Académique Documents

Professionnel Documents

Culture Documents

Kwauk1956 PDF

Transféré par

Daniel Moreno CabreraTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Kwauk1956 PDF

Transféré par

Daniel Moreno CabreraDroits d'auteur :

Formats disponibles

nitial and final pH might give greater 0.5 g.

of sulfide were used, was the best ACKNOWLEDGMENT

decontamination. Accordingly, one addi- result observed in the study. Judging from The services of the following chemists are

tional level was assigned to each of the results at the lower pH levels, halving of gratefully acknowledged: T. C. Tesdahl,

pH factors, namely, Aa = 10 and I4= 6. the amount of sulfide used has no influ- T. G. Linxweiler, and D. R. Spangler.

The iron concentration factor was elimi- ence on the results. The possibility of Mound Laboratory is operated by Mon-

nated by holding it constant at the higher further improving the process with still santo Chemical Company for the U. S.

level. higher values of the pH did not appear -4tomic Energv Commission under con-

A factorial experiment,, devoted to the attractive because of the smallness of tract AT-33-1-GEN-53.

two pH factors, each at four levels, any anticipated effect and the increasing

required 4 X 4 = 16 treatments, seven cost entailed by additional chemical

of which are new. All sixteen results are treatment. LITERATURE CITED

tabulated in Table 8. The expected The value of using a sequence of pro-

improvement, from increasing the final gressively expanding and contracting 1. Lowe, C. S., L. L. Bentx, E. L. Murphy,

pH to 10, is confirmed for all three initial factorial designs in a study devoted to the E. Orban, F. Reichel, C. E. Shoemaker,

establishment of optimum operating con- and T. C. Tesdahl, MLM-662 (Rev.)

pH levels. The advantage of increasing (Dec. 25, 1953).

the initial pH to 6 is slight and appears ditions has been clearly demonstrated. 2. Fisher, R. A,, “The Design of Experi-

only at the highest final p H . Such a procedure generates a series of ments,” 4 ed., Hafner Publishing Com-

coherent conclusions characterized by pany, New York (1949).

maximum reliability and generality. 3. Cochran, W. G., and G. Cox, “Experi-

CONCLUSIONS While the goal of optimum conditions is mental Designs,” John Wiley and Sons,

attained in a highly efficient manner, the Inc., New York (1950).

The decontamination obtained with an functional dependence of the dependent

initial p H of 6 and a final pH of 10, when variable on those conditions is thoroughly Presented at Nuclear Science and Engineering Con-

an iron concentration of 1 mg./ml. and explored. gress, Cleveland.

A System for Counting Variables in

Separation Processes MOOSON KWAUK

Hydrocarbon Research, Inc., N e w York, New York

In the proposed system for counting variables in separation processes theprocesses are and an oxygen-rich vapor bottoms stream

resolved into their simpler component classes, e.g., theoretical plates, heat exchangers, from the low-pressure column. I n this

reboilers, distillation columns, etc., and a distinction is made between those variables case the number of independent variables

which are inherent in the systems and those which may be specified for design. Results

are presented for the most commonly occurring component classes, and all possible process that could be specified is not at all

relations existing among these classes are expressed by a set of generalized equations apparent. However, without a knowledge

[(la) to (19)l. The procedure of counting variables is therefore reduced to composition from of the exact number of independent

variables for the component classes by use of the generalized equations. ’ variables i t is difficult, if not impossible,

to proceed with a design problem in a

I n the design of processes for physical pressure. It is possible to specify for this systematic way. Often experience helps

separation of components by mechanisms column the concentration of either in setting trial values of certain variables

involving mass and heat transfer, the benzene or toluene in either the distillate very close to the correct answer, without

first step usually consists of specification or the bottoms stream, the recovery of the need of actually differentiating the

of process conditions or independent either component in either stream, and implicit from the independent variables.

variables. When the sufficient and neces- the reflux ratio, viz., three independent With recent increase in use of electronic

sary independent variables are fixed, variables. Then the number of theoretical computers for design studies, however, it

the system is determined and other plates both above and below the feed is desirable to know at the outset of a

variables may be found by design com- could be found by the familiar McCabe- problem the correct number of independ-

putations. Normally the variables of a Thiele diagram, thus determining two ent variables as process conditions and

system are interrelated in such a way implicit dependent variables. A formal to feed into the machine neither more

that only a few of them could be expressed analysis shows, however, that for the nor less than those variables that can

as explicit functions of the others; the column there exist four independent be specified, thus letting the machine

remaining ones have to be determined by variables that could be specified. The perform the trial-and-error loops in

lengthy calculations. fourth variable, not stated above, is finding the correct values of the de-

An example is the design of a distilla- implicit in the McCabe-Thiele method, pendent variables. I n such a situation

tion column separating a binary mixture that is, optimum location of the feed experience could hardly substitute for

of benzene and toluene. The column is plate; the stepwise procedure is to be correct logic.

to be designed to have one intermediate transferred from one operating line to

feed, a partial reboiler with a liquid- the other in the vicinity of the inter- PRINCIPLES OF THE METHOD OF ANALYSIS

bottoms-product stream, and a total section of the lines in order to secure a The difficulty of finding the correct

condenser with a liquid-distillate-product minimum total number of plates. number of independent variables was

stream, and it will operate a t atmospheric Another example is a so-called “double- recognized by Gilliland and Reed (2),

distillation column” separating the ter- who proposed a method of attack by use

Tabular material has been deposited as document nary mixture, air-Nz, A, and Oz-with

4807 with the American Documentation Institute of the phase rule and the first law of

Photoduplication Service, Library ofCongress,Wash:

ington 25, D. C., and may be obtained for $5.00 for

vapor air feed to the high-pressure column thermodynamics. Other discussions on

photoprints or $2.25 for 35-mm. microfilm. and a nitrogen-rich vapor distillate stream the subject can be found in the literature

