Académique Documents

Professionnel Documents

Culture Documents

Manufacturing Tolerances For Moulded & Extruded Rubber

Transféré par

StephenDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Manufacturing Tolerances For Moulded & Extruded Rubber

Transféré par

StephenDroits d'auteur :

Formats disponibles

T R EL L EB O RG E N G I N EER ED SYST E M S

Manufacturing Tolerances for Moulded & Extruded Rubber

All products are visually inspected for compliance product then an extrusion die is a cheaper

with the customer’s requirements and our alternative to machining a mould.

stringent workmanship standards.

Minimum order requirements may be requested.

The choice between a moulded and extruded seal

A comparison of dimensional tolerances for rubber

is often a compromise between tolerances and

mouldings (Class M4) and extrusions (Class E3),

tooling costs.

as per the International Standard ISO3302, is

If new tooling is required to manufacture the summarised below.

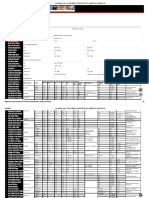

NOMINAL DIMENSIONS MOULDING TOLERANCE (CLASS EXTRUSION TOLERANCE

MM M4) MM+/1 (CLASS E3) MM+/-

0 - 6.3 0.50 0.80

6.3 - 10 0.70 1.00

10 - 16 0.8 1.3

16 - 25 1.00 1.6

25 - 40 1.3 2.00

40 - 63 1.6 2.5

63 - 100 2.00 3.2

100 - 160 2.5 -

160 - 1.5% -

Rubber compound used in the DEEFEND range of The fendering material is extruded natural rubber,

extruded fenders has the following specifications:- compounded to be highly resistant against attack

by sea-water, oxygen, ozone and ultraviolet light

Shore Durometer Hardness encountered in the marine environment.

65 - 75

(AS 1683.15)

Natural rubber is inherently more resilient than

Tensile strength

12 MPa (min.) other elastometric and plastic materials, and is

(AS 1180.2)

ideal in absorbing berthing energy and protecting

Ultimate tensile strain

350% (min.) both the marina and vessel.

(AS 1683.11)

Compression set Standard colours are white, grey and black. Other

35% (max.)

(AS 1683.138) colours are available on special order.

Tear resistance

50kN/m (min.)

(AS 1683.12)

Summary Bolt and Bearing Plate Guide

PROFILE W BOLT SIZE BOLT CENTRES BEARING PLATE T

WIDTH THICKNESS

mm mm mm mm mm

QR D35 35 M8 300 20 3 8

QR D50 50 M10 300 50 5 10

QR D65 65 M10 300 50 5 10

QR D70 70 M10 300 32 5 15

QR D80 80 M10 300 50 5 15

QR D90 90 M10 300 50 5 20

QR D100 100 M10 300 50 5 20

QR D110 110 M10 300 50 5 20

QR L35 35 M8 300 20 3 10

QR L65 65 M10 300 50 5 20

QR P30 This profile is designed to be nailed (30mm long galvanized siding nails) through both top 8

and bottom ‘lips’ at approx. 250mm centres.

QR P35 35 M6 300 20 3 10

PROFILES

QR P50 NOT 50 M8 300 32 5 10

TO SCALE

*Complete fendering system including moulded corner section and end caps is available for these profiles.

17

Vous aimerez peut-être aussi

- Torque Details-Hex Bolt DIN 933Document2 pagesTorque Details-Hex Bolt DIN 933coolkaisy100% (2)

- Aia - Nas Nas 621-1997Document3 pagesAia - Nas Nas 621-1997MAHESHPas encore d'évaluation

- Din 933Document2 pagesDin 933Sugumar0% (1)

- Soil Classification Report-NewDocument12 pagesSoil Classification Report-NewSoundar PachiappanPas encore d'évaluation

- Blow MoldingDocument25 pagesBlow MoldingSam SaPas encore d'évaluation

- ROB - ComparisonDocument6 pagesROB - ComparisonvinoraamPas encore d'évaluation

- SA/AS1548 - 7 - 460R: XlerplateDocument3 pagesSA/AS1548 - 7 - 460R: XlerplatenavPas encore d'évaluation

- Elastomeric Bearing Pads & StripsDocument4 pagesElastomeric Bearing Pads & StripsganmosesPas encore d'évaluation

