Académique Documents

Professionnel Documents

Culture Documents

LEEA - Instruction For Safe Use of Flat Woven Webbing Slings

Transféré par

donnyars19790 évaluation0% ont trouvé ce document utile (0 vote)

362 vues2 pagesLEEA Web Slings

Titre original

LEEA - Instruction for Safe Use of Flat Woven Webbing Slings

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentLEEA Web Slings

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

362 vues2 pagesLEEA - Instruction For Safe Use of Flat Woven Webbing Slings

Transféré par

donnyars1979LEEA Web Slings

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

Instructionsforthesafeuseof:

FlatWovenWebbingSlings

The information in this leaflet should be passed to the user of the equipment

This document is issuedinaccordancewiththerequirementsofSection 6of Storing and Handling Belt Slings

theHealthandSafetyat Work etc Act 1974, amendedMarch1988. It

outlines the care and safe use of man-made fibre FLAT WOVEN Never return wet, damaged or contaminated slings to storage. They

WEBBING SLINGS, commonly known as BELT SLINGS, and is based should be cleaned with clear water and dried naturally. Never force dry

on Section 15 of the LEEA Code of Practice for the Safe Use of Lifting belt slings.

Equipment.* It should be read in conjunction with the requirements for Store belt slings hung from non-rusting pegs which allow the free

general purposeslingingpractice, givenoverleaf, whichform anintegral circulationof air.

part of theseinstructions. The storage area should be dry, clean, free of any contaminates and

This information is of a general nature only covering the main points for shadedfrom direct sunlight.

the safe use of Belt Slings. It may be necessary to supplement this Do not alter, modify or repair a belt sling but refer such matters to a

informationforspecific applications. Competent Person.

NOTE: The material from which the sling is manufactured may be

identified by the colour of the label or printing on the label: Polyester =

ALWAYS: Blue, Polyamide (Nylon) = Green, Polypropylene = Brown and the sling

Storeandhandlebelt slings correctly. may alsobedyedwithacolourcodetoindicateSWL.

Inspectbeltslingsandaccessoriesbeforeuseandbeforeplacinginto

Using Belt Slings Safely

storage.

Do not attempt lifting operations unless you understand the use of the

Followsafeslingingpractices, as givenoverleaf.

Positionthebight forchokelift at 120° (natural angle). equipment, theslingingprocedures andthemodefactors tobeapplied.

Position the sling so that the load is uniformly spread over its width Donot usedefectiveslings oraccessories.

andprotect theslingfrom sharpedges. Check the correct engagement with fittings and appliances, ensure

Applythecorrect modefactorfortheslingingarrangement. smooth radii are formed, do not twist or cross slings and do not

overcrowdfittings.

NEVER: Positiontheslingsothat theloadis uniformlyspreadoverits width.

Attempt toshorten, knot ortiebelt slings. Position the bight for a choke lift at the natural (120°) angle to prevent

Exposebelt slings todirect heat orflames. frictionbeinggenerated.

Use belt slings outside the temperature range stated below without Ensurethat stitchingis inthestandingpartoftheslingawayfrom hooks

consultingthesupplier. andotherfittings.

Exposebelt slings tochemicals without consultingthesupplier. Taketheloadsteadilyandavoidshock loads.

Shock loadbelt slings. Do not leave suspended loads unattended. In an emergency cordon off

Use belt slings which are cut or which have loose or damaged thearea.

stitching. In-service Inspection and Maintenance

Useaslingwithamissing/damagedlabel orillegiblemarkings Maintenancerequirements areminimal. Beltslingsmaybecleanedwith

clear water. Remember weak chemical solutions will become

increasinglystrongerbyevaporation.