Page 240 A.1.Ch.E. Journal June, 1956

(I, 3). As will be shown below, the phase as the composition and flow rate of the

rule contributes toward accounting for feeds, the prcssure on each plate of a

all variables, N., in a system, and the distillation column, and the heat leak, t o

first law toward accounting for all or from each plate. Thus for any system

possible conditions, X , , inherent and the number of thcse normally fixed

necessary in the system. T h e difference variables is

between the possible variables and the

possible conditions represents the inde-

pendent variables, ATi. Thus

N, = N, + N , + No (3)

T h e difference between'the independent

Ni = h'. - N , h

variables, N i , and those,normally fixed,

(1) N., stands for the independent variables

The possible variables of a system, N , , available, N., for process specifications:

could be enumerated as follows:

1. The phase rule gives the degree of free-

N . = Ni - N, (4)

dorn of any singlostage system in which = N, - N. - N, (5)

there exists either one phase or two or more

phases in equilibrium: T h e available indepcndent variables, N , ,

are the principal ones of interest in the

N=C+2-4 (2) solution of design problems, and the

present method is devotcd mainly t o

These degrees of freedom represent the so-

called "intensive" variables such as concen- their enumeration.

tration, temperature, pressure, entropy, and

other thermodynamic properties determined A SYSTEMATIC APPROACH

by the state and independent of the quan- T h e basic principles set forth above

tities of the components present. For a flow are relatively simple, and in theory the

system, however, there is associated with desired number of variahles could always

any stream an additional extensive variable

-its rate of flow-which is not determined be obtained by starting from these funda-

by the state and is therefore not dealt with mentab. I n practice, i t will ht! found

by the phase rule itself. Therefore, for a that such a procedure is not only tedious

one-phase system there arc C + 1 intensive but also sometimes confusing. One

variables, 1 extensive variable, or C + 2 frequent difficulty in applying the fore-

total variables. For a two-phase system, going principles lies in the recognition of

c where the flow rates of both phases could be variables a n d conditions so t h a t none is

eet independently, there are C intensive overlooked or counted twice. As a n

variables, 2 extensive variables, and C + 2 example, from the use of the McCabe-

total variables.

2. For any system, considered as a whole, Thiele method of designing distillation

or any part thereof, there remains, in addi- columns one is likely to reach the err*

tion to the foregoing variables, the degree of neous conclusion t h a t only three indepen-

freedom of choosing the amount, or rate, of dent variables exist in a distillation column

energy exchanged between the system and with a n intermediate feed. As indicated,

its surroundings. the correct number is four. As a further

#-=

In a strict sense the method is applicable example the heat input t o and heat leak

to systems in equilibrium, inasmuch as the from a reboiler may be considered. T h e

basis of the phase rule is equilibrium. There- question arises of whether they are two

fore the analysis will be rigorously correct

for separation processes reducible to a stage- independent variables or just one. Some-

wise nature. Differential types of operation times i t is not easy t o see whether certain

should be viewed as consisting of an infinite conditions should be classed as inherent

number of stages each of which approaches in a system or as normally fixed in design.

some presupposed percentage of equilibrium. For instance, when a stream is divided

t h e operation is adiabatic. T h e fact of no

The conditions inherent and necessctry in heat exchange between the system and

a system, hT,,are enumerated as follows: its surrounding would appear either as

1. A system has to be in material and a n inherent condition of the system or as

energy balanre. The first law of thermo- a normally fixed variable representing

dynamics states that the total amount of zero heat leak.

energy entering any system must be exactly T h e present paper presents a self-

.CP"( equal to that leaving plus any accumulation consistent system of classifying and

Y

of energy within the system. For flow proc- accounting variables and conditions, de-

esses in which changes in kinetic energy, signed t o avoid the errors and dilemmas

potential energy, and work done are negligi- described above. T h e results of this study

ble, the first law is simplified to straightfor-

ward enthalpy, or heat, balance. Normally are tabulated and summarized so t h a t

heat balance determines one cpdjtion in a n y complex system may be analyzed

any system, and as many conditions are with a minimum of time without resorting

fixcd by material balances as there are t o first principles.

components in the system.

2. Additional conditions inherent in a PROPOSED METHOD

system are found in equality of variables of

certain streams, such as those joining diffcr- I n the present method the component

edt parts of a composite system. parts of a separation process or a system

of operations are classified as elements,

For ordinary operations certain of the complex elements, units, and complex

variables are often set by design, such units, in the order of increasing complex-

Vol. 2, No. 2 A.1.Ch.E. Journal Page 241

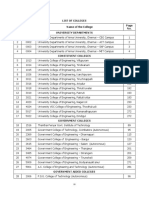

TABLE1. ELEMENTS

h)

Total con-

P Total Partial denser with

h)

Theoretical condenser Heat Condenser condenser or two-phase Pump, heater

Element Mixer Separator plate or reboiler exchanger reboiler reboiler(') product or cooler

Symbol M S P C or R H K C, or R, CZ, J

Variables

Description Number

NO. of 1-4 3 1 2 2 4 4 1 1

streams [2-4 0 1 1 0 0 0 1 1

1 -@ 3(c+2) c+2

2(C+2) 2(C+2) 4(C+2) 4(c+2) c+2 c +2

0 c+2 c+2 0 0 0 c+2 c +2

@

:- 1 1 1 1 1 1 1 1

Total 3c+7 2C+5

3c+7 2C+5 4c+9 4c+9 2C+5 2C+5

Material balance c C C C 2 ~ 4 ) 2 ~ 5 ) C C

Heat balance 1 1 1 1 1 1 1 1

> Nee Q - - - I(&= I(&=

- latent heat) ( 3 ) - - - latent heat) (3)

Equality - -

$m - - - 2(6) - -

Total c+1 c+1 c+1 c+2 2c+1 2C+3 C+l c+2

2C+6 c+4 2C+6 c+3 2C+8 2C+6 c+4 c+3

2(C+2) c+2 2(C+2) c+2 2(C+2) 2(C+2) c $2 c+2

1 1 1 1 2 2 1 1

1 1 1 - 1 1 - -

2C+6 c+4 2C+6 c+3 2C+7 2C+7 c+3 c+3

Noe = N , e - N," 0 0 0 0 1 -1 1 0

Example of Nae Temp. of For assigned Q or P,/P. Discharge

A' or B' heat leak and ratio pressure or

pressures of temperature

streams A and

B both flow

rates of A and

B cannot be

fixed a t

same time.

