNA 10” WG 1975 SMACNA 10” WG

DUCT SPIRAL SPIRAL SPIRAL

DIAMETER DUCT FITTINGS DUCT FITTINGS DUCT FITTINGS

3”-8” 26 26 26 24 26 20

9”-14” 26 26 26 24 26 20

15”-26” 24 24 24 22 24 20

27”-36” 24 22 22 20 22 20

37”-50” 22 20 20 20 20 18

51”-60” 20 18 18 18 18 18

61”-84” 18 16 18 16 18 16

Gauge selection for aluminum type 3003.

Fittings are spot welded and/or gorelocked through 40” diameter. All larger fittings are continuously welded.

All fittings can be provided as continuously welded if required. Brown & Shapre gauge listed in parentheses.

2005 SMACNA 2” WG: POSITIVE 2005 SMACNA 2” WG: NEGATIVE

DUCT SPIRAL SPIRAL

DIAMETER DUCT FITTINGS DUCT FITTINGS

3”-8” 0.025” (22) 0.032” (20) 0.025” (22) 0.040” (18)

9”-14” 0.025” (22) 0.032” (20) 0.032” (20) 0.040” (18)

15”-26” 0.032” (20) 0.040” (18) 0.040” (18) 0.050” (16)

27”-36” 0.040” (18) 0.050” (16) 0.050” (16) 0.063” (14)

37”-50” 0.050” (16) 0.063” (14) 0.063” (14) 0.080” (12)

51”-60” 0.063” (14) 0.080” (12) consult 0.090” (11)

factory

61”-84” consult 0.090” (11) consult consult

factory factory factory

* Because of the limitations of the construction methods we can use, Eastern PCS may require additional sealing in the field.

While the use of this type of material is widespread, ESM urges engineers to always consider the use of stainless steel whenever

possible for systems other than underground.

Eastern PCS is not recommended for use in high visibility exposed applications. Please refer to the Eastern PCS Product Guide

for more information.

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

3

Single-Wall

Eastern Sheet Metal ROUND

SINGLE-WALL ROUND DUCT AND FITTINGS CONSTRUCTION STANDARDS

Negative Pressure

Gauge selection for galvanized steel (ASTM A 653), paint grip steel, type 304 and 316 stainless steel,

and Eastern Poly Coated Steel (PCS).*

Fittings are spot welded and/or gorelocked through 40” diameter. All larger fittings are continuously welded except for

PCS fittings. Check with the plant when ordering. All fittings can be provided as continuously welded if required. All

galvanized and PCS spiral duct 6” and larger is corrugated unless ordered without corrugations. Smaller sizes may also

be corrugated. All spiral duct from other materials will not be corrugated.