Selecting the Correct Sling Before each use inspect belt slings and, in the event of the following

Belt slings are available in a range of materials and sizes in single leg and defects, refer the sling to a Competent Person for thorough examination:

endless sling forms. Select the slings to be used and plan the lift illegible markings; damaged, chaffed or cut webbing;

takingthefollowingintoaccount: damaged or loose stitching; heat damage; burns; chemical damage;

Material - polyester identified by a blue label is resistant to moderate solardegradation; damagedordeformedendfittings.

strength acids but is damaged by alkalis; polyamide (Nylon) identified by

a green label is virtually immune to alkalis but is damaged by acids; and ©LiftingEquipment Engineers Association2004SI No. 3.3

polypropylene identified by a brown label is little affected by acids or Furtherinformationis givenin:

alkalis but is damaged by some solvents, tars and paints and therefore, BS EN 1492-1:2000 – Textile slings – safety – Part 1 Flat woven

suitable for appliances where the highest resistance to chemicals

webbingslings, madeof man-madefibres, forgeneral purposeuse.

otherthansolvents is required.

Capacity - the sling must be both long enough and strong enough for the *TheCodeof PracticefortheSafeUseof LiftingEquipment, publishedby:

load and the slinging method. Apply the mode factor for the slinging LIFTINGEQUIPMENTENGINEERSASSOCIATION

method. 3. OspreyCourt, KingfisherWay,

Temperature-Forflat wovenslings madetoBS EN1492-1:2000 HinchingbrookeBusiness Park, HuntingdonPE296FN

PolyesterAndPolyamide-40°Cto100°C Polypropylene-40°Cto80°C UnitedKingdom

Forflat wovenslings madetootherstandards Tel: + 44(0)1480432801

0°Cto80°C Fax: + 44(0)1480436314

Notethat temperatureranges varyinachemical environment, inwhich E-mail: mail@leea.co.uk

casetheadviceof themanufacturerorsuppliershouldbesought.

If the slings are used in multi-leg arrangement the angle formed

betweenthelegs shouldnot beless than30° orgreaterthan90°.

If abrasion, heat generated by friction or cutting from edges or corners are

likely select a sling fitted with protective sleeves and/or use suitable

packing.

Slings withgrade8fittings andmulti-legslingswithgrade8masterlinks

should not be used in acidic conditions. Contact with acids or acidic

fumes causes hydrogen embrittlement to grade 8 materials. If exposure

tochemicals is likely, themanufacturerorsuppliershouldbeconsulted.

GENERAL PURPOSE SLINGING PRACTICE Safe use of Slings

The following information is based on Section 1 - Appendix 1.5 of oGood slinging practice must ensure that the load is as safe and

the LEEA Code of Practice for the Safe Use of Lifting secure in the air as it was on the ground and that no harm is done

Equipment.* It should be read in conjunction with the instructions to the load, lifting equipment, other property or persons.

for the safe use, given overleaf, of which it forms an integral part oEstablish the weight of the load, ensure the lifting method is

and with any specific instructions issued by the supplier. suitable and inspect the sling and attachments for obvious

This information is of a general nature only covering the main defects. Prepare the landing area making sure the floor is strong

points for the safe use of various types of slings for general lifting enough to take the load. Follow any specific instructions from the

purposes. supplier.

oEnsure the lifting point is over the centre of gravity. Any loose

parts of the load should be removed or secured. Secure the sling

ALWAYS: firmly to the load by hooks onto lifting points or shackles etc. The

Plan the lift, establish the weight of the load and prepare the sling must not be twisted, knotted or kinked in any way.

landing area ensuring that it will take the weight. oUse packing to prevent damage to the sling from corners or

edges and to protect the load.

Check slings and equipment are free of damage, use oDo not exceed the SWL or rated angle. Anychoke angle must

slings/slinging methods suitable for the load and protect slings

from sharp edges and corners. not exceed 120 and any basket 90 .

oDo not hammer, force or wedge slings or accessories into

Attach the sling securely to the load and appliance and position; they must fit freely.

position hooks to face outwards. oWhen attaching more than one sling to the hook of the

Ensure the load is balanced and will not tilt or fall. appliance use a shackle to join the slings and avoid overcrowding

Keep fingers, toes etc clear when tensioning slings and when the hook.

landing loads. oUse an established code of signals to instruct the crane driver.

oEnsure the load is free to be lifted and not, for example, bolted

Ensure that the load is free to be lifted. down.

