Académique Documents

Professionnel Documents

Culture Documents

PVP2017-65970 Friction PDF

Transféré par

Chiranjeevi AnilTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

PVP2017-65970 Friction PDF

Transféré par

Chiranjeevi AnilDroits d'auteur :

Formats disponibles

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/320637053

Nozzle Load Considerations and Misconceptions Introduced by Piping Support

Friction

Conference Paper · July 2017

DOI: 10.1115/PVP2017-65970

CITATIONS READS

0 173

2 authors, including:

Dennis Keith Williams

DR. DENNIS K. WILLIAMS, P.E.

44 PUBLICATIONS 104 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Piping Supports & Restraints View project

All content following this page was uploaded by Dennis Keith Williams on 18 April 2018.

The user has requested enhancement of the downloaded file.

Proceedings of the ASME 2017 Pressure Vessels and Piping Conference

PVP2017

July 16-20, 2017, Waikoloa, Hawaii, USA

PVP2017-65970

NOZZLE LOAD CONSIDERATIONS AND MISCONCEPTIONS INTRODUCED BY PIPING SUPPORT

FRICTION

Bikramjit Singh Antaal

Dennis K. Williams

LISEGA INC

370 E. Dumplin Valley Rd.

Kodak, TN, 37764 USA

Tel: 865-940-5200

Email: Bikram.Antaal@us.lisega.com

Email: Dennis.Williams@us.lisega.com

ABSTRACT NOMENCLATURE

This paper discusses the prescribed requirements contained D Outside diameter of pipe (in.)

within the various ASME B31 Piping Codes and ASME B&PV E Young’s modulus of elasticity (psi)

Code, Section III that specifically address the need to recognize F Friction force (lbf)

the restraint introduced by piping support friction. In addition, Fk Kinetic frictional force (lbf)

the requirement for the design of sliding supports (pipe shoes) Fs Maximum static frictional force (lbf)

and brackets to resist the forces due to friction in addition to the L Length of leg available to absorb thermal expansion (ft)

loads induced by bearing is also reviewed and discussed. As l Length between guides of the expansion loop (ft)

part of the required piping analysis, the questions surrounding N Normal force to surface (lbf)

the inclusion of the maximum coefficients of static friction and S Calculated thermal stress range (psi)

the impact of these often excessively large values on equipment W Weight of the pipe (lbf)

nozzle loadings is reviewed in considerable detail, especially in Δ Thermal displacement to be absorbed (in.)

light of the qualitative guidelines contained within WRC θk Inclined plane angle for kinetic coeff. of friction (degree)

Bulletin 449. Included in the discussions of the considerations θs Inclined plane angle for static coeff. of friction (degree)

associated with the assumed restraint provided by support µk Kinetic coefficient of friction (dimensionless)

friction is the mathematical treatment of extrema (i.e., maxima µs Static coefficient of friction (dimensionless)

and minima) with respect to calculated nozzle loads based upon

the analyst’s choice of the largest published coefficients of static INTRODUCTION

friction. Example problems taken from the authors’ decades of

experience in the field are reviewed in light of the time Piping supports and restraints are an integral part of all

dependent heat up and cooldown rates for the piping systems engineered piping systems. As a minimum, supports and

discussed herein. In most cases, the analyses show that not only restraints are provided to carry the deadweight of the pipe, the

is it highly improbable that the choice of only maximum values fluid medium, the weight of in-line valves, and the attached

of coefficients of friction at each support will exist, but rather it insulation. In addition, the supports and restraints ‘system’

is impossible that this often abusive practice by the unsuspecting serves to direct the thermally and dynamically induced piping

analyst for the “worst case” frictional coefficients to exist displacements (in a judicious manner) in and around critical

simultaneously in a piping installation. Finally, equipment nozzle connections. During the heating and cooling

recommendations for the considerations of the potential restraint cycles associated with the thermal power plant piping system,

induced by piping support friction in the rigorous piping thermal displacements (expansion when going from cold to hot

analyses are tendered. or contraction when going from hot to cold) create relative

movements between the attached piping supports and restraints

Keywords: ASME B31 Piping Codes, ASME Section III, and the rigid supporting structure upon which the supports and

Subsection NF, friction, pipe supports, nozzle loads restraints (herein after simply referred to as the “supports”) bear.

1 Copyright © 2017 ASME

Due to friction that develops between the pipe support and its bodies. An important concept is also pointed out by the same

supporting structure upon which it bears, a non-conservative and authors, which is that the force of static friction is a maximum

retarding force is induced in the opposing direction to that when the two bodies in contact are just ready to slip relative to

generated by the associated thermal displacement of the pipe. each other. The maximum force of friction increases as the

This opposing force may retard the free thermal growth of the normal force between the bodies increase. Furthermore, the

piping system, possibly imposing significantly higher loads on frictional force that exists when two contacting bodies are about

anchors, limit stops, guides, and connecting equipment than to slide relative to one another is generally larger than the

those calculated loads in an assumed, completely frictionless frictional force when the bodies actually are sliding relative to

system of the analyst generated math model. one another. Finally, one concept that is of utmost importance

