Académique Documents

Professionnel Documents

Culture Documents

Go-Cart: Step-By-Step Instruction Manual

Transféré par

juancparra20Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Go-Cart: Step-By-Step Instruction Manual

Transféré par

juancparra20Droits d'auteur :

Formats disponibles

GO-CART

STEP-BY-STEP INSTRUCTION MANUAL

Designed and Built by Kevin Ayer

FamilyFun.com

©FamilyFun

Downloaded from www.Manualslib.com manuals search engine

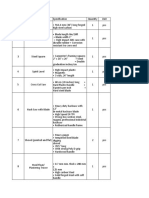

1 MATERIALS:

•

•

1½-inch diameter wood closet rod (at least 4 feet long)

2 (8-foot-long) 2 by 4 spruce studs

TOOLS:

•

•

Tape measure

Carpenter’s square

Go-Cart: You Will Need

• ½-inch AC/sanded plywood, half sheet (24 by 48 inches) • Pencil

• Lawn mower replacement wheels with ½-inch hubs (with ball bearings), • Eye and hearing protection

two (10-inch) for the back and two (8-inch) for the front (we used • Dust mask

Power Care brand) • Work gloves

• 4 hex-style wheel bolts that fit a ½-inch bore wheel hub (generally sold to • Jigsaw

go with the replacement wheels)* • Circular saw (if you don’t have one, a jigsaw will suffice)

• 4 (2- by 4-inch) angle brackets (we used Simpson brand, model #A24) • W-inch power drill

• 20 (2½-inch) coarse thread drywall screws • Drill bits

• 40 (1X-inch) coarse thread drywall screws Spade style: 1½-inch and Y-inch

• 24 (1N-inch) pan head screws Twist syle: E/cb-inch, C/af-inch, W-inch, and ½-inch

• W-inch hex bolt (6 inches long) Phillips power driver

• W-inch hex bolt (3½ inches long) • 2 (I/af-inch) wrenches (or 2 adjustables)

• 10 (W-inch) flat washers • O-inch wrench (or adjustable)

• 4 (½-inch) flat washers • Screwdriver

• 6 (W-inch) lock nuts • 100 grit sandpaper

• 6 (#4, or N- by 2½-inch) eye bolts with wood threads • File

• ½-inch galvanized pipe fittings: 2 flanges and a 3-inch nipple with • Utility knife

threaded ends • Coffee can or paint can (for tracing)

• Lubricating oil

• 2 (7-foot-long) W-inch braided ropes

• Paint and paintbrushes

• Boat floatation cushion with straps

• 18-inch bungee cord

Photograph by Peter N. Fox

* If you can’t find packaged bolts that go with

the wheels, you’ll need 4 (W-inch) hex bolts

with a collar, 2½ inches long.

FamilyFun.com Photograph by Kevin Ayer

©FamilyFun

Downloaded from www.Manualslib.com manuals search engine

2

Go-Cart: Cutting Directions

FIGURE 1

Cut the closet rod and the 2 by 4 spruce studs, as shown.

BRAKE LEVER STEERING BAR WASTE

20” 20”

BRAKE

WASTE BLOCK CENTER SUPPORT FRONT AXLE REAR AXLE

6” 36” 25” 25”

STEERING

COLUMN BRAKE

WASTE FOOT HOLD SUPPORT STEERING COLUMN BLOCK REAR AXLE BLOCKS FRONT AXLE BLOCKS

14” 6O” 21” 6” 11” 11” 10” 10”

FamilyFun.com

©FamilyFun

Downloaded from www.Manualslib.com manuals search engine

3 FIGURE 2

Cut the plywood as shown. To round the

corners on the seat pieces, use a pipe

SIDE PANEL

Go-Cart: Cutting Directions

flange and a large coffee or paint can to

trace circles as shown, then use the jig- WASTE

SEAT BACK SEAT

saw to cut around the outer curves (see

Figures A and B). To make the brake lever

opening in the seat, drill 1½-inch-wide

holes through the wood, as shown, and

then use the jigsaw to cut out the wood

between the holes.