Make a trial lift and trial lower. oCheck that there are no overhead obstacles such as power

NEVER: lines.

oKeep fingers, toes etc clear ensuring they do not become

Use damaged slings or accessories. trapped when lifting, lowering or controlling loads.

Twist, knot or tie slings. oMake a trial lift by raising the load a little to ensure it is balanced,

Hammer slings into position. stable and secure and if not lower it and adjust the slinging

arrangement.

Overload slings due to the weight of the load or the mode of

oWhere appropriate use tag lines to control the load.

use.

oExcept where special provision is made, do not allow anyone to

Trap slings when landing the load. pass under or ride upon the load. The area should be kept clear.

Drag slings over floors etc or attempt to pull trapped slings oMake a trial set down, ensure the sling will not become trapped

from under loads. and the load will not tip when the slings are released. Use

supports which are strong enough to sustain the load without

Allow personnel to ride on loads. crushing.

oNever drag slings over floors etc or attempt to drag a trapped

sling from under a load.

Sling Configurations and Rating oNever use a sling to drag a load.

Slings are available in single, two, three and four leg or endless

form. In practice it will be found that chain, wire rope and fibre oPlace the hooks of free legs back onto the master link and take

rope slings are available in any of these configurations but that care to ensure that empty hooks do not become accidentally

flat woven webbing is limited to single leg and endless whilst engaged.

roundslings are only supplied in endless form. The maximum oNever use slings in contact with chemicals or heat without the

load that a sling may lift in use will be governed by the slinging manufacturers approval.

arrangement (mode of use) and may vary from the marked oNever use damaged or contaminated slings.

SWL.** In the case of textile slings the SWL for the various oOn completion of the lift return all equipment to proper storage.

modes of use is usually given on the information label. In other

cases it is necessary to multiply the marked SWL by a mode

factor.*** Further information is given in:

The following three simple rules will ensure that the sling is not *LEEA Code of Practice for the Safe Use of Lifting Equipment.

overloaded. In some cases this will mean that the sling will be ** BS 6166 Part 1 - Lifting Slings, Methods of Rating.

under utilised although this is unlikely to hinder the user unduly. *** BS 6166 Part 3 - Selection and Safe Use of Lifting Slings for

Where the maximum utilisation is required reference should be Multi-purposes.

made to a Competent Person who understands the factors **** HSE Guidance Note GS39 - Training of Crane Drivers and

involved and who can perform the necessary calculations. Slingers.

(1) For straight lift never exceed the marked SWL and in the case

of multi-leg slings the specified angle or range of angles. Various British Standards covering individual products.

(2) When using slings in choke hitch multiply the marked SWL by

0.8 to obtain the reduced maximum load the sling may

lift ie reduce the safe working load by 20%.

(3) With multi-leg slings, when using less than the full number of

legs, reduce the maximum load in proportion to the number of

legs in use. Simply multiply the marked SWL by the number of

legs in use expressed as a fraction of the total thus: one leg of a

two leg sling = ½ marked SWL, three legs of a four leg sling = ¾ SI GSP 1.1 (2000)

marked SWL and so on.

Operative Training

Slings should only be used by trained operatives who understand

the methods of rating and application of mode factors.****

Vous aimerez peut-être aussi

- Chain Slings SI 1.3Document2 pagesChain Slings SI 1.3reda mesbahPas encore d'évaluation

- Instructions For The Safe Use Of: Wire Rope SlingsDocument2 pagesInstructions For The Safe Use Of: Wire Rope SlingsStuartWilliamGlenniePas encore d'évaluation

- LEEA Lifting and Slinging Course OutlineDocument4 pagesLEEA Lifting and Slinging Course OutlineSankaranarayananPas encore d'évaluation

- LEEA ACADEMY Course Study Materials - MCE - V1.0 Mar 2020-MergedDocument189 pagesLEEA ACADEMY Course Study Materials - MCE - V1.0 Mar 2020-MergedRana DanishPas encore d'évaluation