The force attributed to friction (if any) on a piping system in the analysis of friction in a piping system is that if two bodies

depends on a number of factors, including, but not limited to, the in contact are not sliding relative to each other, the frictional

type and location of the supports, the number of supports, the force between the bodies need not always be equal to the

materials of construction, and the bearing surface upon which maximum static frictional force.

the supports rest. The location of supports should not interfere Friction is non-linear, path dependent, and a time varying

with the progressive thermal expansion of the pipe either during force. Friction coefficients take on two distinct forms in terms

heat up or cool down of the piping system. Additionally, it is of whether or not a sufficient force has been developed to

well understood by piping stress analysts that during the design overcome what is termed the static frictional force. Assuming

of piping systems that are subjected to both thermal and seismic that a force normal to the bearing surfaces exist, the maximum

loads, competing design objectives are ever present by the two static frictional force Fs is defined to be proportional to the

aforementioned types of loadings that must be mediated. This is product of the applied normal force N and the associated

to say that to adequately control the thermal stress range, which coefficient of static friction s. In other words, the static

ultimately affects the fatigue life of the piping system, the piping frictional force is an induced force and may be calculated as

should maintain sufficient flexibility to allow the system to shown below in Eq. (1).

displace freely in the axial direction. In contrast, for seismic

loads, the piping should (in general) be much more rigid so as to = (1)

avoid having low fundamental frequencies in the range where

the peak accelerations could cause unwanted and excessive As observed by Boresi and Schmidt [5], because the

displacements. Associated with excessive displacements are maximum force of static friction is not usually equal to the

generally high stresses, which may in fact, create permanent frictional force while the bodies are sliding relative to one

changes in the piping geometry that are certainly intolerable for another, in most problems (including that of this paper), the

continued safe and efficient plant operation. piping stress analyst needs to know and consider a second

A good piping design should strike a perfect balance coefficient of friction known as the coefficient of kinetic (or

between the thermal flexibility and seismic rigidity by using sliding) friction, k. Analogous to Eq. (1), while the force

sufficient supports and restraints at judiciously selected locations associated with kinetic friction, Fk, is also proportional to the

and a geometric layout that is conducive to directing thermal product of the normal force N, and the associated coefficient of

displacements. For example, according to Peng [1], in cases kinetic friction, k, we have the relationship as shown below in

when the piping system is subjected to vibratory or dynamic Eq. (2).

loads, friction can help stabilize the system by absorbing and

dissipating some of the imparted energy, thereby reducing = (2)

piping stresses and equipment nozzle loads. Peng [1] went on

further to state that there is no rule of thumb as to whether it is The frictional force, whether static or sliding, only exists if

non-conservative to ignore the effects of friction during the there is a displacement of the pipe (in the case at hand, due to

piping analysis. Bakre et al. [2] demonstrated through analytical thermal growth going from cold to hot) and impending sliding

and experimental studies that support friction helps in reducing between the pipe support and its associated support structure.

the dynamic response of a piping system due to ground The coefficient of friction, i.e., either s or k between the two

excitations over a broad range of frequencies. Further work on bearing surfaces is dependent on the nature of materials in

the seismic response of piping systems by taking into account contact with each other. In practice, these coefficients may also

the friction between the piping support and its associated support depend upon the condition of the surface, for example whether

structure was studied extensively by Suzuki et al. [3]. Kolontis there is some form of corrosion between the two surfaces and

[4] also demonstrated the additive nature of frictional forces the maintenance of surfaces in contact over a period of time.

during thermal expansion and contraction cycles of a pipeline The magnitude of these coefficients of friction may vary from

transporting hot fluids. very small values as low as 0.01 to values in excess of 0.50 in

the piping support world. Selected values for a combination of

FRICTION: AN INDUCED FORCE surfaces are given in Table 1 for both static and kinetic

Boresi and Schmidt [5] define a frictional force as the shear coefficients of friction and allow the reader a quick comparison

force that acts tangent to the surface of contact between two of the relative differences between the two types of friction.

bodies. This force opposes sliding motion between the subject

2 Copyright © 2017 ASME

Mokha et al. [7] found from testing on Teflon™ bearing component, or the piping or component shall be designed to

surfaces that friction increases with increasing velocity up to a include the imposed load and frictional resistance of these types

certain value of velocity beyond which it remains constant. of supports; their dimensions shall provide for the designed

Furthermore, the authors [7] concluded that friction drops with movement of the supported piping or component.”

increasing pressure with a rate of reduction that is strongly Subparagraph NF-3124(b) [19] further states, “Sliding supports

dependent on velocity. Based upon their empirical results, (or shoes) and brackets shall be designed to accommodate the

Mokha et al. [7] concluded that friction stabilizes at a value of forces caused by friction in addition to the loads imposed by

bearing pressure between 5,000 and 6,500 psi. Substantial bearing. The dimensions of the support shall provide for the

differences between the breakaway (or static) coefficient of design movement of the supported piping or component.

friction and sliding (or kinetic) coefficient of friction were Material and lubricants used in sliding supports shall be suitable

observed. In general, the breakaway value was found to be two for the environment of the metal at the point of sliding contact

to four times larger than the sliding value. Following the subject and shall be specified in the Design Documents.” Therefore, in

testing, Constantinou et al. [8] (being the same researchers as in at least two specific instances, Subsection NF [19] requires that

reference [7]), developed a mathematical model of the frictional frictional effects either be considered in the design of sliding

behavior of Teflon™ slide bearings for those conditions supports and that the piping be capable of withstanding the

consistent with the base isolation of a structure during a seismic subject retarding forces or the sliding support ensure free

event. The calibration of the authors’ model [8] was based upon movement of the piping to which it is attached.

extensive experimental data that were presented in an For the sake of comparison with other National consensus

accompanying paper [7]. The model was capable of accounting Codes and Standards within the ASME family, a review of one

for the following variables: additional Code is presented to judge any similarities in design

philosophy as related to the effects of friction. Antaal et al.