MAX. 2005 SMACNA 2” WG 2005 SMACNA 4” WG 2005 SMACNA 6” WG

DUCT SPIRAL REIN. & REIN & SPIRAL REIN. & REIN. & SPIRAL REIN. & REIN. &

DIAM. DUCT SPACNG FITTINGS SPACNG DUCT SPACNG FITTINGS SPACNG DUCT SPACNG FITTINGS SPACNG

6” 26 26 26 26 26 26

8” 26 26 26 26 26 26

10” 26 26 26 26 26 24

12” 26 26 26 24 24 24

14” 26 24 24 22 24 22

16” 26 24 24 22 26 A 12 22 A 12

18” 26 A 12 24 A 12 26 A 12 24 A 12 26 A 12 22 A 12

20” 26 A 12 24 A 12 26 A 12 24 A 12 26 A 12 22 A 12

22” 26 A 12 24 A 12 26 A 12 24 A 12 24 A 12 22 A 12

24” 26 A 12 24 A 12 26 A 12 24 A 12 24 A 12 22 A 12

30” 26 A 12 24 A 12 24 A 12 22 A 12 24 A 12 20 A 12

36” 26 A 12 24 A 12 24 A 12 22 A 12 22 B 12 20 B 12

42” 26 A 12 22 A 12 22 B 12 20 B 12 22 B 12 18 B 12

48” 24 A 12 22 A 12 22 B 12 20 B 12 20 B 12 18 B 12

54” 24 B 12 22 B 12 22 B 12 18 B 12 20 C 12 18 C 12

60” 24 B 12 22 B 12 22 C 12 18 C 12 20 C 12 18 C 12

66” 24 B 12 20 B 12 20 C 12 18 C 12 18 E 12 16 E 12

72” 22 B 12 20 B 12 20 D 12 18 D 12 18 E 12 16 E 12

78” 22 C 12 20 C 12 20 E 12 18 E 12 18 E 12 16 E 12

84” 22 C 12 20 C 12 20 E 12 18 E 12 18 F 12 16 F 12

90” 22 D 12 18 D 12 18 E 12 16 E 12 18 G 12 16 G 12

96” 22 E 12 18 E 12 18 E 12 16 E 12 18 G 12 16 G 12

MAX. 2005 SMACNA 10” WG 1985 SMACNA 2” WG RIDCS CLASS 1 2” WG

DUCT SPIRAL REIN. & REIN. & SPIRAL REIN. & REIN. & SPIRAL REIN. & REIN. &

DIAM. DUCT SPACNG FITTINGS SPACNG DUCT SPACNG FITTINGS SPACNG DUCT SPACNG FITTINGS SPACNG

6” 26 26 26 24 22 22

8” 26 24 26 24 22 22

10” 26 24 26 24 22 22

12” 24 22 26 24 22 22

14” 24 A 12 22 A 12 26 24 22 22

16” 24 A 12 22 A 12 24 22 22 22

18” 24 A 12 22 A 12 24 22 20 20 F1 20

20” 24 A 12 22 A 12 24 22 20 20 F1 20

22” 24 A 12 20 A 12 24 22 18 20 F1 20

24” 22 A 12 20 A 12 24 20 18 20 F1 20

30” 22 A 12 18 A 12 22 20 16 18 F1 20

36” 20 B 12 18 B 12 22 20 16 16 F1 12

42” 20 B 12 18 B 12 20 18 20 F1 12 16 F1 12

48” 18 C 12 16 C 12 20 18 20 F1 12 14 F1 12

54” 18 D 12 16 D 12 18 16 20 F1 12 14 F1 12

60” 18 E 12 16 E 12 18 16 18 F1 12 12 F1 12

66” 18 E 12 16 E 10 16 14 18 F1 12 12 F1 12

72” 18 F 12 16 F 10 16 14 18 F1 12 12 F1 12

78” 16 G 12 16 G 6 16 14 18 F1 12 10 F1 12

84” 16 G 12 16 G 6 16 14 18 F1 12 10 F1 12

90” 16 G 12 16 G 6 NA NA 18 F1 12 10 F1 12

96” 16 G 12 16 G 6 NA NA 18 F1 12 10 F1 12

A,B,C,D,E,F,G = Angle ring reinforcements per SMACNAS 2005 HVAC DCS Table 3-2

F1 = F1 reinforcement per SMACNA RIDCS, Chapter 12

* Refer to note on the bottom of page 2.

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

4

Eastern Sheet Metal EASTERN TIGHT™

EASTERN TIGHT Fittings will save you money

by reducing installation time by eliminating

joint sealing. They feature a triple-lipped EPDM

rubber gasket, held in place with a 180º hemmed

edge, that provides a reliable, airtight seal.

EASTERN TIGHT Fittings are suitable for use for

temperatures ranging from -20º F to 212º F. When Before Installation Before Installation

tested in accordance with ASTM E84, EASTERN

TIGHT Fittings have flame-spread and smoke-

3”-24” diameter 26”-36” diameter

developed ratings of 0/0.

Full-bodied fittings, couplings, reducers, elbows,

and taps are available with EASTERN TIGHT After Installation After Installation

in even and odd sizes from 3” through 10” in

diameter, and even sizes up to 36” in diameter.

Fittings are secured to the duct with self-

tapping screws uniformly located around the

circumference per SMACNA standards.

EASTERN TIGHT Fittings are available in single-

wall construction, fabricated from galvanized or

paint grip. EASTERN TIGHT Fittings have been

independently tested and can be used to meet

SMACNA Class 3 leakage standards for -2” WG

to +10” WG.

EASTERN TIGHT ROUND SPIRAL DUCT AND FITTINGS CONSTRUCTION STANDARDS

Gauge selection for galvanized steel (ASTM A653) or paint grip.

Fittings are assembled with stitch welds, spot welds, or standing seams and are sealed. All galvanized spiral duct 6” and larger is

corrugated unless ordered without corrugation. Smaller sizes may also be corrugated. Check with the plant when ordering. All spiral

duct from other materials will be smooth.

2005 SMACNA 10” WG POSITIVE 2005 SMACNA 2” WG NEGATIVE

DUCT SPIRAL SPIRAL

DIAMETER DUCT FITTINGS DUCT FITTINGS

3”-6” 26 26 26 26

7”-18” 26 26 26 26

9”-10” 26 26 26 26

11”-12” 26 26 26 26

13”-14” 26 26 26 24

15”-16” 26 26 26 24

17”-18” 26 26 26R 24R

19”-20” 26 24 26R 24R

21”-22” 26 24 26R 24R

23”-24” 26 24 26R 24R

25”-30” 24 22 26R 24R

31”-36” 24 22 26R 24R

R = Reinforcement ring at 12’ maximum spacing. Individual fittings may not have reinforcement.

EASTERN TIGHT Fittings have been tested in our standard gauges for -2” to +10” WG and have been used to meet SMACNA Class 3 leakage standards.

EASTERN TIGHT Fittings and Couplings are covered by one or more of the following U.S. Patents: D437,034; D435,090; D430,482; D427,673;

D427,668; D427,667; D553,238; D551,336; 7287407; D518,885; D517,679; D516,698; D516,697. Other patents pending.

For more information, refer to Eastern Sheet Metal’s EASTERN TIGHT Product Guide.

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

5

Single-Wall Round

Eastern Sheet Metal CONSTRUCTION

Available

Gauges

GALVANIZED 28-14

STAINLESS STEEL 26-18

ALUMINUM 22-14*

SPIRAL DUCT LOCK SEAM (RL —1) PAINT GRIP 26-16

POLYVINYL CHLORIDE COATED 26-18

PERFORATED 22

*(Brown & Sharp thickness = 0.025” - 0.090”)

LOCKSEAM LOCKSEAM

(2) CORRUGATIONS BETWEEN SEAMS

(GALV AND POLYVINYL CHLORIDE COATED

Available

Gauges

GALVANIZED 26-18

SPIRAL DUCT CORRUGATED (RL—1)

STAINLESS STEEL 26-18

ALUMINUM 22-18*

PAINT GRIP 26-18

POLYVINYL CHLORIDE COATED 26-18

*(Brown & Sharp thickness = 0.025” - 0.090”)

