Académique Documents

Professionnel Documents

Culture Documents

Q Bank Chem MCD Viii 2019

Transféré par

hgbv tttbDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Q Bank Chem MCD Viii 2019

Transféré par

hgbv tttbDroits d'auteur :

Formats disponibles

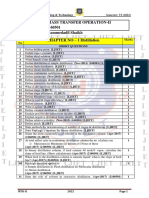

L.J.

Institute of Engineering & Technology Semester: VIII(2019)

Subject Name: MULTI COMPONENT DISTILLATION

Subject Code:2180505

Subject Faculty: Ms. Khushbu K Bhalodiya

Sr

No

CHAPTER – 1 SELECTION OF KEY Marks

COMPONENT

DESCRIPTIVE QUESTIONS

1 Define following: (May-2017)(Oct-2012) [LJIET] 7

1) Light key component

2) Heavy key component

3) Adjacent key

4) Split key

5) Distributed component

6) Non distributed component

7) Optimum reflux ratio

2 Define and Explain in brief following: (May-2015)[LJIET] 7

1) Light key component

2) Heavy key component

3) Adjacent key

3 Explain Light key component, heavy key component, and adjacent key and split key 7

components. (Nov-2014) [LJIET]

4 Define Light key component, heavy key component, and adjacent key and split key 4

components. (May-2014) [LJIET]

5 Define following terms: (May-2013) [LJIET] 7

Light key component, Heavy key component, Non-key component, Distributed

components, Non distributed component, Adjacent keys & Split keys for multi

component distillation.

6 Define light key component, heavy key component and non key component with 4

example. (May-2012) [LJIET]

7 Write a note on selection of key components in multi-component systems (Oct-2016) 7

[LJIET]

8 Explain : (1) Light key (2) Heavy key (3) Split Key (4) Adjacent key (May-2016) 8

[LJIET]

9 Explain following with suitable example: (1) Light Key (2)Heavy Key (3)Split Key 8

(4) Distributed Component (May-2017-New) [LJIET]

10 Define following: 7

Light key component, Heavy key component, Split key, Adjacent key, Non distributed

component, Non key component and Optimum reflux ratio. (Nov-2017) [LJIET]

11 Explain: (1) Light Key (2) Heavy Key (Nov-2017-New) [LJIET] 4

12 Define: (1) Non-key component (2) Distributed component (3) Non-distributed 3

Multicomponent Distillation 2019 Page 1

L.J. Institute of Engineering & Technology Semester: VIII(2019)

component. (Nov-2017-New) [LJIET]

13 Define: 1) Light key 2) Heavy key 3) Adjacent key (May-2018-new) [LJIET] 3

14 Define. (1) Adjacent key component (2) Split key components and (3) non distributed 4

components. (4) Azeotropic mixture.(Nov-2018-New) [LJIET]

CHAPTER – 2 SEQUENCING OF DISTILLATION

COLUMN

DESCRIPTIVE QUESTIONS

1 Discuss Sequencing of multi component distillation columns with example. (May- 7

2017)(May-2012) [LJIET]

2 Discuss “Sequencing of multi component distillation columns”. (May-2014) (May- 7

2016)(Nov-2017-New) [LJIET]

3 What is MESH equation? In multicomponent distillation, for C components and N number of 4

equilibrium stages how many MESH equations can be written? (Sep-2013) (Nov-2017-New)

[LJIET]

4 Discuss heuristics for determining favorable sequences in distillation column. (Sep- 7

2013) [LJIET]

5 What is sequencing of distillation column? Explain it with industrial examples. (Nov- 7

2017) [LJIET]

6 Discuss “Sequencing of multi component distillation columns”. (May-2018-new) 4

[LJIET]

7 Write an expression to calculate the number of possible sequences. Calculate the 3

number of possible sequences for 6 components. (Nov-2018-New) [LJIET]

8 What do you mean by sequencing of multicomponent distillation? How it is 7

important? Discuss marginal vapour method to determine the best possible sequence

for multicomponent distillation? (Nov-2018-New) [LJIET]

CHAPTER – 3 SELECTION OF OPERATING PRESSURE

DESCRIPTIVE QUESTIONS

1 Discuss the selection criteria of operating pressure for distillation column. (May- 7

2017) [LJIET]

OR

Explain how operating pressure of distillation column is determined. (Dec-2015)

[LJIET]

OR

Discuss in detail about selection of operating pressure for distillation column. (Sep-

2013) [LJIET]

2 Explain the fixing of operating pressure in distillation column. (Nov-2017) [LJIET] 7

3 What is Vacuum distillation? Discuss the advantages and disadvantages of Vacuum 7

Distillation (Dec-2015) (May-2015) (Oct-2012) (Oct-2016) (May-2017-New) [LJIET]

4 What are the disadvantages of Vacuum distillation? (Nov-2017-New) [LJIET] 3

5 Discuss the advantages and disadvantages of vacuum distillation. (Nov-2014) (May- 7

Multicomponent Distillation 2019 Page 2

L.J. Institute of Engineering & Technology Semester: VIII(2019)

2013) (May-2012) [LJIET]

6 What are the disadvantages of vacuum distillation? (Sep-2013) [LJIET] 3

7 How VLE data can be determined? (Nov-2017-New) [LJIET] 3

8 Discuss the selection of Operating pressure for various industrial distillation columns 7

with examples. (Oct-2016) (May-2018-new) [LJIET] [LJIET]

9 What is vacuum distillation? Why it is used? State its advantages and disadvantages. 7

(May-2016) [LJIET]

10 Discuss the advantages and disadvantages of Vacuum Distillation. (May-2018-new) 4

[LJIET]

11 Explain the theoretical method to determine VLE data for ideal & non-ideal system. 3

(May-2018-new) [LJIET]

12 Write a short note. "Selection criteria for the operating pressure in multicomponent 7

distillation column. (Nov-2018-New) [LJIET]

13 How to determine vapour liquid equilibrium data? (Nov-2018-New) [LJIET] 7

14 List out disadvantages of Vacuum distillation? (Nov-2018-New) [LJIET] 3

NUMERICALS

1 1000 kg of feed containing 30 % by mass ethylene glycol & remaining water is 7

charged to a batch still. Simple batch distillation is carried out at 30.4 kPa absolute

pressure to get the residue must contain 95 % by mass ethylene glycol. Find the

amount of residue (final product). (May-2013) [LJIET]

VLE data of ethylene glycol- water system at 30.4 kPa are as follow. Data of ethylene

glycol- water system at 30.4 kPa are as follow.