SIDE PANEL

BRAKE LEVER OPENING

48”

12” 16” A

3K”

10O”

24”

24” B

11K”

8”

3O”

FamilyFun.com 1K” Photographs by Kevin Ayer

©FamilyFun

Downloaded from www.Manualslib.com manuals search engine

4 FIGURE 3A

Use the W-inch twist bit to drill one hole through

each of the brake blocks (3 inches from one end

Go-Cart: Drilling Directions

and 1O inches from the side edge) and through

the brake lever (7N inches from the bottom).

7N” BRAKE LEVER

FIGURE 3B

Using the same W-inch bit, drill 1O”

a hole centered on the steering 3”

BRAKE BLOCKS

column 1O inches from the top.

Then slowly drill a W-inch hole

through the center of the steer-

ing bar (as shown in Figure 4). FIGURE 3A

FIGURE 3B

FIGURE 4

Using the K-inch twist bit, slowly drill holes 1K-

inches in from each end of the steering bar, posi-

tioning them at a 90 degree angle to the center

hole. To help index the angle, insert a bolt or drill

bit in the center hole of the steering bar, and make

sure it is parallel with your work surface. W” HOLE

STEERING BAR K” HOLES

Drilling Tip:

1K”

Place a wood block underneath the piece you

are drilling to prevent blow-out splinters and

to protect your work surface. FIGURE 4

FamilyFun.com Photographs by Kevin Ayer

©FamilyFun

Downloaded from www.Manualslib.com manuals search engine

5 FIGURE 5

Create countersunk pivot holes for fitting the pipe

flanges onto the front axle. First, mark a point on the

FIGURE 5

Go-Cart: Drilling Directions

top of the center support 1O inches from the front end

and 1O inches from the edge. Use the 1K-inch spade FLANGE 12K”

bit to drill a W-inch-deep hole at the mark. Drill a

matching countersunk hole on the underside of the

axle 12K inches from the end and 1O inches from the 1O”

edge. Then, use the Y-inch spade bit to drill through 1O”

the center of each of the 1K-inch-wide holes, this time 1O”

going all the way through the wood.

FRONT AXLE

FIGURE 6 FIGURE 6

Go-Cart: Piece Assembly

Thread the 3-inch pipe nipple into one of the

K-inch flanges (first applying a few drops of

lubricating oil to the threaded ends), and then

insert the nipple through the countersunk

hole in the center support. Attach the flange

to the center support using four 1N-inch pan

head screws.

Assembly Tip:

Pre-drill all the screw holes.

FamilyFun.com Photographs by Kevin Ayer

©FamilyFun

Downloaded from www.Manualslib.com manuals search engine

6 FIGURE 7

Unscrew the nipple from the attached flange and

thread it into the second flange. Insert the nipple

Go-Cart: Piece Assembly

up through the countersunk hole on the bottom

of the front axle, flip the axle over, and attach the

flange, again using four 1N-inch pan head screws.

FRONT AXLE

FIGURE 7

FIGURE 8 FIGURE 8

Next, thread the free end of the nipple into the

first flange, turning the axle to tighten the con-

nection until there is about C/af-inch between the

center support and the front axle, and the pieces

CENTER SUPPORT

pivot freely.

FRONT AXLE

Photograph by Peter N. Fox

FamilyFun.com Photographs by Kevin Ayer

©FamilyFun

Downloaded from www.Manualslib.com manuals search engine

7 FIGURE 9

To assemble the go-cart frame, first use three 2K-inch

drywall screws to attach the back end of the center

Go-Cart: Piece Assembly

support to the center of the rear axle, positioning it so CENTER

SUPPORT

that the end of the support extends N inch past the

back edge of the axle. Then use drywall screws to

attach the rear axle blocks to the top of the rear axle,

positioning them so that they overhang the back edge

by N inch just as the center support does. They should

also extend N inch over the ends of the axles where

the wheels will go. (Note: Overhanging these pieces N” OVERHANG

will help to better support the seat back and the

wheels when you attach them later).

FIGURE 9

FIGURE 10 FIGURE 10

Attach the front axle blocks next, overhanging them

N inch past the wheel ends of the axle but keeping

them flush with the long edges. (Note: while one end

of each front block supports the wheels, the other end

helps control the steering by acting as a stop that

prevents the axle from turning too far.)

