Académique Documents

Professionnel Documents

Culture Documents

WCu Tungsten-Copper Web

Transféré par

ktusaCopyright

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentWCu Tungsten-Copper Web

Transféré par

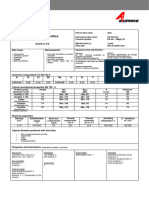

ktusaData Sheet

Tungsten-Copper (WCu) [also: Copper-Tungsten CuW]

Tungsten-Copper (WCu) is a composite material with a heterogeneous

structure. Typically, a porous blank is produced by pressing and sintering

tungsten powder. The remaining pores are sealed by immersing in liquid

copper (=infiltration). Furthermore, the production of WCu can also be

carried out by means of liquid-phase sintering. Depending on the grain size

of the W-powder as well as pressing and sintering parameters, various

contents of Tungsten respectively Copper can be selected. Tungsten-Copper

combines many typical characteristics of the single elements Tungsten and

Copper as for example the hardness, wear and burn-off resistance of Tungs-

ten together with the good electrical and thermal conductivity of Copper.

Tungsten-Copper is used for example for eroding electrodes (EDM), heat

sinks, electrical contacts, medium and high voltage breakers (SF6), welding

electrodes (contact / resistance welding), balancing weights and others.

Tungsten-Copper is frequently used as an electrode material, in case that the

typical copper contact materials (e.g. Copper-Chrome-Zirconium CuCrZr

and others) have reached their limits.

Significant Characteristics and Applications Machining

| Good machinability The machining is carried out by carbide tools. The properties when machining

| High density are very good. Compared to various Copper alloys there are no deformations

| Very good dimensional stability due to the high hardness and high E-Modulus. A very good surface quality

| Low coefficient of expansion can be achieved with almost burr- and nick-free edges.

| High surface quality

| High wear resistance

| High thermal conductivity ASTM Standard Specification

| High burn-off resistance

ASTM B702 (Copper-Tungsten Electrical Contact Material)

All descriptions and statements regarding characteristics or properties are made according to our knowledge and are subject to change.

Properties of the most important material types

Tungsten-Copper WCu

50/50 60/40 70/30 75/25 80/20 90/10

Class A Class B Class C Class D Class E —

Chemical Composition

Copper (Cu) [%] 50±2 40±2 30±2 25±2 20±2 10±2

Tungsten (W) [%] Rest Rest Rest Rest Rest Rest

Additives [max. %] 1 1 1 1 1 1

Physical Properties

Density [g/cm³] 11.7 12.7 13.7 14.3 15.0 16.5

Electrical Conductivity [% IACS]* 56-64 49-57 44-52 41-48 38-45 <30

Coefficient of Thermal Expansion [10-6 K-1] 13.0 11.9 10.3 9.5 8.8 <7.5

Thermal Conductivity [W/m · K-1] — — 200 190 180 170

Mechanical Properties

Hardness [HRB] 69-83 77-90 85-98 89-102 94-106 —

E-Modulus [GPa] — — 220 260 280 290

Tensile Strength Rm [MPa] 344-413 379-448 516-585 585-654 620-689 700

Typical values, partly standardised according to ASTM B702

* International Annealed Copper Standard, 100 % IACS is equivalent to 58 MS/m

Range of Products

Rods, squares, plates, foils and sheets, small tubes, contacts and finished parts according to drawings.

WHS Sondermetalle e.K. | Industriepark ob der Tauber | Waltersberg 24 | 97947 Grünsfeld | Germany © Copyright

tel +49 (0) 93 46-92 789-0 | fax +49 (0) 93 46-92 789-29 | info@whs-sondermetalle.de | www.whs-sondermetalle.de 07-2014

Vous aimerez peut-être aussi

- Data Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKDocument2 pagesData Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKMuhammad Asif IqbalPas encore d'évaluation

- Data Sheet CuZn20Al2AsDocument1 pageData Sheet CuZn20Al2AsJean Carlos Reyna PascualPas encore d'évaluation

- Data Sheet: Oxygen-Free Copper Cu-OF Standard Grade - Luvata Alloy Cu-OFDocument2 pagesData Sheet: Oxygen-Free Copper Cu-OF Standard Grade - Luvata Alloy Cu-OFMuhammad Asif IqbalPas encore d'évaluation