Temperature (0C) X y

69.5 1.00 1.000

76.1 0.77 0.998

78.9 0.69 0.997

83.1 0.60 0.990

89.6 0.46 0.980

103.1 0.27 0.940

118.4 0.15 0.870

128.0 0.10 0.780

134.7 0.07 0.700

145.0 0.03 0.530

160.7 0.00 0.530

Multicomponent Distillation 2019 Page 3

L.J. Institute of Engineering & Technology Semester: VIII(2019)

2 Feed mixture to a distillation column contains 30 % n-hexane, 32 % n-propane, 20 % 10

n-butane and 18 % n-pentane (by mole). Total flow rate of the feed is 100 kmol/h. If

butane & pentane are selected as light key & heavy key components, respectively then

find the product compositions. Operating pressure at the top of the column is 1600

kPa. Pressure drop in the column is 30 kPa. At dew point temperature 72 0C KPr =

1.55, KBu = 0.6, KPe = 0.25, KHe = 0.11. At bubble point temperature of residue 180

0C KBu = 2.5, KPe = 1.3, KHe = 0.79, KPr = 4.25. (May-2013) [LJIET]

CHAPTER – 4 METHODS FOR FINDING THEORETICAL

STAGES

DESCRIPTIVE QUESTIONS

1 State the algorithm or steps for Lewis Matheson method to calculate theoretical 7

stages in rectification section & also state feed tray identification. (May-2017) (Dec-

2015) (May-2013) [LJIET]

2 Discuss FUG method to determine theoretical stages for multicomponent distillation. 7

(May-2017) (Oct-2012) (Dec-2015) (May-2015) (Nov-2014) [LJIET]

3 State the steps for Theile Geddes method for calculation of theoretical stages in 7

stripping section. (Dec-2015)(May-2013)(May-2017-New) [LJIET]

OR

Explain the stepwise procedure of Thiele Geddes method for Multi component

distillation (May-2015) (Nov-2014)(May-2012)(Oct-2016) [LJIET]

4 Explain Theile- Geddes method in detail (Nov-2017) (Nov-2017-New) [LJIET] 7

5 Explain in detail the equation tearing procedure for multi component distillation. 14,10

(May-2015) (Nov-2014) (May-2012)(May-2016) [LJIET]

6 Discuss Lewis-Matheson method for multicomponent distillation. Also explain about 14

how to start the second trial calculation and arrive on final solution. (May-2014) (Oct-

2016) [LJIET]

7 Discuss Equation-Tearing Procedure using Tridiagonal matrix algorithm for 7,10

multicomponent distillation. (May-2014) (Nov-2017) [LJIET]

8 List out the variables that are to be specified as input data for Thiele- Geddes method. 10

Explain the stepwise procedure of Thiele Geddes method for stripping section of

Multicomponent distillation. (Sep-2013) [LJIET]

9 How will you identify feed tray location in Lewis –Matheson method of 4

Multicomponent distillation? (Sep-2013) (Nov-2017-New) [LJIET]

10 Write down Hegstebeck and Geddes equation for approximate distribution of non key 2

components in top product and bottom product. (Sep-2013) [LJIET]

11 Write short note on FUG method. (May-2016) [LJIET] 7

12 Write short note on Optimum reflux ratio. (May-2016) (Nov-2017-New) [LJIET] 4

OR

Explain optimum reflux ratio. (May-2017-New)[LJIET]

13 Explain the stepwise procedure of Thiele Geddes method for Multi component 7

Multicomponent Distillation 2019 Page 4

L.J. Institute of Engineering & Technology Semester: VIII(2019)

distillation. (May-2016) [LJIET]

14 Discuss stepwise procedure of Lewis-Matheson method for finding number of 7,14

theoretical stages required for desired separation. (May-2017-New)[LJIET]

OR

Write down stepwise procedure for Lewis-Matheson method to determine theoretical

stages in rectification section. (Nov-2017-New) [LJIET]

15 Explain Lewis Matheson method in detail. (Nov-2017) [LJIET] 7

16 Describe determination of optimum reflux ratio.(Nov-2017) [LJIET] 7

17 Explain : (1) distribution co-efficient (2) Selectivity (Nov-2017-New) [LJIET] 4

18 What is the application of hegstebeck and gedded equation? Discuss the equation. 3

(May-2018-new) [LJIET]

19 List out the variables that are to be specified as input data for Thiele-Geddes method. 7

Explain the stepwise procedure of Thiele Geddes method for stripping section of

Multicomponent distillation. (May-2018-new) [LJIET]

20 Discuss the equation tearing procedure, MESH equation with matrix algorithm for 7

multi component distillation. (May-2018-new) [LJIET]

21 Explain Lewis Matheson method for rectification section along with feed tray 4

identification. (May-2018-new) [LJIET]

22 Write a Kirk Bride equation with detail specifications for finding the feed stage 3

location in multicomponent distillation column. (Nov-2018-New) [LJIET]

23 List out various methods used for calculating the number of theoretical stages for 4

multicomponent distillation. (Nov-2018-New) [LJIET]

24 What do you mean by optimum reflux ratio. (Nov-2018-New) [LJIET] 4

25 Write an equation to determine the minimum reflux ratio for multicomponent 3

distillation. (Nov-2018-New) [LJIET]

26 Explain in detail. "Steps for Theile- Geddes method for finding theoretical stages of 7

multicomponent distillation column. (Nov-2018-New) [LJIET]

27 State the algorithm or steps for Lewis Matheson method to calculate theoretical 7

stages in rectification section & also state feed tray identification. (Nov-2018-New)

[LJIET]

28 How will you identify feed tray location in Lewis Matheson method in 4

Multicomponent distillation? (Nov-2018-New) [LJIET]

NUMERICALS

1 Determine the minimum reflux ratio for the binary distillation at standard 10, 14

atmospheric pressure based on the following data. (May-2017) (May-2013) [LJIET]

Feed = 100 kmol/h

Feed mixture: benzene – toluene

Mole fraction of benzene in feed = 0.4

Condition of feed = at 30 0C

Mole fraction of benzene in distillate required = 0.99

Mole fraction of benzene in residue required = 0.02

Multicomponent Distillation 2019 Page 5

L.J. Institute of Engineering & Technology Semester: VIII(2019)

Average relative volatility = 2.25

ln pvB = 15.9008 – 2788.51/(T–52.36) for benzene in torr

ln pvT = 16.0137 – 3096.52/(T–53.67) for toluene in torr

Normal boiling point of benzene = 80.1 0C

Normal boiling point of toluene = 110.6 0C

Property data of benzene & toluene :

Component CL at 62.65 0C, kJ/(kmol. 0C) λ at 95.3 0C, kJ/kmol

Benzene 146.96 29391.3

Toluene 173.33 34666.7

OR

Determine the minimum reflux ratio for the binary distillation at standard atmospheric

pressure based on the following data. (Dec-2015) [LJIET]

Feed = 100 kmol/h

Feed mixture: benzene – toluene

Mole fraction of benzene in feed = 0.4

Condition of feed = at 30 0C

Mole fraction of benzene in distillate required = 0.99

Mole fraction of benzene in residue required = 0.02

Average relative volatility = 2.25

ln pvB = 15.9008 – 2788.51/(T–52.36) for benzene in torr

ln pvT = 16.0137 – 3096.52/(T–53.67) for toluene in torr

Normal boiling point of benzene = 80.1 0C

Normal boiling point of toluene = 110.6 0C

Property data of benzene & toluene

Component CL at 62.65 0C, kJ/(kmol. 0C) λ at 95.3 0C, kJ/kmol

Benzene 146.96 29391.3

Toluene 173.33 34666.7

2 Find the distribution (or mol/h) of n-Butane in distillate and in residue by Thiele – 14

Geddes method based on the following data. (May-2017) (May-2014) [LJIET]

Table : Feed Composition

(i) Component mole %

n–Butane 37

i–Pentane 32

n–Pentane 21

n–Hexane 10

n–Butane is light key component and i– Pentane is heay key component.

(ii) Feed flow rate F = 4750 mol/h. Feed is saturated liquivd at its bubble point.