N” OVERHANG

FamilyFun.com Photographs by Kevin Ayer

©FamilyFun

Downloaded from www.Manualslib.com manuals search engine

8 FIGURE 11

Now it’s time to attach the wheels to the axles (the

larger ones to the back, the smaller to the front). To

METAL COLLAR

Go-Cart: Piece Assembly

ANGLE

create the assembly for each one, use a screwdriver BRACKET

to remove the small plastic hub in the center of the

wheel rim. Then, thread a metal collar on a wheel bolt,

leaving about K inch of bolt threads exposed between

the head of the bolt and the collar. Insert the bolt

through the K-inch hole on the smaller face of an

angle bracket as shown.

Slide a K-inch washer onto the bolt and insert the bolt

through the center of the wheel. Slide on a W-inch

washer, then screw on a W-inch lock nut, tightening it

FIGURE 11

until the assembly is snug but the wheel still spins freely.

FIGURE 12 (A & B) FIGURE 12 (B)

Use four 1N-inch pan head screws to attach the wheel

brackets to the underside of the axle ends.

UNDERSIDE

UNDERSIDE OF AXLE OF

FRAME

FIGURE 12 (A)

FamilyFun.com Photographs by Kevin Ayer

©FamilyFun

Downloaded from www.Manualslib.com manuals search engine

9 FIGURE 13

Mark the steering column 9 inches from the top. Butt

the steering column support up against the steering

Go-Cart: Piece Assembly

column, centering it on the mark. Use two 2K-inch

drywall screws to secure the two pieces together.

FIGURE 13

FIGURE 14 (A & B)

Using eight 1X-inch drywall screws, attach the

steering column side panels, lining the edges up

with the top of the steering column and the side of FIGURE 14 (B)

the steering column support, as shown.

STEERING

COLUMN

STEERING

COLUMN

SUPPORT

FIGURE 14 (A)

FamilyFun.com Photographs by Kevin Ayer

©FamilyFun

Downloaded from www.Manualslib.com manuals search engine

10 FIGURE 15

Attach the remaining plywood parts to the frame with

FIGURE 15

1X-inch drywall screws. Start with the seat back, lin-

Go-Cart: Piece Assembly

ing up the bottom edge with the bottom of the rear

axle, and screw into both the axle and the axle blocks.

Next, set the seat on the frame, butting it up against

the seat back, and screw it to the axle blocks and the

center support.

Position the steering column assembly on top of the

center support, butting it up against the seat. Fasten

it in place by screwing through the plywood into the

center support on both sides.

FIGURE 16 FIGURE 16

Attach the steering bar to the top of the steering col-

umn with a W- by 3K-inch bolt, sandwiching W-inch

washers between all pieces. Thread a W-inch lock nut

onto the end of the bolt and tighten it until it’s snug

but still allows the bar to pivot.

FamilyFun.com Photographs by Kevin Ayer

©FamilyFun

Downloaded from www.Manualslib.com manuals search engine

11 FIGURE 17

Assemble the brake by slipping a W-inch washer onto

a W- by 6-inch bolt and then inserting the bolt through

Go-Cart: Piece Assembly

one of the previously drilled brake blocks, two W-inch

washers, the brake lever, two more W-inch washers,

the second brake block, and one more W-inch washer.

Finally, screw on a W-inch lock nut and turn it until it’s

snug but still allows the lever to pivot.

Thread the long end of the brake lever through the slot

in the seat from the bottom, angling it toward the

front of the go-cart. Butt the brake blocks up against

the rear axle and use 1X-inch drywall screws to fasten

them in place, screwing down through the seat top. FIGURE 17

Make sure the brake lever is centered in the hole so

that it can operate freely.

FIGURE 18

Turn the go cart on its side and, using three 2K-inch

drywall screws, attach the footrest to the underside of

the center support about 5 inches back from and paral-

lel to the front axle. Attach the seat cushion, too, loop-

ing one of the handles over the break lever on the seat

and using the bungee cord to connect the strap handles

under the go cart. In this position, the bungee cord

BRAKE

serves to hold the brake lever up when it’s not in use. ASSEMBLY

FOOTREST

FIGURE 18

FamilyFun.com Photographs by Kevin Ayer

©FamilyFun

Downloaded from www.Manualslib.com manuals search engine

12 FIGURE 19

Sand and paint the go-cart, if you like. Then complete

the steering assembly. Start by drilling C/af-inch holes in

Go-Cart: Finishing Touches

the steering column and axle where shown. Screw eye

bolts into the holes. (Tip: to tighten them, insert the FIGURE 19

shaft of a screwdriver through the eye bolt and twist.)

