Académique Documents

Professionnel Documents

Culture Documents

High Density Polyethylene GF4950: Description

Transféré par

cesar1scribdDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

High Density Polyethylene GF4950: Description

Transféré par

cesar1scribdDroits d'auteur :

Formats disponibles

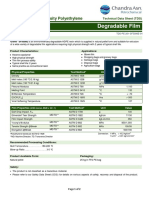

Data Sheet

Review 1 (March/09)

High Density Polyethylene GF4950

Description:

HDPE GF4950 is a copolymer high-density polyethylene, developed for the blow-molding segment

with well balanced properties between impact and stiffness, combined with high environmental

stress cracking resistance and processability.

Application:

Bottles for cleaning products. food products, surface-active agents and cosmetics.

Others application: Blends for irrigation pipes.

Process:

Blow Molding.

Control Properties:

ASTM Method Units Values

Melt Flow Rate (190/2.16) D 1238 g/10 min 0.34

Melt Flow Rate (190/21.6) D 1238 g/10 min 28

Density D 792 g/cm3 0.956

Typical Properties:

Plaque Propertiesa

ASTM Method Units Values

Tensile Strength at Yield D 638 MPa 28

Tensile Strength at Break D 638 MPa 31

Flexural Modulus – 1% Secant D 790 MPa 1060

Shore D Hardness D 2240 - 63

Izod Impact Strength D 256 J/m 145

Environmental Stress Cracking Resistanceb D 1693 h/F50 20

Environmental Stress Cracking Resistancec D 1693 h/F50 55

Deflection Temperature under Load at 0.455 MPa D 648 ºC 75

Vicat Softening Temperature at 10 N D 1525 °C 129

(a) Test specimens prepared from compression molded sheet made according to ASTM D 4703.

(b) Compression molded 2 mm thickness, 0.3 mm notched-plaques. 10% Igepal. 50ºC.

(c) Compression molded 2 mm thickness, 0.3 mm notched-plaques. 100% Igepal. 50ºC.

Final Remarks:

1. This resin meets the requirements for olefin polymers as defined in 21 CFR, section 177.1520 issued by FDA – Food and Drug Administration in force on the

date of publication of this specification. The additives present are covered in appropriate regulation by FDA

2. The information presented in this Data Sheet reflects typical values obtained in our laboratories, but should not be considered as absolute or as warranted

values. Only the properties and values mentioned on the Certificate of Quality are considered as guarantee of the product.

3. In some applications, Braskem has developed tailor-made resins to reach specific requirements.

4. In case of doubt regarding utilization, or for other applications, please contact our Technical Assistance.

5. For information about safety, handling, individual protection, first aids and waste disposal, please see MSDS. CAS Registry number: 25087-34-7.

6. The mentioned values in this report can be changed at any moment without Braskem previous communication.

7. Braskem does not recommend this grade for packages, parts or any kind of product manufacture that will be used for storage or contact with solution that

will have internal contact with human body.

8. Braskem polyolefin products do not have additives with metals or other substances on purpose of oxidegradation. These additives and the decomposition

and disintegration of polyolefins caused by oxidegradation phenomenon can cause environmental pollution, decrease the package performance and increase

migration of package constituent to food, compromising resin approval regarding the requirements of Anvisa Resolution 105/99. The use of these additives

with Braskem polyolefin products implies immediate loss of performance guarantee described in this data sheet.

9. The content of this Data Sheet replaces previous revisions published for this product.

Vous aimerez peut-être aussi

- High Density Polyethylene HC7260LS-L: DescriptionDocument1 pageHigh Density Polyethylene HC7260LS-L: DescriptionJaime222Pas encore d'évaluation

- PP - Braskem - CP 442 XP PDFDocument1 pagePP - Braskem - CP 442 XP PDFAdemilson Alves Dos SantosPas encore d'évaluation

- PN2021 enUS ASTMDocument1 pagePN2021 enUS ASTMChu Nguyễn Anh QuânPas encore d'évaluation

- JV060U Ing Rev.10Document2 pagesJV060U Ing Rev.10nicolas yoris marcogliesePas encore d'évaluation

- Low Density Polyethylene LD7000A: DescriptionDocument1 pageLow Density Polyethylene LD7000A: DescriptionJaime222Pas encore d'évaluation