NOTES: (1) Equality of intensive variables of all product streams.

(2) Pressure of system equals pressure of feed.

(3) Net heat exchange with surrounding including latent heat and heat leak.

c (4)Since there is no material exchange between streams AA' arid BB', there are C material balances for each stream, or altogether 2C material balances.

C ( 5 ) Sinre there is no material exchange between streams ALA, and B,BL, there are C material balancrs for each stream, or altogether 2C material balances.

3

(D (6) Heat exchanged equal to latent heat of vaporization of both streams.

I (7) An evaporator is a special case of R,.

(8) Constant heat leak for pump, or constant pressure for heater and cooler.

ity. The classification is somewhat An example of an element is the case

arbitrary and is made for convenience' of a theoretic:il plate, P. Two single-

sake. An element is a single-stage equip- phase streams containing C vomponents

ment, such as a flash drum, a total each are fed to the plate in the form of

condenser, a theoretical plate, etc. A liquid from the plate above and vapor

complex element is an element with from the plate below. The total number

ccrtain minor additional features, such of variables of these two streams is

as a total condenser with reflux-that is,

a total condenser from which the con-

2(C + 2). h a v i n g the plate are two

streams in equilibrium, vapor to the

densate is divided into a distillate stream plate above and liquid to the plate below.

and a reflux stream. Another example of These two streams in equilibrium are

a complex element is a repetition of counted as a two-phase system repre-

theoretical plates in series so as to form +

senting c 2 variables. Another variable

a multiplate contactor, a particular case is found in any heat exchange with the

of which is found in an absorber. A com- surroundings. Therefore the total number

bination of elements or complex elements of variables is

gives rise to a unit, such as a stripping

column, which is a multiplate contactor N o " = 2(C + 2) + (C + 2) + 1

combined with a reboiler. When units,

complex elements, or elements are con- =3c+7

nected, they form complex units, such as The inherent conditions are material

a petroleum fractionator with strippers balances for the C components and one

attached to side drawoff streams. It can heat balance of all the streams entering

be seen that a more complex, or major, and leaving the plate:

class (such as a stripping column) is

composed of less complex, or minor, Nc6 = c+1

classes (theoretical plates and reboiler of

the stripping column). Therefore according to Equation (6)

The problem of enumerating variables

and conditions is therefore reduced to N,e = (3C + 7) - (C + 1)

the following two stages:

=2C+6

1. Enumeration of vnriuhles and eondi-

ditions of the simplest class, the element, The usually fixed variables are the

by dirert application of the principles compositions and flow rates of the two

adopted.

2. E8tablishment of relations among the

feeds, 2(C + 2), and the pressure on

plate, 1, and the heat exchange (heat leak)

various rlasses so that the major classes with the surrounding, 1, or

might be analyzed by applying the results

obtained for the minor classes without re-

sort to the first principlrs. N Z L= 2(C + 2) + 1 + 1

Throughout this study the normally =2C+6

fixed variables for any system will be Therefore

limited to the composition and flow rate

of the feed,* the pressure of the system,

and heat exchanged between the system

N,," = (2C + 6) - (2C + 6)

and its surroundings. This selection of =o

fixed variables is arbitrary, but the logic

of the method is hardly affected by any A little reflection will show that a con-

other selection. stant-pressure theoretical plate with fixed

vapor and liquid feeds and fixed heat leak

Elements is a nonvariant system.

Table lt repeats the foregoing analysis

For the first stage of the problem, a for a number of representative elements,

start will be made with the element. The viz., mixer, separator, divider, condenser

number, A', representing variables or or reboiler, total condenser with two--

conditions, mill be assigned a supcrscript phase product, and pump, heater, or

to designate one of the four classes listed cooler, all of which are illustrated sche-

above and a subscript denoting the nature matically in Figure I . Each element is

of the variable or condition. For example, assigned a symbol, such as P for the

N.4 denotes the number of independent theoretical plate, and is dcscribed in a

variables for an element. Equations ( l ) , sketch in Figure 1. In what follows it will

(4), and (5) could be written for any be seen that the results set forth in

element as follows: Table 1 may be used directly in deriving

variables of more complex classes without

need to refer to first principles.

Complex Elemants

-4 complex element is essentially a

*Exceptions r i l l be found in which the flow rate of modified element, the modification usu-

a feed in not normally fixed. For instance. the flow ally being the addition or division of a

rate of the strip ant in a strippcr is usually conaidered

a variable avaiLble for process specification. In this

case one more variable will therefor0have to be +ded

to the number resulting from the present analysls. t h e footnote on page 240.

VOl. 2#No. 2 A.1.Ch.E. Journal Page 243

TABLE

2. COMPLEX

ELEMENTS

Side drawoff hlul t iplate Total condenser or

Complex element Feed plate plate con tactor reboiler with reflux

Symbol p/ Pd pn C , or tl,

Variables

3 2 2 1

1 1 2(n - 1) 1

1 0 0 0

0 1 0 1

1 1 n 0

0 0 0 1

1 1 n -

-Af 2C+6 2C+6 - - -

T C+m+l - c+3 - c+3

N,B P 2C+6 2C+6 2C+6 n(2C+ 6) -

C or R c+3 - - - c+3

Q: 1 0 0 1 -

.Total 4C+12 3c+9 2nC+Gn+l 2CfG

c+2 c+2 2(n- 1)(C+2) c+2

3CS10 2C+7 2n +2C +5 c+4

3(C+2) 2(C+2) 2(C+2) c+2

2 - - -

- 0 - 0

2 2 2n -

- - - 1

3C+10 2C+6 +

2n 2C +4 cs3

0 1 1 1

Flow rate K'umbcr of Reflux ratio

of side plates or concen- or Q

drawoff tration of any

component in

either of two

product streams.

stream. For a complex element, Equa- tions specific to the complex element. This to pressure and heat leak, N , - N p .

tions (l), (4), and (5) can be written as illustrates a rule of counting variables Since a complex element and its compo-

follows: devised to avoid redundancy. It will be nent element will often have common

referred to as the rule of coverage, which feeds, the foregoing division is designed

(9) will be used repeatedly in this study. to avoid redundancy in enumeration.