- CuW Sintered E USDocument5 pagesCuW Sintered E USanuragsngPas encore d'évaluation

- Ductle Iron Spec2Document18 pagesDuctle Iron Spec2윤병택Pas encore d'évaluation

- Material Datasheet Cu-OFDocument2 pagesMaterial Datasheet Cu-OFmohsen_267Pas encore d'évaluation

- Characteristics of Cutting Steels and Saw Tooth Forms: Metal Cutting Circular Saws Vary in 7 AspectsDocument8 pagesCharacteristics of Cutting Steels and Saw Tooth Forms: Metal Cutting Circular Saws Vary in 7 AspectsAlvaro RochaPas encore d'évaluation

- Cu DHPDocument3 pagesCu DHPLUIGIPas encore d'évaluation

- Schmidthammer: Elektrokohle GMBHDocument20 pagesSchmidthammer: Elektrokohle GMBHudhayPas encore d'évaluation

- WA Applications For HydropowerDocument6 pagesWA Applications For Hydropowersuharto ekoPas encore d'évaluation

- Cu Ofe c10100 Pna 203 - enDocument2 pagesCu Ofe c10100 Pna 203 - enNitin KumarPas encore d'évaluation

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaPas encore d'évaluation

- Cu-HCP: C10300 Industrial RolledDocument7 pagesCu-HCP: C10300 Industrial RolledpierocarnelociPas encore d'évaluation

- Cu-ETP: C11000 Industrial RolledDocument4 pagesCu-ETP: C11000 Industrial Rolledsrsivaraman81Pas encore d'évaluation

- Name: Nur Huda Binti Hamzah Registration Number: 08Dkm19F1063 Class: Dkm5BDocument5 pagesName: Nur Huda Binti Hamzah Registration Number: 08Dkm19F1063 Class: Dkm5BSyahzlan IskandarPas encore d'évaluation

- PBN DatasheetDocument1 pagePBN DatasheetLove MishraPas encore d'évaluation

- History: Why Aluminium?Document5 pagesHistory: Why Aluminium?electrical zuhairPas encore d'évaluation

- Characteristics of Ggg40: Standards / DesignationsDocument2 pagesCharacteristics of Ggg40: Standards / DesignationsSaeid Mir100% (1)

- Aluminum Alloy Specification'Document12 pagesAluminum Alloy Specification'ArjunPas encore d'évaluation

- K Type Thermocouple Extension Cable KXYY (1-50) Pairs X 1.5 MM 300 VDocument1 pageK Type Thermocouple Extension Cable KXYY (1-50) Pairs X 1.5 MM 300 VArthurPas encore d'évaluation

- Edigcse Aap sc15.14wDocument2 pagesEdigcse Aap sc15.14wHassan EL ACHEKPas encore d'évaluation

- Electrode Properties EdmDocument6 pagesElectrode Properties Edmomer21Pas encore d'évaluation

- Dual Shield 9000b3 PDFDocument1 pageDual Shield 9000b3 PDFqaPas encore d'évaluation

- Ophelia SlidesCarnivalDocument32 pagesOphelia SlidesCarnivalQuel LePas encore d'évaluation

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoPas encore d'évaluation

- 2219 Aluminium Alloy - WikipediaDocument2 pages2219 Aluminium Alloy - WikipediaVysakh VasudevanPas encore d'évaluation

- CuZn40 01 2019 PDFDocument7 pagesCuZn40 01 2019 PDFMisaelPas encore d'évaluation

- TALAT Lecture 4500: Resistance WeldingDocument23 pagesTALAT Lecture 4500: Resistance WeldingCORE MaterialsPas encore d'évaluation

- CuZn10-PNA 222 - ENDocument2 pagesCuZn10-PNA 222 - ENYulwido AdiPas encore d'évaluation

- EA Copper Tungsten Alloy Data SheetDocument2 pagesEA Copper Tungsten Alloy Data SheetpeterPas encore d'évaluation

- Crucible: Data SheetDocument2 pagesCrucible: Data SheetLuis DiazPas encore d'évaluation

- Reamber (Or, Technically, Resinite) Is: Nitric Acid CelluloseDocument7 pagesReamber (Or, Technically, Resinite) Is: Nitric Acid CelluloseNikkiting Santiago MataPas encore d'évaluation