(iii) Reflux ratio, R = 3

(iv) D = 1250 mol/h, W = 3500 mol/h

(v) Operating pressure, p = 2 atm a

(vi) Assume constant molal overflow. Total condenser is used.

Multicomponent Distillation 2019 Page 6

L.J. Institute of Engineering & Technology Semester: VIII(2019)

Equilibrium Constants Data for n-Butane

Tray number Temperature, oC KC4

1 22 1.086

2 24 1.156

3 28 1.308

4 32 1.474

5 41 1.904

Reboiler 48 2.303

3 A saturated liquid, consisting of phenol and cresols with some xylenols, is fractioned 7,14

to give a top product of 95.3 mole % phenol. Metacresol is heavy key and phenol is

light key component. Total condenser is used. The compositions of the top product

and of the phenols in the bottoms are given. (Dec-2015) (Nov-2014) (Oct-2012)

[LJIET]

Component αav Feed, mole % Top product, Bottom

mole % product, mole

%

Phenol 1.98 35 95.3 5.24

o – Cresol 1.59 15 4.55 -

m – Cresol 1.00 30 0.15 -

Xylenols 0.59 20 - -

100 100

(1) Compute the material balance over the still for a feed rate of 100 kmol/h.

(2) Calculate the minimum reflux ratio by Underwood’s method.

OR

A saturated liquid, consisting of phenol and cresols with some xylenols, is fractioned

to give a top product of 95.3 mole % phenol. Metacresol is heavy key and phenol is

light key component. Total condenser is used. The compositions of the top product

and of the phenols in the bottoms are given. (Nov-2017)[LJIET]

Component αav Feed, mole % Top product, Bottom

mole % product, mole

%

Phenol 1.98 35 95.3 5.24

o – Cresol 1.59 15 4.55 -

m – Cresol 1.00 30 0.15 -

Xylenols 0.59 20 - -

100 100

Multicomponent Distillation 2019 Page 7

L.J. Institute of Engineering & Technology Semester: VIII(2019)

(1) Compute the material balance over the still for a feed rate of 1000 kmol/h.

(2) Calculate the minimum reflux ratio by Underwood’s method.

OR

A saturated liquid, consisting of phenol and cresols with some xylenols, is fractioned

to give a top product of 95.3 mole % phenol. Metacresol is heavy key and phenol is

light key component. Total condenser is used. The compositions of the top product

and of the phenols in the bottoms are given. (May-2015)(May-2013) [LJIET]

Component αav Feed, mole % Top product, Bottom

mole % product, mole

%

Phenol 1.98 35 95.3 5.24

o – Cresol 1.59 15 4.55 -

m – Cresol 1.00 30 0.15 -

Xylenols 0.59 20 - -

100 100

(1) Compute the material balance over the still for a feed rate of 100 kmol/h.

(2) Calculate the minimum reflux ratio by Underwood’s method

(3) For R=3Rm, calculate the composition of apour entering to the top most tray by

Lewis-Matheson method.

OR

A saturated liquid consisting of phenol and cresols with some xylenols is fractionated

to give a top product of 95.3 mol% phenol. Meta cresol is heavy key component and

phenol is light key component. Total condenser is used. The composition of the top

product and of the phenol is in the bottom are given. (Nov-2018-New) [LJIET]

(a) Complete the material balance over the still for a feed rate of 100 kmol / hr.

(b) Calculate the minimum reflux ratio by Underwood’s method.

Component αav Feed, mole % Top product, Bottom

mole % product, mole

%

Phenol 1.98 35 95.3 5.24

o – Cresol 1.59 15 4.55 ?

m – Cresol 1.00 30 0.15 ?

Xylenols 0.59 20 - ?

100 100

4 A saturated liquid, consisting of phenol and cresols with some xylenols, is fractioned 14

to give a top product of 95.3 mole % phenol. Metacresol is heavy key and phenol is

light key component. Total condenser is used. The compositions of the top product

and of the phenols in the bottoms are given (Sep-2013) [LJIET]

Multicomponent Distillation 2019 Page 8

L.J. Institute of Engineering & Technology Semester: VIII(2019)

Component αav Feed, mole % Top product, Bottom

mole % product, mole

%

Phenol 1.98 35 95.3 5.24

o – Cresol 1.59 15 4.55 -

m – Cresol 1.00 30 0.15 -

Xylenols 0.59 20 - -

100 100

(a) Compute the material balance over the still for a feed rate of 100

kmol/h.

(b) If R=3Rm, calculate the composition of vapour entering to the top

most tray by Lewis –Matheson method. Assume Rm= 1.67.

5 200 kmol/h of feed, containing 50% benzene, 25% toluene and 25% o-xylene, is to be 14

separated in batch distillation with a rectification column. Top product must contain

99% benzene. All compositions are mole%. Composition of distillate should remain

constant throughout the batch distillation. Distillation is to be continued until the

moles of benzene are reduced to 10 kmol in residue. Average relative volatility for

benzene, toluene and o-xylene is 2.497,1 and 0.3459 respectively. Determine the

Reflux ratio Vs. Time data. (Dec-2015) (May-2015) (Nov-2014) (Oct-2012) (May-

2018-New) [LJIET]

6 A distillation column is to separate 4750 mol/h of feed composed of 37% n-butane, 7

32% iso-pentane, 21% n-pentane and 10% n-hexane. The column operates at an

average pressure of 2 atm a and will produce a distillate product containing 95% n-

butane and 5% iso-pentane. The bottom product is allowed to contain no more than

570 mol/h of n-butane. Feed is 25% (by mole) vapour. Assume ideal apour-liquid

equilibrium. All compositions are mole%. Complete material balance over distillation

column. if reflux ratio is 3, determine the number of theoretical stages required for

desired separation. (Nov-2017-New) [LJIET]

7 A distillation column is to separate 4750 mol/h of feed composed of 37% n-butane, 3,4

32% iso-pentane, 21% n-pentane and 10% n-hexane. The column operates at an

average pressure of 2 atm a and will produce a distillate product containing 95% n-

butane and 5% iso-pentane. The bottom product is allowed to contain no more than

570 mol/h of n-butane. Feed is 25% (by mole) vapour. Assume ideal apour-liquid

equilibrium. All compositions are mole%. Complete material balance over distillation

column. (Nov-2017-New) [LJIET]

For case given above,

If if average relative volatility for nbutane, iso-pentane, n-pentane and n-hexane is

2.567,1,0.762 and 0.236 respectively, determine the minimum reflux for the required

separation. (Nov-2017-New) [LJIET]

8 A distillation column is to separate 4750 mol/h of feed composed of 37% n-butane, 3

Multicomponent Distillation 2019 Page 9

L.J. Institute of Engineering & Technology Semester: VIII(2019)

32% iso-pentane, 21% n-pentane and 10% n-hexane. The column operates at an

average pressure of 2 atm a and will produce a distillate product containing 95% n-

butane and 5% iso-pentane. The bottom product is allowed to contain no more than

570 mol/h of n-butane. Feed is 25% (by mole) vapour. Assume ideal apour-liquid

equilibrium. All compositions are mole%. Complete material balance over distillation

column. (Nov-2017-New) [LJIET]