The conditions inherent and necessary This measure is arbitrary, but as long as

in the complex element are limited to it is followed consistently the present

those streams interconnecting the com- system of counting variables will maintain

ponent elements. These streams will be its validity.

Since a complex element is made up referred to as interstreams. When two Substitution of Equations (12) and (13)

of a combination of elements, the follow- elements are connected by a n inter- in Equations (9) and (11) yields

ing relat,ion between the complex element stream, the stream leaving one element

and its component elements holds: and the stream entering the other, which

are considered as two independent

N." = Ni" +N, (12) streams when the elements are treated

NaB= c Ni' -+ N , - N," - Np"

separately, necessarily possess the same

- c (N,"- NP") (15)

This equation states that the lohl number

of variables of a complex element is intensive and extensive variables. Such

equal to the sum of the independent equality in the intensive and extensive

variables constitutes the inherent and As an example of a complex element

variables of the component elements, one may consider a multiplate contactor,

plus N , , which stands for the freedom of necessary conditions of an interstream.

If an interstream is single phase, these of which a gas absorber is a particular

choice of the number of times which any

component element could be repeated. conditions stand for C + 2 variables. case. (See Table 2*.) With the number of

plates equal to n, from Table 1, for a

In counting the normally fixed vari-

The variable, No, is not equal to the

number of such repetitions but represents ables for a complex element, the followingtheoretical plate, iVia = 2C +

6. For n

relation is adopted : theoretical plates the number of variables

the single degree of freedom with which is n(2C -I- 6). Since the number of plates,

the number of such repetitions could be

chosen. By means of Equation (12), the N," = N I B +C (N,' - Np") (13) n, could be specified by design, the

specification of n represents one addi-

inherent conditions in the component This equation divides the normally fixed tional independent variable, or N , = 1.

elements which are already covered in variables into two groups, those pertain-

N,* will not be counted again as condi- ing to the feed, N,, and those belonging *See footnote on page 240.

Page 244 A.1.Ch.E. Journal June, 1956

LJ

f

N class system S y mbal N, N,

-

Mixer M 2C+6 0

Separator S c+4 0

Divider T c+2 m-1

Theoretical plate P 2C+G 0

Total condenser or

reboiler C or R C+3 c+3 0

Elements Heat exchanger H 2C+8 2C+7 1

Condenser reboiler K 2C+G 2C+7 -1

Partial condenser

or reboiler C, or R, c+4 1 c+3 1

Total condenser

with twephasc c,~ ci-3 1 c+3 0

product

Pump, heater, or

- cooler J c+4 1 Ct3 1

3C+10 4 3C+ 10 0

2C+7 2 2C+G 1

elements contactor pn 2n 2C+ 5

+ 2n 2n+2C+4 1

Total condenser or

c+4 1 c+3 1

- Multiplatc contactor I+d+l

with sidc fwds

and sidc drawoffs ’ld

2 C ni+.f(C+G)+2d+2C+4 f+2d+1

Stripper J. 2n+ 1 2n+C+3 2

Rectifier P 2n+ 1 2n+C+3 2

Stripper with side

fecds and side J.~~,

drawoffs

bd Units Rectifier with side f+d+l f+d+l

P feeds and side

01 Pfd 2 c ni+f(C+7)+4d+C+5 2 c ni+4f+2d+1 f+2d+2

drawoffs 1 1

Distillation column

with one inter- 6 4

mediate feed

Distillation column

with side feeds

and side drawoffs

f +2d+3

Extractor with

extract reflux 4

* * *

Distillation columns

in series 2 C1 n , + ~ + 2 2 1

2 &+la 2 C1n , + C + 1 4 8

Distillation column

5 5 5

with auxiliary

stripper or 2 c1n , + C + 2 4 2 x1n , + 1 3 2 c1n i + C + 1 5 9

rectifier

Distillation column 6 6 6

with auxiliary 2 xn,+C+31 2 Cn,+18 2 Cn,+C+20

complete column 1 1 1

Simple double

column

Double column with

Complex side feeds and

units side drawoffs

Binary azeotropic

distillation

column

Twin azeotropic

distillation

(6+*)20

columns

Absorption-desorp-

tion cycle (2 -

pressures; 3*

1 temp.)

Absorption-desorp-

tion cycle (2 -

pressures; 6*

2 temp.)

*see footnote * on page 243.

Therefore where the superscript y, stands for a n y

major class and Emlnar for the appropriate

N." = n(2C + 6) + 1 summation of all classes minor to y.

Figures 3 and 4 illustrate representative

Every two adjacent plates arc connected units and complex units respectively. The

by two interstreams, each representing

C + 2 conditions, or iV," = C 2 per + results of analysis of Figures 1 to 4 are

summarized in Table 3* in a form con-

interstream. As there are 2(n - I) inter- venient for carrying out the variable-

streams for the n theoretical plates, there

are 2(n - l)(C +

2 ) inherent conditions

counting procedure. Table 3 includes t h e

more important components of separation

associated with these interstreams, or processes frequently encountered in chem-

'yeE= 2(n + 2)

- 1)(C ical plant design.

Nit' = n(2C + G ) + I Examples

T h e application of the preceding gen-

- 2(n - 1)(C + 2) eral relations will be ihstrtrted with two

examples, one for a unit and one for a

=2C+2n+5 complex unit.