- LEEA ACADEMY STEP NOTES - Foundation - Aug2018 - v1.8 Print PDFDocument72 pagesLEEA ACADEMY STEP NOTES - Foundation - Aug2018 - v1.8 Print PDFSelva GanapathiPas encore d'évaluation

- LEEA 032 Guide To Written Schemes Free VersionDocument7 pagesLEEA 032 Guide To Written Schemes Free VersionGaniyu100% (1)

- LEEA 059 5 Guidance To Documentation & Marking Part5Document23 pagesLEEA 059 5 Guidance To Documentation & Marking Part5GaniyuPas encore d'évaluation

- Annual Report: Lifting Standards WorldwideDocument20 pagesAnnual Report: Lifting Standards WorldwideUlviyye ElesgerovaPas encore d'évaluation

- BS 07121-2-4-2013Document36 pagesBS 07121-2-4-2013Abdel Rahman SalahPas encore d'évaluation

- Guidance On The Use of U-Bolt Type Wire Rope Grips: Document Reference: LEEA-049Document6 pagesGuidance On The Use of U-Bolt Type Wire Rope Grips: Document Reference: LEEA-049Ganiyu100% (1)

- Opito Rigger TrainingDocument61 pagesOpito Rigger TrainingTasia DiPas encore d'évaluation

- LEEA-015 BSI Reference Library List - Version 09 - Jan 2021Document32 pagesLEEA-015 BSI Reference Library List - Version 09 - Jan 2021GaniyuPas encore d'évaluation

- LEEA Handbook PDFDocument1 pageLEEA Handbook PDFparamarthasom1974Pas encore d'évaluation

- Web-Sling-Recommended-Operating-and-Inspection-GuidelineDocument12 pagesWeb-Sling-Recommended-Operating-and-Inspection-GuidelineibrahimPas encore d'évaluation

- As 1353.1-1997 Flat Synthetic-Webbing Slings Product SpecificationDocument7 pagesAs 1353.1-1997 Flat Synthetic-Webbing Slings Product SpecificationSAI Global - APAC0% (1)

- Foundation Course (FOU) : DescriptionDocument15 pagesFoundation Course (FOU) : DescriptionVinu VincentPas encore d'évaluation

- Banksman SlingerDocument9 pagesBanksman SlingerPirlo PoloPas encore d'évaluation

- LEEA-051 Guidance On Design Inspection and Use of Water Bags As Test Weights in The Offshore Industry Version 1 October 2012Document7 pagesLEEA-051 Guidance On Design Inspection and Use of Water Bags As Test Weights in The Offshore Industry Version 1 October 2012Ganiyu100% (1)

- LEEA 059 6 Documentation&Marking-Part6Document24 pagesLEEA 059 6 Documentation&Marking-Part6GaniyuPas encore d'évaluation

- LEEA-036 (A) - Academy Practical Training Courses Jan - June 2020 Version 1 October 2019Document18 pagesLEEA-036 (A) - Academy Practical Training Courses Jan - June 2020 Version 1 October 2019kaito kurabaPas encore d'évaluation

- LEEA-062 General Guidance To The Manufacturer of Lifting Equipment To The Development of Instructions For Use Version 1 April 2015 PDFDocument11 pagesLEEA-062 General Guidance To The Manufacturer of Lifting Equipment To The Development of Instructions For Use Version 1 April 2015 PDFUlviyye ElesgerovaPas encore d'évaluation

- LEEA-064 Guidance To CE Marking of Lifting Equipment For Which There Is No Harmonised Standard Version 1 July 2015Document9 pagesLEEA-064 Guidance To CE Marking of Lifting Equipment For Which There Is No Harmonised Standard Version 1 July 2015Deepak RMPas encore d'évaluation

- 59-1 Man BasketDocument3 pages59-1 Man BasketAkhil100% (1)

- Guidance To The Verification of Sockets and Davits.: Document Reference LEEA 061Document18 pagesGuidance To The Verification of Sockets and Davits.: Document Reference LEEA 061GaniyuPas encore d'évaluation

- Api RP 2D - Offshore Crane Inspector Certification ProgramDocument5 pagesApi RP 2D - Offshore Crane Inspector Certification Programzulfadli izaraeePas encore d'évaluation