9 A distillation column is to separate 4750 mol/h of feed composed of 37% n-butane, 14

32% iso-pentane, 21% n-pentane and 10% n-hexane. The column operates at an

average pressure of 2 atm a and will produce a distillate product containing 95% n-

butane and 5% iso-pentane. The bottom product is allowed to contain no more than

570 mol/h of n-butane. Use Underwood’s method to determine the minimum reflux

for the required separation. Feed is 25% (by mole) apour. Assume ideal apour-

liquid equilibrium. All compositions are mole%. (May-2015) [LJIET]

Component αav

n-butane (LK) 2.567

Iso-pentane (HK) 1

n-pentane 0.762

n-hexane 0.236

10 A distillation column is to separate 4750 mol/h of feed composed of 37 % n-butane, 14

32 % iso-pentane, 21 % n-pentane and 10 % n-hexane. The column operates at an

average pressure of 2 atm and will produce a distillate product containing 95 % n-

butane 5 % iso-pentane. The bottom product is allowed to contain no more than 570

mol/h of n-butane. Compute material balance and use Underwood’s method to

determine the minimum reflux for the required separation. Feed is 25 % (by mole)

vapour. Assume ideal vapour-liquid equilibrium. All compositions are mole%. Also

calculate Nm and actual no. of theoretical stages. T top = 295 K, Tbottom = 320 K

Vapour Pressure top Vapour Pressure bottom

Component

(atm) (atm)

n-butane 2.17 4.478

iso-pentane 0.8 1.842

n-pentane 0.6 1.426

n-hexane 0.173 0.476

N-butane is light key component and iso-pentane is heavy key component (Oct-2016)

[LJIET]

11 By using Lewis-Matheson method, calculate the composition of liquid 14

leaving the second tray from the top of the column for following case. (Nov-

2014)(May-2012) [LJIET]

(b) Distillation column details

Component Feed, Distillate, Residue,

Multicomponent Distillation 2019 Page 10

L.J. Institute of Engineering & Technology Semester: VIII(2019)

mole% mole % mole %

n-butane 37 95.0 16.3

i-pentane 32 5.0 41.6

n-pentane 21 - 28.5

n-hexane 10 - 13.6

(b) F = 4750 mol/hr, D = 1250 mol/hr and q =1

(C) Operating pressure, Pt = 2 atm a

(d) Reflux ratio = 3

(e) Vapour pressure of Component

ln Pv = A – B / (T +C) , Pv in mm Hg and T in K

Component A B C

n-butane 15.6782 2154.9 -34.42

i-pentane 15.6338 2348.67 -40.05

n-pentane 15.8333 2477.07 -39.34

n-hexane 15.8366 2697.55 -48.78

12 A distillation column is to separate 4750 mol/h of feed composed of 37% nbutane, 14

32% iso-pentane, 21% n-pentane and 10% n-hexane. The column operates at an

average pressure of 2 atm a and will produce a distillate product containing 95% n-

butane and 5% iso- pentane. The bottom product is allowed to contain no more than

570 mol/h of n-butane. If minimum reflux ratio is 1.45, then determine number of

theoretical stages required for separation. (Nov-2014) (Oct-2012) [LJIET]

13 A distillation column is to separate 4750 mol/h of feed composed of 37% n-butane, 14

32% iso-pentane, 21% n-pentane and 10% n-hexane. The column operates at an

average pressure of 2 atm a and will produce a distillate product containing 95% n-

butane and 5% iso-pentane. The bottom product is allowed to contain no more than

570 mol/h of n-butane. Complete material balance.. Feed is 25% (by mole) apour.

Assume ideal apour-liquid equilibrium. All compositions are mole%. Average

relative volatility for n-butane, iso-pentane, n-pentane and n-hexane is 2.567, 1, 0.762

and 0.236 respectively. For reflux ratio R=3, Determine the number of theoretical

stages required for desired separation by FUG method. (May-2016) [LJIET]

OR

A distillation column is to separate 4750 mol/h of feed composed of 37% n-butane,

32% iso-pentane, 21% n-pentane and 10% n-hexane. The column operates at an

average pressure of 2 atm a and will produce a distillate product containing 95% n-

butane and 5% iso-pentane. The bottom product is allowed to contain no more than

570 mol/h of n-butane. The minimum reflux ratio is 1.45. The average relative

volatility of light key component is 2.567.

(a) Complete the material balance over still.

(b) Calculate number of theoretical stages required for desired separation by FUG

Multicomponent Distillation 2019 Page 11

L.J. Institute of Engineering & Technology Semester: VIII(2019)

method. (Nov-2017) [LJIET]

14 A saturated liquid, consisting of phenol and cresols with some xylenols, is fractioned 14

to give a top product of 95.3 mole% phenol. Metacresol is heavy key and phenol is

light key components. Total condenser is used. (May-2014)(May-2016) [LJIET]

The composition of the top product and of the phenols in the bottoms is given.

(a) Complete the material balance over the column for a feed rate of 100 kmol/h.

(b) Calculate the minimum reflux ratio by Underwood’s method.

(c) For R = 3Rm, calculate the composition of vapour entering to the top most tray by

Lewis–Matheson method.

Distillation Column Data and Relative Volatilities values are given in following

Table.

Component αav Feed, mole % Top product, Bottom

mole % product, mole

%

Phenol 1.98 35 95.3 5.24

o – Cresol 1.59 15 4.55 -

m – Cresol 1.00 30 0.15 -

Xylenols 0.59 20 - -

100 100

15 A saturated liquid, consisting of phenol and cresols with some xylenols, is fractioned 14

to give a top product of 95.3 mole % phenol. Metacresol is heavy key and phenol is

light key component. Feed rate is 100 kmol/hr. Total condenser is used. For reflux

ratio 5, determine number of theoretical stages for desired separation. The

compositions of the top product and of the phenols in the bottoms are given. (May-

2017-New)[LJIET]

Component αav Feed, mole % Top product, Bottom

mole % product, mole

%

Phenol 1.98 35 95.3 5.24

o – Cresol 1.59 15 4.55 -

m – Cresol 1.00 30 0.15 -

Xylenols 0.59 20 - -

100 100

16 In the production of chloromethanes, a saturated liquid mixture consisting of 60% 14

methyl chloride(CH3Cl), 28% methylene chloride(CH2Cl2), 9% chloroform(CHCl3)

and 3% carbon tetra chloride(CCl4)(by mass), is sent to distillation for separation of

pure products. In first distillation column 99.9% (by mass) pure methyl chloride is

separated as top product and 738 kmol/h pure methyl chloride is present in distillate.

Feed is saturated liquid mixture and flow rate is 1000 kmol/h.

Multicomponent Distillation 2019 Page 12

L.J. Institute of Engineering & Technology Semester: VIII(2019)

Component Average Relative Volatility

Methyl chloride 6.224

Methylene chloride 1

Chloroform 0.4954

Carbon tetra chloride 0.3126

Determine the following of distillation column:

(a) Do the complete material balance.

(b) Minimum reflux ratio by Underwood’s method

(c) If R= 3Rm, calculate the number of theoretical stages required for

desired separation. (Sep-2013) [LJIET]

17 A fatty acid mixture contains palmitic acid, steric acid and oleic acid. Compositions 14

for feed, distillate and residue is given as follows (Oct-2012) [LJIET]

Average

Distillate Residue

Component Feed Mole % Relative

Mole % Mole %

Volatility

Palmitic acid 11.94 99 1 1.9089

Steric Acid 3.91 0 4 0.7654

Oleic acid 84.15 1 95 1

Molar flow rates of distillate and residue are 3.2 kmol/ h and 0.4 kmol/ h respectively.

