Académique Documents

Professionnel Documents

Culture Documents

MI199 Training Flow Measurement

Transféré par

T S VirdiCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MI199 Training Flow Measurement

Transféré par

T S VirdiDroits d'auteur :

Formats disponibles

TATA-STEEL CGL FURNACE Page 1 /9

TRAINING MI199

Flow Measurement March 2014

GENERALITY

Direct Mass Flow-meters

A direct measure of the mass flow would be the

easiest for combustion control.

Mass-flow-meters could be:

‐ Thermal flow-meters,

Main drawback: requires a very stable flow

in order to be accurate, usually not

applicable on industrial furnaces (too long

straight pipes).

‐ Coriolis flow-meters

Main drawback: very costly

MI199_training _Flow measurement.docx

TATA-STEEL CGL FURNACE Page 2 /9

TRAINING MI199

Flow Measurement March 2014

Volume Flow-meters

The volume flow-meters are widely used on

industrial processes.

Volume flow-meters could be:

‐ Variable area flow-meters (Rotameter™)

‐ Electromagnetic flow-meters

‐ Ultrasonic flow-meters

‐ Differential pressure flow-meters (orifice

plate, Venturi tubes, …)

‐ ….

All these flow-meters give an m³/h value, which is

not enough to correctly control the combustion!

The combustion control requires a control of

“moles” (= mass control).

Consequently, the volume flow-meters measure

should be transformed into a mass flow value;

this is done by using the density:

→ the fluid density should be known, since the

density varies with the temperature and pressure,

both value should also be measured.

MI199_training _Flow measurement.docx

TATA-STEEL CGL FURNACE Page 3 /9

TRAINING MI199

Flow Measurement March 2014

Drever practice:

‐ The orifices are designed to measure the flow

referring to the “normal” conditions (Nm³/h),

the normal conditions are 0°C and 101325 Pa

(1013.25 mbar).

‐ By referring to predefined and fixed

conditions - fixed density - the flow value

(Nm³/h) is equivalent to a certain mass flow.

‐ Real fluid temperature and pressure should

be measured in order to convert the flow-

meter value into the corresponding Nm³/h.

MI199_training _Flow measurement.docx

TATA-STEEL CGL FURNACE Page 4 /9

TRAINING MI199

Flow Measurement March 2014

GAS DENSITY

Definition

The gas density is the weight of a certain volume

of gas; it is expressed in kg/m³; usual symbol is

“ρ”

Density variation with T° and Pr.

The density depends upon the quantity of gas

molecules.

For a same gas volume – 1 m³ – the quantity of

molecules varies with the pressure and

temperature:

‐ At high T°, the gas is expanded and 1 m³

contains less molecules than at lower T° →

ρ↓

‐ At high Pr, the gas is compressed and 1 m³

contains more molecules than at lower Pr →

ρ↑

‐ …

MI199_training _Flow measurement.docx

TATA-STEEL CGL FURNACE Page 5 /9

TRAINING MI199

Flow Measurement March 2014

To be representative, the gas density should

refer to certain T° & Pr “absolute values”.

Usual practice defines 2 references conditions:

‐ Normal conditions

0°C & 1 atmosphere

273 K & 101325 Pa

‐ Standard conditions

15 °C & 1 atmosphere

288 K & 101325 Pa

Drever documents usually refer to the normal

conditions (Nm³, Nm³/h, …)

Expression to convert the density

Conditions 1 refers to T1 and P1,

Conditions 2 refers to T2 and P2

∗ ∗

P & T in absolute values

MI199_training _Flow measurement.docx

TATA-STEEL CGL FURNACE Page 6 /9

TRAINING MI199

Flow Measurement March 2014

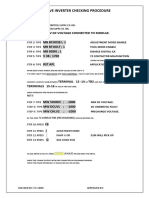

DIFFERENTIAL PRESSURE FLOW-

METER:

Introduction

These flow-meters are widely used due to their

good price / accuracy ratio; moreover they are

based on simple pieces of equipment which do

not require continuous maintenance.