- Capral Extrusion Catalogue - Vol4Document144 pagesCapral Extrusion Catalogue - Vol4maaathanPas encore d'évaluation

- Kleline and Sealine Hoses: Catalogue 2012/2013Document28 pagesKleline and Sealine Hoses: Catalogue 2012/2013Yoyok SusantoPas encore d'évaluation

- Kleline and Sealine Hoses: Catalogue 2012/2013Document28 pagesKleline and Sealine Hoses: Catalogue 2012/2013Yoyok SusantoPas encore d'évaluation

- Chiyoda Welding Products: Combination Welding and Cutting TorchesDocument13 pagesChiyoda Welding Products: Combination Welding and Cutting Torchesandi permanaPas encore d'évaluation

- Flexible Pavement DesignDocument39 pagesFlexible Pavement DesignSaurabh KumarPas encore d'évaluation

- Berger Lahr - Linear Tables PDFDocument16 pagesBerger Lahr - Linear Tables PDFofanPas encore d'évaluation

- Armox 370T Class 1: General Product DescriptionDocument2 pagesArmox 370T Class 1: General Product DescriptionSuneelPas encore d'évaluation

- 9775 Marine Fenders 20Document20 pages9775 Marine Fenders 20StephenPas encore d'évaluation

- TDS BOPP Clear LSA47 TaghleefDocument2 pagesTDS BOPP Clear LSA47 TaghleefEmmanuel AlvarezPas encore d'évaluation

- FRANK SeparadoresDocument4 pagesFRANK SeparadorespablopelaPas encore d'évaluation

- TR50 Data SheetDocument2 pagesTR50 Data SheetAnupam GhoshPas encore d'évaluation

- 01.01.02.01 Spesifikasi-Soilfelt LSDocument2 pages01.01.02.01 Spesifikasi-Soilfelt LSjogja raya100% (1)

- Dripnet PC AS Thick Walled Dripperlines Product SheetDocument2 pagesDripnet PC AS Thick Walled Dripperlines Product SheetIgnacio RinaldiPas encore d'évaluation

- Dripnet PC Thick Walled Dripperlines Product SheetDocument2 pagesDripnet PC Thick Walled Dripperlines Product SheetIgnacio RinaldiPas encore d'évaluation

- SafetyPlus Loosebolt Spec DataDocument1 pageSafetyPlus Loosebolt Spec DataKarl FarrugiaPas encore d'évaluation

- Kemco V Sepa enDocument2 pagesKemco V Sepa enDanilaGAdPas encore d'évaluation

- 1.4466 (310L Ug)Document4 pages1.4466 (310L Ug)ramramjeyPas encore d'évaluation

- MG CatalogDocument21 pagesMG CatalogSanket IchakePas encore d'évaluation

- 0607 Carcoseal Un Data SheetDocument2 pages0607 Carcoseal Un Data SheetMarco FrancesePas encore d'évaluation

- Dripnet PC HWD Technical Product SheetDocument16 pagesDripnet PC HWD Technical Product SheetMartín BrunelloPas encore d'évaluation

- Renew Woltman Flange DN50-300-KATALOG CALIBRATE (2) (1) - DikompresiDocument4 pagesRenew Woltman Flange DN50-300-KATALOG CALIBRATE (2) (1) - DikompresiIrwan PangaribuanPas encore d'évaluation

- Woltman Flange DN50-300-KATALOG CALIBRATEDocument4 pagesWoltman Flange DN50-300-KATALOG CALIBRATENurdin FahimPas encore d'évaluation

- Docol 1300M: General Product DescriptionDocument2 pagesDocol 1300M: General Product DescriptionAnonymous wR1jrmpYAPas encore d'évaluation

- STG Series Specifications・How to order・Dimensions (2MB)Document75 pagesSTG Series Specifications・How to order・Dimensions (2MB)Gustavo MezaPas encore d'évaluation

- Uvtape e p034Document6 pagesUvtape e p034Habib AliPas encore d'évaluation

- Diamond and CBN WheelsDocument22 pagesDiamond and CBN WheelsM. AguiarPas encore d'évaluation

- Beam Splitter Output Coupler Coatings (Materiais para Laser)Document1 pageBeam Splitter Output Coupler Coatings (Materiais para Laser)AndréPas encore d'évaluation

- INDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Document6 pagesINDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Roberto AlvarezPas encore d'évaluation

- Quality Pressure G Auge: All Stainless Steel Construction Robust, Designed For Severe Operating ConditionsDocument2 pagesQuality Pressure G Auge: All Stainless Steel Construction Robust, Designed For Severe Operating ConditionsChhomPas encore d'évaluation

- Home About Us Products & Market Media Contact: Minimum Standard RequirementsDocument4 pagesHome About Us Products & Market Media Contact: Minimum Standard RequirementsAtiqur RahmanPas encore d'évaluation

- Home About Us Products & Market Media Contact: Minimum Standard RequirementsDocument4 pagesHome About Us Products & Market Media Contact: Minimum Standard RequirementsMohamed AlkharashyPas encore d'évaluation

- Engineering DetailDocument30 pagesEngineering DetailSatyaprakash PrakashPas encore d'évaluation

- DatasheetDocument1 pageDatasheetStuxnetPas encore d'évaluation

- Metal Coated Structural Steels, EN10346:2015: General Product Description Mechanical PropertiesDocument3 pagesMetal Coated Structural Steels, EN10346:2015: General Product Description Mechanical PropertiesSrikanth SrikantiPas encore d'évaluation

- Zhengtan Belting Rubber Conveyor BeltDocument24 pagesZhengtan Belting Rubber Conveyor BeltJohn Renzel Rivera IIIPas encore d'évaluation

- Unibraze ER316L PDFDocument1 pageUnibraze ER316L PDFsmpoe017Pas encore d'évaluation

- Entech TPE Resin Datasheet 1Document4 pagesEntech TPE Resin Datasheet 1Ermin CisicPas encore d'évaluation

- FT GeotextilesDocument2 pagesFT GeotextilesElber Ramiro Olivares BareñoPas encore d'évaluation

- Tuyau en Fonte Ductile Ekoval ChoixDocument52 pagesTuyau en Fonte Ductile Ekoval ChoixmmfayistPas encore d'évaluation

- Hydraulic Breakers and Silent Demolition ToolsDocument24 pagesHydraulic Breakers and Silent Demolition ToolssinanPas encore d'évaluation

- Price List: PVC Conduit PipesDocument2 pagesPrice List: PVC Conduit PipesabhishitewariPas encore d'évaluation

- En Abra10Document2 pagesEn Abra10Filipe SantosPas encore d'évaluation

- S355 420 460 Toughcore Voestalpine EN 020720Document4 pagesS355 420 460 Toughcore Voestalpine EN 020720Joost de HaanPas encore d'évaluation

- 1.4435 - C Stainless Steel DetailsDocument3 pages1.4435 - C Stainless Steel DetailsmeenakshiPas encore d'évaluation

- Practicas Standar KingDocument5 pagesPracticas Standar Kingjesus francoPas encore d'évaluation

- SCRM BrochureDocument6 pagesSCRM BrochureRizwan TonoyPas encore d'évaluation

- 02 Track 2 - Wu 0 A Comprehensive Characterization of NEXMET 1000 Formability-2019 - FinalDocument21 pages02 Track 2 - Wu 0 A Comprehensive Characterization of NEXMET 1000 Formability-2019 - FinalSilverio AcuñaPas encore d'évaluation

- Breakers: Make An ImpactDocument10 pagesBreakers: Make An ImpactVICTOR BEMENGUEPas encore d'évaluation

- Mix Design M-35 MCDocument15 pagesMix Design M-35 MCRana MahatoPas encore d'évaluation

- Model: TT: FeaturesDocument1 pageModel: TT: FeaturespoongodiskPas encore d'évaluation

- Molycop - Tech Sheet Small Size Balls 003 MCAU - SMLTS1.3 - 290519 PDFDocument3 pagesMolycop - Tech Sheet Small Size Balls 003 MCAU - SMLTS1.3 - 290519 PDFreza razaviPas encore d'évaluation

- NIC Components NACC SeriesDocument3 pagesNIC Components NACC SeriesNICCompPas encore d'évaluation

- APERAM Electrical SteelDocument14 pagesAPERAM Electrical SteelEkaitz NipuPas encore d'évaluation