SEALER LAP SEAM

spot weld Available

seam weld Gauges

stitch weld

button punch GALVANIZED 20-10

rivet STAINLESS STEEL 22-10

ALUMINUM 16-1/4”*

PAINT GRIP 20-16

HOT ROLLED 16-1/4”

*(Brown & Sharp thickness = 0.05” - 0.25”)

BUTT-WELDED SEAM

Available

Gauges

GALVANIZED 26-18

STAINLESS STEEL 26-22

ALUMINUM 22-16

PAINT GRIP 26-18

SEALER POLYVINYL CHLORIDE COATED 26-18

GORELOCKED SEAM

*(Brown & Sharp thickness = 0.025” - 0.050”)

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

6

Single-Wall Round

Eastern Sheet Metal ELBOWS

90° PRESSED ELBOW 45° PRESSED ELBOW

3” DIA. THRU 12” PE90 3” DIA. THRU 12” PE45

D1

D1

R=D1 R= D1

2" 2"

90° 5-PC.ELBOW E90 45° 3-PC. ELBOW E45

D1 D1

R=D1

R=D1

2" 2"

221⁄2° AND 30° 2-PC. ELBOW

60° 3-PC. ELBOW E60

E22/E30

D1

D1

R=D1 R=D1

2" 2"

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

7

Single-Wall Round

Eastern Sheet Metal ELBOWS

90° 3-PC. ELBOW WITH 90° 2-PC. ELBOW With or without vanes.

HEEL TAP E90L E290/EV290

D2 D1 No. of

Vanes

2" 3-7 1

8-10 3

4" 10-60 5

> 60 max

spacing

=12”

D1

2"

2"

R=D1

2"

D1

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

8

Single-Wall Round

Eastern Sheet Metal PRESSED TEES

FIELD INSTALLED PRESSED

TAP PFT

D3/D1 R L (PT)

4”/4” .394” 14”

D3 4”/6” .394” 14”

4”/8” .394” 14”

R 4”/10” .394” 14”

11/2" 4”/12” .394” 14”

6”/6” .787” 16”

6”/8” .787” 16”

6”/10” .787” 16”

6”/12” .787” 16”

D1

6”/14” .787” 16”

6”/16” .787” 16”

6”/18” .787” 16”

8”/8” .787” 18”

8”/10” .787” 18”

8”/12” .787” 18”

8”/14” .787” 18”

8”/16” .787” 18”

8”/18” .787” 18”

8”/20” .787” 18”

8”/22” .787” 18”

8”/24” 1.0” 20”

10”/10” 1.0” 20”

10”/12” 1.0” 20”

PRESSED TEE PT 10”/14” 1.0” 20”

10”/16” 1.0” 20”

10”/18” 1.0” 20”

10”/20” 1.0” 20”

10”/22” 1.0” 20”

10”/24” 1.0” 20”

D3 12”/12” 1.0” 22”

12”/14” 1.0” 22”

12”/16” 1.0” 22”

R

11/2" 12”/18” 1.0” 22”

12”/20” 1.0” 22”

12”/22” 1.0” 22”

12”/24” 1.0” 22”

D1

L

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

9

Single-Wall Round

Eastern Sheet Metal STRAIGHT TEES

TEE T REDUCING TEE TR X= D1-D2

4” Minimum

D3 D3

2" 2"

2" 2"

2" 2"

2" 2"

2" 2"

D1 D2

D1

2" D3 + 4" 2" 2" D3 + 4" x

TEE CROSS TX REDUCING TEE CROSS TRX X= D1-D2

4” Minimum

D3 D3

2" 2"

2" 2"

2" 2" 2" 2"

2" 2"

D1 D3 + 4

D1 D3 + 4" D2

2"

2" 2" 2" x

2" 2"

2"

D4

D4

D3 ≥ D4 D3 ≥ D4

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

10

Single-Wall Round

Eastern Sheet Metal CONICAL TEES

REDUCING CONICAL TEE

CONICAL TEE CT X= D1-D2

CTR

4” Minimum

D3 D3

2" 2"

2" 2"

5" 1" 1" 5" 1" 1" 2" 2"

2" 2" 2" 2"

D1 D2

D1

2" D3+6" 2" 2" D3+ 6" X

REDUCING CONICAL

CONICAL CROSS CTX X= D1-D2

CROSS CTRX

4” Minimum

D3

D3

2"

2" 2"

2"

5" 1" 1"

5" 1" 1"

2" 2" 2" 2"

2" 2"

D1 D3+6"

D1 D3+ 6" D2

5" 1" 1" 2"

5" 1" 1" X

2"

2"

2"

2"

D4

D3 ≥ D4 D3 ≥ D4 D4

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

11

Single-Wall Round

Eastern Sheet Metal COMBINATION TEES

3 ≤ D3 ≤ 8 Y= 4” REDUCING COMBINATION 3 ≤ D3 ≤ 8 Y= 4”

COMBINATION TEE CB 9 ≤ D3 ≤ 14 Y= 7” 9 ≤ D3 ≤ 14 Y= 7”

TEE CBR

15 ≤ D3 ≤ 26 Y=10” 15 ≤ D3 ≤ 26 Y=10”

27 ≤ D3 Y=13” 27 ≤ D3 Y=13”

D3 D3

2" 2"

2" 2"

