Académique Documents

Professionnel Documents

Culture Documents

Liturature On Slab

Transféré par

Heng SreymomTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Liturature On Slab

Transféré par

Heng SreymomDroits d'auteur :

Formats disponibles

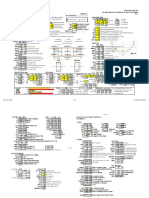

RC SLAB TO ACI DIRECT METHOD (ACI318-14 cl.8.

10) SSE-EXCEL-SECTION

Refs: Nilson 14 SI The author will not be responsible for any uses of this software!

v1.06

1. Inputs

TYPE= 1 1=slab on beams, 2=flat slab f'c= 28 MPa 1st interior support fct= 0 0=no, 1=yes Job: GF-S1

L1= 6 m to axe fy= 420 MPa shear at d= 0 0=no, 1=yes

L2= 7.5 m to axe g= 0 t/m2 super dead load a= 0.4 m column dimension >> PDF

h= 0.18 m slab's thickness q= 0.7 t/m2 live load b= 0.4 m column dimension

e= 0.03 m cover to axe of bar gc= 2.4 t/m3 unit weight concrete fcts= 0.45 crack slab's factor (0.25 to 0.45)

-1.1

-1.1

beams: b(m) h(m) flang* supp. I(cm4) slab I(cm4) αf %B %S** * 1 -2.76 t.m**

1 0.35 0.5 0.32 1 72.92 6 29.2 2.5 0.85 0.15

2 0.35 0.5 0.32 1 72.92 6 29.2 2.5 0.85 0.15 t.m

2 -0.51 1.57 t.m -1.92

3 0.35 0.5 0.32 0 54.69 3.75 18.2 3 0.87 0.13 * 0 4 1*

0.60

0.60

4 0.35 0.5 0.32 1 72.92 7.5 36.5 2 0.82 0.18 M= -0.19 3 2.3 t.m M= -2.78 t.m L1

*cl.8.4.1.8 average (αfm)= 2.5 cl. 8.10.2.7 1.5 t.m

**fcts cracked factor β= 1.25 long/short 1 -0.51 1.57 t.m -1.92

***b=0 for flat slab w/o edge beam Lmax= 7.5 m =max(L1,L2) * 1 -2.76 t.m Mu (t.m/m)

-1.1

-1.1

h min= 0.166 m cl.8.3.1.2 * 0=edge, 1=continue Col's strip

L2

column strip= 1.88 1.5 m cl.8.4.1.5 **Moment at middle-strip Case of flat slab

2. Design

Load pu= 1.638 t/m2 Reinf' Design:

Middle Strip Pos Mu R a z Asreq no./m dia. spc. Aspro Asmin***

fct to M: 1-2 3-4 Col str end1 end2 Li M0 NegM NegM PosM 1-2 midy 1.487 0.03 0.005 0.15 2.66 5 12 0.2 5.65 3.24 OK

Neg.int M= 0.65 0.7 1 0 1 6 62.8 -10.1 -44 35.8 1 -2.76 0.06 0.009 0.15 5.02 5 14 0.2 7.70 3.24 OK

Neg.ext M= 0.65 0.16 2 0 1 6 62.8 -10.1 -44 35.8 2 -2.76 0.06 0.009 0.15 5.02 5 12 0.2 5.65 3.24 OK

Pos. M= 0.35 0.57 3 1 1 3.75 24.5 -15.9 -15.9 8.58 3-4 midx 2.268 0.05 0.007 0.15 4.1 5 12 0.2 5.65 3.24 OK

cl.8.10.4.2 4 1 1 7.5 49 -31.9 -31.9 17.2 3 -0.19 0 0.001 0.15 0.34 5 14 0.2 7.70 3.24 OK

M0=1/8.pu.Li*Ln^2 cl.8.10.3.2 4 -2.78 0.06 0.009 0.15 5.06 5 14 0.2 7.70 3.24 OK

NegM, PosM=fct*M0, Ln is clear span Mu in t.m/m = Mmid strip in table 1 / col strip *** 0.18%

Shear Vu= 4.628 t/m =-fct*pu*(Lx/2-b/2-d) Column Strip Pos Mu R a z Asreq no./m dia. spc. Aspro Asmin***