- Alloy CuMg0,2Document17 pagesAlloy CuMg0,2Tarun BhatejaPas encore d'évaluation

- CatalogDocument76 pagesCatalogPhay KhamPas encore d'évaluation

- Electronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionD'EverandElectronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionPas encore d'évaluation

- 3 Engineering Materials Non Ferrous MaterialsDocument28 pages3 Engineering Materials Non Ferrous Materialsg googlePas encore d'évaluation

- Recent Developments in Joining of Aluminum AlloysDocument16 pagesRecent Developments in Joining of Aluminum AlloysBenny TavlovichPas encore d'évaluation

- Comparative Studies of The Susceptibility of Copper and Aluminum To Processing in Wire Drawing ProcessDocument7 pagesComparative Studies of The Susceptibility of Copper and Aluminum To Processing in Wire Drawing ProcessIJAR JOURNALPas encore d'évaluation

- Hard - Facing Welding - Electrodes PDFDocument3 pagesHard - Facing Welding - Electrodes PDFreeet87Pas encore d'évaluation

- CuZn38Pb2 CW608N ENDocument4 pagesCuZn38Pb2 CW608N ENTaner DemirelPas encore d'évaluation

- Manganin: Manganin Is A Trademarked Name For An Alloy of Typically 84%Document3 pagesManganin: Manganin Is A Trademarked Name For An Alloy of Typically 84%samridh guptaPas encore d'évaluation

- CuETP PDFDocument2 pagesCuETP PDFlovelyshreePas encore d'évaluation

- R2 CableDocument1 pageR2 CableKristaPas encore d'évaluation

- Paul 2012Document5 pagesPaul 2012Ricardo QueirogaPas encore d'évaluation

- Cu Etp c11000 Pna - 211 sm0008 - enDocument2 pagesCu Etp c11000 Pna - 211 sm0008 - enNitin KumarPas encore d'évaluation

- Material Datasheet Cuzn30Document2 pagesMaterial Datasheet Cuzn30alex94kgPas encore d'évaluation

- CuZn10-PNA 222 - ENDocument2 pagesCuZn10-PNA 222 - ENjurreijndersPas encore d'évaluation

- Armco Pure Iron PDFDocument12 pagesArmco Pure Iron PDFsmith willPas encore d'évaluation

- 6063 ProfilesDocument1 page6063 ProfilesBPP-Tech PythonPas encore d'évaluation

- Stainless SteelDocument1 pageStainless SteelSadashiva sahoo100% (1)

- 1 4501 Super Duplex TubesDocument3 pages1 4501 Super Duplex TubesAlma JakirovićPas encore d'évaluation

- Aircraft MaterialsDocument71 pagesAircraft MaterialsArif AdjaPas encore d'évaluation

- Welding Processes 11Document97 pagesWelding Processes 11akabhinav32100% (2)

- El Efecto de Cerium Sobre El Comportamiento Abrasivo de Desgaste de Aleación Del Hardfacing PDFDocument5 pagesEl Efecto de Cerium Sobre El Comportamiento Abrasivo de Desgaste de Aleación Del Hardfacing PDFJuan Altamirano RojasPas encore d'évaluation

- The Designer's Guide To Tungsten CarbideDocument52 pagesThe Designer's Guide To Tungsten Carbideshaneparker100% (1)

- Cw008a Cu-Of Version1Document1 pageCw008a Cu-Of Version1Gaka RtaPas encore d'évaluation

- Standard Tungsten Carbide Cladding Formulas - OilfieldDocument2 pagesStandard Tungsten Carbide Cladding Formulas - OilfieldTamara Maria Ortiz MendezPas encore d'évaluation

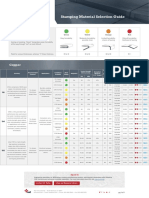

- Raw Material Selection Guide CopperDocument1 pageRaw Material Selection Guide CopperSantosh KumarPas encore d'évaluation

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantD'EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Notifier Design Guide - Little - Black - BookDocument144 pagesNotifier Design Guide - Little - Black - BookKao Sophearak100% (1)

- SH 09 12 BWH Service ManualDocument54 pagesSH 09 12 BWH Service ManualAndrew BienPas encore d'évaluation

- Electrolux Mini Fridge RM - 4200Document10 pagesElectrolux Mini Fridge RM - 4200Predrag SaponjicPas encore d'évaluation