If minimum reflux ratio is 9, then find the number of theoretical stages required for

desired separation. Also, determine feed tray location.

18 Determine the minimum reflux ratio, minimum number of theoretical stages required 14

and number of theoretical stages required for the desired separation for the following

system by FUG method. Feed flow rate is 70 kmol/hr and feed is saturated liquid.

Composition of Distillation column streams and average relatives volatilities of all

components of feed are as follows: (May-2012) (May-2018-New) [LJIET]

Component α av Feed, Distillate, Residue,

Mole % mole % mole %

Benzene 8.96 2.2 22.8 0

Toluene 2.8407 7.4 72.2 0.5

Ethyl Benzene 1 43.4 5.0 47.5

Styrene 0.6596 47 0 52.0

Toluene is light key and ethyl benzene is heavy key component

19 A distillation column is to separate 5000 mol/h of feed composed of 40% n-butane, 14

30% iso-pentane, 20% n-pentane and 10% n-hexane. The column operates at an

average pressure of 2 atm a and will produce a distillate product containing 95% n-

Multicomponent Distillation 2019 Page 13

L.J. Institute of Engineering & Technology Semester: VIII(2019)

butane and 5% iso-pentane. The bottom product is allowed to contain no more than

600 mol/h of n-butane. Feed is 25% (by mole) vapor. Assume ideal vapor-liquid

equilibrium. All compositions are mole%. Average relative volatility for n-butane,

iso-pentane, n-pentane and n-hexane is 2.567,1, 0.762 and 0.236 respectively.

Determine: the number of theoretical stages required for desired separation for reflux

ratio R=2Rm (May-2017-New) [LJIET]

20 A distillation column is to separate 4750 mol/h of feed composed of 37% n-butane, 4

32% iso-pentane, 21% n-pentane and 10% n-hexane. The column operates at an

average pressure of 2 atm a and will produce a distillate product containing 95% n-

butane and 5% iso-pentane. The bottom product is allowed to contain no more than

570 mol/h of n-butane. The minimum reflux ratio is 1.45. The average relative

volatility of light key component is 2.567. Complete the material balance over still.

(May-2018-New) [LJIET]

21 A distillation column for the separation between propane and n-butane is to have 7

the following feeds. Data: R / Rmin =1.39. (Nov-2018-New) [LJIET]

Use Fensky equation to estimate the number

of stages that should be placed between two feeds. (Refer Chart provided)

Upper flow Lower flow

Temperature 170 230

Pressure 245 245

Component flow rate (lb mol/hr)

Ethane 2.5 0.5

Propane 14 6

n-Butane 10 18

n-Pentane 5 30

n-Hexane 0.5 4.5

CHAPTER – 5 AZEOTROPICAND EXTRACTIVE

DISTILLATION

DESCRIPTIVE QUESTIONS

1 Discuss concept and working principle of azeotropic distillation with industrial 7

example. (Dec-2015)(Oct-2012) [LJIET]

2 Discuss the advantages and disadvantages of extractive distillation over azeotropic 7

distillation. (May-2017) (May-2014) [LJIET]

3 Explain azeotropic distillation with industrial example (May-2017)(May-2015) (Oct- 7

2016) [LJIET]

4 Discuss the criteria for selection of solvent for extractive distillation. (Dec-2015) 7

(May-2015) (Nov-2014)(Oct-2012) [LJIET]

Multicomponent Distillation 2019 Page 14

L.J. Institute of Engineering & Technology Semester: VIII(2019)

5 Explain the working principle of Azeotropic Distillation with flow sheet of one 7

industrial application. (Nov-2014) (May-2014) (Nov-2017) [LJIET]

OR

Explain working principle of Azeotropic distillation with neat sketch. (Nov-2017-

New) [LJIET]

6 Discuss selection criteria of solvent for successful extractive distillation sequence. 5

(Sep-2013) [LJIET]

7 Explain concept and working principle of azeotropic distillation with industrial 9

example . (Sep-2013) [LJIET]

8 Distinguish between azeotropic distillation & extractive distillation with suitable 5

examples. (May-2013) [LJIET]

9 Define following terms: (May-2013) [LJIET] 4

Homogeneous Maximum Boiling Azeotrope,

Heterogeneous Minimum Boiling Azeotrope,

Pressure Swing Distillation,

Entrainer

10 Explain the Azeotropic distillation with the suitable example. (May-2012) 7

11 Discuss Extractive distillation with industrial examples. (Oct-2016) [LJIET] 7

12 Discuss residue curve maps in azeotropic distillation and state properties of entrainer 7

(Oct-2016) [LJIET]

13 What is azeotrope? Explain azeotropic distillation with suitable example (May-2017- 7

New) [LJIET]

14 Compare Azeotropic distillation and extractive distillation. (Nov-2017-New) [LJIET] 7

15 States the advantages and disadvantages of extractive distillation over azeotropic 4

distillation.(May-2018-new) [LJIET]

16 Explain azeotropic distillation with industrial example. .(May-2018-new) [LJIET] 4

17 Differentiate between Azeotropic distillation and extractive distillation. (Nov-2018- 7

New) [LJIET]

NUMERICALS

1 Isopropyl Alcohol (IPA) forms a minimum boiling azeotrope with water at 80.40C 7

and 101.325 kPa, having composition of 31.47 mole% water. A feed consisting of 23

mole%. IPA under saturated liquid conditions is to be distilled to give 67.5 mole%

IPA as distillate and 0.1 mole% IPA in bottoms. Find the number of theoretical stages

required for the separation at 1 atm. Reflux ratio is 3. VLE data for IPA-water at 1 atm

are as follows: (Oct-2012) [LJIET]

are as follows:

x 0 0.02 0.05 0.1 0.2 0.3 0.4 0.5 0.6 0.6853 0.8 0.9 1

*

y 0 0.25 0.4 0.49 0.537 0.55 0.57 0.6 0.64 0.6853 0.77 0.87 1

Multicomponent Distillation 2019 Page 15

L.J. Institute of Engineering & Technology Semester: VIII(2019)

CHAPTER – 6 TOWER DIAMETER AND PRESSURE

DROP

DESCRIPTIVE QUESTIONS

1 Define: Jet flooding, Down comer flooding, Liquid entrainment, Weeping. (May- 4

2017) (May-2013) [LJIET]

2 Discuss the criteria of selection among various types of trays. (May-2017) [LJIET] 7

OR

Discuss the selection criteria for different types of trays used in tray tower. (Nov-

2014) (May-2012)(Oct-2016)

OR

What are the parameters on the basis of which various types of trays selected explain

in detail? (Nov-2017) [LJIET]

3 List various types of trays (Nov-2017-New) [LJIET] 3

4 Explain the method of determining tower diameter in sieve tray tower. (May-2017) 7

(Sep-2013)(Dec-2015)(Nov-2017-New) [LJIET]

5 Discuss criteria for selection between tray tower and packed tower with industrial 7,6

examples. (Dec-2015) (May-2015) (Oct-2012) (May-2012) (Oct-2016) (May-2016)

(May-2017-New) (Nov-2017-New) [LJIET]

6 Discuss various factors that must be considered for the selection of tray type in tray 7

tower. (Sep-2013) [LJIET]