ΦVc= 10.12 t/m =0.75*0.17*sqrt(f'c).1.d OK Pos max 1.566 0.03 0.005 0.15 2.81 5 12 0.2 5.65 3.24 OK

Pos min 0.595 0.01 0.002 0.15 1.06 5 12 0.2 5.65 3.24 OK

Pu col= t =imposed punching load Neg. max -1.92 0.04 0.006 0.15 3.46 5 12 0.2 5.65 3.24 OK

Vu= 0 t =Pu, other wise taking as L1*L2*pu Neg. min -0.51 0.01 0.002 0.15 0.91 5 12 0.2 5.65 3.24 OK

Φ.Vc= 0 t =0.75*0.33*1*sqrt(f'c)*b0*d Mu in t.m/m = Mmid strip in table 1 / col strip *** 0.18%

Table 1 Ext. Neg Moment Pos. Moment Int Neg Moment

αf1*l2/l1 Tors. x y x y C(cm4) βt %Col %mid col str beam slab Mmid %Col %mid col str beam slab Mmid %Col %mid col str beam slab Mmid

1 2 1 0.35 0.5 0.18 0.32 44 0.75 94.3 5.73 -9.5 -8.0 -1.4 -0.6 81 19 29.0 24.6 4.4 6.8 81 19 -35.6 -30.2 -5.43 -8.4

2 2 1 0.35 0.5 0.18 0.32 44 0.75 94.3 5.73 -9.5 -8.0 -1.4 -0.6 81 19 29.0 24.6 4.4 6.8 81 19 -35.6 -30.2 -5.43 -8.4

3 3.75 0 0.35 0.5 0.18 0.32 0 0 0 0 0.0 0.0 0.0 0.0 67.5 32.5 5.8 5.0 0.8 2.8 67.5 32.5 -10.8 -9.4 -1.4 -5.2

4 2.5 0 0.35 0.5 0.18 0.32 0 0 0 0 0.0 0.0 0.0 0.0 67.5 32.5 11.6 9.5 2.1 5.6 67.5 32.5 -21.5 -17.6 -3.95 -10.4

C=sum(1-0.63.x/y).x^3.y/3 cl.8.10.5.2

βt=C/2/Inertia_b cl.8.10.5.2

%col, % beam = interpolation from table 2 below

Table 2 (cl.8.10.5.1, cl.8.10.5.2, & cl.8.10.5.5)

Int.&Ext Neg Moment l2/l1 sort 1.25 Interp. sort 0.8 Interp.

no torsion αf1*l2/l1 0.5 1 2 1 2 1.25 0.5 1 0.8

0 75 75 75 75 75 75 75 75 75

1 90 75 45 75 45 67.5 90 75 81

Ext. Neg Moment l2/l1 sort 1.25 Interp. sort sort 0.8 Interp. sort

torsion αf1*l2/l1 βt 0.5 1 2 1 2 1.25 0.75 0.5 1 0.8 0.75

0 0 100 100 100 2 100 100 100 92.5 100 100 100 92.5

2.5 75 75 75 3 75 75 75 75 75 75

1 0 100 100 100 4 100 100 100 90.2 100 100 100 94.3

2.5 90 75 45 5 75 45 67.5 90 75 81

Positive Moment l2/l1 sort 1.25 Interp. sort 0.8 Interp.

αf1*l2/l1 0.5 1 2 1 2 1.25 0.5 1 0.8

0 60 60 60 60 60 60 60 60 60

1 90 75 45 75 45 67.5 90 75 81

Condition applied (Nilson, 14ed):

1. There must be a minimum of three continuous spans in each direction

2. The panels must be rectangular, with the ratio of the longer to the shorter spans

within a panel not greater than 2.

3. The successive span lengths in each direction must not differ by more than onethird

of the longer span.

4. Columns may be offset a maximum of 10 percent of the span in the direction of

the offset from either axis between centerlines of successive columns.

5. Loads. must be due to gravity only, and the unfactored live load must not exceed

2 times the unfactored dead load.

6. If beams are used on the column lines, the relative stiffness of the beams in the

two perpendicular directions, given by the ratio afln/af 2n, must be between 0.2

and 5.0.