(1) Unidirectional and multidirectional motion at the previously presented the friction considerations [20] required by

Teflon-steel interface; ASME B31.3 [9]. Paragraph 319.1.1 entitled “Piping Flexibility

(2) Velocity and pressure dependence of the coefficient of – Basic Requirements” of ASME B31.3 [9] maintains that

piping systems shall have sufficient flexibility to prevent

sliding friction; and

thermal expansion or contraction or movements of piping

(3) Breakaway (or static) friction effects. supports and terminals from causing:

The Constantinou et al. [8] model was characterized by four (a) Failure of piping or supports from overstress or fatigue

parameters. These parameters included the minimum and

maximum values of the sliding coefficient of friction (k), the (b) Leakage at joints

ratio of breakaway to sliding coefficients of friction at initiation

of sliding, and a parameter that described the variation of the (c) Detrimental stresses or distortion in piping and valves

sliding coefficient of friction with velocity. So it is clear from or in connected equipment (pumps and turbines, for

the aforementioned published data that the treatment of friction example), resulting from excessive thrusts and moments in

in a piping system must be undertaken with some due the piping.

consideration of the relative differences between the static

coefficient of friction and the smaller, but more applicable ASME B31.3 [9], paragraph 319.4.3 further requires that,

kinetic coefficient of friction. “In calculating the flexibility of a piping system between anchor

points, the system shall be treated as a whole. The significance

TABLE 1

Coefficients of Dry Static & Kinetic Friction for Various

of all parts of the line and of all restraints introduced for the

Bearing Surfaces ([5], [6]) purpose of reducing moments and forces on equipment or small

Surfaces in Contact µs µk branch lines, and also the restraint introduced by support

friction, shall be recognized.” In addition, paragraph 321.2.1(b)

PTFE on PTFE 0.12 – 0.15 0.05 – 0.10

[9] states, “to protect terminal equipment or other (weaker)

PTFE on Stainless Steel 0.10 0.03 – 0.13

portions of the system, restraints (such as anchors and guides)

Steel on Steel (new) 0.20 0.03

shall be provided where necessary to control movement or to

Steel on Steel 0.20 – 0.74 0.03 – 0.57 direct expansion into those portions of the system which are

Graphite on Steel 0.10 < 0.10 designed to absorb them. In addition to the other thermal forces

Steel on Concrete 0.57 – 0.70 n/a and moments, the effects of friction in other supports of the

Steel on Ice 0.04 0.01 system shall be considered in the design of such anchors and

guides.” Therefore, in at least two specific instances, B31.3

requires that frictional effects be “recognized” and “considered”

ASME SECTION III, DIVISION 1, SUBSECTION NF in the design of any applicable piping system. In any event,

REQUIREMENTS REGARDING FRICTION while the qualitative requirement is present to consider the

Subparagraph NF-3124(a) [19] clearly states, “Rolling and effects of friction, there is no prescribed method or additional

sliding supports shall permit free movement of the piping or restrictions on the analyst as how to account for said effects of

friction.

3 Copyright © 2017 ASME

WRC BULLETIN 449, PUMP PIPING SYSTEMS references citied within this section agree that friction should be

utilized to increase the load on the supports and the restraints

The WRC Bulletin 449 [10] provides detailed guidelines for

where uplifting may be expected during operation. In addition,

dealing with excessive friction in piping systems, especially

the references are also in agreement that any reduction in the

those that include large diameter piping with heavy valves and

loads due to friction, for example in a vibration or seismic

for the pump piping systems. The large diameter piping can

analysis, should be ignored from the standpoint of assuming that

have very high frictional loads as both the static and kinetic

there will be benefit gained from its assumed existence.

friction forces are proportional to the applied normal force,

which for horizontal piping is the weight carried by the

TREATMENT OF PIPE SUPPORT FRICTION WITH

respective support. In comparison, pump piping systems

EXAMPLES OF SIMPLE GEOMETRIES

become very sensitive to small increases in the external piping

loads. The purpose of this paper is to develop a simple, robust and

The authors of the subject Bulletin [10] urge that the piping easy to use FEA procedure for calculating loads due to pipe-

stress and flexibility analyses be executed properly. support friction. There are two main approaches to introduce

Furthermore, the Bulletin [10] states that the analyst do the and hence solve the piping support friction problem that

piping flexibility calculations for the majority of pump piping historically, have been discussed in the literature. The first

installations to assure an accurate assessment of the loads approach requires inserting a calculated stiffness at the support

transmitted to the pump nozzles. The analyst is urged to locations where the friction is considered to be significant and

carefully review these calculations during the design phase to that must be overcome by the thermal displacement of the

verify that the operating reactions resulting from weight, thermal attached pipe. The second approach requires the application of a

expansion, and friction effects do not exceed the specified force opposite in direction to the thermal displacement at the

allowable nozzle loads. Within these referenced sections of support locations of interest. A commercially available piping