Two main designs are mainly used in industrial

applications:

‐ Restriction types (orifice plates, Venturis)

‐ Pitot tubes (Annubar™)

Only the restriction type is described here-after.

MI199_training _Flow measurement.docx

TATA-STEEL CGL FURNACE Page 7 /9

TRAINING MI199

Flow Measurement March 2014

Physical principle

‐ Fluid flow:

S1 = the internal pipe surface in front of the

orifice (m²)

S2 = the internal pipe surface in the orifice

(m²)

v1 = the fluid speed mean value in front of

the orifice (m/s)

v2 = the fluid speed mean value in the

orifice (m/s)

Q = the fluid flow = S*v1 = S2*v2 (m³/s)

The difficulty is to measure v1 & v2

MI199_training _Flow measurement.docx

TATA-STEEL CGL FURNACE Page 8 /9

TRAINING MI199

Flow Measurement March 2014

‐ At any location of the stream, the fluid

“mechanical” energy is equal to the total

pressure:

Pdynamic is the pressure exerted by the fluid

velocity, it is measured in a direction

parallel to the fluid movement; ∗

∗

Pstatic is the pressure exerted by fluid onto

the pipe wall, it is measured in a direction

perpendicular to the fluid movement.

MI199_training _Flow measurement.docx

TATA-STEEL CGL FURNACE Page 9 /9

TRAINING MI199

Flow Measurement March 2014

‐ The restriction inserted into the stream creates

an acceleration of the fluid, by applying the

principle of “energy conservation” we may write:

1 1 2 2

1 2 2 1 ∆

∆ ∗ ∗ )

1

∆ ∗ ∗ ∗ 1

2

2∗∆ 1

∗

1

∗ ∗ √∆

Base on that theoretical equation, construction

norms (ISO 5167, ANSI 2530, ….) defines the

design rules to take into account the real fluids

characteristics (exact position of “1” and “2”,

S1/S2 acceptable ratio, variation of density ….).

MI199_training _Flow measurement.docx

Vous aimerez peut-être aussi

- Training - FlowDocument32 pagesTraining - FlowTimothy LeonardPas encore d'évaluation

- Pelevic LNG Flow Module v2Document40 pagesPelevic LNG Flow Module v2DiwanEfendiEfendiPas encore d'évaluation

- Coriolis Flow Meter Theory of Operation and Marine Fuel ManagementDocument17 pagesCoriolis Flow Meter Theory of Operation and Marine Fuel ManagementThu An Ngô ThịPas encore d'évaluation

- T14 Control Charts PDFDocument9 pagesT14 Control Charts PDFVictor Enrique Rosales ParadaPas encore d'évaluation

- Chemtrols Corporate PresentationDocument33 pagesChemtrols Corporate PresentationHarshith Rao VadnalaPas encore d'évaluation

- Operating Manual for Petrol Instruments Tank ProversDocument7 pagesOperating Manual for Petrol Instruments Tank ProversWilfredo MolinaPas encore d'évaluation

- 10 Level-MeasurementsDocument48 pages10 Level-Measurementsjohnpaul varonaPas encore d'évaluation

- Presentation 1-1 OverviewDocument18 pagesPresentation 1-1 OverviewfaisalardhyPas encore d'évaluation

- Daniel Compact Prover: ProversDocument12 pagesDaniel Compact Prover: ProversCarlos EduardoPas encore d'évaluation

- Flow MeasurementDocument49 pagesFlow MeasurementClara gustavaPas encore d'évaluation

- Dan Sof TG 0122Document30 pagesDan Sof TG 0122Erick Trujillo100% (1)

- Gas Metering PT-4Document30 pagesGas Metering PT-4brianPas encore d'évaluation

- Best Training For Flow 1Document51 pagesBest Training For Flow 1Crispin HungPas encore d'évaluation