An example of a unit is a conventional

The conditions normally fixed for each distillation column, 6, consisting of an

theoretical plate are its pressure, 1, and intermediate feed, a total condenser with

heat leak, 1 (see Table 1 and Figure 2 ) or reflux and liquid distillate product (or a

2 per plate. Therefore for n plates partial condenser with vapor distillate

c (N," - N,") = 2n'

product), and a total reboiler with vapor

bottoms product (or n partial reboiler

The variables set by specifying the two with liquid bottoms product). Such a

feed streams t o the multiplate contactor column is shown as the sixth case, 6, in

are Figure 3.

Before the appropriate equations are

N F " = 2(c + 2) applied t o a n analysis of the preceding

L

case, i t is desirable to define precisely the

Thereforc minor classes of which the system consists,

the interstreams among these minor

= 2(C + 2) + 2n classes, and the streams entering and

leaving the system as a whole. T h e

and present system could be broken into the

N." = [2C + 2n + 51 following minor classes:

one feed plate, Pf

- [2(C + 2) + 2n] = 1 two multiplate contartors, P,,

one partial condcnser, C,, or one total

One way of interpreting this single condenser with reflux, C,

available independent variable, T\.oE = 1, one partial rrboiler, R,, or one tota1

is t h a t for two given feeds the two product reboiler with reflux, R,

streams are entirely determined if the

number of plates of a n absorber is Reference t o the sketch of this system

specified. shown in Figurc 3 indicates one feed a n d

Table 2 repeats the foregoing analysis eight interstreams.

for representative complex elements, via., Therefore according t o Equation (16)

feed plate, sidedrawoff plate, multiplate the total number of variables is as follows:

contactor, and total condenser or reboiler (See results given in Table 1.)

with reflux. These complex elements are one feed plate, Pf:3C 10 +

shown in Figurc 2. two multiplate contnctors, P,: 2(nl n2) +

Units and Complex Units

+ 2(2C + 5)

one condenser, C, or C , : C +

4

I n a similar manner, i t can be shown

one reboiler, R, or R,: C 4 +

t h a t the following relations hold between Nu: 0 (since no component class is

repeated)

major and minor classes:

Therefore N.. = 2(nl n,) + + + 9C 28

N.' = c iyi + N,

minor

(16) The only conditions inherent in com-

bining the foregoing minor classes arc

Ni' = C Ni + N , - N,' (17) those offered by the eight interstreams, or

N,' =

minor

Np' - c (N, - Np) (18)

N," = 8(C + 2)

minor

Therefore the total number of inde-

pendent variables is, according to Equa-

N.' =

minor

Ni + hr, - N,' - ATF" tion (17),

- c (N, - N,)

minor

(19)

*9ee footnote ou page 240.

Vol. 2, No. 2 A.1.Ch.E. Journal Page 247

+ + +

Ni” = [2(n1 nz) 9C 281 . , the total number of vari-

Eauation (16)

Ltbies is

ACKNOWLEDGMENT

The author gratefully acknowledges the

+ + + 12

- 8(C + 2) = 2(nl n,) C one cooler, one heater, and one pump:

criticism and changes made by A. M.

Squires and Manson Benedict on the ori&

The normally fixed variables of the 3(C+ 4)

minor classes, except feed, are a s follows: one heat exchanger: 2C 8 +

two simple multi&te contactors: 2(n1+

nal manuscript.

(SeeTable 2.)

one feed plate, P,: 4

n,)

N,: 0

+ +

4c 10 NOTATION

C = condenser; also component

+

two multiplate contactors, P,: 2(n1 nz)

one condenscr, C, or C,: 1

one reboiler, R , or R,: 1

T h e inherent conditions are represented f = side feed

C + +

( N , - iYr) = 2()t1 n,) 6 b y the seven interstreams: F

H

=

=

feed, terminal

heat exchanger

m,nor

The normally fixed variables for the unit

N,“ = 7(C + 2) J

K

=

=

pump, heater or cooler

condenser reboiler

are, according to Equation (18), greater Therefore the total number of independ- L = liquid stream

than the preceding by those variables ent variables is, according t o Equation m = number of divided stream

represented by the feed into the unit, or (171, M = mixer

+

C 2. Therefore

Xiu = 2(n1 + n,) + 9C + 30 n

N

= number of theoretical plates

= number of variables or conditions

N,‘ = (C + 2) + + n,) + 61

P(n1 - 7(C + 2) p = product

2(n1 + 4 + C + 8

P = theoretical plate

=

And, according to Equation (lo),

2(n1 + + 2C + 16

12,) Q = heat exchanged between system

and surroundings

T h e normally fixed variables, except feed, R = reboiler

Ar.” = [2(% n J + +c+ 121 of the minor classes are S

T

= separator

= divider

+ + +

- [“(ni nd C

one cooler, one heater, and one pump: 3

81 one heat cxchanger: 3 V

w

= vapor stream

= bottoms stream

two simple multiplate contactors:

= 4

2(n1 + n?) 6

E

= distillation column

= extraction column

This number of 4 was discussed in the

introduction, and the independent vari- C

mtnor

- .V,) = 2(nl + +

n,) 6 p

A

= milltiplate contactor

= pressure

ables often chosen t o give this number will

p = rectifier

not be repeated here. One fact which is T h e variables fixed by fixing the two feed

u =f+d+l

of interest is that the number of normally streams entering the absorptiondesorp-

available independent variables, N , . = 4, tion cycle are 2(C + 2). 4

fi

= phase

= stripper

is not affected by the number of compo-

nents, C , which the unit involves. This Therefore Subscripts

fact would be found true for the even .Vzu = 2(C

more complex combinations of the

+ + + +

2) 2(n, n,) 6 a = av:iilable variables for process spec-

various classes, as may be seen in Table 3.