Y Y

2" 2" 2" 2" 2" 2" 2" X

2" 2"

D1 D1

D2

D3 +Y + 4" D3 +Y + 4"

X= D1-D2

4” Minimum

COMBINATION CROSS 3 ≤ D3 ≤ 8 Y= 4” REDUCING COMBINATION 3 ≤ D3 ≤ 8 Y= 4”

CBX 9 ≤ D3 ≤ 14 Y= 7” CROSS CBRX 9 ≤ D3 ≤ 14 Y= 7”

15 ≤ D3 ≤ 26 Y=10” 15 ≤ D3 ≤ 26 Y=10”

D3 27 ≤ D3 Y=13” D3 27 ≤ D3 Y=13”

2" 2"

2" 2"

Y3 Y3

2" 2" 2" 2" 2" 2"

2"

2" 2"

D1 D3 +Y + 4" D1 D3 + Y + 4" D2

X

Y4 Y4

2" 2"

2" 2" X= D1-D2

D3 ≥ D4 D3 ≥ D4 4” Minimum

D4 D4

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

12

Single-Wall Round

Eastern Sheet Metal STRAIGHT LATERALS

REDUCING LATERAL 45º

LATERAL 45º L X= [ D1-D2 ]

LR

4” Minimum

2"

2"

D3 D3

2"

2"

2" 2"

2" 2" 2" 2"

D1 D1 D2

2" (D3 x 1.414)+ 4" 2" 2" (D3 x 1.414)+ 4" x

REDUCING 45º LATERAL

LATERAL CROSS 45º LX

CROSS LRX

2"

2"

D3 D3

2"

2"

2" 2"

2" 2" 2" 2" 2" 2"

D1 D1 (D3 x 1.414)+ 4" D2

(D3 x 1.414)+4"

x

2"

2"

2"

D4 D4

X= D1-D2

D3 ≥ D4 D3 ≥ D4 4” Minimum

2"

2"

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

13

Single-Wall Round

Eastern Sheet Metal CONICAL LATERALS

REDUCING CONICAL

CONICAL LATERAL 45º CL X= D1-D2

LATERAL CLR

4” Minimum

"

D3 D3

2"

2

"

2"

2

5" 5"

2" 2"

2" 2" 2" 2"

D2

D1 D1

2" 2" 2" X

[(D3+2") x 1.414]+4" [(D3+2") X 1.414]+4"

CONICAL LATERAL 45º REDUCING CONICAL 45º

CROSS CLX LATERAL CROSS CLRX X= D1-D2

4” Minimum

2"

D3

2"

2"

D3

2"

5" 5"

2" 2"

2" 2" 2" 2" 2"

D1 D1 D2

[(D3+2") x 1.414]+4" [(D3+2") x 1.414]+4"

2" 2" X

D4 D4

2"

2"

D3 ≥ D4 D3 ≥ D4

2"

2"

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

14

Single-Wall Round

Eastern Sheet Metal REDUCERS

CONCENTRIC REDUCER RD X= D1-D2 PRESSED REDUCER PRD

4” Minimum

D2

2" 2" X

2" 2"

L

D1 D2

D1

D1/D2 L

4”/3” 17⁄8”

5”/3” 23⁄4”

5”/4” 17⁄8”

6”/4” 31⁄8”

6”/5” 21⁄4”

7”/5” 35⁄8”

7”/6” 23⁄4”

X= 2 [ D1-D2 ]

ECCENTRIC REDUCER RDE 4” Minimum

8”/5” 41⁄2”

8”/6” 35⁄8”

8”/7” 23⁄4”

9”/6” 41⁄2”

9”/7” 35⁄8”

9”/8” 23⁄4”

10”/6” 53⁄8”

2" 2" x 10”/7” 41⁄2”

10”/8” 35⁄8”

2" 2" 10”/9” 23⁄4”

12”/8” 53⁄8”

12”/9” 41⁄2”

D1 12”/10” 35⁄8”

D2

Protected by US Patent 6,548,760

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

15

Single-Wall Round

Eastern Sheet Metal MISCELLANEOUS

D1

DAMPER D

3”

4”

5”

6”

7”

D1 8”

9”

10”

12”

14”

Dampers come standard with: 16”

• 3⁄8” locking handle 18”

• Nylon bushings 20”

• Insulation stand off 22”

24”

PIPE COUPLINGS PCP FITTING COUPLINGS FCP

2" 2"

2" 2"

D1

D1

PRESSED END CAP PEC END CAP EC

2" 2"

D1 D1

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

16

Single-Wall Round

Eastern Sheet Metal MISCELLANEOUS

D1+4"

30º OFFSET OFF RECTANGLE TO ROUND RSQ

D1

(D1 x .27) + (0 x 1.73)+4"

2"

2"

D1 2" 2"

L

0

2"

W2 x D 2

Y BRANCH Y REDUCING Y BRANCH YR

2"

2"

D3 D4 D3 2" D4

2"

2"

2"

2"

2"

2"

2" 2"

2"

D1

D1

BULL HEAD With or without vanes. REDUCING BULL HEAD With or without vanes.

TEE BHT/BHTV TEE BHTR/BHTRV

2" D1+12" 2"

D1-D3 D1+12" D1-D4

D1 No. of D1 No. of

Vanes Vanes 4" Min. 4" Min.