- Flow Measurement Techniques: Brijesh B Menon C&I DepartmentDocument15 pagesFlow Measurement Techniques: Brijesh B Menon C&I DepartmentLiji BrijeshPas encore d'évaluation

- The 7 Flow Meters Used in The Oil and Gas IndustryDocument19 pagesThe 7 Flow Meters Used in The Oil and Gas IndustryصادقمحسنPas encore d'évaluation

- CV Trim Us CopesDocument2 pagesCV Trim Us Copesesakkiraj1590Pas encore d'évaluation

- FPSO and Offshore Measurement Technology Article 1.01!08!18.compressedDocument4 pagesFPSO and Offshore Measurement Technology Article 1.01!08!18.compresseddekra abdoPas encore d'évaluation

- Coriolis Part 3: Density: Maintenance Training Schlumberger Well ServicesDocument12 pagesCoriolis Part 3: Density: Maintenance Training Schlumberger Well Servicesyao nestorPas encore d'évaluation

- PGT005 Control Valves TrainingDocument12 pagesPGT005 Control Valves TrainingJom BonhayagPas encore d'évaluation

- JDC HSQE policy for drilling servicesDocument1 pageJDC HSQE policy for drilling servicesOws AnishPas encore d'évaluation

- Vacuum Booster Application of Bernoulli's PrincipleDocument9 pagesVacuum Booster Application of Bernoulli's PrincipleDouglas OngomPas encore d'évaluation

- Control Valve OpeningDocument3 pagesControl Valve OpeningConnor SailorPas encore d'évaluation

- Introduction to Metering & Allocation ProcessesDocument22 pagesIntroduction to Metering & Allocation ProcessesSameer AhmadPas encore d'évaluation

- Level Measurement: - Some of The Most Commonly Used Liquid-Level Measurement Methods AreDocument27 pagesLevel Measurement: - Some of The Most Commonly Used Liquid-Level Measurement Methods AredliyaxPas encore d'évaluation

- 04 Flow MeasurementDocument10 pages04 Flow MeasurementVo Dang Gia PhatPas encore d'évaluation

- Flow Measurement Workshop Papers on Reducing UncertaintyDocument8 pagesFlow Measurement Workshop Papers on Reducing UncertaintyjohnzrwPas encore d'évaluation

- API - Valve StandardsDocument38 pagesAPI - Valve StandardsK LandryPas encore d'évaluation

- Process Control and Automation Network Selection 1674135121Document113 pagesProcess Control and Automation Network Selection 1674135121Fabricio FebresPas encore d'évaluation

- Gas Metering TrainingDocument276 pagesGas Metering Trainingsushant shirsatPas encore d'évaluation

- MosaBook - PortugueseDocument45 pagesMosaBook - PortugueseclelianaPas encore d'évaluation

- Floating Production TechnologyDocument19 pagesFloating Production TechnologyHtin Lin AungPas encore d'évaluation

- TRG Module PPT - Flow MeasurementsDocument30 pagesTRG Module PPT - Flow Measurementspawan deepPas encore d'évaluation

- Coriolis Flowmeters Are Relatively New Compared To Other Flowmeters. They WereDocument9 pagesCoriolis Flowmeters Are Relatively New Compared To Other Flowmeters. They WereAyu AgustinaPas encore d'évaluation

- PSV Sizing ManualDocument10 pagesPSV Sizing ManualAkshay bhuranPas encore d'évaluation

- 143 756 Flowatch 2013 1Document8 pages143 756 Flowatch 2013 1YLW-BEKASIPas encore d'évaluation

- Valve Selection EssentialsDocument8 pagesValve Selection EssentialsdigecaPas encore d'évaluation

- TEC Buruq AvadanlıqlarıDocument33 pagesTEC Buruq AvadanlıqlarıSirac QəytərənovPas encore d'évaluation