Vous aimerez peut-être aussi

- Solution Manual for an Introduction to Equilibrium ThermodynamicsD'EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsPas encore d'évaluation

- SSE Analysis Beam - v1 - 09 - G1 - 20210819 - 2147 - 37Document1 pageSSE Analysis Beam - v1 - 09 - G1 - 20210819 - 2147 - 37SES DESIGNPas encore d'évaluation

- SSE Analysis Beam - v1 - 09 - G1 - 20210819 - 2223 - 31Document1 pageSSE Analysis Beam - v1 - 09 - G1 - 20210819 - 2223 - 31SES DESIGNPas encore d'évaluation

- SSE RC Beam Designer EC2 Sheet v1.21Document6 pagesSSE RC Beam Designer EC2 Sheet v1.21SES DESIGNPas encore d'évaluation

- Pile Cap Aci Ssev1.03Document4 pagesPile Cap Aci Ssev1.03Achraf CharfeddinePas encore d'évaluation

- SSE Sheet Pile Analysis Sheet v1.10Document3 pagesSSE Sheet Pile Analysis Sheet v1.10SES DESIGNPas encore d'évaluation

- SSE Analysis Beam - v1 - 09 - G1 - 20210819 - 2223 - 04Document1 pageSSE Analysis Beam - v1 - 09 - G1 - 20210819 - 2223 - 04SES DESIGNPas encore d'évaluation

- SSE Analysis Beam - v1 - 09 - G1 - 20210819 - 2223 - 54Document1 pageSSE Analysis Beam - v1 - 09 - G1 - 20210819 - 2223 - 54SES DESIGNPas encore d'évaluation

- Beam 20x40Document3 pagesBeam 20x40chhay longPas encore d'évaluation

- S3a s4 Design NoteDocument116 pagesS3a s4 Design NoteBrielle Ekira BermudezPas encore d'évaluation

- Sse RC Beam: Continue Beam Section CantileverDocument3 pagesSse RC Beam: Continue Beam Section Cantileverchhay longPas encore d'évaluation

- Diagrama de Interacción de La ColumnaDocument5 pagesDiagrama de Interacción de La ColumnaLEONARDO DIEGO TRUJILLO CARDENASPas encore d'évaluation

- Gaya Dan Momen Gelombang Pada SLTT (A)Document22 pagesGaya Dan Momen Gelombang Pada SLTT (A)kometmayorPas encore d'évaluation

- SSE RC Beam Designer ACI Sheet v1.12Document4 pagesSSE RC Beam Designer ACI Sheet v1.12Sophea PhanPas encore d'évaluation

- Composite Steel Beams GuideDocument23 pagesComposite Steel Beams GuideAhmed lbrahimPas encore d'évaluation

- Load Chase Down On Beam Sse-Excel Section W1: The Author Will Not Be Responsible For Any Uses of This Software! v1.04Document1 pageLoad Chase Down On Beam Sse-Excel Section W1: The Author Will Not Be Responsible For Any Uses of This Software! v1.04chhay longPas encore d'évaluation

- Calc Pile Slab - PengambanganDocument12 pagesCalc Pile Slab - PengambanganSyahriar 'Thian' CoolPas encore d'évaluation

- Matriz de Rigidez para Placa Elemento 1 F M F C N Ancho 0.25 Alto 0.4 Largo 3 Ancho D Muro 0.14 Area 2.688Document6 pagesMatriz de Rigidez para Placa Elemento 1 F M F C N Ancho 0.25 Alto 0.4 Largo 3 Ancho D Muro 0.14 Area 2.688Alan VillanuevaPas encore d'évaluation

- 2.5-Fizik-Skema-Kertas 3 Set ADocument9 pages2.5-Fizik-Skema-Kertas 3 Set AmurniPas encore d'évaluation

- 1.0 Input 1.1 Design Soil Parameters: 0.0 0.0 Ground LevelDocument4 pages1.0 Input 1.1 Design Soil Parameters: 0.0 0.0 Ground LevelSurat WaritPas encore d'évaluation

- STRIP FOUNDATION DESIGNDocument45 pagesSTRIP FOUNDATION DESIGNPhilip NguyenPas encore d'évaluation

- Half-Life Period Method Rate EquationDocument6 pagesHalf-Life Period Method Rate EquationParthapratim GuptaPas encore d'évaluation