- Stainless Steel 1.4401 316Document3 pagesStainless Steel 1.4401 316Luis LoayzaPas encore d'évaluation

- Specification of ABS-Like Resin: Writer Proofreader Translator: ReviewersDocument8 pagesSpecification of ABS-Like Resin: Writer Proofreader Translator: ReviewersAlejandro PerezPas encore d'évaluation

- K01 PExDocument2 pagesK01 PExclaiberth castillo villanuevaPas encore d'évaluation

- Post TensionDocument8 pagesPost Tensionedc1312Pas encore d'évaluation

- British Commercial Computer Digest: Pergamon Computer Data SeriesD'EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesPas encore d'évaluation

- GB CE Abrasive Materials HandlingDocument8 pagesGB CE Abrasive Materials HandlingStephenPas encore d'évaluation

- Catalogue Trelline GBDocument12 pagesCatalogue Trelline GBStephenPas encore d'évaluation

- Alsun Aluminium Catalogue PDFDocument104 pagesAlsun Aluminium Catalogue PDFStephen100% (2)

- Aluminium CatalogueDocument36 pagesAluminium Cataloguesinger areyoureadyPas encore d'évaluation

- Capral AlloySpecs Brochure v6 - June2015Document7 pagesCapral AlloySpecs Brochure v6 - June2015Mihaela NastasePas encore d'évaluation

- En Performerceramic 2017 Encours LRDocument2 pagesEn Performerceramic 2017 Encours LRStephenPas encore d'évaluation

- Catalogue REELINE GBDocument16 pagesCatalogue REELINE GBStephenPas encore d'évaluation

- GB AA Wines AlcoholsDocument8 pagesGB AA Wines AlcoholsStephenPas encore d'évaluation

- Teguflex P - ING 2008Document2 pagesTeguflex P - ING 2008StephenPas encore d'évaluation

- GB CP Chemical IndustryDocument8 pagesGB CP Chemical IndustryStephenPas encore d'évaluation

- Teguflex Catalogue 2014Document8 pagesTeguflex Catalogue 2014StephenPas encore d'évaluation

- Teguflex FFI - ING 2008Document2 pagesTeguflex FFI - ING 2008StephenPas encore d'évaluation

- Food Processing Industry: Fluid Transfer SolutionsDocument8 pagesFood Processing Industry: Fluid Transfer SolutionsStephenPas encore d'évaluation

- TeguflexC ING 2011Document2 pagesTeguflexC ING 2011StephenPas encore d'évaluation

- Brochure Oilandmarine GBDocument20 pagesBrochure Oilandmarine GBStephenPas encore d'évaluation

- GB Fluid Transfer SolutionsDocument8 pagesGB Fluid Transfer SolutionsStephenPas encore d'évaluation

- Flame Guard - Data Sheet (00000002)Document2 pagesFlame Guard - Data Sheet (00000002)StephenPas encore d'évaluation

- Catalogue REELINE GBDocument16 pagesCatalogue REELINE GBStephenPas encore d'évaluation

- GB AA Wines AlcoholsDocument8 pagesGB AA Wines AlcoholsStephenPas encore d'évaluation

- GB CP Oil HydrocarbonsDocument8 pagesGB CP Oil HydrocarbonsStephenPas encore d'évaluation

- Catalogue Trelline GBDocument12 pagesCatalogue Trelline GBStephenPas encore d'évaluation

- TRELLEBORG - PotBearingsDocument8 pagesTRELLEBORG - PotBearingsAngga AlfiannurPas encore d'évaluation

- Brochure Oilandmarine GBDocument20 pagesBrochure Oilandmarine GBStephenPas encore d'évaluation

- Food Processing Industry: Fluid Transfer SolutionsDocument8 pagesFood Processing Industry: Fluid Transfer SolutionsStephenPas encore d'évaluation

- Brochure Liftingbags TrelleborgDocument5 pagesBrochure Liftingbags TrelleborgStephenPas encore d'évaluation

- 9869 Omega SealsDocument12 pages9869 Omega SealsStephenPas encore d'évaluation

- Application Methodology - ShaliEnamelDocument5 pagesApplication Methodology - ShaliEnamelPradeep SinghPas encore d'évaluation