- 5 DanalyzerDocument37 pages5 Danalyzermalik shahzad AbdullahPas encore d'évaluation

- Allocation Metering: Daniel Micro Motion Coriolis MetersDocument8 pagesAllocation Metering: Daniel Micro Motion Coriolis MetersNaser JahangiriPas encore d'évaluation

- Valves & Controls: Crosby Safety Valves Style HSLDocument12 pagesValves & Controls: Crosby Safety Valves Style HSLeborresonPas encore d'évaluation

- Composition Measurement of Multiphase FlowDocument17 pagesComposition Measurement of Multiphase FlowsalemPas encore d'évaluation

- Dynamic Measuremen Training LPGDocument58 pagesDynamic Measuremen Training LPGRomandon RomandonPas encore d'évaluation

- Fundamentals of Orifice Metering PDFDocument3 pagesFundamentals of Orifice Metering PDFshiryPas encore d'évaluation

- MPFM-050 PresentationDocument19 pagesMPFM-050 Presentationrocket-vtPas encore d'évaluation

- Valve Standards Petrochemical RefiningDocument5 pagesValve Standards Petrochemical RefiningSohaib ZafarPas encore d'évaluation

- EGP Measurement ManualDocument57 pagesEGP Measurement ManualMohd HassanudinPas encore d'évaluation

- Leaflet NG FPSO WebDocument2 pagesLeaflet NG FPSO Webharward66Pas encore d'évaluation

- Daniel Series 500-700 Control Valves HandbookDocument40 pagesDaniel Series 500-700 Control Valves Handbookjafo_211Pas encore d'évaluation

- Teach Me About SamplingDocument12 pagesTeach Me About SamplingApostolos PatsiasPas encore d'évaluation

- Krohne Rebuilt Gas Metering StationDocument46 pagesKrohne Rebuilt Gas Metering Stationmfg_serviciosPas encore d'évaluation

- Floboss S600+ Flow Computer: Sistem Arsitektur Dan InstalasiDocument24 pagesFloboss S600+ Flow Computer: Sistem Arsitektur Dan InstalasiricardoPas encore d'évaluation

- Presentation On Automation, PLC and Scada: By, Saikat Rahut Instrumentation and Control EngineeringDocument15 pagesPresentation On Automation, PLC and Scada: By, Saikat Rahut Instrumentation and Control EngineeringShivani SrivastavaPas encore d'évaluation

- Flow Tutorial - PD Positive Displacement Flow MetersDocument9 pagesFlow Tutorial - PD Positive Displacement Flow MetersBrian McMorris100% (2)

- OPC UA Vs OPC Classic: Security and Communication ComparisonDocument10 pagesOPC UA Vs OPC Classic: Security and Communication ComparisonKhaelle GottzPas encore d'évaluation

- Flow MeasurementDocument62 pagesFlow MeasurementLiji BrijeshPas encore d'évaluation

- Handbook: Turbine Gas MeterDocument27 pagesHandbook: Turbine Gas MeterBhagyesh BrahmbhattPas encore d'évaluation

- Handbook: Please Note Newer Operating Instructions!Document27 pagesHandbook: Please Note Newer Operating Instructions!Ibrahim Fadhl KalajengkingPas encore d'évaluation

- Handbook: Please Note Newer Operating Instructions!Document27 pagesHandbook: Please Note Newer Operating Instructions!Eslam MouhamedPas encore d'évaluation

- Numerical Modeling of The Performance of A Centrifugal Compressor Impeller With Low Inlet Flow CoefficientDocument13 pagesNumerical Modeling of The Performance of A Centrifugal Compressor Impeller With Low Inlet Flow CoefficientVicPas encore d'évaluation

- What Is The Difference Between Actual Standard and Normal FlowsDocument13 pagesWhat Is The Difference Between Actual Standard and Normal FlowskasebPas encore d'évaluation