- Periodic Inspection Sling GBDocument2 pagesPeriodic Inspection Sling GBjeanmichelqPas encore d'évaluation

- LEEA-036 (B) - Academy ITS Practical Training Courses Jan - June 2020 Version 1 October 2019Document18 pagesLEEA-036 (B) - Academy ITS Practical Training Courses Jan - June 2020 Version 1 October 2019kaito kurabaPas encore d'évaluation

- Leea Question and Answer 2cDocument3 pagesLeea Question and Answer 2cYAKUBU A. AROGEPas encore d'évaluation

- Authorised Examiners Lifting EquipmentDocument13 pagesAuthorised Examiners Lifting EquipmentdunglxPas encore d'évaluation

- BS-7121-11-1998 Offshore CranesDocument23 pagesBS-7121-11-1998 Offshore CranesAkram DriraPas encore d'évaluation

- LEEA Passing CriteriaDocument1 pageLEEA Passing CriteriaKhurram S. Muzammil50% (2)

- ToolboxTalks D-D Ratio 041315 PDFDocument1 pageToolboxTalks D-D Ratio 041315 PDFkaniniuserPas encore d'évaluation

- Loler AcopDocument71 pagesLoler AcopMoheb BotrosPas encore d'évaluation

- Appointed Person: Planning and Regulatory RequirementsDocument6 pagesAppointed Person: Planning and Regulatory RequirementssamPas encore d'évaluation

- Leea Question and Answer 2Document3 pagesLeea Question and Answer 2YAKUBU A. AROGEPas encore d'évaluation

- Banksman Slinging R2Document31 pagesBanksman Slinging R2Ilyas ZeriPas encore d'évaluation

- Module 3.1Document35 pagesModule 3.1Akash VermaPas encore d'évaluation

- Wire Rope SlingsDocument5 pagesWire Rope SlingsEr Faiyaz AhmedPas encore d'évaluation

- Wire Rope Sling Tech InfoDocument6 pagesWire Rope Sling Tech InfoDaud PirriPas encore d'évaluation

- No. 8 - Chain & Chain SlingsDocument11 pagesNo. 8 - Chain & Chain SlingsAhmed AtefPas encore d'évaluation

- BS en 13414-1 2003 PresentationDocument6 pagesBS en 13414-1 2003 PresentationAlbadeel Inspection & Conformity Co. ltd100% (1)

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithPas encore d'évaluation

- 2012 OL1 1.2 E Student 017717 Marker 42Document3 pages2012 OL1 1.2 E Student 017717 Marker 42alexedamalaPas encore d'évaluation

- LEEA Think Lifting Portrait A4 4pp v2Document4 pagesLEEA Think Lifting Portrait A4 4pp v2Muhammad KamranPas encore d'évaluation

- SS-22 Forklift Safety Management Training - Materi PDFDocument54 pagesSS-22 Forklift Safety Management Training - Materi PDFAgung PramonoPas encore d'évaluation

- LEEA Oil & Gas Webinar Presentation - 280422Document27 pagesLEEA Oil & Gas Webinar Presentation - 280422Mohammed Ahmed NasherPas encore d'évaluation

- LOLER Lifting Equipment Inspection Duties EbookDocument19 pagesLOLER Lifting Equipment Inspection Duties EbookumnartkhPas encore d'évaluation

- LEEA 039a Accreditation Scheme Appendix 1Document25 pagesLEEA 039a Accreditation Scheme Appendix 1Irshad Akhter100% (1)

- Side Boom TrainingDocument40 pagesSide Boom TrainingMauricio Bulla ValenciaPas encore d'évaluation

- BSEN-16191 Venkatesh Mohan Tunnel Safety Specalist PDFDocument54 pagesBSEN-16191 Venkatesh Mohan Tunnel Safety Specalist PDFVenkatesh MohanPas encore d'évaluation