7 Write short note on selection of equipment for distillation (May-2013) [LJIET] 4

8 Write method to find out tower diameter & pressure drop in distillation column. 8

(May-2013) [LJIET]

9 Discuss the parameter for selection of tray in distillation column. (May-2013) 6

[LJIET]

10 Discuss the criteria of selection among various types of plates. (Oct-2012) (May- 7

2016) (May-2017-New) [LJIET]

11 Compare tray tower and packed tower (May-2016) [LJIET] 7

12 Discuss the criteria of selection among various types of packings. (May-2017-New) 7

[LJIET]

13 List various types of packings. (Nov-2017-New) [LJIET] 3

14 What are the selection criteria between packed column and tray column? (Nov-2017) 7

[LJIET]

15 Explain Jet flooding, Down comer flooding in detail (Nov-2017) [LJIET] 7

16 Explain: (1)Jet flooding (2) Down comer flooding. (Nov-2017-New) [LJIET] 4

17 Explain the stepwise procedure to determine tower diameter and pressure drop 7

calculation for sieve tray tower. (May-2018-new) [LJIET]

18 Explain jet flooding and downcomer flooding. (May-2018-new) [LJIET] 3

19 Explain tray efficiency and also explain one of the method. (May-2018-new) [LJIET] 7

Multicomponent Distillation 2019 Page 16

L.J. Institute of Engineering & Technology Semester: VIII(2019)

20 Discuss the criteria of selection among various types of plates. (May-2018-new) 3

[LJIET]

21 Discuss the concept of HETP. (May-2018-new) [LJIET] 3

22 Explain in brief. "Jet flooding: (Nov-2018-New) [LJIET] 3

23 Explain in brief. "Downcomer flooding" (Nov-2018-New) [LJIET] 3

24 What do you mean by tray efficiency. List out the methods to determine the tray 4

efficiency. (Nov-2018-New) [LJIET]

25 Explain the selection criteria among various types of trays. (Nov-2018-New) [LJIET] 4

26 Explain the selection criteria among various types of packings. (Nov-2018-New) 4

[LJIET]

NUMERICALS

1 Nitric acid water mixture forms maximum boiling azeotrope at 1atm a and at 122°C, 14

with a composition of 64.1% by mass of HNO3. Distillate contains 99.9% HNO3 (by

mass) and residue contains 1% HNO3 ( by mole). Separation is achieved from the

azeotropic mixture by extractive distillation using concentrated sulphuric acid (99%

by mass) as solvent. Residue of this extractive distillation column is 80% by mass

H2SO4 and remaining water. Extractive distillation is carried out in glass packed tower

type distillation column at 180 Torr a pressure. Glass Raschig rings are used as a

packing material. Determine height of packing required for the desired separation in

this extractive distillation column.Average relative volatility of nitric acid-water

mixture in presence of large amount of sulphuric acid is 95.Assuming that feed is

saturated liquid. (May-2014) [LJIET]

CHAPTER – 7 MULTICOMPONENT BATCH

DISTILLATION

DESCRIPTIVE QUESTIONS

1 Discuss the step wise procedure for the process design of multicomponent batch 14

distillation with rectification. (May-2017) (May-2012) (May-2016) [LJIET]

2 Discuss the stepwise procedure for process design of multicomponent batch 14

distillation with rectification and with constant overhead composition. (May-2014)

(Oct-2016) [LJIET]

3 Explain the step wise procedure for the process design of multicomponent batch 12

distillation with rectification. (Sep-2013) [LJIET]

4 Discuss batch distillation with rectification. (May-2013) (May-2017-New) (Nov- 7

2017) (N0v-2017-New) [LJIET]

5 Enlist the steps involved in designing a distillation column (Oct-2016) [LJIET] 7

6 Discuss the batch distillation with rectification. (Nov-2018-New) [LJIET] 3

CHAPTER – 8 ENERGY SAVING IN DISTILLATION

DESCRIPTIVE QUESTIONS

1 Discuss about heat integration & optimum design of distillation column. (May-2017) 7

(May-2013) [LJIET]

Multicomponent Distillation 2019 Page 17

L.J. Institute of Engineering & Technology Semester: VIII(2019)

2 Discuss the use of heat pump with auxiliary heat transfer medium for saving the 7

energy consumption of distillation column. (May-2017) [LJIET]

3 Explain the concept of heat integration in distillation column. (Dec-2015) [LJIET] 7

4 List out the various design options for energy conservation in distillation column. 7

Also discuss the energy saving in distillation column by direct vapour compressor.

(Dec-2015) [LJIET]

5 List various design options to decrease the energy consumption of distillation. (Nov- 3

2017-New) [LJIET]

6 Discuss the use of heat pump with refrigerant in distillation column for energy saving. 14,10,7

(May-2015) (May-2012) (Oct-2016) (May-2017-New) [LJIET]

7 Discuss the use of heat pump with auxiliary heat transfer medium (or use of Vapour 7

Compression Refrigeration Cycle) for saving the energy consumption of distillation

column. (May-2014) [LJIET]

8 Discuss Thermally coupled distillation columns. (May-2014)(May-2012) (May-2016) 7

[LJIET]

9 List out the various design options for energy conservation in distillation column. 9

Also discuss the energy saving in distillation column by direct vapour compressor.

(Sep-2013) [LJIET]

10 Explain the concept of heat integration in distillation column. (Sep-2013) [LJIET] 5,4

OR

Explain the concept of Heat integration for energy conservation in Distillation

column. (May-2012) (Nov-2017-New) [LJIET]

11 Write short note on thermally coupled distillation column with diagram. (May-2013) 5

[LJIET]

12 Write short note on heat pump. (May-2013) (Nov-2017-New) [LJIET] 3

13 Discuss Thermally Coupled Distillation. (Oct-2012) [LJIET] 7

14 Write a note on energy conservation methods in Distillation column and discuss 7

thermally coupled distillation in detail (Oct-2016) [LJIET]

15 Explain thermally coupled distillation with the suitable example. (May-2017-New) 7

[LJIET]

16 Write the steps for distillation column design. (Nov-2017) [LJIET] 7

17 Explain energy saving in thermally coupled distillation column. (Nov-2017) [LJIET] 7

18 Discuss energy saving in distillation column by heat integration (Nov-2017) [LJIET] 7

19 Explain the thermally coupled distillation column in detail (May-2018-New) 7

[LJIET]

20 Discuss energy saving in distillation column by heat pumps. (May-2018-New) 7

[LJIET]

21 Discuss the applications of heat pumps in distillation column. (Nov-2018-New) 4

[LJIET]

22 Write an expression Bogart equation with all terms. (Nov-2018-New) [LJIET] 3

23 Discuss energy saving in distillation column by thermally coupled distillation.. (Nov- 7

2018-New) [LJIET]

Multicomponent Distillation 2019 Page 18

L.J. Institute of Engineering & Technology Semester: VIII(2019)

Multicomponent Distillation 2019 Page 19

Vous aimerez peut-être aussi

- 2004 Service Manual SubaruDocument4 420 pages2004 Service Manual SubaruReza SiavoshiPas encore d'évaluation

- Einstein 1937Document12 pagesEinstein 1937JonathanHdzPas encore d'évaluation

- Following the Trend: Diversified Managed Futures TradingD'EverandFollowing the Trend: Diversified Managed Futures TradingÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Full Download Ebook Ebook PDF Longitudinal Data Analysis by Donald Hedeker PDFDocument41 pagesFull Download Ebook Ebook PDF Longitudinal Data Analysis by Donald Hedeker PDFsarah.steir690100% (42)