WRC 449 there is no guidance given to ascertain the difference stress FEA code [13] uses the former approach (i.e., the

in the overall effects of considering the coefficient of static inclusion of a pseudo-stiffness) based upon the methodology

friction versus utilizing the coefficient of kinetic friction. The described in the literature by Sobieszczanski [14]. Frictional

authors [10] do emphasize that during the piping flexibility forces by nature are non-linear and the resulting displacement at

modeling efforts that nozzle load limits must be satisfied for a point in a piping system where friction must be considered

applicable combinations of: may be thought of in terms of a discontinuous step function.

The subject friction problem is much easier to solve by

(1) thermal, dead weight, friction loads, and for breaking down the non-linear problem into a simpler linear

(2) any specified seismic, fluid hammer (shock) and problem as demonstrated by Reddy et al. [15]. In the

settlement loads. aforementioned paper, the non-linear nature of pipe support

friction is methodically undertaken by converting it into a linear

Finally the use of directional restraints, guides, or stops to direct problem and executing a series of analyses employing another

excessive thermal or friction loads away from pump nozzles is commercially available general purpose FEA code [16]. The

recommended by the authors [10]. application of an opposing frictional force to the thermal

From a very practical standpoint, WRC Bulletin 449 [10] displacement is employed in the current effort described herein.

points out that in order to minimize frictional effects at resting Furthermore, in the current effort, only static analyses were

supports, PTFE or other low friction type bearing plates may be conducted on the piping geometries discussed below as the

used. This approach may be especially appropriate for larger authors are in agreement that friction can and should be ignored

diameter piping or at supports carrying heavy loads such as at in dynamic analyses.

valves or long vertical runs. Low friction bearing plates are not

necessary where analysis shows acceptable friction forces. Once

again, however, “acceptable” frictional forces are not

specifically detailed within the subject guidelines [10].

Lastly, the Bulletin [10] emphasizes the need to address the

lifting of pipe from its support under [cold] operating conditions.

The additional friction force at a support bearing additional

weight of the piping system due to uplifting of the pipe at a

nearby support should be considered and evaluated.

Baniotopoulos [11] and later, Baniotopoulos et al. [12] carried

out a detail study on unilateral contact conditions (uplifting of

pipe from its saddle). In the latter publication [12], the authors

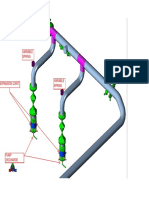

FIG. 1 FIRST GEOMETRY (Z-BEND)

first considered the unilateral contact problem assuming that the

friction forces were known. In fact, the friction factors and the

resulting frictional forces are seldom, if ever, known in the field Three simple piping systems (geometries), a Z-bend, an

unless the support system is instrumented as if in a test scenario. equal leg L-bend, and a 2-D expansion loop are considered as

Nevertheless, WRC Bulletin 449 [10] and the majority of examples to study the effect of restraint induced due to piping

4 Copyright © 2017 ASME

support friction. The three geometries used along with location standpoint, as it is very difficult to completely restrain rotational

of their supports (frictional supports, guides, and anchors) are movement at a point. It may be noted that the rotational

shown in Figures 1, 2, and 3, respectively. Additionally, two flexibility of the selected piping geometries is not considered

nominal pipe sizes, a small bore, four inch standard wall significant for the purposes of addressing support friction and

thickness and a large bore, twelve inch standard wall thickness furthermore, is not discussed in this paper.

are considered for each of the three geometries. Finally, two

operating temperatures, 300°F and a fairly harsh temperature of

650°F are considered for the aforementioned piping geometries

and pipe sizes to observe the effects of piping-support friction.

Before studying the effect of pipe support friction, the three

geometries were analyzed to determine the thermal expansion

stresses. Stresses in geometries 1 and 2 (i.e., the Z-bend and the

equal leg L-bend, respectively) were calculated employing the FIG. 2 SECOND GEOMETRY (L-BEND)

guided cantilever formula [17] as given by Eq. (3). Stresses in

geometry 3 (i.e., the 2-D expansion loop) were calculated using After modeling each of the piping configurations shown in

the M. W. Kellogg method [17] as given by Eq. (4) and utilizing Figures 1, 2, and 3, inclusive, the analysis was carried out in

the M. W. Kellogg expansion loop nomogram for the design of four distinct steps. First, a static deadweight analysis was

stress loops. While the relationship shown in Eq. (4) requires carried out to determine the vertical force, W (weight) at each

the use of charts based upon various geometric parameters, there deadweight support of the respective piping system. The

were other similar methods of the same vintage proposed by deadweight analysis includes the self-weight of the pipe and its

competing organizations such as the Tube Turns Charts 2, 3, and contents, which was taken to be water (liquid). The calculated

4 published in reference [18] that allowed the piping designer to downward vertical force at each node (support) was multiplied

achieve virtually the same desired stress range. Stress analyses by the assumed coefficient of friction, µs to obtain the induced

for all three geometries were completed utilizing a commercially frictional force at a particular support location as given by Eq.

available FEA code [16]. The results of the stress analyses, per (1).

se, are not presented herein. The purpose of the stress analyses

was to ensure that the calculated deadweight and thermal

expansion stresses in the three piping systems were well below

the ASME B31.3 [9] allowable stresses.