- Design of Abutment Shaft ParametersDocument4 pagesDesign of Abutment Shaft ParametersamitkuknaPas encore d'évaluation

- 1.0 Input 1.1 Design Soil Parameters: 0.0 0.0 Ground LevelDocument4 pages1.0 Input 1.1 Design Soil Parameters: 0.0 0.0 Ground LevelSurat WaritPas encore d'évaluation

- C1-C2 Columns Footing DesignDocument12 pagesC1-C2 Columns Footing DesignVivekCivilPas encore d'évaluation

- FISICADocument5 pagesFISICAValeska RuizPas encore d'évaluation

- SSE Sheet Pile Analysis Sheet v1.09Document3 pagesSSE Sheet Pile Analysis Sheet v1.09SES DESIGNPas encore d'évaluation

- SSE Shear Design - EC2v1 - 07 - G1 - 20211027 - 2233 - 53Document4 pagesSSE Shear Design - EC2v1 - 07 - G1 - 20211027 - 2233 - 53SES DESIGNPas encore d'évaluation

- Design of Concrete Structure I: Dr. Mustafa AltayebDocument13 pagesDesign of Concrete Structure I: Dr. Mustafa AltayebBashar ToshtashPas encore d'évaluation

- EC2 EC2 0.225: Mpa 0.4 0.6 (1-fck/250) fck/1.5 M U0+4 PI DDocument2 pagesEC2 EC2 0.225: Mpa 0.4 0.6 (1-fck/250) fck/1.5 M U0+4 PI DSES DESIGNPas encore d'évaluation

- Stair Case Calculation For LoadsDocument4 pagesStair Case Calculation For Loadsfuda HasenPas encore d'évaluation

- KEMREX PILE CALCULATION for HMC-PP4 PROJECTDocument15 pagesKEMREX PILE CALCULATION for HMC-PP4 PROJECTSurat WaritPas encore d'évaluation

- Submission 1Document3 pagesSubmission 1syahirahPas encore d'évaluation

- Vortrag Da Wu LiangjunDocument33 pagesVortrag Da Wu LiangjunsubuhpramonoPas encore d'évaluation

- One-Level-basement-wall ACI SSE v1.06Document1 pageOne-Level-basement-wall ACI SSE v1.06SES DESIGNPas encore d'évaluation

- 22.0 Pile Capacity (A2) : (IS:2911 (Part I Sec 2) - 2010 Case 1: Pile in Soil (Cohesive + Cohesionless) 1.2 25.00Document6 pages22.0 Pile Capacity (A2) : (IS:2911 (Part I Sec 2) - 2010 Case 1: Pile in Soil (Cohesive + Cohesionless) 1.2 25.00Anonymous jLLjBdrPas encore d'évaluation

- Newtonian mechanics free vibration simulationDocument20 pagesNewtonian mechanics free vibration simulationasdi kusworoPas encore d'évaluation

- Faculty of Civil Engineering and Planning Civil Engineering Department Petra Christian UniversityDocument31 pagesFaculty of Civil Engineering and Planning Civil Engineering Department Petra Christian UniversityarfinpattyPas encore d'évaluation

- Surface Irrigation Design Assignment Ahmed Abdilahi IsmailDocument16 pagesSurface Irrigation Design Assignment Ahmed Abdilahi IsmailEng Ahmed abdilahi IsmailPas encore d'évaluation

- Diseño de Zapata Excentrica Entre 5-5 Y A-ADocument1 pageDiseño de Zapata Excentrica Entre 5-5 Y A-AMiguel Egoavil TaipePas encore d'évaluation

- 5 ConclusionDocument81 pages5 ConclusionFebriansyah NurdinPas encore d'évaluation

- Faculty of Civil Engineering and Planning Civil Engineering Department Petra Christian UniversityDocument31 pagesFaculty of Civil Engineering and Planning Civil Engineering Department Petra Christian Universitykenny liePas encore d'évaluation

- Gaya Dan Momen Gelombang Pada SLTT (A)Document20 pagesGaya Dan Momen Gelombang Pada SLTT (A)kometmayorPas encore d'évaluation

- 1 Propiedades Geometricas de La SeccionDocument3 pages1 Propiedades Geometricas de La SeccionHansc CondoriPas encore d'évaluation