- Unit 1.14 - Shackles: 1.1 Body and Pin Forging 1.2 Heat Treatment 1.3 FinishDocument8 pagesUnit 1.14 - Shackles: 1.1 Body and Pin Forging 1.2 Heat Treatment 1.3 Finisheetua100% (2)

- LEG 5 Day Diploma 2010 1Document49 pagesLEG 5 Day Diploma 2010 1Zayauddin AnsariPas encore d'évaluation

- User Manual - X904Document26 pagesUser Manual - X904Foad MirzaiePas encore d'évaluation

- Draft Revisions, February 2015 Not For Publication: Winches Used With Web Tie DownsDocument15 pagesDraft Revisions, February 2015 Not For Publication: Winches Used With Web Tie DownsSebastian ZarzyckiPas encore d'évaluation

- Lifting Gear Inspection & MaintenanceDocument15 pagesLifting Gear Inspection & MaintenanceAnis Kacem100% (1)

- LEEA Academy MCE Module Quiz Paper - ANSWERS Mar20Document39 pagesLEEA Academy MCE Module Quiz Paper - ANSWERS Mar20Rana Danish100% (1)

- Rigging Gear Store Management RegisterDocument6 pagesRigging Gear Store Management RegisterKhawaja Arslan Ahmed0% (1)

- LEEA-080 Information On EU Use of Work Equipment Legislation Version 1 March 2020Document36 pagesLEEA-080 Information On EU Use of Work Equipment Legislation Version 1 March 2020GaniyuPas encore d'évaluation

- Foundation Course E-Learning Course Guide v1.0 Dec 16Document9 pagesFoundation Course E-Learning Course Guide v1.0 Dec 16mohammad eldeebPas encore d'évaluation

- Instructions For The Safe Use of Flat Woven Webbing SlingsDocument4 pagesInstructions For The Safe Use of Flat Woven Webbing SlingsavisheklochunPas encore d'évaluation

- Technology WeldingDocument925 pagesTechnology Weldingdonnyars1979Pas encore d'évaluation

- Analysis of Eddy Current Capabilities For The Detection of Outer Diameter StressDocument9 pagesAnalysis of Eddy Current Capabilities For The Detection of Outer Diameter Stressdonnyars1979Pas encore d'évaluation

- Weldability of A36 Material To A572 MaterialDocument7 pagesWeldability of A36 Material To A572 Materialdonnyars1979Pas encore d'évaluation

- Bhel Welding GuidelinesDocument64 pagesBhel Welding Guidelinesashutoshsachan100% (3)

- HSE - Use of Winches in Directional Felling and TakedownDocument4 pagesHSE - Use of Winches in Directional Felling and Takedowndonnyars1979Pas encore d'évaluation

- SMAW PrinciplesDocument89 pagesSMAW Principlesdonnyars1979Pas encore d'évaluation

- HSE - Manual Handling Asessment ChartDocument13 pagesHSE - Manual Handling Asessment Chartdonnyars1979Pas encore d'évaluation

- Strahlenschutzkommission: Electromagnetic Fields of New TechnologiesDocument31 pagesStrahlenschutzkommission: Electromagnetic Fields of New Technologiesdonnyars1979Pas encore d'évaluation

- Forestry LOLER: How The Regulations Apply To: HSE Information SheetDocument4 pagesForestry LOLER: How The Regulations Apply To: HSE Information Sheetdonnyars1979Pas encore d'évaluation

- Wire Rope Slings: Recommended Guideline For Proof Test Procedures ForDocument22 pagesWire Rope Slings: Recommended Guideline For Proof Test Procedures Fordonnyars1979Pas encore d'évaluation

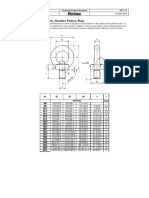

- Forged Eye Bolts, Metric, Shoulder Pattern, Plain: Page 1 of 2 REV-01 Date: August 9, 2012 M.Feb - SH.PDocument2 pagesForged Eye Bolts, Metric, Shoulder Pattern, Plain: Page 1 of 2 REV-01 Date: August 9, 2012 M.Feb - SH.Pdonnyars1979Pas encore d'évaluation

