Académique Documents

Professionnel Documents

Culture Documents

Astm d2290 12 PDF

Transféré par

m 4180 évaluation0% ont trouvé ce document utile (0 vote)

90 vues36 pagesTitre original

kupdf.net_astm-d2290-12.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

90 vues36 pagesAstm d2290 12 PDF

Transféré par

m 418Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 36

‘Copyrighted mater icensedto Gaus Aramco. No furhar reproduction or bution permite

Printed / viewed by: (husasin drwish@scamco.com) @ 2019-1204

COPYRIGHT NOTICE & TERMS OF USE

‘This document is the copyright of the Publisher. All rights reserved.

The contract allowing you to use this document contains the following terms of use which must be

followed:-

(@) You may view and print a single copy of a document contained in the Subscription for reference

purposes only and only for internal purposes within the site on which such copies are made,

providing such copies are dated and destroyed after the reference usage, typically no more than 60

working days after use, subject to the exception described in clause (b) below. Such copies may not

be filed to form part of any hard copy reference collection.

(b) Where you have a specification or tender requirement to reproduce a document or portions of a

document as part ofits documentation for external submission in response to a tender, the necessary

ages of the document, including the whole document if required, may be reproduced and submitted

Provided @ copyright notice is included. You shall notify SAI Global of any such use. For internal and

archival purposes only, a paper copy may be attached to your documentation and shall be

considered a permanent part of that documentation.

(©) Under no circumstances are you permitted to reproduce all or part of any document for external

Use or for use in any other site or group of sites, except as set forth in (b) above.

(@ You may not remove any proprietary markings or electronic watermarks, including any

‘copyrights and trademarks.

(©) You may copy a maximum of 25% of the content of a document within the Subscription and

paste it to another document for internal use. The copied content in the new document must contain

‘a copyright notice "Copyright [name of publisher] Date where date is the date of copyrighted material

‘Such content is licensed for use only for the duration of the relevant Subscription,

() For ISO standards, the material is reproduced from ISO publications under International

Organization for Standardization (ISO) Copyright License number SAI GLOBAL/MCEA/2008. Not for

resale. No part of these ISO publications may be reproduced in any form, electronic retrieval system

or otherwise, except as allowed under the copyright law in the country of use, or with the prior written

consent of ISO (Case postale 6, 1211 Geneva 20, Switzerland, email: copyright@iso.org) or ISO's

Members.

# SAI GLOBAL

SAI GLOBAL, Index House, Ascot, Berks, SL5 7EU, UK

‘B. +44 (0) 1344 636300. Fax: +44 (0)1344 291194, E-mail: standards@saiglobal.com. wwwli.co.uk

SAI GLOBAL, 610 Winters Avenue, Paramus, NJ 07652, USA

‘@ 201-986-1131. Fax: 201-986-7886. E-mail: sales@ili-info.com. wwwili-info.com

SAI GLOBAL, 286 Sussex Street, Sydney NSW 2000, Australia

‘+61 2 8206 6060. Fax: +61 2 8208 6019, E-mail: sales@saiglobal.com, wawsaiglobal.com

Copyiahted matil icons o Saws Aemee, No ther reproduction or detrbuton permit

et cr soa ne ‘ ACSI S A MGSHT AMGEN ERT ORAS rnin tall aes te Sar sane

I Designation: B2290—08 2290

Standard Test Method for

Apparent-Hoop-Tensile Strength of Plastic or Reinforced

I Plastic Pipe-by Split-Disk Method’

This tnd seed unr to fet igation 02250 the name mms flloning the designation ind te year of

vigil gapton oi Ue eee of vison, de year fin evi. A nein prentze nes he en Teepe.

Superscript) ndeates an er change see he ast olson of capa

Ph suns aso pte for ra hy nc of the Deprimet of fone:

I 1. Scope Scope

1.1. This test method covers the determination of the comparative apparent tensile strength of most plastic produets utilizing a

I. split disk or ring segment test fixture, when tested under defined conditions of preteatment, temperature, humidity, and test

machine speed. This test method is applicable to reinforeed-thermoseting resin pipe regardless of fabrication method. This test

method also is applicable to extraded and molded thermoplastic pipe

“A Procedure A is used for reinforced-thermosetingeesin pige; Procedure Bis used for thermoplastic pipe of any size; Procedure

iif Tor thetnoplasOe pipe wiih nominal diameter of 44 i, 110 mum) and greats. Procedure D is used for

polyethylene pipe wth a nominal diameter of 1 in. (380 mm) and greater and preferably having wall thickness | in, GS mm).and

‘reat

1.2 The values stated in inch-pound units are to be regarded as standard, The values given in parentheses are mathematical

conversions to SI units that are provided fr information only and are not considered standard

+13 This standard does not purport to address all ofthe safety concerns, any, associated with ts us. It 18 the responsiblity

of the user of this standard 10 establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior 10 we.