- He150 Enus AstmDocument1 pageHe150 Enus AstmDiegoAlvarezHuguezPas encore d'évaluation

- 3019PE enUS ASTMDocument1 page3019PE enUS ASTMgawronPas encore d'évaluation

- LLBF 218aDocument1 pageLLBF 218aYefrain J. ArzolayPas encore d'évaluation

- HC7260LS L enUS ASTMDocument1 pageHC7260LS L enUS ASTMCristian Tomas Del Solar EspoueysPas encore d'évaluation

- GM5340PRK enUS ASTMDocument2 pagesGM5340PRK enUS ASTMDuongthithuydungPas encore d'évaluation

- Linear Low Density Polyethylene SLL318: DescriptionDocument1 pageLinear Low Density Polyethylene SLL318: DescriptionRoberto De Mesa PPas encore d'évaluation

- GP100ORXP enUS ASTMDocument1 pageGP100ORXP enUS ASTMRaul ArmendarizPas encore d'évaluation

- LLBF 122FDocument1 pageLLBF 122FYefrain J. ArzolayPas encore d'évaluation

- PRB 0131-enUS-ASTMDocument1 pagePRB 0131-enUS-ASTMquanghoang10986Pas encore d'évaluation

- HD7255LS L enUS ASTMDocument1 pageHD7255LS L enUS ASTMHamza MohamedPas encore d'évaluation

- Certene L.A. LLBF-122D (Sustituto 11PG4) ActualizadaDocument1 pageCertene L.A. LLBF-122D (Sustituto 11PG4) ActualizadadianaPas encore d'évaluation

- High Density Polyethylene HS5407: Descrip OnDocument1 pageHigh Density Polyethylene HS5407: Descrip OnJosiola MariledoPas encore d'évaluation

- H 301-enUS-ASTMDocument1 pageH 301-enUS-ASTMfernandoincesaPas encore d'évaluation

- Titanpro PD701 Product Data PDFDocument1 pageTitanpro PD701 Product Data PDFJoni Sie MssPas encore d'évaluation

- Tds DGDX 6097 Astm ButeneDocument2 pagesTds DGDX 6097 Astm ButeneLakshay UniplarPas encore d'évaluation

- CP 191-enUS-ASTMDocument1 pageCP 191-enUS-ASTMAndersonPas encore d'évaluation

- LDF201FG R01Document1 pageLDF201FG R01Oscar Tan IIIPas encore d'évaluation

- TDS DGDZ 6097 ASTM HexeneDocument2 pagesTDS DGDZ 6097 ASTM HexenegauravmishraanalystPas encore d'évaluation

- TDS Pe 201 Sf5008eDocument2 pagesTDS Pe 201 Sf5008eOktaviandri SaputraPas encore d'évaluation

- Product Data: Titanlene Ldf200GgDocument1 pageProduct Data: Titanlene Ldf200GgchinchotarngPas encore d'évaluation

- H 103 - ISO - Rev10 - INGDocument1 pageH 103 - ISO - Rev10 - INGandersmorais86Pas encore d'évaluation

- Special Characteristics:: Innoplus Ll7420DDocument1 pageSpecial Characteristics:: Innoplus Ll7420DFahad MohamedPas encore d'évaluation

- Lotte Titanpro PM903 Product DataDocument1 pageLotte Titanpro PM903 Product DataJoni Sie MssPas encore d'évaluation

- Sabic Lldpe MG200024: PolymersDocument2 pagesSabic Lldpe MG200024: PolymersYoshie IwaiPas encore d'évaluation

- SABIC® LLDPE M500026: Linear Low Density Polyethylene For Masterbatch CompoundingDocument2 pagesSABIC® LLDPE M500026: Linear Low Density Polyethylene For Masterbatch CompoundingAnas AbdoPas encore d'évaluation

- TDS Pe 200 SF5007Document2 pagesTDS Pe 200 SF5007Oktaviandri SaputraPas encore d'évaluation

- Product Data: Titanpro Sm198Document1 pageProduct Data: Titanpro Sm198李万福Pas encore d'évaluation

- Polypropylene CP 741: Sub-GroupDocument1 pagePolypropylene CP 741: Sub-GroupAnonymous m4MucCPas encore d'évaluation