∆

= (3)

∆

= (4)

The first piping system consisting of a four inch standard

wall thickness pipe (NPS 4, STD) was modeled using a FIG. 3 THIRD GEOMETRY (2-D EXPANSION LOOP)

commercially available FEA code [16]. PIPE16 and PIPE18

elements of the FEA code [16] were employed to model the Second, a thermal analysis was performed for the two

straight pipe portion and the elbows, respectively. The element operating temperatures of 300°F and 650°F (as two load steps).

types are the typical three-dimensional beam elements that are The results of the thermal analyses were then reviewed to

specific to right circular cylinders, while the elbow element is a ascertain the directions of movement of the pipe at each support.

modified “pipe element” with additional flexibility The reference (ambient) temperature was chosen to be 70°F in

characteristics. The supports and restraints (supports with the thermal analysis, consistent with the authors’ experience in

friction as required, guides, and anchors) were modeled using the discipline. For the chosen geometric configurations

appropriate displacement boundary conditions. The supports discussed herein, prediction of the thermal displacements were

with friction (as required) were modeled using restraints in the almost a straight forward academic exercise, this most probably

vertical direction (piping system restrained against displacement is not true for more complex geometric piping configurations

in the downward vertical direction) at the nodes representing the operating at a multitude of temperatures.

respective pipe-to-support interface. Guides were modeled to

restrain movement of the pipe in the lateral direction and TABLE 2

anchors (at the termination points) were modeled to restrain the Geometry 1 Anchor Reactions NPS 4

system against displacement in three orthogonal translations and Reaction at Anchors in Axial (Z) Direction (lbf)

three rotational directions. The supports in the FEA model were µ 0.00 0.16 0.30 0.40

assumed to be rigid (having infinite stiffness). Likewise, the 300°F -13.1 -91.1 -159.3 -208.0

anchors were modeled as true anchors. It may be noted that in 650°F -33.3 -111.2 -179.4 -228.1

practice, true anchors are very rare, from a practical design

5 Copyright © 2017 ASME

A third analysis was conducted in which the frictional increment. The second, third, and fourth steps consist of 100°F

forces calculated in the first step were applied to the piping temperature increments over a period of two hours, each with

system in the proper (i.e., predominantly axial) direction to the final step consisting of a 50°F increment over period of one

oppose the thermal displacement, as observed in the second step hour, thereby ramping up to the final temperature representing

of the analyses. These frictional forces were applied in addition the maximum operating temperature of 650°F.

to the thermal body loads on each piping configuration.

700

TABLE 3

Geometry 1 Anchor Reactions NPS 12 600

Reaction at Anchors in Axial (Z) Direction (lbf)

µ 0.00 0.16 0.30 0.40 500

300°F -356 -825 -1236 -1529

Temperature (°F )

650°F -901 -1370 -1781 -2074 400

Finally, the results from the first and the third analyses 300

were combined (by algebraic summation) and the combined

results were post-processed to obtain the pertinent reactions at

200

the anchors (which could be assumed to be rigid equipment

100

nozzles or termination points) due to thermal and frictional

forces. What should be an obvious point to piping analysts is 0

that the application of the calculated frictional force should 0 2 4 6 8 10 12

never push the pipe backwards under any circumstances, i.e., the Time (hour)

frictional force is always an “induced force” arising from the

FIG. 4 HEAT-UP RATE OF 50°F PER HOUR

impending displacement of the piping support with respect to the

ultimate supporting structure. The frictional force, regardless of A combination of piping system layouts and pipe sizes

whether it is assumed to be that due to breakaway (i.e., static) or resulted in a total of six piping configurations being investigated

sliding (i.e., kinetic) can only resist the pipe from moving, but in the present study. The displacements (and subsequently the

can never move the pipe. Furthermore, internal pressure was not support velocities) with respect to the fixed bearing surfaces at

used in the analysis but could be easily incorporated in the first each of the respective support locations were calculated at the

step of the procedure should analysts need to do so for any end of each of the previously defined temperature increments.

reason. The three piping geometric configurations were each modeled

The methodology for addressing the effects of the employing two different pipe sizes of NPS 4 and NPS 12,

frictional forces at support locations of interest may sound resulting in the total of six piping geometries.

tedious, especially for calculating the vertical force at each

support in a large system, multiplying the respective bearing

load (force) by the respective coefficient of friction, and then

introducing the product of the coefficient of friction times the

bearing load as an opposing force into the thermal analysis, but

in reality, all of these steps can be easily accomplished by using

the *GET command of the chosen FEA code [16]. In other

cases, the same post-processing result may be achieved through

some easily applied computing routines of similar computational

tools. Similarly, the procedure is repeated for various

combinations of geometries, pipe sizes, temperatures and

different values of µs or µk.