- RSA Reliability and Maintenance Newsletter Vault Collection Supplementary Series on World Class Maintenance Management - The 12 Disciplines: 1, #8D'EverandRSA Reliability and Maintenance Newsletter Vault Collection Supplementary Series on World Class Maintenance Management - The 12 Disciplines: 1, #8Pas encore d'évaluation

- Q Bank Chem Pmso Viii 2020Document14 pagesQ Bank Chem Pmso Viii 2020Patel DaxPas encore d'évaluation

- Q Bank - CHEM - CET-I - III - 2020Document20 pagesQ Bank - CHEM - CET-I - III - 2020Kp ModiPas encore d'évaluation

- Mba III Operations Management (10mba33) Question PaperDocument13 pagesMba III Operations Management (10mba33) Question Paperharishway2Pas encore d'évaluation

- Q - Bank - CHEM - AST - SEM VI - 2022Document15 pagesQ - Bank - CHEM - AST - SEM VI - 2022Patel DhruvilPas encore d'évaluation

- Q Bank Chem Mto2 Sem Vi 2022Document29 pagesQ Bank Chem Mto2 Sem Vi 2022Patel DhruvilPas encore d'évaluation

- Subject Name: Subject Code:2150504 CHAPTER - 1 Introductory ConceptsDocument31 pagesSubject Name: Subject Code:2150504 CHAPTER - 1 Introductory ConceptsJ PatidarPas encore d'évaluation

- Subject Name: Operation Research Subject Code: 2163201: Mrs. Suman Ashish SharmaDocument98 pagesSubject Name: Operation Research Subject Code: 2163201: Mrs. Suman Ashish SharmajayPas encore d'évaluation

- 061 - ME8791, ME6702 Mechatronics - Important QuestionsDocument7 pages061 - ME8791, ME6702 Mechatronics - Important QuestionsAVIDI CHINNA HANUMANTHUPas encore d'évaluation

- 061 - ME8791, ME6702 Mechatronics - Important QuestionsDocument7 pages061 - ME8791, ME6702 Mechatronics - Important QuestionsSamsudeen APas encore d'évaluation

- Me6702/ Mechatronics Mech QBDocument6 pagesMe6702/ Mechatronics Mech QBNandha KumarPas encore d'évaluation

- Subject Name: Compiler Design Subject Code:2170701Document15 pagesSubject Name: Compiler Design Subject Code:2170701Ramya IyengarPas encore d'évaluation

- Me6005-Ppce QuestionbankDocument15 pagesMe6005-Ppce Questionbankrobinston jeyasinghPas encore d'évaluation

- Me 63021Document6 pagesMe 63021Kumar SubramanianPas encore d'évaluation

- Cse-Vii-java and J2EE (10cs753) - Question PaperDocument4 pagesCse-Vii-java and J2EE (10cs753) - Question PaperVrijeshMGPas encore d'évaluation

- Q Bank Chem PRPC Sem Vi 2022Document15 pagesQ Bank Chem PRPC Sem Vi 2022Patel DhruvilPas encore d'évaluation

- Ise-Vii-java and J2EE (10is753) - Question PaperDocument4 pagesIse-Vii-java and J2EE (10is753) - Question PaperYashas PraveenPas encore d'évaluation

- WSE Question Bank ProductivityDocument10 pagesWSE Question Bank ProductivityAzlan KhanPas encore d'évaluation

- Fatima Michael College of Engineering & Technology: An ISO 9001:2008 Certified InstitutionDocument6 pagesFatima Michael College of Engineering & Technology: An ISO 9001:2008 Certified InstitutionDamo Daran GPas encore d'évaluation

- ME2028 QBDocument6 pagesME2028 QBsameer1894Pas encore d'évaluation

- Q Bank CL As Sem IV 2017Document31 pagesQ Bank CL As Sem IV 2017Sural JaniPas encore d'évaluation

- Question Bank: Fatima Michael College of Engineering & TechnologyDocument6 pagesQuestion Bank: Fatima Michael College of Engineering & TechnologySri RamPas encore d'évaluation

- Mechatronics QBDocument6 pagesMechatronics QB18MECH4020 P.PONMALAI PANDIPas encore d'évaluation

- 0.1 Installation of R PackagesDocument10 pages0.1 Installation of R PackagesRajulPas encore d'évaluation

- Standard ISO 14001 2015 Easy VersionDocument10 pagesStandard ISO 14001 2015 Easy VersionMani ShivakumarPas encore d'évaluation

- Mg6863 EECA QBDocument17 pagesMg6863 EECA QBMáJéStîC PâNDãPas encore d'évaluation

- 056 - ME8099, ME6010 Robotics - Question BankDocument6 pages056 - ME8099, ME6010 Robotics - Question BanksathishskymechPas encore d'évaluation

- Ec8351 Electronic Circuits I 1901883722 Ec8351 Ec IDocument19 pagesEc8351 Electronic Circuits I 1901883722 Ec8351 Ec IyogiPas encore d'évaluation

- Emm Question Paper Model ExamDocument4 pagesEmm Question Paper Model ExamRohit MunaPas encore d'évaluation

- Ppe QBDocument4 pagesPpe QB028MECH KESAVA KRISHNAN D SPas encore d'évaluation

- Question Topic WiseDocument5 pagesQuestion Topic WisePagan jatarPas encore d'évaluation

- TedDocument94 pagesTednethajiratnaPas encore d'évaluation

- Question Topic WiseDocument5 pagesQuestion Topic WiseAakash ChopraPas encore d'évaluation

- Me 2028-Robotics - Question Bank Unit 1 - Fundamentals of Robot Two Mark QuestionsDocument6 pagesMe 2028-Robotics - Question Bank Unit 1 - Fundamentals of Robot Two Mark QuestionsKannathal3008 88Pas encore d'évaluation

- Unit Wise Important QuestionsDocument5 pagesUnit Wise Important Questionssivashiva0% (1)

- Industrial Engineering Question Bank Vishal Shinde Kbtcoe NashikDocument4 pagesIndustrial Engineering Question Bank Vishal Shinde Kbtcoe NashikAashishPas encore d'évaluation

- Acet Q Bank Sem-Vii-2022.Document8 pagesAcet Q Bank Sem-Vii-2022.Jyotin KateshiaPas encore d'évaluation

- Shree Swaminarayan Institute of Technology, BhatDocument10 pagesShree Swaminarayan Institute of Technology, BhatHerry MahetaPas encore d'évaluation

- A Fuzzy Logic Model For Evaluation of Oil-Film Pressure in Hydrodynamic BearingDocument8 pagesA Fuzzy Logic Model For Evaluation of Oil-Film Pressure in Hydrodynamic BearingAnonymous pKuPK3zUPas encore d'évaluation

- MSE-2 Q Bank - AT - VI - MECH - 2022 - UPDATEDDocument11 pagesMSE-2 Q Bank - AT - VI - MECH - 2022 - UPDATEDPratik ChavdaPas encore d'évaluation

- Submit The List of Items On Which You Intend To Respond: Required ActionDocument205 pagesSubmit The List of Items On Which You Intend To Respond: Required ActionJagrit LuthraPas encore d'évaluation