3-7 1 3-7 1

8-10 3 8-10 3

10-60 5 10-60 5 D3 D4

> 60 max > 60 max

6" 6"

spacing spacing 6" 6"

=12” 2" 2" =12”

2" 2" 2" 2" 2" 2"

2"

D1

D1

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

17

Single-Wall Round

Eastern Sheet Metal MISCELLANEOUS

Also available as shop-installed SRTA

RECTANGULAR or field-installed accessory FRTA. SPUN BELL MOUTH SB

ACCESS SECTION RTA

D1

ACCESS+4"

R

L

D1

1" D2 1"

2" 2"

STANDARD SHORT RADIUS

BELL MOUTH BELL MOUTH

D1 D2 L R D1 D2 L

D1 ACCESS SIZE 13” 19” 4” 3” 13” 15” 31⁄2”

8” to 12” 8” x 8” 14” 21” 4” 3” 14” 16” 31⁄2”

13” to 17” 12” x 12” 15” 24” 5” 4” 15” 17” 31⁄2”

18” and OVER 18” x 18” 16” 26” 5” 4” 16” 18” 31⁄2”

Negative and positive pressure. 17” 19” 31⁄2”

17” 25” 5” 4”

18” 26” 5” 4” 18” 20” 31⁄2”

19” 27” 5” 4” 19” 21” 31⁄2”

20” 28” 5” 4” 20” 22” 31⁄2”

PRESSED BELL MOUTH 21” 29” 5” 4” 21” 23” 31⁄2”

D1 R 22” 24” 31⁄2”

GALVANIZED ONLY PB 4” .394”

22” 32” 6” 5”

23” 33” 6” 5” 23” 25” 31⁄2”

5” .472”

6” .787” 24” 34” 6” 5” 24” 26” 31⁄2”

7” 1.0” 26” 38” 7” 6” 26” 28” 31⁄2”

8” 1.0” 28” 40” 7” 6” 28” 30” 31⁄2”

9” 1.0” 30” 42” 7” 6” 30” 32” 31⁄2”

10” 1.0”

12” 1.0” 32” 46” 8” 7” 32” 34” 31⁄2”

D1

34” 48” 8” 7” 34” 36” 31⁄2”

36” 50” 8” 7” 36” 38” 31⁄2”

38” 52” 8” 7” 38” 40” 31⁄2”

40” 56” 9” 8” 40” 42” 31⁄2”

R 42” 58” 9” 8” 42” 44” 31⁄2”

44” 60” 9” 8” 44” 46” 31⁄2”

46” 62” 9” 8” 46” 48” 31⁄2”

48” 64” 9” 8” 48” 50” 31⁄2”

50” 52” 31⁄2”

52” 54” 31⁄2”

54” 56” 31⁄2”

56” 58” 31⁄2”

56” 60” 31⁄2”

60” 62” 31⁄2”

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

18

Single-Wall Round

Eastern Sheet Metal ACCESSORIES

SHOP INSTALLED/ FIELD INSTALLED

SHOP/FIELD INSTALLED SHOP/FIELD INSTALLED

TAP ST/FT CONICAL TAP STC/FTC

D3 D3

2" 2"

2"

2"

5"

D1

D1

Standard flange is 1/2”. Standard flange is 1/2”.

2” flange is also available. 2” flange is also available.

SHOP/FIELD INSTALLED SHOP/FIELD INSTALLED 3 ≤ D3 ≤ 8 Y= 4”

LATERAL TAP SL/FL COMBINATION TAP SCB/FCB 9 ≤ D3 ≤ 14 Y= 7”

15 ≤ D3 ≤ 26 Y=10”

D3 27 ≤ D3 Y=13”

D3

2"

2"

2"

2" Y"

D3x1.414

D3+Y

D1

D1

Standard flange is 1/2”. Standard flange is 1/2”.

2” flange is also available. 2” flange is also available.

SHOP/FIELD INSTALLED FIELD INSTALLED

RECTANGLE ON ROUND SRR/FRR STANDARD DOOR FA

W3 x D 3

FLANGE IN OR OUT

D1

D1

6"

1/2"FLANGE

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

19

Single-Wall Round

Eastern Sheet Metal INSTALLATION

SINGLE-WALL SLIP JOINT Installation of Installation of

Eastern Sheet Metal fittings are sized to slip into, and should Slip Joint Connector Eastern Flange Connector

be used with, Eastern Sheet Metal spiral duct. A tight fit is

necessary to minimize friction loss and to promote proper

sealing. Care should be taken during handling and installation

to avoid dents and distortions that can cause improper fit or

difficult installation.

1. Bring the bottom of the fitting collar into the spiral duct at a

slight angle.

2. Carefully work the rest of the collar into the spiral duct

until approximately one inch of the collar remains exposed

between the end of the spiral duct and the stop bead of the

1/2"

fitting collar. Do not use a screwdriver or knife to help make

the connection. Apply pressure with the heal of your hand or

1

with your fist to help slip the fitting into the duct. 5 8

3. Apply duct sealer to this exposed area. Skip this step if

Screw

installing EASTERN TIGHT fittings. 4 Placement 3

Sequence

4. Push the fitting into the spiral duct until the stop bead meets 1

the edge of the spiral duct. 5 8 7 6

2

5. Fasten the fitting into the spiral duct with screws per the Screw

4 Placement 3

chart at right. The screws should be evenly spaced around the Sequence

perimeter of the connection, approximately 1/2” back from

7 6

the stop bead. Placement of the screws should be opposite of

2

each other as demonstrated in the diagram.