- Datos: HABLLAMOS EL T PermisibleDocument3 pagesDatos: HABLLAMOS EL T PermisibleAlain Dax SanchezPas encore d'évaluation

- RC Slab ACI - Direct Method Ref: Thonier Tome 2 and Nilson 14th SIDocument2 pagesRC Slab ACI - Direct Method Ref: Thonier Tome 2 and Nilson 14th SISES DESIGNPas encore d'évaluation

- SSE RC Corbel Designer - EC2v1 - 11 - TM-GB-G9-5 - 20211023 - 1952 - 45Document1 pageSSE RC Corbel Designer - EC2v1 - 11 - TM-GB-G9-5 - 20211023 - 1952 - 45SES DESIGNPas encore d'évaluation

- Cbse Test Paper-01 CLASS - XI PHYSICS (Physical World & Measurement) Topic: - Physical World & Measurement (ANSWERS)Document5 pagesCbse Test Paper-01 CLASS - XI PHYSICS (Physical World & Measurement) Topic: - Physical World & Measurement (ANSWERS)anon_204662609Pas encore d'évaluation

- Shear-Wall-Design ACI SSEv1.02Document1 pageShear-Wall-Design ACI SSEv1.02Sophea PhanPas encore d'évaluation

- Caida VerticalDocument2 pagesCaida VerticalHander Rivera SalinasPas encore d'évaluation

- Mechanical Engineering Design Tables for Stress Concentration FactorsDocument10 pagesMechanical Engineering Design Tables for Stress Concentration FactorsĞôřqûî ĀğūîřřêPas encore d'évaluation

- Design of Concrete Structure I: Dr. Mustafa AltayebDocument33 pagesDesign of Concrete Structure I: Dr. Mustafa AltayebBashar ToshtashPas encore d'évaluation

- Zapata Conectada Zap - IntDocument4 pagesZapata Conectada Zap - IntHERBERT JESUS ZEVALLOS GUZMANPas encore d'évaluation

- FIXED Strip FootingDocument10 pagesFIXED Strip FootingWanda BeasleyPas encore d'évaluation

- Introduction to Fluid Mechanics Chapter SolutionsDocument23 pagesIntroduction to Fluid Mechanics Chapter Solutionsb0bfath3rPas encore d'évaluation

- Structural-Computation-Analysis-TWO-2-STOREY-COMMERCIAL-HALLDocument12 pagesStructural-Computation-Analysis-TWO-2-STOREY-COMMERCIAL-HALLAndie PanaliganPas encore d'évaluation

- Ion Beams for Materials AnalysisD'EverandIon Beams for Materials AnalysisR. Curtis BirdPas encore d'évaluation

- Workbook to Accompany Physics for Students of Science and EngineeringD'EverandWorkbook to Accompany Physics for Students of Science and EngineeringPas encore d'évaluation

- 7Document58 pages7Heng SreymomPas encore d'évaluation

- 8Document70 pages8Heng SreymomPas encore d'évaluation

- First Floor Column Layout Scale: 1:100: ProjectDocument1 pageFirst Floor Column Layout Scale: 1:100: ProjectHeng SreymomPas encore d'évaluation

- Contoh Soal Psikotes Kerja Dan Kunci JawabanDocument74 pagesContoh Soal Psikotes Kerja Dan Kunci JawabanYulia RimadaniPas encore d'évaluation

- Guide To Concrete Repair (2015)Document376 pagesGuide To Concrete Repair (2015)Fernando EscriváPas encore d'évaluation

- Back Stari Detai Revise Final (29!11!16) Detail c1cDocument1 pageBack Stari Detai Revise Final (29!11!16) Detail c1cHeng SreymomPas encore d'évaluation

- Assignment PhearumDocument1 pageAssignment PhearumHeng SreymomPas encore d'évaluation

- Back Stari Detai Revise Final (29-11-16) Detail c1c PDFDocument1 pageBack Stari Detai Revise Final (29-11-16) Detail c1c PDFHeng SreymomPas encore d'évaluation

- DebugDocument14 pagesDebugMigui94Pas encore d'évaluation

- Central Angles and Inscribed Angles GuideDocument22 pagesCentral Angles and Inscribed Angles GuideEric de Guzman100% (1)