- LLDPE - Lotrene Q1018N PDFDocument2 pagesLLDPE - Lotrene Q1018N PDFNilay TanrıverPas encore d'évaluation

- Linear Low Density Polyethylene: Blown Film GradeDocument1 pageLinear Low Density Polyethylene: Blown Film GradeChetan BholePas encore d'évaluation

- Linear Low Density Polyethylene Resin Special CharacteristicsDocument1 pageLinear Low Density Polyethylene Resin Special CharacteristicsFahad MohamedPas encore d'évaluation

- Product Data: Titanpro For ThermoformingDocument1 pageProduct Data: Titanpro For ThermoformingFarah99hanPas encore d'évaluation

- Qatofin Lotrene Q2018Document2 pagesQatofin Lotrene Q2018HichamSalamaPas encore d'évaluation

- Exelene Hdpe 20000 2021Document1 pageExelene Hdpe 20000 2021diana sarmientoPas encore d'évaluation

- LL7410D1Document1 pageLL7410D1Nitin MaheshwariPas encore d'évaluation

- Equate EGDA 6888Document2 pagesEquate EGDA 6888akshayPas encore d'évaluation

- Dow Elite 5400G TDSDocument2 pagesDow Elite 5400G TDSAli RazuPas encore d'évaluation

- Lotrene LLDPE Datasheet PDFDocument6 pagesLotrene LLDPE Datasheet PDFThụy Thảo LinhPas encore d'évaluation

- Lotte Titanpro PM803 Product DataDocument1 pageLotte Titanpro PM803 Product DataJoni Sie MssPas encore d'évaluation

- TDS Pe 002 Uf1810t 03Document2 pagesTDS Pe 002 Uf1810t 03qc jrpPas encore d'évaluation

- CG220NA enUS ASTMDocument1 pageCG220NA enUS ASTMRaphael Robson Dantas FonsecaPas encore d'évaluation

- TDS Pe 001 Uf1810Document2 pagesTDS Pe 001 Uf1810asrilPas encore d'évaluation

- Technical Data SheetDocument2 pagesTechnical Data Sheetnadaelbeltagy4Pas encore d'évaluation

- Surat Jastifikasi - (SANFAB PE - ST)Document5 pagesSurat Jastifikasi - (SANFAB PE - ST)arungrifqy putraaditPas encore d'évaluation

- Luban DFDC-7080: Linear Low Density PolyethyleneDocument2 pagesLuban DFDC-7080: Linear Low Density PolyethyleneNazmul - Polymet SAPas encore d'évaluation

- ELITE 5401G: Blown Film ResinDocument2 pagesELITE 5401G: Blown Film ResinEndayenew MollaPas encore d'évaluation

- TDS Pe 003 Uf1810s1 03Document2 pagesTDS Pe 003 Uf1810s1 03qc jrpPas encore d'évaluation

- TDS Pe 100 Ub5206h 02 PDFDocument2 pagesTDS Pe 100 Ub5206h 02 PDFOktaviandri SaputraPas encore d'évaluation

- PP PP9074MED DatasheetDocument1 pagePP PP9074MED DatasheetDiogo SouzaPas encore d'évaluation

- SABIC® HDPE M200056: High Density Polyethylene For Injection MouldingDocument2 pagesSABIC® HDPE M200056: High Density Polyethylene For Injection MouldingMuhammad Noman MehboobPas encore d'évaluation

- Lldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalDocument2 pagesLldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalĐỗ Ngọc TúPas encore d'évaluation

- Titanpro 6531 MDocument1 pageTitanpro 6531 MErnesto CheguavaraPas encore d'évaluation

- TDS Pe 010 Uf1820t 04Document2 pagesTDS Pe 010 Uf1820t 04Lenggana SukriaPas encore d'évaluation

- New Tally 3Document3 pagesNew Tally 3Yashaswini JettyPas encore d'évaluation

- Chenrezi Sadhana A4Document42 pagesChenrezi Sadhana A4kamma100% (7)

- Nonviolent Communication Lessons 2-20-18Document210 pagesNonviolent Communication Lessons 2-20-18Ice George100% (1)

- Banana Oil LabDocument5 pagesBanana Oil LabjbernayPas encore d'évaluation

- Holidays Homework 12Document26 pagesHolidays Homework 12richa agarwalPas encore d'évaluation