Next, connect the steering bar to the front axle using

the 7-foot lengths of rope. Tie an overhand knot in the

end of one length and thread the other end through

one of the holes in the steering bar and then through

the eyebolts on the same side of the steering column

and the front axle. Do the same with the second length O”

of rope on the opposite side of the steering assembly.

Now make sure the front axle and steering bar are

parallel. Pull each rope taut and knot it around the axle

eyebolt. Trim the rope ends, leaving a little excess so you

14”

can retie them if they loosen. Now you’re ready to roll!

O”

SAFE DRIVING PRECAUTIONS 4”

As with all vehicles, this go-cart

requires routine maintenance and

should be driven with caution.

Regularly check the nuts and bolts

and the steering ropes to make sure 1K”

they’re sufficiently tight. And keep 1K”

an eye on the brake — you’ll want to

replace the lever when the bottom

becomes worn.

FamilyFun.com Photograph by Mark Mantegna

©FamilyFun

Downloaded from www.Manualslib.com manuals search engine

Vous aimerez peut-être aussi

- Wood - Magazine - 273 - Mar 2021Document86 pagesWood - Magazine - 273 - Mar 2021Adam Niddrie100% (1)

- Wood Magazine - Issue 255 - September 2018 PDFDocument92 pagesWood Magazine - Issue 255 - September 2018 PDFKen Lock100% (2)

- Wilson Tool Wheel Tool WebinarDocument51 pagesWilson Tool Wheel Tool WebinarAndres Byke SepulvedaPas encore d'évaluation

- Textured Kumihimo NecklaceDocument3 pagesTextured Kumihimo NecklaceTracey AlfaroPas encore d'évaluation

- Toriconical Head Ver 1.1Document4 pagesToriconical Head Ver 1.1Iqbal AhmadsPas encore d'évaluation

- Massive MIMO AAU5613 Training SlideDocument32 pagesMassive MIMO AAU5613 Training SlideApeng RadziPas encore d'évaluation

- 1x7nh La WOOD Magazine September2016Document92 pages1x7nh La WOOD Magazine September2016Edson Pereira100% (1)

- Diy Portable Miter Saw Station v5Document17 pagesDiy Portable Miter Saw Station v5Carlos CostaPas encore d'évaluation

- Popular Woodworking - April 2021Document68 pagesPopular Woodworking - April 2021joao a100% (1)

- Diy Portable Miter Saw Station Plan v7Document17 pagesDiy Portable Miter Saw Station Plan v7AndriyPas encore d'évaluation

- 2019-04-01 Firearms NewsDocument112 pages2019-04-01 Firearms NewsTACTICALOTD SergioPas encore d'évaluation

- Walltopia Training Boards Brochure PDFDocument11 pagesWalltopia Training Boards Brochure PDFsuning bjPas encore d'évaluation

- Wood Magazine 255 2018Document92 pagesWood Magazine 255 2018cgsharp100% (5)

- Barn Owl Nest BoxDocument2 pagesBarn Owl Nest Boxmohan niagaraPas encore d'évaluation

- Leopold Bench PlansDocument8 pagesLeopold Bench PlanshammerloPas encore d'évaluation

- Unit II - Turning Machines PDFDocument137 pagesUnit II - Turning Machines PDFKanda SamyPas encore d'évaluation

- Building Legs and Feet of Clay: You'Ll Need These SuppliesDocument1 pageBuilding Legs and Feet of Clay: You'Ll Need These Suppliesdenby_mPas encore d'évaluation

- Tool PolicyDocument2 pagesTool PolicyAaron BordenPas encore d'évaluation

- Unit II - Turning MachinesDocument137 pagesUnit II - Turning MachinesKanda SamyPas encore d'évaluation

- Concrete Lintel Guide 2021Document12 pagesConcrete Lintel Guide 2021M. Murat ErginPas encore d'évaluation