EASTERN FLANGE

Eastern Flanges come factory-mounted on fittings and spiral DUCT #OF SCREWS

duct. Eastern Flanges are standard for all duct over 61” in DIAMETER SLIP FIT EASTERN FLANGE

diameter, but are available on smaller sizes. Stainless steel 4”-9” 3 NA

Eastern Flanges are only available for round diameters of 16” 10” 3 4

and longer. 11”-16” 3 6

17”-21” 4 8

1. Place closed cell neoprene gasket on the face of one of the

22”-26” 5 10

mating flanges.

27”-30” 6 12

2. Push the flanges together keeping the edges of the flanges 32”-36” 7 14

aligned. 38”-42” 8 16

3. Clamp the flanges to help hold them in place. 44”-46” 9 18

4. Screw the flanges together with self-tapping screws per the 48”-52” 10 20

chart at right. The screws should be evenly spaced around the 54”-56” 11 22

perimeter of the connection. Placement of the screws should 58”-60” 12 24

be opposite of each other as demonstrated in the diagram. 62”-66” NA 26

68”-72” NA 28

74”-76” NA 30

Protected by the following U.S. Patents: 7,287,407; D518,885;

D517,679; D516,698; D516,697. 78”-84” NA 32

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

20

Single-Wall

Eastern Sheet Metal ROUND

PE90 E90 E60 PE45 E45 E22/E30

E90L E290/EV290 PT TR TRX CTR

CTRX CBR CBRX LR LRX CLR

CLRX RD RDE PRD D PCP

FCP PEC EC OFF RSQ Y YR

BHTR/BHTRV RTA PB SB ST/FT STC/FTC

SL/FL SCB/FCB SRR/FRR FA

EASTERN TIGHT is a trademark of Eastern Sheet Metal, LLC and may not be used without prior written authorization.

Eastern Sheet Metal • 800 348 3440 • www.easternsheetmetal.com

Vous aimerez peut-être aussi

- Universal Milling Machine Catalog PDFDocument2 pagesUniversal Milling Machine Catalog PDFDharmik SoniPas encore d'évaluation

- Scope: Procter and GambleDocument30 pagesScope: Procter and GambleIrshad AhamedPas encore d'évaluation

- Pigeon Disease - The Eight Most Common Health Problems in PigeonsDocument2 pagesPigeon Disease - The Eight Most Common Health Problems in Pigeonscc_lawrence100% (1)

- Uas MR1Document2 pagesUas MR1IvanPas encore d'évaluation

- Round: Spiral Duct & FittingsDocument20 pagesRound: Spiral Duct & FittingsgabisaPas encore d'évaluation

- Spiral Gauge Chart S-WDocument1 pageSpiral Gauge Chart S-WJose backupPas encore d'évaluation

- HVAC Duct Round CatalogDocument12 pagesHVAC Duct Round CatalogMoses_JakkalaPas encore d'évaluation

- Flat Oval Spiral Pipe & Fittings: Sheet Metal Connectors, Inc. (SMC)Document4 pagesFlat Oval Spiral Pipe & Fittings: Sheet Metal Connectors, Inc. (SMC)Shaun SullivanPas encore d'évaluation

- BN-DS-C5 Dimensions 30° & 60° BendsDocument1 pageBN-DS-C5 Dimensions 30° & 60° BendsEHT pipePas encore d'évaluation

- Bridas Gran Diametro Catalogo Completo PDFDocument54 pagesBridas Gran Diametro Catalogo Completo PDFvalentinPas encore d'évaluation

- RodconsumptionDocument3 pagesRodconsumptionStephen RajPas encore d'évaluation

- Stanley Mitre Boxes 1915Document3 pagesStanley Mitre Boxes 1915OSEAS GOMEZPas encore d'évaluation

- Curva Horizontal SoportekDocument1 pageCurva Horizontal SoportekMarlene Treviño RamirezPas encore d'évaluation

- Duep Midsem ResultDocument2 pagesDuep Midsem Resultrathodmayanksinh9727Pas encore d'évaluation

- PDS01.10.002-A - Wouter Witzel - EVFS InstallationDocument1 pagePDS01.10.002-A - Wouter Witzel - EVFS InstallationVilius BukysPas encore d'évaluation

- Kitchen Floorplan ElevationsDocument4 pagesKitchen Floorplan ElevationsaudioxtraPas encore d'évaluation

- High Pressure Gas Piping BOM 12-11-19Document3 pagesHigh Pressure Gas Piping BOM 12-11-19MELVIN MAGBANUAPas encore d'évaluation

- Installation Data - EVTLSDocument1 pageInstallation Data - EVTLSnastyn-1Pas encore d'évaluation

- Catalog Rev 12Document3 pagesCatalog Rev 12Dennier CHÁVEZ GARROPas encore d'évaluation

- 1995 Single Wall - ChartDocument1 page1995 Single Wall - Chartsjanes24Pas encore d'évaluation

- Dennis - Floor PlansDocument4 pagesDennis - Floor Plansapi-293339640Pas encore d'évaluation

- Volume de Concreto - T 02, 03 e 04 - JI2Document26 pagesVolume de Concreto - T 02, 03 e 04 - JI2Ueslei ConceiçãoPas encore d'évaluation

- Chambered Spark Arresting Silencers: Better Chamber Type Spark Arresting: Expected Attenuation Is 21 To 24 dBADocument1 pageChambered Spark Arresting Silencers: Better Chamber Type Spark Arresting: Expected Attenuation Is 21 To 24 dBAAntonio SerranoPas encore d'évaluation