As a second example illustrating the

= 2(n, + + +n,) 2c 10 ification

c = conditions inherent in system

application of the general relations given -4ccording to Equation (19) d = with side drawoffs

f = with side feeds

by Equations (16), (17), (18), and (19),

one may consider a case of the complex N o u = [3(nl + + +n,) 2C 161 F = feeds

unit-an absorptiondesorption cycle op-

erating a t two pressures arid two temper-

+ + +

- [2(?2, n,) 2c 101

h = high-pressure column of 6*

i = total independent variables

atures. Such an operation is exemplified in = G I = low-pressure column of

the purification of gases by removal of Q = he:it exchanged between system

its curbon dioxide content with an ethan- T h e following represents a possible com- and surroundings

olamine solution. The carbon dioxide is bination of the six variables available for u = total variables of system

absorbed by the etlianolamine solution in process specification: I = normally fixed variables

an absorber at a lower temperature and a = repetitions of elements

1. Concentration of a key component in A = pressure

higlier pressure. The dissolved carbon the stream leaving the absorber.

diouidc in the ethanoliiniine solution is 2. Concentration of this key c-omponent

removed in a stripper by steam a t a in the lean liquor entering the absorber. Superscripts

higher temperature and loner pressure. 3. Circulation ratesof theabsorbing liquor. e = eleriicnt

Interconnecting the absorber tirid stripper 4. Rate of hrat exchange in heat es- E = complex element

are heat exchangers for cooling and warm- changer. u = unit

ing the liquid streams and a circulating 5. Tcmperaturc approach to cooling iva- U = complex unit

pump. This cycle is given as the last case ter6in cooler.

. Temprrature approach to heating me-

of the complex units in Figure 4. The cycle dium in heater.

LITERATURE CITED

could be broken into the following minor

classes: As noted earlier*, a n exception to nor- 1. Dunstan, A. E.,et sl., “The Science of

Petroleum,” p. 1563, Oxford University

one cooler, one heater, and one pump: J mally fixing the flow rate of a feed is Press, Oxford (1938).

one heat cxchanger: H found in the flow rate of a strippant in a

2. Gillilancl, E. R., and C. E. Reed, Ind.

two multiplate coiitactors ~ i t hno side stripper. Therefore, there is a seventh Eng. Chem., 34, 551 (1942).

feeds and side drawoffs: pOa variable available for process specifica- 3. Robinson, C. S., and E. R. Gilliland,

tion, viz., the strippant flow rate. “Elements of Fractional Distillation,’’

The sketch in Figure 4 shows two feeds p. 215, McGraw-Hill Book Company,

and seven interstreams. According to *See footnote on page 243. Lnc., New York (1950).

Page 248 A.1.Ch.E. Journal June, 1956

Vous aimerez peut-être aussi

- A Generalized Thermodynamic Correlation Based On Three-Parameter Corresponding StatesDocument18 pagesA Generalized Thermodynamic Correlation Based On Three-Parameter Corresponding StatesSebastian Montaño Rodriguez100% (1)

- Correlation For Boiling Heat Transfer T O Saturated Fluids in Convective FlowDocument8 pagesCorrelation For Boiling Heat Transfer T O Saturated Fluids in Convective FlowbarelihbPas encore d'évaluation

- Byoyancy Flow in Free Fluids PDFDocument12 pagesByoyancy Flow in Free Fluids PDFAl Farabi100% (1)

- Dumont's Theory of Caste.Document4 pagesDumont's Theory of Caste.Vikram Viner50% (2)

- Hankinson - Location Branding - A Study of The Branding Practices of 12 English CitiesDocument16 pagesHankinson - Location Branding - A Study of The Branding Practices of 12 English CitiesNatalia Ney100% (1)

- 3 Deals With Applications ofDocument3 pages3 Deals With Applications ofsritejaPas encore d'évaluation

- A Case of Negative Apparent Activation Energy Due To Pore Diffusion EffectsDocument3 pagesA Case of Negative Apparent Activation Energy Due To Pore Diffusion EffectsBamrung SungnoenPas encore d'évaluation

- Unifac PDFDocument13 pagesUnifac PDFBalmore ZambranoPas encore d'évaluation

- Capillary Super Critical FluidDocument8 pagesCapillary Super Critical FluidCarlos Alberto Rueda SanabriaPas encore d'évaluation

- Parametric Pumping: A Dynamic Principle For Separating Fluid MixturesDocument4 pagesParametric Pumping: A Dynamic Principle For Separating Fluid MixturesShafaq AbbasPas encore d'évaluation

- Theory of DistillationDocument18 pagesTheory of DistillationjaviercdeaePas encore d'évaluation

- Diffusivities Water in Nonpolar Gases: O'Connell, M. D. Gillespie, W. D. Krostek, and J. PrausnitzDocument5 pagesDiffusivities Water in Nonpolar Gases: O'Connell, M. D. Gillespie, W. D. Krostek, and J. PrausnitzBrayan UribePas encore d'évaluation

- Intrinsic and Global Reaction Rate of Methanol Dehydration Over 7-A1203 PelletsDocument6 pagesIntrinsic and Global Reaction Rate of Methanol Dehydration Over 7-A1203 PelletsHectorPas encore d'évaluation

- Spe 707 G PDFDocument11 pagesSpe 707 G PDFMayankShrivastavaPas encore d'évaluation

- Ammonium Chloride-Reaction EquilibriumDocument6 pagesAmmonium Chloride-Reaction Equilibriumfatemeh afariPas encore d'évaluation

- D. S. Corti Et Al - Constraints, Metastability, and Inherent Structures in LiquidsDocument13 pagesD. S. Corti Et Al - Constraints, Metastability, and Inherent Structures in LiquidsSodaMoussezPas encore d'évaluation

- Dynamic Numerical Simulation of Gas-Liquid Two-Phase Flows Euler/Euler Versus Euler/LagrangeDocument16 pagesDynamic Numerical Simulation of Gas-Liquid Two-Phase Flows Euler/Euler Versus Euler/Lagrangeamin_zargaranPas encore d'évaluation

- Buoyancy Flow in Free Fluids: Created in COMSOL Multiphysics 5.4Document12 pagesBuoyancy Flow in Free Fluids: Created in COMSOL Multiphysics 5.4Sadegh AhmadiPas encore d'évaluation