- MI199 Training Combustion AdjustmentDocument11 pagesMI199 Training Combustion AdjustmentT S VirdiPas encore d'évaluation

- Tata CGL Sj700 Bitmapping v02Document1 pageTata CGL Sj700 Bitmapping v02T S VirdiPas encore d'évaluation

- Welder Iba SignalsDocument3 pagesWelder Iba SignalsT S VirdiPas encore d'évaluation

- Spare Checked From HV PanelsDocument1 pageSpare Checked From HV PanelsT S VirdiPas encore d'évaluation

- PS Controller Implimentation PDFDocument123 pagesPS Controller Implimentation PDFT S VirdiPas encore d'évaluation

- BOM Incomer Panels FINALDocument19 pagesBOM Incomer Panels FINALT S VirdiPas encore d'évaluation

- Backup ProcedureDocument36 pagesBackup ProcedureT S Virdi100% (1)

- SOP-Hitachi DrivesDocument2 pagesSOP-Hitachi DrivesT S VirdiPas encore d'évaluation

- Rockwell Automation - Basics of Circuit BreakersDocument102 pagesRockwell Automation - Basics of Circuit Breakersrobertspiteri100% (1)

- SMP DrivesDocument3 pagesSMP DrivesT S VirdiPas encore d'évaluation

- SJ-700 Parameter ListDocument3 pagesSJ-700 Parameter ListT S VirdiPas encore d'évaluation

- SMP DrivesDocument3 pagesSMP DrivesT S VirdiPas encore d'évaluation

- Drives 1.0Document10 pagesDrives 1.0T S VirdiPas encore d'évaluation

- Checklists JobsDocument3 pagesChecklists JobsT S VirdiPas encore d'évaluation

- Model Work Place Check ListDocument5 pagesModel Work Place Check ListT S VirdiPas encore d'évaluation

- Commissioning Test Report: Tata Steel LTD, Jamshedpur Cgl2 RevampingDocument6 pagesCommissioning Test Report: Tata Steel LTD, Jamshedpur Cgl2 RevampingT S VirdiPas encore d'évaluation

- Hall Effect Sensors TheoryDocument12 pagesHall Effect Sensors TheoryPrateek BhatnagarPas encore d'évaluation

- Cgl2 Revamping: Commissioning Test ReportDocument7 pagesCgl2 Revamping: Commissioning Test ReportT S VirdiPas encore d'évaluation

- Grounding Matrix Grounding DiagramDocument3 pagesGrounding Matrix Grounding DiagramT S VirdiPas encore d'évaluation

- APG Non HealthDocument14 pagesAPG Non HealthT S VirdiPas encore d'évaluation

- Spoken LanguageDocument13 pagesSpoken LanguageT S VirdiPas encore d'évaluation

- QuenchDocument17 pagesQuenchT S VirdiPas encore d'évaluation

- Template For Capturing Drive Failure Data - R1Document1 pageTemplate For Capturing Drive Failure Data - R1T S VirdiPas encore d'évaluation

- Adolescent Girl 24.8 Part 2Document9 pagesAdolescent Girl 24.8 Part 2T S VirdiPas encore d'évaluation

- Overflux InrushcurrDocument4 pagesOverflux InrushcurrT S VirdiPas encore d'évaluation

- Sop For Motor Changing JobDocument10 pagesSop For Motor Changing JobT S Virdi50% (2)

- Voice of VillagersDocument7 pagesVoice of VillagersT S VirdiPas encore d'évaluation

- ABB ACS 600 DC Bus OvervoltageDocument2 pagesABB ACS 600 DC Bus OvervoltageT S VirdiPas encore d'évaluation

- Bearing Failure Due To CurrentDocument2 pagesBearing Failure Due To CurrentT S VirdiPas encore d'évaluation

- Cambridge IGCSE: PHYSICS 0625/41Document20 pagesCambridge IGCSE: PHYSICS 0625/41minionhead1936Pas encore d'évaluation