2. Referenced Documents

2.1 ASTM Standards?

D618 Practice for Conditioning Plastics for Testing

11599 Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

4 Practices for Force Verification of Testing Machines

2 Sipimaer octet ated

1 3:1Grhe For Procedures ADB, and C.the tat specimen is loaded through the suggested selfaligning spit disk test fixture (Fig

1) which applies tensile sess to the testing. An apparent tensile strength rate than a true tensile strength is obtained in this test

because of a bending moment imposed during test at the split between the split dsk test fixture. This moment is induced by the

change in contour of the ring between the two disk sections as they separate. The tet finture is designed to minimize the eet

of this bending moment

3.2 For Procedure D, ring segment test specimen pairs are loaded into the suogested self-aligning test fixtures (Fig, 2) that ere

designed to apply direct tensile stress to the reduced areas of the ring seament (est specimens (Fig. 3) with minimal bending

moment,

4 Significance and Use

[41 Split disk tension-and ring seament tensile tests, properly interpreted, provide reasonably accurate information with regard

to the apparent tensile strenath of plastic pipe when employed under conditions approximating those uncer which the tests are

made.

“A Summary of Changs seston appears at the end ofthis standard

Ceprg@ ASTM itera 100 Bar er Oe, FO Bau TED en Crate FA 198EO.2I6. te et

‘Copyrighted mate cence to Saud Aramco. No further repteduton ar dtrbaton permite

Printed viewed by: (usssn dawieh@aramco com] @ 2013-12-08

lp 02200 - 12

FIG. 4 Tost Fixture: Typical

4.2 Fension-Ring tensile tests may provide data for research and development, engineering design, quality control, acceptance

or rejection under specifications, and for special purposes. The test cannot be considered significant for applications differing

‘widely from the load-time scale of the standard test

‘Nore I—ProcedureC has been used on polyethylene end polybutylene pipe fo produce results equivalent to Quick Burst results (Test Method D199)

for i, 10 8 lps,

5. Apparatus

5.1. Micrometers—Suitable botltype-ball anviltype micrometers, reading to at least 0.001 in., for measuring the width and

thickness of the test specimens.

5.2 Testing Machine—A universal testing machine ofthe constant-ate-of-eross-head-movement type and comprising essentially

the following:

5.2.1 Drive Mechanism—A drive mechanism for imparting to the crosshead 2 uniform controlled velocity with respect to the

‘base, this velocity to be regulated as specified in Section 9.

5.2.2 Load Indicator—A load-indicating mechanism capable of showing the total tensile load carried by the test specimen. This

‘mechanism shall be essentially fre from inertia lag atthe specified rate of testing and shall indicate the load with an accuracy of

61 % of the indicated value, The accuracy of the testing machine shall be verified in accordance with Method E4.

5.3 Procedue A, B. and C Test Fisture—The recommended test fixture Procedures A, B, and C is shown in Fig. 1. The width

othe split isk, for Procedure A and P shall be atleast 0. in, grester than the width of the specimen, The width ofthe

split Procedure C in. The supports for Folding the tension test ixtute shall be selaligning that s,

they shall be attached to the fixed and movable member ofthe test machine, respectively, in such a manner that they move freely

into alignment as soon as any load is applied, so that the direction of the applied pull is directly perpendicular to the split axis of

the test fixture,

5.4 Procedure D Test Fixiure—A tension test fixture for Procedure D is illustrated in Fig, 2. The suppors for holding the tension

test fixture shall be self-aligning thats, they shall be attached to the fixed and movable member ofthe test machine, respectively

n_such a manner that they move fieely into alignment as soon as any load is applied, so thatthe direction of the applied pull is

lirectly perpendicular to the split axis of the test fixture.