- CKL30 - SN 62739aDocument1 pageCKL30 - SN 62739adonnyars1979Pas encore d'évaluation

- ITP InstrumentationDocument9 pagesITP InstrumentationzhangyiliPas encore d'évaluation

- Schneider EngineeringDocument1 pageSchneider EngineeringT.J. MayesPas encore d'évaluation

- Dynamic Cone Penetrometers: In-Situ CBR in 10 Minutes With Dual-Mass DcpsDocument2 pagesDynamic Cone Penetrometers: In-Situ CBR in 10 Minutes With Dual-Mass Dcpsd'Hell CaesarPas encore d'évaluation

- Noise and Vibration During CosntructionDocument12 pagesNoise and Vibration During Cosntructionpierre3101Pas encore d'évaluation

- Bs en 00378 3 2016Document30 pagesBs en 00378 3 2016Darius VinPas encore d'évaluation

- Iec60092-350 (Ed2 0) enDocument7 pagesIec60092-350 (Ed2 0) enAzad RahmanPas encore d'évaluation

- Compact 40/25Document58 pagesCompact 40/25znim04Pas encore d'évaluation

- VLE Lactic Acid Ethyl Lactate Esterification PDFDocument7 pagesVLE Lactic Acid Ethyl Lactate Esterification PDFAseem Kashyap0% (1)

- DT NotesDocument117 pagesDT NotestessPas encore d'évaluation

- 2013 11 DUPLEX EasyDocument21 pages2013 11 DUPLEX EasyAnonymous HC0tWePas encore d'évaluation

- Autodesk Inventor - Sheet Metal Punch IfeaturesDocument6 pagesAutodesk Inventor - Sheet Metal Punch IfeaturesNdianabasi UdonkangPas encore d'évaluation

- Doing Hot Work On Gas ShipDocument5 pagesDoing Hot Work On Gas ShipAnonymous icnhaNsFPas encore d'évaluation

- Propeller DesignDocument1 pagePropeller DesignKeerthana MaheswarlaPas encore d'évaluation

- Creating REST API Using NodeJS and Consuming in AngularJSDocument8 pagesCreating REST API Using NodeJS and Consuming in AngularJSserignemodouPas encore d'évaluation

- Component Modeling - HDocument5 pagesComponent Modeling - HVasu IyerPas encore d'évaluation

- Woodworking Plans - Wheelbarrow PlanterDocument3 pagesWoodworking Plans - Wheelbarrow PlanterMirel HotescuPas encore d'évaluation

- Astm D3359Document9 pagesAstm D3359Angel GuachaminPas encore d'évaluation

- Concept of Circulation in A Free Vortex FlowDocument55 pagesConcept of Circulation in A Free Vortex FlowAnil KumarPas encore d'évaluation

- Islamic Law - WaterDocument12 pagesIslamic Law - WaterAnum FaheemPas encore d'évaluation

- The Reef Wayfinding Plan and Signage Design Concept 28 August 2019Document51 pagesThe Reef Wayfinding Plan and Signage Design Concept 28 August 2019Michele MontoloPas encore d'évaluation

- 20 Site SummaryDocument2 pages20 Site SummaryMuzammil WepukuluPas encore d'évaluation

- 007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCDocument43 pages007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCpietoePas encore d'évaluation

- Chapter 19A ConcreteDocument10 pagesChapter 19A ConcreteMofasa EPas encore d'évaluation

- SinxbyxDocument9 pagesSinxbyxGreeshmaPas encore d'évaluation

- Fluid Mechanics Seventh Edition by Frank M. WhiteDocument1 pageFluid Mechanics Seventh Edition by Frank M. WhiteDarKaiserPas encore d'évaluation

- Heat Transfer - A Basic Approach - OzisikDocument760 pagesHeat Transfer - A Basic Approach - OzisikMaraParesque91% (33)

- CH 1: Materials Used in Pipework & Plumbing FittingsDocument10 pagesCH 1: Materials Used in Pipework & Plumbing FittingsEmad BassemPas encore d'évaluation