- Foundations and Column Pedestals: General NotesDocument3 pagesFoundations and Column Pedestals: General NotesMaher ElabdPas encore d'évaluation

- Epoxy Method StatementDocument8 pagesEpoxy Method StatementALLAN KIBIRIGEPas encore d'évaluation

- Swedish LadderDocument11 pagesSwedish Ladderrauljrz146Pas encore d'évaluation

- Ge Ge752 User Manual 79 80Document2 pagesGe Ge752 User Manual 79 80RICHARDPas encore d'évaluation

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureDocument12 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaPas encore d'évaluation

- Pallakki NDT Excellence Center Pvt. LTD.: Radiographic Examination ReportDocument1 pagePallakki NDT Excellence Center Pvt. LTD.: Radiographic Examination ReportCharles JacobPas encore d'évaluation

- Bonding Process by AdhesivesDocument2 pagesBonding Process by AdhesivesPritam100% (1)

- Filtration and Separation Technology: Lenzing AKF / KKF - Automatic Backwash FilterDocument6 pagesFiltration and Separation Technology: Lenzing AKF / KKF - Automatic Backwash FilterseinthaiserPas encore d'évaluation

- Steel Crankshaft HardeningDocument2 pagesSteel Crankshaft Hardening13311A0341 S SHIVA SAI KIRANPas encore d'évaluation

- 2 TI/TC/ NCVT Certificate (Fitter/ Turner/Machinist) : - CNC Nos)Document2 pages2 TI/TC/ NCVT Certificate (Fitter/ Turner/Machinist) : - CNC Nos)venkatcipetPas encore d'évaluation

- Anclaje HHD-SDocument2 pagesAnclaje HHD-SIngeniero Miguel VillarroelPas encore d'évaluation

- TO - Time: - TO - : Contract Name: Contract No.: Hot Work To Be Performed: Authorised Duration DateDocument1 pageTO - Time: - TO - : Contract Name: Contract No.: Hot Work To Be Performed: Authorised Duration Datepony loverPas encore d'évaluation

- HASTELLOY® C-22HS™alloyDocument16 pagesHASTELLOY® C-22HS™alloyYudha SatriaPas encore d'évaluation

- Fused Flimant FabricationDocument11 pagesFused Flimant FabricationInnovae3dPas encore d'évaluation

- ZRC Zero VocDocument2 pagesZRC Zero Vochksn77Pas encore d'évaluation

- Xtra ReportDocument9 pagesXtra ReportStjepan CrnkovićPas encore d'évaluation

- Galvalume Fact Sheet-1Document1 pageGalvalume Fact Sheet-1Ewo50 NewPas encore d'évaluation

- Cold Work Steels: Available Product ShapesDocument6 pagesCold Work Steels: Available Product ShapesSangHak LeePas encore d'évaluation

- CPP Pipeline Proposed Pwps List For Mol Project: 36' Pipe To Anchor Flange Repair WeldingDocument2 pagesCPP Pipeline Proposed Pwps List For Mol Project: 36' Pipe To Anchor Flange Repair WeldingYasar ArshadPas encore d'évaluation

- STULLER x1 WHITE GOLD ALOYDocument4 pagesSTULLER x1 WHITE GOLD ALOYFarah ShurbajiPas encore d'évaluation

- Sikagard®-62: Product Data SheetDocument4 pagesSikagard®-62: Product Data Sheetantonsugiarto20_7049Pas encore d'évaluation

- Ss 400 61 orDocument1 pageSs 400 61 orBrian Aplin0% (1)

- Welding FundamentalsDocument6 pagesWelding FundamentalsChinmay Das100% (1)

- Chapter 9 (Cleaning and Fettling of Castings), 2003Document32 pagesChapter 9 (Cleaning and Fettling of Castings), 2003Desalegn DgaPas encore d'évaluation

- Machine Shop Theory: Classification, Applications and Operations of MachinesDocument5 pagesMachine Shop Theory: Classification, Applications and Operations of MachinesIsmaeli KielPas encore d'évaluation

- Literature Review: 3D Printing TechniquesDocument3 pagesLiterature Review: 3D Printing TechniquesShakir KhanPas encore d'évaluation

- Aming Members Sept 04Document16 pagesAming Members Sept 04Edison BecerraPas encore d'évaluation