Nom 2-tn Fig. 2, the 2.00 (50.8 mm) wide by 5.0. (127 mm) long openines ae suitable fr ring seament specimens tha a 1,6 8 in 40.6

1p 457 in) wide ad fom 004.5 (28.40 (143 mm) wal this For rng sepmen specimen wll hikes ereaer than 43 in (1.3 mm)

‘pening size may be adjusted appropriately. Opening size shoul allow 0.10 (23 rm) minimum wich leranes on ish sie. ond ot fast 0.50 (12.7

‘on all hokness clearance, Rig seamen! st spee men securing pins 0,50 2.7 nn) diameter have heen aund sable, Teperng or roading the

‘id ofthe soouring ers pins facliates installation ino ts ing seaments specimens. See a, 2 and Fi, 3

5.5 Conaltioning Apparatus—Apparatus for maintaining the-stenderd-taboratory-atmoepheri-temperstte-of 23-6226 4734-6—

:68F ane S0- She ten ty for conditioning prior to test, ar-defined-in-Procedure-ofin accordance

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Form No. 12BB: (See Rule 26C)Document2 pagesForm No. 12BB: (See Rule 26C)m 418Pas encore d'évaluation

- Preliminary PagesDocument3 pagesPreliminary Pagesm 418Pas encore d'évaluation

- Chanakya NeetiDocument150 pagesChanakya NeetiPrashant Sunagar75% (4)

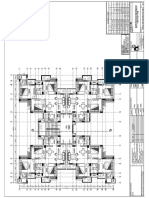

- Floor Plan (2nd Floor) - Township - 2Document1 pageFloor Plan (2nd Floor) - Township - 2m 418Pas encore d'évaluation

- Floor Plan (1st Floor) - TownshipDocument1 pageFloor Plan (1st Floor) - Townshipm 418Pas encore d'évaluation

- I Want To Close My Loan ADocument1 pageI Want To Close My Loan Am 418Pas encore d'évaluation

- Floor Plan (1st Floor) - TownshipDocument1 pageFloor Plan (1st Floor) - Townshipm 418Pas encore d'évaluation

- Fatigue Life Estimation of A Butt Welded Joint by S-N ApproachDocument5 pagesFatigue Life Estimation of A Butt Welded Joint by S-N Approachm 418Pas encore d'évaluation

- FRP Pipe Stress Calculation Sheet - Edition 18-July-15Document12 pagesFRP Pipe Stress Calculation Sheet - Edition 18-July-15Prashant AgrawalPas encore d'évaluation

- PDFVManualSm PDFDocument1 pagePDFVManualSm PDFgeorgex72Pas encore d'évaluation

- Conditions For Erection of "Elmech" Cranes.: Purchaser'S / Consignees ObligationsDocument1 pageConditions For Erection of "Elmech" Cranes.: Purchaser'S / Consignees Obligationsm 418Pas encore d'évaluation

- Annexure-I - Pipeline Tie-In Schedule PDFDocument1 pageAnnexure-I - Pipeline Tie-In Schedule PDFm 418Pas encore d'évaluation

- Flameproof Reference ListDocument20 pagesFlameproof Reference Listm 418Pas encore d'évaluation

- PDFVLicense PDFDocument2 pagesPDFVLicense PDFgiosoyPas encore d'évaluation

- Annexure-I - Pipeline Tie-In Schedule PDFDocument1 pageAnnexure-I - Pipeline Tie-In Schedule PDFm 418Pas encore d'évaluation

- Ijarme Vol1 Iss2 06 PDFDocument6 pagesIjarme Vol1 Iss2 06 PDFm 418Pas encore d'évaluation

- Full TextDocument341 pagesFull Textcevapcic100Pas encore d'évaluation

- Bondstrand Design Manual: For Marine Piping SystemsDocument97 pagesBondstrand Design Manual: For Marine Piping Systemsm 418Pas encore d'évaluation

- Rubber Ring - RM Data SheetDocument1 pageRubber Ring - RM Data Sheetm 418Pas encore d'évaluation

- Fiberstrong Piping System Above Ground Installation Manual 1Document36 pagesFiberstrong Piping System Above Ground Installation Manual 1m 418Pas encore d'évaluation

- FluidFlow 3.44Document1 pageFluidFlow 3.44m 418Pas encore d'évaluation

- TPL 1044 39720 Ec Ga 0600 - SH PDFDocument1 pageTPL 1044 39720 Ec Ga 0600 - SH PDFm 418Pas encore d'évaluation

- Above Ground PipeDocument2 pagesAbove Ground Pipem 418Pas encore d'évaluation

- HTTP Devilonwheels PDFDocument9 pagesHTTP Devilonwheels PDFm 418Pas encore d'évaluation

- List of Laboratory EquipmentsDocument3 pagesList of Laboratory Equipmentsm 418Pas encore d'évaluation

- FluidFlow 3.44Document1 pageFluidFlow 3.44m 418Pas encore d'évaluation

- HAMMER QuickStartDocument52 pagesHAMMER QuickStartkamelPas encore d'évaluation

- Rohit Ticket SL-CSTMDocument2 pagesRohit Ticket SL-CSTM123Pas encore d'évaluation

- Lesson 3 - NonMetallic PipingDocument12 pagesLesson 3 - NonMetallic Pipingm 418Pas encore d'évaluation