- Contoh DVDocument5 pagesContoh DVHiruma YoishiPas encore d'évaluation

- Rule 108 Republic Vs TipayDocument1 pageRule 108 Republic Vs TipayShimi Fortuna100% (1)

- Critical LengthDocument3 pagesCritical LengthRamiro RamirezPas encore d'évaluation

- 1404 1284 PDFDocument150 pages1404 1284 PDFJohannRoaPas encore d'évaluation

- Resonant Excitation of Coherent Cerenkov Radiation in Dielectric Lined WaveguidesDocument3 pagesResonant Excitation of Coherent Cerenkov Radiation in Dielectric Lined WaveguidesParticle Beam Physics LabPas encore d'évaluation

- 1 Hot Metal Tapping SOPDocument25 pages1 Hot Metal Tapping SOPSANJAY KUMAR PATIPas encore d'évaluation

- Finman CH 18 SolmanDocument32 pagesFinman CH 18 SolmanJoselle Jan Claudio100% (1)

- Jyotsna G. Singh - Shakespeare and Postcolonial Theory (2019)Document265 pagesJyotsna G. Singh - Shakespeare and Postcolonial Theory (2019)luisaPas encore d'évaluation

- LESSON PLAN IN wRITING A REPORTDocument2 pagesLESSON PLAN IN wRITING A REPORTMarkaton Dihagnos100% (4)

- Mapua Cwtsstudentsmodule (Ay08 09)Document62 pagesMapua Cwtsstudentsmodule (Ay08 09)anon-805332Pas encore d'évaluation

- G.R. No. 178511 - Supreme Court of The PhilippinesDocument4 pagesG.R. No. 178511 - Supreme Court of The PhilippinesJackie Z. RaquelPas encore d'évaluation

- Tiktok, Identity Struggles and Mental Health Issues: How Are The Youth of Today Coping?Document6 pagesTiktok, Identity Struggles and Mental Health Issues: How Are The Youth of Today Coping?Trúc NgânPas encore d'évaluation

- Delos Reyes Preliminary ExamDocument7 pagesDelos Reyes Preliminary ExamJp Delos ReyesPas encore d'évaluation

- (2010) Formulaic Language and Second Language Speech Fluency - Background, Evidence and Classroom Applications-Continuum (2010)Document249 pages(2010) Formulaic Language and Second Language Speech Fluency - Background, Evidence and Classroom Applications-Continuum (2010)Như Đặng QuếPas encore d'évaluation

- Tax 2 2018 CasesDocument400 pagesTax 2 2018 CasesRussel SirotPas encore d'évaluation

- Aluminium, Metal and The SeaDocument186 pagesAluminium, Metal and The SeaMehdi GhasemiPas encore d'évaluation

- Physicochemical, Phytochemical, Mineral Analysis and Invitro Anti-Oxidant Activity of Shatavari Ghrita (Polyherbal Formulation)Document11 pagesPhysicochemical, Phytochemical, Mineral Analysis and Invitro Anti-Oxidant Activity of Shatavari Ghrita (Polyherbal Formulation)International Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Lampiran 18-Lesson Plan 02Document5 pagesLampiran 18-Lesson Plan 02San Louphlii ThaPas encore d'évaluation

- Thesis For Driving AgeDocument6 pagesThesis For Driving Agestefanieyangmanchester100% (2)

- Term Coalition Has Been Derived From The Latin Word 'Coalitio' Which Means To Grow Up TogetherDocument2 pagesTerm Coalition Has Been Derived From The Latin Word 'Coalitio' Which Means To Grow Up TogetherShree MishraPas encore d'évaluation

- Soal Inggris PrintDocument3 pagesSoal Inggris Printmtsn1okus ptspPas encore d'évaluation

- Modal VerbsDocument2 pagesModal VerbsDICX7770% (1)

- MVVNL RGGVY Approved Vendor List: S.NO. Name of Material Vendor Name AddressDocument10 pagesMVVNL RGGVY Approved Vendor List: S.NO. Name of Material Vendor Name AddressELMEF LaboratoryPas encore d'évaluation

- 2014 Price ListDocument17 pages2014 Price ListMartin J.Pas encore d'évaluation

- Jacksonville's Taste 2012Document100 pagesJacksonville's Taste 2012Ali KhanPas encore d'évaluation