- Novel Approach To Job's MethodDocument6 pagesNovel Approach To Job's Methodiabureid7460Pas encore d'évaluation

- Pyrolisis de Sustancias AromaticasDocument8 pagesPyrolisis de Sustancias AromaticasDiana RiosPas encore d'évaluation

- Bubble Cap DistillationDocument26 pagesBubble Cap DistillationFrost OrchidPas encore d'évaluation

- AIChE Journal - November 1970 - Stevens - Applied Numerical Methods B Comahan H A Luther and J O Wilkes John WileyDocument2 pagesAIChE Journal - November 1970 - Stevens - Applied Numerical Methods B Comahan H A Luther and J O Wilkes John WileyVEFA KukuşPas encore d'évaluation

- 10.1351 Pac196102010207Document4 pages10.1351 Pac196102010207Vladimiro LelliPas encore d'évaluation

- Numerical Study of The Detonation Wave Structure in Et Hylene-Oxygen MixturesDocument7 pagesNumerical Study of The Detonation Wave Structure in Et Hylene-Oxygen MixturesBananaliksPas encore d'évaluation

- Buoyancy Driven Mixing Studies of Natural Circulation Flows at The Rocom Facility Using The Ansys CFX CodeDocument8 pagesBuoyancy Driven Mixing Studies of Natural Circulation Flows at The Rocom Facility Using The Ansys CFX CodeSajjad AhmedPas encore d'évaluation

- Elison HR J Chem Educ 2005 82 1086Document3 pagesElison HR J Chem Educ 2005 82 1086Daniel ButlerPas encore d'évaluation

- A Simple and Practical Theoretical Model For InterDocument43 pagesA Simple and Practical Theoretical Model For Interjmeneses1Pas encore d'évaluation

- Effectiveness Factor For Porous Catalysts: Langmuir-Hiizshelwood Kinetic ExpressionsDocument6 pagesEffectiveness Factor For Porous Catalysts: Langmuir-Hiizshelwood Kinetic ExpressionsnoviPas encore d'évaluation

- AdsorptionDocument17 pagesAdsorptionAbi Nash100% (2)

- Thermodynamics Cycles Lectures 1 - 2 - Chapter 1Document77 pagesThermodynamics Cycles Lectures 1 - 2 - Chapter 1nandi777100% (1)

- Theory and Application Voltammetry Measurement of Electrode Reaction KineticsDocument5 pagesTheory and Application Voltammetry Measurement of Electrode Reaction KineticsJubin KumarPas encore d'évaluation

- Anderson Et Al, 1992Document8 pagesAnderson Et Al, 1992Amit SharmaPas encore d'évaluation

- Similitude and Approximation TheoryDocument1 pageSimilitude and Approximation TheoryAmbardi WicaksonoPas encore d'évaluation

- Transport Processes in Thin Liquid Films During High-Vacuum DistillationDocument9 pagesTransport Processes in Thin Liquid Films During High-Vacuum DistillationmahsaPas encore d'évaluation

- L3 Competencies: This One Is Too EasyDocument12 pagesL3 Competencies: This One Is Too Easykrymxen100% (1)

- The Rice InstituteDocument52 pagesThe Rice InstituteAyush SinghPas encore d'évaluation

- Vapor-Liquid Equilibrium at High PressuresDocument15 pagesVapor-Liquid Equilibrium at High PressuresJCKARLPas encore d'évaluation

- Fundamentals of Fixed Bed Adsorption Processes Analysis of Adsorption Breakthrough and Desorption Elution CurvesDocument9 pagesFundamentals of Fixed Bed Adsorption Processes Analysis of Adsorption Breakthrough and Desorption Elution CurvesAlfonso BlancoPas encore d'évaluation

- Colorimetric Determination of Ethyl AlcoholDocument6 pagesColorimetric Determination of Ethyl AlcoholgustavopsoPas encore d'évaluation

- Loba To 2006Document4 pagesLoba To 2006usercmdmcPas encore d'évaluation

- Alcanos PDFDocument2 pagesAlcanos PDFJOANPas encore d'évaluation

- Alkanes: Vapor-Liquid Equilibria ModelDocument2 pagesAlkanes: Vapor-Liquid Equilibria ModelJOANPas encore d'évaluation

- Hayden 1975Document8 pagesHayden 1975SandraColoradoPas encore d'évaluation

- Bourdet 1985Document12 pagesBourdet 1985husseinhshPas encore d'évaluation

- Group Contribution Estimation of Activity Coefficient in Non Ideal MixsDocument14 pagesGroup Contribution Estimation of Activity Coefficient in Non Ideal MixsArun EbenezerPas encore d'évaluation

- Important Activity AIChE J21, 1086Document14 pagesImportant Activity AIChE J21, 1086m_adnane_dz3184Pas encore d'évaluation

- Computer Experiments On Classical Fluids. I. Thermodynamical Properties of Lennard-Jones MoleculesDocument6 pagesComputer Experiments On Classical Fluids. I. Thermodynamical Properties of Lennard-Jones MoleculesLorem IpsumPas encore d'évaluation

- Articol 23-24Document9 pagesArticol 23-24Antonia LorenaPas encore d'évaluation

- A New Simulation Method For Absorber, Stripper and Reboiled Absorber With Multicomponent Non-Ideal SystemsDocument9 pagesA New Simulation Method For Absorber, Stripper and Reboiled Absorber With Multicomponent Non-Ideal SystemsFizzerPas encore d'évaluation

- Three-Parameter Cubic Equation of State For Normal SubstancesDocument4 pagesThree-Parameter Cubic Equation of State For Normal SubstancesFiorela VillalobosPas encore d'évaluation

- Detonation Characteristics Hydrogen-Oxygen Mixtures High Initial PressuresDocument5 pagesDetonation Characteristics Hydrogen-Oxygen Mixtures High Initial PressuresGustavo Gabriel JimenezPas encore d'évaluation