- In The Lap of Luxury: WoodshopDocument60 pagesIn The Lap of Luxury: WoodshopGeorge Vlad AndronicPas encore d'évaluation

- Scotchman CatalogDocument44 pagesScotchman CatalogANIL KUMAR KPas encore d'évaluation

- Two-Chamber Rocket Box: Cross SectionDocument2 pagesTwo-Chamber Rocket Box: Cross SectionShining Mountain AdamsPas encore d'évaluation

- Popular Woodworking - June 2019Document68 pagesPopular Woodworking - June 2019Patrick Tollgren lazarov100% (1)

- 03 PDFDocument68 pages03 PDFGeorge Vlad AndronicPas encore d'évaluation

- 1C Getting Started - Tools and MaterialsDocument2 pages1C Getting Started - Tools and MaterialsGramma JoPas encore d'évaluation

- 02 PDFDocument76 pages02 PDFGeorge Vlad AndronicPas encore d'évaluation

- 04 PDFDocument60 pages04 PDFGeorge Vlad AndronicPas encore d'évaluation

- Tool List - Electrical: Helper & Apprentice Electrician & Journeyman (In Addition To Helper & Apprentice List)Document4 pagesTool List - Electrical: Helper & Apprentice Electrician & Journeyman (In Addition To Helper & Apprentice List)Hamza RouachedPas encore d'évaluation

- AmPro New Catalog - Empty Waongs & ChestsDocument2 pagesAmPro New Catalog - Empty Waongs & Chestspdtmww7ngpPas encore d'évaluation

- WWJ #2 1990Document68 pagesWWJ #2 1990Nickolay100% (1)

- Popular Woodworking Issue 266 August 2022Document68 pagesPopular Woodworking Issue 266 August 2022Avinash yadav100% (1)

- Presented By: Fasahat Ahmed Butt ROLL# 36 Group: CDocument45 pagesPresented By: Fasahat Ahmed Butt ROLL# 36 Group: CFarzana ShereenPas encore d'évaluation

- Grade 9 MetalworkDocument13 pagesGrade 9 MetalworkAidan O'HaraPas encore d'évaluation

- Dog Tag/ Key ChainDocument13 pagesDog Tag/ Key ChainAidan O'HaraPas encore d'évaluation

- Lesson 1 Sewing ToolsDocument80 pagesLesson 1 Sewing Toolshermie espirituPas encore d'évaluation

- Grade 7 Supplies Grade 8 Supplies Grade 9 Supplies Art SuppliesDocument1 pageGrade 7 Supplies Grade 8 Supplies Grade 9 Supplies Art SuppliesAbdullahMofarrahPas encore d'évaluation

- Slickline Tool String: Khathayut Senitantikun Completion EngineerDocument80 pagesSlickline Tool String: Khathayut Senitantikun Completion EngineerSarawut AssavamateerungrojPas encore d'évaluation

- Wood - Magazine - 259 - Mar 2019Document92 pagesWood - Magazine - 259 - Mar 2019Adam Niddrie100% (1)

- Work HoldingDocument138 pagesWork HoldingHuron Industrial SupplyPas encore d'évaluation

- How Build Rov Ver 1Document14 pagesHow Build Rov Ver 1David ClodePas encore d'évaluation

- BIG Bigger: Tools SavingsDocument12 pagesBIG Bigger: Tools SavingsRiverland Welding and Tool SuppliesPas encore d'évaluation

- GD - January 2016Document140 pagesGD - January 2016Dennis Shongi100% (1)

- Spacetec Certification Readiness Course: Applied MechanicsDocument117 pagesSpacetec Certification Readiness Course: Applied MechanicstahirabbasPas encore d'évaluation

- 23 Inch Compact Sawhorses by One Minute WorkbenchDocument7 pages23 Inch Compact Sawhorses by One Minute WorkbenchFrancois LandryPas encore d'évaluation

- U3-01 - List of Tools and Materials - ENDocument4 pagesU3-01 - List of Tools and Materials - ENAndres LizarraldePas encore d'évaluation

- GD Shooters Guide - 2016 USADocument84 pagesGD Shooters Guide - 2016 USADennis Shongi100% (1)