PIPE SUPPORT VELOCITIES DURING HEAT UP

The aforementioned three piping geometries as shown in

Figures 1, 2, and 3 were further analyzed to simulate the heat-up

cycle of a typical thermal piping system by subjecting the

system to a heat-up rate of 50°F per hour. The analysis was

carried out in five steps starting at the assumed ambient

temperature of 70°F.

Figure 4 shows the linear heat-up ramp of 50°F per hour to FIG. 5 INCLINED PLANE KINETIC COF FBD

which the piping geometries were subjected. The first step

consists of heating the pipe from 70°F to 200°F over a period of

2.6 hours, i.e., enforcing a 130°F T over the 2.6 hour time

6 Copyright © 2017 ASME

CALCULATING KINETIC (SLIDING) COEFFICIENT OF consisted of the carbon steel pipe shoe with a three foot length

FRICTION - INCLINED PLANE METHOD of pipe on the carbon steel inclined plane; and finally, the third

set of measurements consisted of the carbon steel pipe bearing

The force of friction always acts in the direction opposite

on the carbon steel inclined plane. The methodology as

to the direction of motion of a rigid body. If an externally

described in reference [21] was utilized to collect the

applied force is just equal to the force of the static friction, then

experimental data for all three configurations. The average

the pipe or shoe is on the verge of slipping, and the coefficient

values of θs and θk from all three sets are shown in Table 4.

of friction involved is called the coefficient of static friction, s.

If an externally applied force is equal to the force of the kinetic TABLE 4

friction, Fk as shown in Fig. 5, then the pipe or shoe slides at a Angle of Inclined Plane (deg.)

constant velocity, and the coefficient of friction involved is Shoe on plate Shoe and pipe on plate Pipe on plate

called the coefficient of kinetic friction, k. θs θk θs θk θs θk

During heat up and cool down of thermal piping systems, 15.4 9.1 15.1 8.7 16.2 11.5

the pipe at each support location will move and slide at a

constant velocity, however large or small that velocity may be. The coefficients of static and kinetic friction can be calculated

Because of the aforementioned constant velocity movement of utilizing Eq. (5) and Eq. (6), respectively. The calculated

the pipe, the inclined plane method was used to assess and coefficients of static and kinetic friction are presented in Table

calculate the coefficient of kinetic friction, k between the steel 5. The magnitude of the coefficient of kinetic friction, µk is

pipe supports and the steel bearing surface. This effort was found to be 60% - 67% of the coefficient of the static friction, µs.

accomplished by setting up a friction measurement test

apparatus at the LISEGA Inc. fabrication facilities located in s = tan(s) (5)

Kodak, TN, USA. The inclined plane test apparatus, as shown

in Fig. 6 and Fig. 7, had the capability of changing the angle of k = tan(k) (6)

inclination by fractions of a degree. A digital protractor was

used to measure the angle of inclination of the sloped plane TABLE 5

throughout its travel. A carbon steel pipe shoe, an NPS 4 Coefficients of Static and Kinetic Friction

standard wall thickness pipe made from ASTM A-106 Gr. B, Shoe on plate Shoe and pipe on plate Pipe on plate

and a carbon steel plate were utilized as the bearing surfaces in µs µk µs µk µs µk

contact to complete the friction measurement. 0.26 0.16 0.26 0.16 0.33 0.21

STATIC VERSUS KINETIC COEFFICIENT OF FRICTION

Because both the ASME B&PV Code, Section III,

Division 1, Subsection NF [19] and the ASME B31.3 Process

Piping Codes [9] require that the frictional effects be considered

and recognized by the support designer and the piping stress

analysts, the question then becomes which of the two

aforementioned coefficients of friction and which value should

be utilized in a given analysis. Based upon the review of the

current authors’ experience, most analysts who do incorporate

some form of coefficient of friction in an analysis are most often

drawn to choosing the dry static coefficient of friction. Again,

based upon experience, the rationale for doing so is most often

justified by the thinking that the largest value will yield the most

conservative results, especially in and around critical rotating

FIG. 6 INCLINED PLANE FRICTION APPARATUS equipment nozzles where often times the allowable piping loads

tend toward zero (as pointed out by WRC Bulletin 449 [10]).

Utilizing the inclined plane method in the present case, the Without arguing that point, that approach is almost guaranteed

tangent of the angle at which the pipe shoe or pipe slides down to fail to simulate the installed condition of the piping system of

the steel plate bearing surface at constant velocity provides the interest because no two supports and restraints would most

coefficient of kinetic friction between the two respective bearing likely have the same static coefficient if tested.

surfaces. Three sets of experiments were conducted to measure A more realistic approach is one that would attempt to

the inclined plane angle associated with the coefficient of static utilize the kinetic coefficient of friction, especially in and around

friction, θs, and the angle associated with coefficient of kinetic critical rotating equipment nozzles. The basis for this discussion

friction, θk, utilizing three different configurations of surfaces in and methodology stems from the fact that as the piping system

contact. The first set consisted of the carbon steel pipe shoe begins to heat up to operating temperature, the maximum static

(without pipe) on the carbon steel inclined plane; the second set coefficient of friction is reached during the transition from the