- K. Nordlund Et Al - Structure and Stability of Non-Molecular Nitrogen at Ambient PressureDocument7 pagesK. Nordlund Et Al - Structure and Stability of Non-Molecular Nitrogen at Ambient PressureMutrexczPas encore d'évaluation

- ThermoDocument70 pagesThermoSankhaPas encore d'évaluation

- 2006-1488: Laboratory Demonstrations/Experiments in Free and Forced Convection Heat TransferDocument15 pages2006-1488: Laboratory Demonstrations/Experiments in Free and Forced Convection Heat TransferMaten NasradinPas encore d'évaluation

- A Computer Design Method For Vertical Thermosyphon ReboilersDocument13 pagesA Computer Design Method For Vertical Thermosyphon ReboilersSrihari Kodimela100% (1)

- Thermophysical Properties of Fluids Dynamic Viscos PDFDocument13 pagesThermophysical Properties of Fluids Dynamic Viscos PDFOmodolor StevedanPas encore d'évaluation

- Teoria y Aplicacion de A CiclicaDocument5 pagesTeoria y Aplicacion de A CiclicaMAVERICK_HUNTER1234936Pas encore d'évaluation

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringD'EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringPas encore d'évaluation

- Pressure Transient Formation and Well Testing: Convolution, Deconvolution and Nonlinear EstimationD'EverandPressure Transient Formation and Well Testing: Convolution, Deconvolution and Nonlinear EstimationÉvaluation : 2 sur 5 étoiles2/5 (1)

- Treatise on Irreversible and Statistical Thermodynamics: An Introduction to Nonclassical ThermodynamicsD'EverandTreatise on Irreversible and Statistical Thermodynamics: An Introduction to Nonclassical ThermodynamicsÉvaluation : 1 sur 5 étoiles1/5 (1)

- Working Guide to Vapor-Liquid Phase Equilibria CalculationsD'EverandWorking Guide to Vapor-Liquid Phase Equilibria CalculationsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Unit 3 RequirementsDocument4 pagesUnit 3 Requirementsravioli kimPas encore d'évaluation

- Finding Neverland Study GuideDocument7 pagesFinding Neverland Study GuideDean MoranPas encore d'évaluation

- Science Technology and SocietyDocument46 pagesScience Technology and SocietyCharles Elquime GalaponPas encore d'évaluation

- 5Document3 pages5Carlo ParasPas encore d'évaluation

- TNEA Participating College - Cut Out 2017Document18 pagesTNEA Participating College - Cut Out 2017Ajith KumarPas encore d'évaluation

- Information: Republic of The Philippines Regional Trial Court 8 Judicial Region Branch VIDocument2 pagesInformation: Republic of The Philippines Regional Trial Court 8 Judicial Region Branch VIlossesaboundPas encore d'évaluation

- 1INDEA2022001Document90 pages1INDEA2022001Renata SilvaPas encore d'évaluation

- Ict - chs9 Lesson 5 - Operating System (Os) ErrorsDocument8 pagesIct - chs9 Lesson 5 - Operating System (Os) ErrorsOmengMagcalasPas encore d'évaluation

- HDFC Bank-Centurion Bank of Punjab: Presented By: Sachi Bani Perhar Mba-Ib 2010-2012Document40 pagesHDFC Bank-Centurion Bank of Punjab: Presented By: Sachi Bani Perhar Mba-Ib 2010-2012Sumit MalikPas encore d'évaluation

- Jesus Chavez AffidavitDocument21 pagesJesus Chavez AffidavitThe Dallas Morning NewsPas encore d'évaluation

- Damodaram Sanjivayya National Law University VisakhapatnamDocument6 pagesDamodaram Sanjivayya National Law University VisakhapatnamSuvedhya ReddyPas encore d'évaluation

- Intro To Law CasesDocument23 pagesIntro To Law Casesharuhime08Pas encore d'évaluation

- PSIG EscalatorDocument31 pagesPSIG EscalatorNaseer KhanPas encore d'évaluation

- Iluminadores y DipolosDocument9 pagesIluminadores y DipolosRamonPas encore d'évaluation

- PS4 ListDocument67 pagesPS4 ListAnonymous yNw1VyHPas encore d'évaluation

- The Music Tree Activities Book Part 1 Music Tree Summy PDF Book by Frances ClarkDocument3 pagesThe Music Tree Activities Book Part 1 Music Tree Summy PDF Book by Frances ClarkRenata Lemes0% (2)

- Chemistry InvestigatoryDocument16 pagesChemistry InvestigatoryVedant LadhePas encore d'évaluation

- Psychology Research Literature Review ExampleDocument5 pagesPsychology Research Literature Review Exampleafdtsebxc100% (1)

- Introduction To Emerging TechnologiesDocument145 pagesIntroduction To Emerging TechnologiesKirubel KefyalewPas encore d'évaluation

- Improving Downstream Processes To Recover Tartaric AcidDocument10 pagesImproving Downstream Processes To Recover Tartaric AcidFabio CastellanosPas encore d'évaluation

- 5f Time of Legends Joan of Arc RulebookDocument36 pages5f Time of Legends Joan of Arc Rulebookpierre borget100% (1)

- TrematodesDocument95 pagesTrematodesFarlogy100% (3)

- Kozier Erbs Fundamentals of Nursing 8E Berman TBDocument4 pagesKozier Erbs Fundamentals of Nursing 8E Berman TBdanie_pojPas encore d'évaluation

- Book TurmericDocument14 pagesBook Turmericarvind3041990100% (2)

- Death and The King's Horseman AnalysisDocument2 pagesDeath and The King's Horseman AnalysisCelinaPas encore d'évaluation

- Assignment File - Group PresentationDocument13 pagesAssignment File - Group PresentationSAI NARASIMHULUPas encore d'évaluation

- Answer Key For 1st QaurterDocument5 pagesAnswer Key For 1st QaurterSteffi89% (9)

- Weird Tales v14 n03 1929Document148 pagesWeird Tales v14 n03 1929HenryOlivr50% (2)