- PGDFT Question PapersDocument27 pagesPGDFT Question PapersAthoi Leitanthem100% (1)

- Automobile University QuestionsDocument4 pagesAutomobile University QuestionsMr.Kumar K MPas encore d'évaluation

- How To Use This Manual: General InformationDocument3 pagesHow To Use This Manual: General InformationCristiab BurteaPas encore d'évaluation

- March 2015 To July 2020 FULL PapersDocument110 pagesMarch 2015 To July 2020 FULL PapersWalker GamingPas encore d'évaluation

- LPG QuestionnaireDocument6 pagesLPG QuestionnaireSushama SinghPas encore d'évaluation

- 4315 Ijmech 11Document10 pages4315 Ijmech 11Tertsegha IpilakyaaPas encore d'évaluation

- Amd Q Bank Sem I 2013Document9 pagesAmd Q Bank Sem I 2013Priya SharmaPas encore d'évaluation

- Unit 5: Pneumatics - Components, Control Valves and CircuitsDocument1 pageUnit 5: Pneumatics - Components, Control Valves and CircuitsShivanand TalwarPas encore d'évaluation

- Ajt Question Bank 2016Document7 pagesAjt Question Bank 2016Tapaswee Dixit100% (2)

- Chapter 2Document5 pagesChapter 2yared abebePas encore d'évaluation

- Question Bank: Elements of Mechanical Engineering 15EME14Document5 pagesQuestion Bank: Elements of Mechanical Engineering 15EME14ShamsPas encore d'évaluation

- Question BankDocument4 pagesQuestion BankSuganya NandagopalPas encore d'évaluation

- Inventory Management.Document3 pagesInventory Management.vinaycool12344150Pas encore d'évaluation

- At6601 QBDocument12 pagesAt6601 QBpceautohod100% (1)

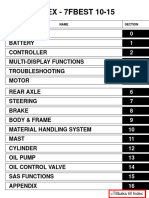

- 7fbest 10Document16 pages7fbest 10luis tocoraPas encore d'évaluation

- TedDocument93 pagesTedanvignesh18Pas encore d'évaluation

- Service Systems Management and Engineering: Creating Strategic Differentiation and Operational ExcellenceD'EverandService Systems Management and Engineering: Creating Strategic Differentiation and Operational ExcellencePas encore d'évaluation

- ALA-PRPC - List - 2014 BatchDocument2 pagesALA-PRPC - List - 2014 Batchhgbv tttbPas encore d'évaluation

- Processing of Petroleum-1000 PDFDocument12 pagesProcessing of Petroleum-1000 PDFhgbv tttbPas encore d'évaluation

- Personal Profile: Phone Email Address Goal Career ObjectiveDocument2 pagesPersonal Profile: Phone Email Address Goal Career Objectivehgbv tttbPas encore d'évaluation

- Essar Sample QuestionsDocument3 pagesEssar Sample Questionshgbv tttbPas encore d'évaluation

- AP Stats Reference SheetDocument7 pagesAP Stats Reference SheetRamenKing12Pas encore d'évaluation

- Application of Conformal Mapping For ElectromagneticDocument21 pagesApplication of Conformal Mapping For ElectromagneticBrown MountainPas encore d'évaluation

- Eqps + Notes (TCS)Document92 pagesEqps + Notes (TCS)vinayak pawarPas encore d'évaluation

- Sample 5th Grade Lesson PlanDocument2 pagesSample 5th Grade Lesson PlanJune Lee CamarinPas encore d'évaluation

- AI - Lecture 2 - Uninformed SearchDocument20 pagesAI - Lecture 2 - Uninformed SearchHunterxHunter03Pas encore d'évaluation

- Lesson Plan - Maths - Create Graphs Based On Data CollectedDocument2 pagesLesson Plan - Maths - Create Graphs Based On Data Collectedapi-464562811Pas encore d'évaluation

- Anova 1Document11 pagesAnova 1vijay2101Pas encore d'évaluation

- ASB-410 JQL in Jira Service Desk Slides and NotesDocument198 pagesASB-410 JQL in Jira Service Desk Slides and NotesCarlos GarciaPas encore d'évaluation

- Newsletter April 3-7Document1 pageNewsletter April 3-7api-245696657Pas encore d'évaluation

- Problem Set #5 Solutions: CopolymerizationDocument10 pagesProblem Set #5 Solutions: Copolymerizationmuzammil hussainPas encore d'évaluation

- Stat Module 5Document10 pagesStat Module 5Remar Jhon PainePas encore d'évaluation

- A K 2 0 0 e R R o R M e S S A G e e X P L A N A T I o N SDocument142 pagesA K 2 0 0 e R R o R M e S S A G e e X P L A N A T I o N SYatno GomiPas encore d'évaluation

- CA-course FileDocument12 pagesCA-course FileSivagami ManiPas encore d'évaluation

- Introduction To Vectors in C++ Word PDFDocument3 pagesIntroduction To Vectors in C++ Word PDFKarima BabaPas encore d'évaluation

- Discuss The Concept of Semantics and Elaborate NameDocument4 pagesDiscuss The Concept of Semantics and Elaborate NameAnonymous R99uDjYPas encore d'évaluation

- Solving Word Problems Involving Exponential FunctionsDocument15 pagesSolving Word Problems Involving Exponential FunctionsSherwin Jay Bentazar100% (1)

- The Undiscovered Self - Carl Gustav JungDocument25 pagesThe Undiscovered Self - Carl Gustav JungYusuf IrawanPas encore d'évaluation

- Unit 8 AnswersDocument8 pagesUnit 8 Answerspyropop3Pas encore d'évaluation

- Liceo de Pulilan CollegesDocument2 pagesLiceo de Pulilan Collegesjv_cindyPas encore d'évaluation

- Diagnostics of Subsynchronous Vibrations in Rotating Machinery - Methodologies To Identify Potential InstabilityDocument99 pagesDiagnostics of Subsynchronous Vibrations in Rotating Machinery - Methodologies To Identify Potential InstabilityMuhammad afzalPas encore d'évaluation

- Solved Multiple Choice Questions of DataDocument40 pagesSolved Multiple Choice Questions of Datamini projectPas encore d'évaluation

- 3 - ANN Part One PDFDocument30 pages3 - ANN Part One PDFIsmael EspinozaPas encore d'évaluation

- Sabour & Poulin 2006Document22 pagesSabour & Poulin 2006ali basyaPas encore d'évaluation

- Latent Graph Diffusion A Unified Framework For Generation and Prediction On GraphsDocument21 pagesLatent Graph Diffusion A Unified Framework For Generation and Prediction On GraphslinkzdPas encore d'évaluation

- Modelacion Calida Agua Parte 1Document14 pagesModelacion Calida Agua Parte 1Gisell AguilarPas encore d'évaluation

- Second Order Hold Based Discretization Method ofDocument5 pagesSecond Order Hold Based Discretization Method ofvitinrjPas encore d'évaluation

- Bacp - Module 1 - Mini ProjectDocument25 pagesBacp - Module 1 - Mini ProjectPavithra ManjakuppamPas encore d'évaluation

- Quarter: First Quarter Month: March 2021 QF010-A - ELEMENTARY - Goldfield ESDocument5 pagesQuarter: First Quarter Month: March 2021 QF010-A - ELEMENTARY - Goldfield ESJocelyn BuslotanPas encore d'évaluation