7 Copyright © 2017 ASME

impending movement or sliding to the sliding of the bearing a poorly maintained piping system, respectively. The

surfaces proper. In other words, the temperature at which experimentally measured value of coefficient of kinetic friction

sliding would actually be anticipated to begin in heating up from equal to 0.16 and coefficient of static friction equal to 0.26

70°F would be, in fact, at a temperature as low as 100°F. The (which is very close to the commonly used coefficient of friction

axial force necessary to prohibit movement of a pipe during of 0.30) are of the most interest to the piping stress analyst.

thermal expansion is most often a magnitude times greater than Tables 2 and 3 summarize the results for the first pipe geometry

that of the induced frictional restraining force. For instance, a as shown in Fig. 1. Tables 2 and 3 show the reactions in the

pipe shoe that is attached to the expanding pipe of interest, axial direction (Z-direction) at the anchors for the NPS 4 and

assuming a water-filled NPS 4 standard wall thickness carbon NPS 12 models, respectively. The second column in both tables

steel pipe, utilizing span lengths of 20 ft, the “equivalent” axial gives the reaction load without friction. As the coefficient of the

force at 300°F is predicted to be in excess of 144,000 lbf friction increases, the reactions at the anchors increase

compared to a frictional restraining force of only 100 lbf at significantly for both of the selected temperatures.

breakaway. In comparison, once the pipe begins to slide, the

frictional restraining force is on the order of no more than 15 to TABLE 6

20 lbf. During thermal expansion, the pipe must first reach the Geometry 2 Anchor Reactions NPS 4

breakaway point (i.e., where µs is indeed a maximum, but at a Reaction at Anchors in Axial (X) Direction (lbf)

much lower temperature than the design or operating µ 0.00 0.16 0.30 0.40

temperature) and then for the remainder of the heat-up period of 300°F -33.2 -171.7 -293.0 -379.6

time is subject to the sliding frictional effects, not the static 650°F -84.0 -222.6 -343.8 -430.4

frictional effects. The end result is that the equipment nozzle

loadings are more apt to be representative of the effects of µk

rather than µs. In cases where the piping designer and the TABLE 7

Geometry 2 Anchor Reactions NPS 12

analyst need to ensure a maximum margin of safety or operating

margin, then for the critical supports that may be subjected to Reaction at Anchors in Axial (X) Direction (lbf)

µ 0.00 0.16 0.30 0.40

varying environmental conditions affecting the friction between

300°F -901.5 -1733.8 -2462.1 -2982.3

the bearing surfaces, obviously the clear, but more expensive

650°F -2278.9 -3111.3 -3839.5 -4359.8

choice, would be the selection of low coefficient of friction

bearing surfaces (i.e., Teflon™ and graphite as shown in Table

1). Tables 6 and 7 highlight the reactions at the anchors for

Geometry 2, whereas Tables 7 and 8 present the results for

Geometry 3 for the same conditions as previously discussed for

Geometry 1. Furthermore, the results for Geometry 2 and

Geometry 3 strengthen the argument of the realization of

increased loads on anchors due to the increase in friction at pipe-

support interfaces and the need for a more reasonable approach

in simulating the effects of friction at critical support locations.

TABLE 8

Geometry 3 Anchor Reactions NPS 4

Reaction at Anchors in Axial (Z) Direction (lbf)

µ 0.00 0.16 0.30 0.40

300°F 13.5 116.5 206.6 271.0

650°F 34.3 137.3 227.4 291.7

TABLE 9

Geometry 3 Anchor Reactions NPS 12

Reaction at Anchors in Axial (Z) Direction (lbf)

FIG. 7 INCLINED PLANE FRICTION APPARATUS µ 0.00 0.16 0.30 0.40

300°F 301.2 899.4 1422.8 1796.7

RESULTS OF THE ANALYSES 650°F 761.4 1359.7 1883.1 2257.0

A number of finite element analyses were carried out for A number of finite element analyses were conducted for

the three different geometries; two pipe sizes, two temperatures, the three different geometries, two pipe sizes, and a heat-up

and four different values of the coefficient of friction. Values from an assumed ambient temperature of 70°F to a maximum

for µs (or µk as the case may be) of 0.00, 0.16, 0.30, and 0.40 operating temperature of 650°F at a typical heat-up rate of

were used to simulate the conditions of frictionless, 50°F/hour. Different values for the coefficient of friction

experimentally measured kinetic coefficient of friction,

varying from no friction to µ=0.30 were incorporated into the

generally accepted coefficient of steel to steel static friction, and

analyses to study the effect of friction on the velocities of pipe at

8 Copyright © 2017 ASME

the particular support location. The finite element analyses were are very significant and cannot be ignored. The effect is greater

carried out considering different combinations of the for the large diameter pipe as discussed in WRC Bulletin 449

aforementioned variables resulting in the following observations [10] and as shown by the results of the NPS 12 diameter models.

being made.

(1) Pipe size does not affect the velocities of the supports

as the displacement is a function of coefficient of

thermal expansion, which in turn is a function of the

pipe material and the temperature of the pipe.

(2) The introduction of friction does not affect the support

velocities as the thermal forces during expansion and

contraction cycles overpower any dissipative frictional

forces.

(3) The farther the support is away from a point of fixity,

the larger the velocity of the support. The supports

close to the nozzles move slowly relative to other

supports in the piping system. The reduction of

frictional forces at these supports should be of greater

interest.