- Module002 LaboratoryExercise002Document2 pagesModule002 LaboratoryExercise002Joaquin SmithPas encore d'évaluation

- The Right Stuff PDFDocument4 pagesThe Right Stuff PDFNeelank Tiwari100% (1)

- Welcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthD'EverandWelcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthÉvaluation : 4 sur 5 étoiles4/5 (59)

- Crazy for the Storm: A Memoir of SurvivalD'EverandCrazy for the Storm: A Memoir of SurvivalÉvaluation : 3.5 sur 5 étoiles3.5/5 (217)

- The Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerD'EverandThe Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerÉvaluation : 4 sur 5 étoiles4/5 (23)

- Survive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveD'EverandSurvive!: Essential Skills and Tactics to Get You Out of Anywhere—AlivePas encore d'évaluation

- Merle's Door: Lessons from a Freethinking DogD'EverandMerle's Door: Lessons from a Freethinking DogÉvaluation : 4 sur 5 étoiles4/5 (326)

- Left for Dead: My Journey Home from EverestD'EverandLeft for Dead: My Journey Home from EverestÉvaluation : 3.5 sur 5 étoiles3.5/5 (129)

- The Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsD'EverandThe Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsPas encore d'évaluation

- The Art of Resilience: Strategies for an Unbreakable Mind and BodyD'EverandThe Art of Resilience: Strategies for an Unbreakable Mind and BodyÉvaluation : 4.5 sur 5 étoiles4.5/5 (118)

- 438 Days: An Extraordinary True Story of Survival at SeaD'Everand438 Days: An Extraordinary True Story of Survival at SeaÉvaluation : 4.5 sur 5 étoiles4.5/5 (188)

- Transformed: Moving to the Product Operating ModelD'EverandTransformed: Moving to the Product Operating ModelÉvaluation : 4 sur 5 étoiles4/5 (1)

- Grandma Gatewood's Walk: The Inspiring Story of the Woman Who Saved the Appalachian TrailD'EverandGrandma Gatewood's Walk: The Inspiring Story of the Woman Who Saved the Appalachian TrailÉvaluation : 4.5 sur 5 étoiles4.5/5 (309)

- Dark Summit: The True Story of Everest's Most Controversial SeasonD'EverandDark Summit: The True Story of Everest's Most Controversial SeasonÉvaluation : 4 sur 5 étoiles4/5 (154)

- At the Pond: Swimming at the Hampstead Ladies' PondD'EverandAt the Pond: Swimming at the Hampstead Ladies' PondÉvaluation : 4 sur 5 étoiles4/5 (13)

- Free Outside: A Trek Against Time and DistanceD'EverandFree Outside: A Trek Against Time and DistanceÉvaluation : 4 sur 5 étoiles4/5 (26)

- Divided: A Walk on the Continental Divide TrailD'EverandDivided: A Walk on the Continental Divide TrailÉvaluation : 4 sur 5 étoiles4/5 (17)

- Laws of UX: Using Psychology to Design Better Products & ServicesD'EverandLaws of UX: Using Psychology to Design Better Products & ServicesÉvaluation : 5 sur 5 étoiles5/5 (9)

- Hiking Through: One Man's Journey to Peace and Freedom on the Appalachian TrailD'EverandHiking Through: One Man's Journey to Peace and Freedom on the Appalachian TrailÉvaluation : 4 sur 5 étoiles4/5 (99)

- The Optimist: A Case for the Fly Fishing LifeD'EverandThe Optimist: A Case for the Fly Fishing LifeÉvaluation : 4.5 sur 5 étoiles4.5/5 (18)

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderD'EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderÉvaluation : 4 sur 5 étoiles4/5 (283)

- Upside Down in the Yukon River: Adventure, Survival, and the World's Longest Kayak RaceD'EverandUpside Down in the Yukon River: Adventure, Survival, and the World's Longest Kayak RaceÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Death Clutch: My Story of Determination, Domination, and SurvivalD'EverandDeath Clutch: My Story of Determination, Domination, and SurvivalÉvaluation : 4.5 sur 5 étoiles4.5/5 (62)