- Toolkits For Carpentry and Masonry NC IIDocument3 pagesToolkits For Carpentry and Masonry NC IIKaJong JaclaPas encore d'évaluation

- Lathe Accessories of Production Drawing - GDLCDocument63 pagesLathe Accessories of Production Drawing - GDLCUsama AnsariPas encore d'évaluation

- Technology of Machine Tools: Thread-Cutting Tools and ProceduresDocument21 pagesTechnology of Machine Tools: Thread-Cutting Tools and ProceduresAnibal DazaPas encore d'évaluation

- 26 B Mount Blocks 04222020Document15 pages26 B Mount Blocks 04222020CarlosAgustoPinedaSanchezPas encore d'évaluation

- Battle Axe Pattern Revised Jan 2018Document4 pagesBattle Axe Pattern Revised Jan 2018Joelle GrondinPas encore d'évaluation

- Wind Tubes: Things To TryDocument7 pagesWind Tubes: Things To TryZogarPas encore d'évaluation

- Lab 1 - Machine Shop Basics: Layout, Band Saw, Drill Press, TappingDocument19 pagesLab 1 - Machine Shop Basics: Layout, Band Saw, Drill Press, TappingKiên Trung NguyễnPas encore d'évaluation

- Stripper PlateDocument18 pagesStripper Platenilam100% (1)

- Lec. 1 Center - LatheDocument38 pagesLec. 1 Center - LatheABDELRHMAN ALIPas encore d'évaluation

- Popular Woodworking 215 (December 2014)Document68 pagesPopular Woodworking 215 (December 2014)chrix100% (1)

- Workbench - Paul SellersDocument6 pagesWorkbench - Paul SellersChris SpraguePas encore d'évaluation

- Carpentry Tool List ContDocument12 pagesCarpentry Tool List ContShella CortezPas encore d'évaluation

- DIY Outdoors Woodworking Projects Easy Steps Guide To Outdoor Woodworking Projects For Beginners by Victor PH.D, George (Victor PH.D, George)Document43 pagesDIY Outdoors Woodworking Projects Easy Steps Guide To Outdoor Woodworking Projects For Beginners by Victor PH.D, George (Victor PH.D, George)vijesh varmaPas encore d'évaluation

- Rolling Storage Ottoman Coffee TableDocument10 pagesRolling Storage Ottoman Coffee TableWilliam JamesonPas encore d'évaluation

- Birthday Seesaw: Ana WhiteDocument16 pagesBirthday Seesaw: Ana Whitejuancparra20Pas encore d'évaluation

- Box Car Toybox: Ana WhiteDocument12 pagesBox Car Toybox: Ana Whitejuancparra20100% (1)

- Equivalencia de Matariales (Material Class For Stainless Steel)Document15 pagesEquivalencia de Matariales (Material Class For Stainless Steel)juancparra20Pas encore d'évaluation

- Juntas Flanchadas, Empaques y PernosDocument8 pagesJuntas Flanchadas, Empaques y Pernosjuancparra20Pas encore d'évaluation

- Z180 Family: FeaturesDocument12 pagesZ180 Family: FeaturesAhmadPas encore d'évaluation

- Base Isolation of Structures: Presentation by:-P.Damodar Reddy, B151190, AB1-101, Department of CivilDocument19 pagesBase Isolation of Structures: Presentation by:-P.Damodar Reddy, B151190, AB1-101, Department of CivilDamodar Reddy100% (1)

- Defence Engine: 261-336 KW (350-450 HP) 1491-1850 NM (1100-1364 LB-FT)Document2 pagesDefence Engine: 261-336 KW (350-450 HP) 1491-1850 NM (1100-1364 LB-FT)Aamir ArainPas encore d'évaluation

- Microsoft Word - PIC16F877A Micro Controller Project TutorialDocument19 pagesMicrosoft Word - PIC16F877A Micro Controller Project TutoriallocthanhPas encore d'évaluation

- Hazard Study 4 - Compress AirDocument12 pagesHazard Study 4 - Compress AirSaran rasayaPas encore d'évaluation

- Project LeftDocument6 pagesProject Leftseham hejaziPas encore d'évaluation

- Curvo BBT Design Engg 16092017Document91 pagesCurvo BBT Design Engg 16092017vignesh vikkyPas encore d'évaluation