- Apl 1117Document18 pagesApl 1117anacer55Pas encore d'évaluation

- Questions Bank Electronic BasicDocument96 pagesQuestions Bank Electronic Basiccsar_pc0% (1)

- Sheet (1) : An Iron Ring Has A Cross-Sectional Area of 3 CMDocument2 pagesSheet (1) : An Iron Ring Has A Cross-Sectional Area of 3 CMKhalifa MohamedPas encore d'évaluation

- Ricme Diaz@deped Gov PHDocument11 pagesRicme Diaz@deped Gov PHShekaina Faith Cuizon Lozada100% (1)

- DynamicsDocument12 pagesDynamicsmigs_gomezPas encore d'évaluation

- (LAB 9) FrictionDocument9 pages(LAB 9) FrictionMuhammad ShadzrinPas encore d'évaluation

- Electro Magnetic Field MCQ PDFDocument64 pagesElectro Magnetic Field MCQ PDFAnonymous gFcnQ4go100% (3)

- Analysis of windscreen wiper mechanism using MSC AdamsDocument15 pagesAnalysis of windscreen wiper mechanism using MSC AdamsDeepak SomanPas encore d'évaluation

- Gravitational FieldDocument30 pagesGravitational FieldAng Yu LongPas encore d'évaluation

- Mechanical Properties of FluidsDocument8 pagesMechanical Properties of FluidsMokshPas encore d'évaluation

- Week 10 - Kirchhoffs LawDocument6 pagesWeek 10 - Kirchhoffs LawRowen PratherPas encore d'évaluation

- 8-Fuel Air CyclesDocument19 pages8-Fuel Air Cyclesxemovi7309Pas encore d'évaluation

- IR Drop PDFDocument3 pagesIR Drop PDFarammartPas encore d'évaluation

- Year 9 IGCSE Physics Outline 2013-2014Document19 pagesYear 9 IGCSE Physics Outline 2013-2014Shaikh Usman Ai100% (1)

- 1754 1611 7 28Document15 pages1754 1611 7 28rezqPas encore d'évaluation

- Projectile Motion Equations and SolutionsDocument32 pagesProjectile Motion Equations and SolutionsAditya SahayPas encore d'évaluation

- gr9 PhyDocument2 pagesgr9 PhybatoulPas encore d'évaluation

- 603 DDocument8 pages603 DreluPas encore d'évaluation

- Direct Current CircuitDocument48 pagesDirect Current CircuitSanjay Mani TripathiPas encore d'évaluation

- API - STD - 521 Fire Gas ExpansionDocument3 pagesAPI - STD - 521 Fire Gas Expansioneliealtawil100% (1)

- Verify Thevenin and Norton TheoremsDocument5 pagesVerify Thevenin and Norton Theoremskrishnareddy_chintalaPas encore d'évaluation

- ECE 476 Exam #1 Thursday, October 6, 2016: Name: - AnswersDocument8 pagesECE 476 Exam #1 Thursday, October 6, 2016: Name: - AnswersTaher JebreelPas encore d'évaluation

- Marcet BoilerDocument5 pagesMarcet BoilerqusayPas encore d'évaluation

- Common Feats CalcerDocument65 pagesCommon Feats Calcer23Đại LộcPas encore d'évaluation

- Cambridge International AS & A Level: PHYSICS 9702/22Document16 pagesCambridge International AS & A Level: PHYSICS 9702/22NigelPas encore d'évaluation

- Paper 4Document16 pagesPaper 4Sayan Kumar KhanPas encore d'évaluation

- Physics Notes ExerciseDocument127 pagesPhysics Notes ExerciseNaeem AhmadPas encore d'évaluation

- Assignment-3-Centre of MassDocument6 pagesAssignment-3-Centre of MassSwarnalatha SwarnalathaPas encore d'évaluation

- Rotational Motion Part-BDocument25 pagesRotational Motion Part-Bsmi_santhosh100% (1)