- TFP1090 08 2018 PDFDocument28 pagesTFP1090 08 2018 PDFBenga AdrianPas encore d'évaluation

- SB Unimax EnglishDocument6 pagesSB Unimax Englishmohsen_267Pas encore d'évaluation

- GRP and Hdpe PipeDocument1 pageGRP and Hdpe Pipemoejamal80100% (2)

- Concrete Fireproofing Analysis Evaluation and Repair StrategiesDocument30 pagesConcrete Fireproofing Analysis Evaluation and Repair StrategiessvprskPas encore d'évaluation

- Jain PE Piping System, p17 - Old PipesDocument119 pagesJain PE Piping System, p17 - Old PipesVaios Anyfantis100% (1)

- Movable BridgeDocument263 pagesMovable BridgeCharbel Ghanem100% (1)

- Stress AnalysisDocument60 pagesStress AnalysisTejas DesaiPas encore d'évaluation

- X CR Direct Fastening Technology Manual DFTM 2018 Product Page Technical Information ASSET DOC 2597830 PDFDocument6 pagesX CR Direct Fastening Technology Manual DFTM 2018 Product Page Technical Information ASSET DOC 2597830 PDFBogdanPas encore d'évaluation

- Shear Wall - Wikipedia, The Free EncyclopediaDocument2 pagesShear Wall - Wikipedia, The Free EncyclopediazidaaanPas encore d'évaluation

- Chapter 19 First Law of Thermodynamics: 1 Calorie 4.186 JDocument16 pagesChapter 19 First Law of Thermodynamics: 1 Calorie 4.186 Jطلحه سحيل صديقىPas encore d'évaluation

- 6th International Symposium On Deformation Characteristics of Geomaterials Argetina 2015Document1 236 pages6th International Symposium On Deformation Characteristics of Geomaterials Argetina 2015Sebastian Tituaña50% (4)

- Carrier - Company ProfileDocument1 pageCarrier - Company Profiledeboline mitraPas encore d'évaluation

- Code of Practice For Installation and Maintenance of Power Cables Up To and Including 33 KV RatingDocument1 pageCode of Practice For Installation and Maintenance of Power Cables Up To and Including 33 KV RatingtceterexPas encore d'évaluation

- All Pentek HousingsDocument8 pagesAll Pentek HousingsRomankoPas encore d'évaluation

- Specification For Lighting Columns: NotesDocument9 pagesSpecification For Lighting Columns: Notessattar12345Pas encore d'évaluation

- Durazone 37 A Non-Migratory AntiozonantDocument18 pagesDurazone 37 A Non-Migratory Antiozonanttomcroft100% (4)

- Start Up System and Seperator Logics - 660MW (DHI Make) BoilerDocument44 pagesStart Up System and Seperator Logics - 660MW (DHI Make) BoilerHemendra VermaPas encore d'évaluation

- Condensia Catalogue BrochureDocument24 pagesCondensia Catalogue Brochure吉启周Pas encore d'évaluation

- Understanding Stresses and Modular Ratio - RCC Structures - Civil Engineering ProjectsDocument2 pagesUnderstanding Stresses and Modular Ratio - RCC Structures - Civil Engineering ProjectslearnafrenPas encore d'évaluation

- External FlowDocument64 pagesExternal FlowHardik RadadiyaPas encore d'évaluation

- Unit Weight of Materials Used at Construction SiteDocument5 pagesUnit Weight of Materials Used at Construction SiteJames Mcguire100% (2)

- Manual ColdheatDocument2 pagesManual ColdheatGustavo HerePas encore d'évaluation

- Heat Dissipation of LED Lamp - Pin Fin Heat Sink - LED Heat Sink - LED CoolerDocument2 pagesHeat Dissipation of LED Lamp - Pin Fin Heat Sink - LED Heat Sink - LED CoolermingfaPas encore d'évaluation

- Etag004 Fg004 Etics Fin2Document87 pagesEtag004 Fg004 Etics Fin2Serban RaduPas encore d'évaluation

- ASA Question BankDocument2 pagesASA Question Bankmayur22785Pas encore d'évaluation

- TaraNath - Reinforced - Concrete - Design - of - Tall - Build 8Document1 pageTaraNath - Reinforced - Concrete - Design - of - Tall - Build 8jcvalenciaPas encore d'évaluation