- Java 8 Interview QuestionsDocument31 pagesJava 8 Interview QuestionsAmit Sharma100% (2)

- Lighting SchemesDocument7 pagesLighting SchemesSharath CherryPas encore d'évaluation

- Fix Disk & Partition ErrorsDocument2 pagesFix Disk & Partition Errorsdownload181Pas encore d'évaluation

- Applications and Interpretation Standard SpecimensDocument56 pagesApplications and Interpretation Standard SpecimensNahir ClaraPas encore d'évaluation

- Diffusion Weber and MorrisDocument12 pagesDiffusion Weber and MorrisFarah El ShahawyPas encore d'évaluation

- B 2Document12 pagesB 2Mohamed Sayed Abdel GaffarPas encore d'évaluation

- Chapter 1Document11 pagesChapter 1bekemaPas encore d'évaluation

- Weld CheckDocument6 pagesWeld CheckArnold c ElverPas encore d'évaluation

- SQL SlidesDocument65 pagesSQL SlidescopsamostoPas encore d'évaluation

- Sling PsychrometerDocument8 pagesSling PsychrometerPavaniPas encore d'évaluation

- Code - Aster: Multiaxial Criteria of Starting in FatigueDocument44 pagesCode - Aster: Multiaxial Criteria of Starting in FatigueYoyoPas encore d'évaluation

- 01238-00-AD TY96 Installation ManualDocument42 pages01238-00-AD TY96 Installation ManualJohan SwanepoelPas encore d'évaluation

- Writing Iap Smarten Up in Maths Age 7 8Document38 pagesWriting Iap Smarten Up in Maths Age 7 8lphoune100% (1)

- Structural Steel Design: Design of Tension Members 2: Universal College of ParañaqueDocument36 pagesStructural Steel Design: Design of Tension Members 2: Universal College of ParañaqueFritz LuzonPas encore d'évaluation

- AdvancesDocument328 pagesAdvanceshanumsj123Pas encore d'évaluation

- A Conjunction Is The Glue That Holds WordsDocument2 pagesA Conjunction Is The Glue That Holds WordsYamson MillerJrPas encore d'évaluation

- Artificial Intelligence in The GPs Office A Retrospective Study On Diagnostic AccuracyDocument13 pagesArtificial Intelligence in The GPs Office A Retrospective Study On Diagnostic Accuracymarj611582Pas encore d'évaluation

- Https WWW - Joinpaknavy.gov - PK Web Checkstatus Rollno 410219516621 PDFDocument1 pageHttps WWW - Joinpaknavy.gov - PK Web Checkstatus Rollno 410219516621 PDFZainab KhatoonPas encore d'évaluation

- Chapter 13: The Electronic Spectra of ComplexesDocument42 pagesChapter 13: The Electronic Spectra of ComplexesAmalia AnggreiniPas encore d'évaluation

- Balmer PDFDocument3 pagesBalmer PDFVictor De Paula VilaPas encore d'évaluation

- List of Practical Cs With SolutionDocument57 pagesList of Practical Cs With SolutionArjun KalaPas encore d'évaluation

- p-4500 Technical InformationDocument13 pagesp-4500 Technical InformationElhoiPas encore d'évaluation

- Unit 6 - Quantitative Analysis NotesDocument53 pagesUnit 6 - Quantitative Analysis Notesapi-182809945Pas encore d'évaluation

- Ajmera - Treon - FF - R4 - 13-11-17 FinalDocument45 pagesAjmera - Treon - FF - R4 - 13-11-17 FinalNikita KadamPas encore d'évaluation

- No.1 PrestressedDocument10 pagesNo.1 PrestressedKristin ArgosinoPas encore d'évaluation

- Ansoff Matrix Template User GuideDocument6 pagesAnsoff Matrix Template User Guidebernardo95Pas encore d'évaluation

- Westminster Academy, Islamabad: Physics (0625) Topic Test:Sound WavesDocument5 pagesWestminster Academy, Islamabad: Physics (0625) Topic Test:Sound Wavessaimee77Pas encore d'évaluation

- Virtual Retinal DisplayDocument17 pagesVirtual Retinal Displaysaket_mnPas encore d'évaluation