- 29792+Fastrac+4000+&+8000+Series+e Brochure+en NA+Issue+1Document9 pages29792+Fastrac+4000+&+8000+Series+e Brochure+en NA+Issue+1Márton SzőkePas encore d'évaluation

- CSS10 - Teacher - Made - Home - Task - MELC 1.2 Computer Hardware IdentificationDocument7 pagesCSS10 - Teacher - Made - Home - Task - MELC 1.2 Computer Hardware IdentificationFaye LouranePas encore d'évaluation

- Stop e MasterDocument0 pageStop e MasterAngels Córdova AlegríaPas encore d'évaluation

- Micom 12x NewDocument26 pagesMicom 12x NewShahzad AhmedPas encore d'évaluation

- XL4015Document9 pagesXL4015Jose M PeresPas encore d'évaluation

- Development of Vehicle Longitudinal Dynamics: Prepared By: Muhammad Luqman Hakim Abd. RahmanDocument19 pagesDevelopment of Vehicle Longitudinal Dynamics: Prepared By: Muhammad Luqman Hakim Abd. RahmanMuhammad Luqman HakimPas encore d'évaluation

- Data Man Pro Plus SpecificationDocument2 pagesData Man Pro Plus SpecificationAfolabi OlaniyiPas encore d'évaluation

- Manual de Uso Rm6Document82 pagesManual de Uso Rm6Leonel Márquez EspinozaPas encore d'évaluation

- DAIKOOL Cassette Type CHW FCUDocument1 pageDAIKOOL Cassette Type CHW FCUmep luckyonePas encore d'évaluation

- Capacitor Technologies Characterization Selection and Packaging For Next-Generation Power Electronics ApplicationsDocument11 pagesCapacitor Technologies Characterization Selection and Packaging For Next-Generation Power Electronics Applicationssueng666Pas encore d'évaluation

- Vdocuments - MX Atlas Copco Pneumatic Rock Drilling RigsDocument8 pagesVdocuments - MX Atlas Copco Pneumatic Rock Drilling RigsMohamed SadekPas encore d'évaluation

- GSR Di 24Vdc 1Nc/2Nc/Ossd/Sm 2No-Sfty 1Ss-Aux Catalogue NoDocument2 pagesGSR Di 24Vdc 1Nc/2Nc/Ossd/Sm 2No-Sfty 1Ss-Aux Catalogue NoInfanteria DarkPas encore d'évaluation

- Stray Voltage: 1 ScopeDocument4 pagesStray Voltage: 1 ScopeMouna NjPas encore d'évaluation

- Bettery ChargerDocument2 pagesBettery ChargerArun GuptaPas encore d'évaluation

- INIM Catalogo Incendio ENG Rev3.00 MediumRes PDFDocument76 pagesINIM Catalogo Incendio ENG Rev3.00 MediumRes PDFnedzadPas encore d'évaluation

- Doc-A.14-Text Editor On A LCD Using At89c51 Micro Controller and KeyboardDocument48 pagesDoc-A.14-Text Editor On A LCD Using At89c51 Micro Controller and KeyboardRockson Kwame AgyemanPas encore d'évaluation

- M/V Mamola Melody: Multi Purpose Supply Vessel Accommodation & Maintenance Support Fifi 1 / 4PmDocument4 pagesM/V Mamola Melody: Multi Purpose Supply Vessel Accommodation & Maintenance Support Fifi 1 / 4PmCandisftPas encore d'évaluation

- Catalogue of Insulator and Surge Arrester - Orient ChinaDocument66 pagesCatalogue of Insulator and Surge Arrester - Orient Chinapham thang0% (1)

- CrosswayDocument16 pagesCrosswayMehdi SamiPas encore d'évaluation

- Cleaning List Bullet JournalDocument1 pageCleaning List Bullet JournalOnofrei Emima SaraPas encore d'évaluation

- GOTIE Karta - GBE-200Z - enDocument1 pageGOTIE Karta - GBE-200Z - enbeizanisPas encore d'évaluation

- ITB InstallationDocument11 pagesITB Installationapi-3739726100% (1)