- 1000series 1Document2 pages1000series 1willy HPas encore d'évaluation

- Pipe Flanges PDFDocument1 pagePipe Flanges PDFRitesh singhPas encore d'évaluation

- JoistTopChordWidth PDFDocument2 pagesJoistTopChordWidth PDFthe_dehumanizerPas encore d'évaluation

- Joist Top Chord WidthDocument2 pagesJoist Top Chord WidthRamume188Pas encore d'évaluation

- JoistTopChordWidth PDFDocument2 pagesJoistTopChordWidth PDFthe_dehumanizerPas encore d'évaluation

- 13 Nos Vessel BOM For Checking 10 05 19Document35 pages13 Nos Vessel BOM For Checking 10 05 19sandeshpetarePas encore d'évaluation

- Ai Kb252 w2 A1 Shockey eDocument1 pageAi Kb252 w2 A1 Shockey eBeth ShockeyPas encore d'évaluation

- Kitchen Cabinet-200825Document4 pagesKitchen Cabinet-200825Mugi JayadiPas encore d'évaluation

- DIAG Test Result ESPDocument1 pageDIAG Test Result ESPMark Anthony QuilestinoPas encore d'évaluation

- Rectangular Ductwork SubmittalDocument25 pagesRectangular Ductwork SubmittalAmr Kamel100% (1)

- ScheduleDocument21 pagesScheduleHenrique Anderson da SilvaPas encore d'évaluation

- Lab Draft CircuitsDocument5 pagesLab Draft CircuitsJake GuzmanPas encore d'évaluation

- Kitchen Floorplan ElevationsDocument4 pagesKitchen Floorplan ElevationsaudioxtraPas encore d'évaluation

- Plot Plot Plot Plot Plot Plot Plot: 839.03 SQ - YdDocument1 pagePlot Plot Plot Plot Plot Plot Plot: 839.03 SQ - YdChaudhari SAnketPas encore d'évaluation

- Vertical Milling Machine Catalog PDFDocument2 pagesVertical Milling Machine Catalog PDFDharmik SoniPas encore d'évaluation

- PDS01.11.002-A - Wouter Witzel - EVFL InstallationDocument1 pagePDS01.11.002-A - Wouter Witzel - EVFL InstallationVilius BukysPas encore d'évaluation

- 2 - Auger Price List 2018Document2 pages2 - Auger Price List 2018alexjos1Pas encore d'évaluation

- Persol Spring 2022 CATALOGDocument88 pagesPersol Spring 2022 CATALOGAzur DiffusionPas encore d'évaluation

- No. Chanel Load/Tds Koefisien Poin Satuan KeteranganDocument3 pagesNo. Chanel Load/Tds Koefisien Poin Satuan KeteranganAbdulf QitlerPas encore d'évaluation

- RotolockDocument1 pageRotolockR M Abdullah WakeelPas encore d'évaluation

- 4727 Waterside Cabinets and CountertopsDocument8 pages4727 Waterside Cabinets and CountertopsThe Cultural CommitteePas encore d'évaluation

- Vasupujya 44 VillaDocument1 pageVasupujya 44 VillaVatsal ShahPas encore d'évaluation

- Midas Cable CoordinatesDocument24 pagesMidas Cable CoordinatesPraveen CyssanPas encore d'évaluation

- CLPL 11 09Document30 pagesCLPL 11 09Ilham SipalaPas encore d'évaluation

- CREDITOS 16.9 PruebaDocument35 pagesCREDITOS 16.9 PruebaAnggie ValenzuelaPas encore d'évaluation

- Rotation Load - Hidro Test 13-04-23Document3 pagesRotation Load - Hidro Test 13-04-23Kelompok 1 PKKMB FT UNJ 2018Pas encore d'évaluation

- Perbandingan Harga Pipa PVCDocument1 pagePerbandingan Harga Pipa PVCniki RizkiPas encore d'évaluation

- CK42 6" 12" 30mm 12": Model No. Photograph Dial Size Length Width HeightDocument7 pagesCK42 6" 12" 30mm 12": Model No. Photograph Dial Size Length Width HeightGaurav GehlotPas encore d'évaluation

- "Ok-1" Kickover ToolDocument1 page"Ok-1" Kickover ToolebePas encore d'évaluation

- Horizontal Milling Machine Catalog PDFDocument2 pagesHorizontal Milling Machine Catalog PDFDharmik SoniPas encore d'évaluation

- Kitchen USADocument4 pagesKitchen USAmadiaz0495Pas encore d'évaluation

- 1835 Radar DimensionsDocument1 page1835 Radar Dimensionslutvi engineeringPas encore d'évaluation

- Stock AlmacenDocument50 pagesStock AlmacenD. V. A.Pas encore d'évaluation

- Catalogo Racing MasterpowerDocument74 pagesCatalogo Racing MasterpowerVando FerreiraPas encore d'évaluation

- Shimano Malaysia Production Calendar Shimano Malaysia Production CalendarDocument1 pageShimano Malaysia Production Calendar Shimano Malaysia Production CalendarMohd Khalid Noor KhalidPas encore d'évaluation

- BastDocument16 pagesBastfauziPas encore d'évaluation

- Flexco Alligator LacingDocument4 pagesFlexco Alligator LacingramPas encore d'évaluation

- 1606-5YY3007 InductorDocument117 pages1606-5YY3007 InductorDjurdjina PetkovicPas encore d'évaluation

- 13723, 24, 25 - Fire Fighting Pipes & FittingsDocument8 pages13723, 24, 25 - Fire Fighting Pipes & FittingsMohamedSulthanPas encore d'évaluation

- Technical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionD'EverandTechnical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionPas encore d'évaluation

- Pipe Schedule DataDocument1 pagePipe Schedule DataNaniPas encore d'évaluation

- PLC or DCS PDFDocument12 pagesPLC or DCS PDFsafvanshaikhPas encore d'évaluation

- Merv Rating Chart PDFDocument1 pageMerv Rating Chart PDFNaniPas encore d'évaluation

- Reference Data: Schedule 40 Steel Pipe DataDocument2 pagesReference Data: Schedule 40 Steel Pipe DataKareem HelalPas encore d'évaluation

- Dr. Sajjad Hussain Sumrra Isomerism (CHEM-305) Inorganic Chemistry-IIDocument48 pagesDr. Sajjad Hussain Sumrra Isomerism (CHEM-305) Inorganic Chemistry-IITanya DilshadPas encore d'évaluation

- RRC Group D Notification 70812Document11 pagesRRC Group D Notification 70812admin2772Pas encore d'évaluation

- Guinea Pig: Domestication: Basic Species InformationDocument4 pagesGuinea Pig: Domestication: Basic Species InformationBondPas encore d'évaluation

- CBEU Service ConditionsDocument623 pagesCBEU Service ConditionsAtul ModiPas encore d'évaluation

- Neopuff PDFDocument4 pagesNeopuff PDFoechimPas encore d'évaluation

- Contractor: Item No. MRS-1st 2021 Ref. Description Unit Quantity Rate of Contractor Unit Rate in Words AmountDocument1 pageContractor: Item No. MRS-1st 2021 Ref. Description Unit Quantity Rate of Contractor Unit Rate in Words AmountusmanaliPas encore d'évaluation

- Soil SSCDocument11 pagesSoil SSCvkjha623477Pas encore d'évaluation

- Pantera 900Document3 pagesPantera 900Tuan Pham AnhPas encore d'évaluation

- Electri RelifDocument18 pagesElectri Relifsuleman247Pas encore d'évaluation

- Updoc - Tips Dictionar Foraj e RDocument37 pagesUpdoc - Tips Dictionar Foraj e RDaniela Dandea100% (1)

- Making Creams With Olive M 1000Document28 pagesMaking Creams With Olive M 1000Nicoleta Chiric0% (1)

- Organogram - Qa / QC: Srinivasan SrinivasanDocument4 pagesOrganogram - Qa / QC: Srinivasan SrinivasanGowtham VenkatPas encore d'évaluation

- A Project Report On A Study On Amul Taste of India: Vikash Degree College Sambalpur University, OdishaDocument32 pagesA Project Report On A Study On Amul Taste of India: Vikash Degree College Sambalpur University, OdishaSonu PradhanPas encore d'évaluation

- OPSS1213 Mar98Document3 pagesOPSS1213 Mar98Tony ParkPas encore d'évaluation

- DT 2107Document1 pageDT 2107Richard PeriyanayagamPas encore d'évaluation

- Art of Facing InterviewsDocument15 pagesArt of Facing Interviewskrish_cvr2937100% (2)

- Indian Standard (First Revision) : Method of Chemical Analysis of Hydraulic CementDocument44 pagesIndian Standard (First Revision) : Method of Chemical Analysis of Hydraulic CementArijit dasguptaPas encore d'évaluation

- GrowNote Faba South 3 Pre PlantingDocument22 pagesGrowNote Faba South 3 Pre PlantingDawitPas encore d'évaluation

- Task 5 Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Document5 pagesTask 5 Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Samir Mosquera-PalominoPas encore d'évaluation

- NORSOK M-630 Edition 6 Draft For HearingDocument146 pagesNORSOK M-630 Edition 6 Draft For Hearingcaod1712100% (1)

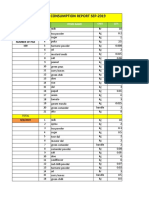

- Daily Staff Food Consumption Reports Sep-2019Document4 pagesDaily Staff Food Consumption Reports Sep-2019Manjit RawatPas encore d'évaluation

- Bhert - EoDocument2 pagesBhert - EoRose Mae LambanecioPas encore d'évaluation

- 2022-Brochure Neonatal PiccDocument4 pages2022-Brochure Neonatal PiccNAIYA BHAVSARPas encore d'évaluation

- S ELITE Nina Authors Certain Ivey This Reproduce Western Material Management Gupta Names Do OntarioDocument15 pagesS ELITE Nina Authors Certain Ivey This Reproduce Western Material Management Gupta Names Do Ontariocarlos menaPas encore d'évaluation

- AFMAN91-201 NewDocument458 pagesAFMAN91-201 NewbombtechPas encore d'évaluation

- CONTROLTUB - Controle de Juntas - New-Flare-Piping-Joints-ControlDocument109 pagesCONTROLTUB - Controle de Juntas - New-Flare-Piping-Joints-ControlVss SantosPas encore d'évaluation

- 'Bubble Kid' Success Puts Gene Therapy Back On TrackDocument5 pages'Bubble Kid' Success Puts Gene Therapy Back On TrackAbby Grey Lopez100% (1)