Figure 8 depicts the displacement versus time plot of

FIG. 8 VELOCITY OF VARIOUS PIPE SUPPORTS

various supports from the three geometries consolidated into a DURING HEAT-UP TO 650°F

single graph. The slopes of the various curves represent the

velocity of the particular pipe support. It is clear from the

displacement versus the time plots that the supports closer to the CONCLUSIONS

point of fixity (nozzle, anchors, etc.) move slower as compared

to the supports away from the anchors. Furthermore, the Loads due to friction are transient loads and are only active

velocity of a particular support from the start of heat up to the either when the pipe support slides or when sliding is pending

end of heat up is fairly linear over a wide range of temperature, and the static coefficient is at its maximum value. The opposing

e.g. from 70°F to 650°F for the cases presented. frictional force is a retarding force and can never move the pipe;

There is one additional, often overlooked, fact regarding it can only oppose the movement of the pipe.

the consideration of friction in support design that must be Equipment nozzles in general and especially critical

brought to the forefront. Often times, pipe straps are employed rotating equipment (i.e., pumps, compressors, turbines, etc.)

in longer runs of piping in an attempt to ‘guide’ the thermal should be protected from reaction loads due to excessive

movement of the piping. In a properly designed strap, the bend friction, in addition to thermally induced loads, by carefully

radius of the strap is sufficiently larger than the outside pipe locating anchors and guides. Friction should always be treated

diameter (including any outside diameter tolerance as specified as the non-conservative energy it creates, i.e., no credit should

either by standards or material specifications). While ASME be taken in an analysis especially if the induced frictional forces

B&PV Code, Section III, Division 1, Subsection NF [19] more help in reducing dynamic loads on nozzle connections, anchors,

than implies that certain defined types of supports “shall be or guides.

designed to accommodate the forces caused by friction in The piping system should be analyzed with and without

addition to the loads imposed by bearing,” what is definitely friction to understand the behavior of friction on the system.

implied is that there exists an associated bearing area over which Large diameter pipes can induce high frictional forces at the

the frictional forces may act. In the case of pipe strap-to-pipe pipe-support interface and may result in failure of the directional

interfaces, for the previously defined ‘properly designed’ strap, anchors if the breakaway forces become overwhelming. Slides

the contact interface becomes, at best, a line. This line contact with PTFE or graphite bonded to steel bearing plates and other

can be considered an infinitesimal area that approaches zero in friction reducing components must be considered in piping

most cases (i.e., as the length of the line in contact with the pipe systems generating excessive frictional forces. Proper

approaches zero, so does the interfacial bearing area). maintenance of friction reducing components should be carried

Ultimately, this infinitesimally small contact area implies that out and the composite supports must be kept free of dirt, debris,

the shear stress created by any piping movement that is retarded and corrosion. The variation (increase with time) of both the

by friction increases without bound, which cannot be physically static and the kinetic coefficients of friction (µs and µk) should

correct. Therefore, supports and restraints where friction must also be minimized through the enforcement of a periodic

be considered by the Code [19] should or must have some inspection and maintenance schedule.

clearly definable contact or bearing area. Restraints such as anchors, directional stops, guides, etc.,

The results of the analyses of the three geometries showed are almost always treated as rigid elements in the commercially

that the increase in the loads on anchors (and therefore, on available FEA codes. The additional restraint and associated

equipment nozzles and connections) or limit stops due to friction

9 Copyright © 2017 ASME

loads introduced due to pipe-support friction should also be Vessels and Piping, 77, Elsevier Science Ltd., London, pp. 297-

considered while designing the aforementioned restraints. 301.

In modeling the effects of friction between the bearing [5] Boresi, A. P. and Schmidt, R. J., 2000, Engineering

surfaces of a pipe support and the ultimate supporting structure, Mechanics-Statics, Brooks/Cole, Pacific Grove, CA.

a more realistic approach than what is commonly employed by [6] Bowden, F. P. and Tabor, D., 2001, The Friction and

many analysts is one that would attempt to utilize the kinetic Lubrication of Solids, Oxford University Press, New York.

coefficient of friction, µk, in place of the static coefficient of [7] Mokha, A. S., Constantinou, M. C.,and Reinhorn, A. M.,

friction, µs. This technique becomes especially important in and 1990, “Teflon Bearing in Base Isolation I: Testing,” Journal

around critical rotating equipment nozzles. The basis for this Structural Engineering, ASCE 116 (2), pp. 438–454.

discussion and methodology stems from the fact that as the [8] Constantinou, M. C., Mokha, A. S., Reinhorn, A. M., 1990,

piping system begins to heat up to operating temperature, the “Teflon Bearing in Base Isolation II: Modeling,” Journal

maximum static coefficient of friction is reached during the Structural Engineering, ASCE 116 (2), pp. 455–474.

transition from the impending sliding of the pipe support at a [9] ASME, 2006, ASME B31.3, “Process Piping,” American

much lower temperature than that of the design temperature, in Society of Mechanical Engineers, New York, USA.

general. The point in the thermal cycle when the coefficient of [10] Carucci, V. A. and Payne, J. A., 2000, WRC Bulletin 449,

friction is a maximum is not typically coincident with the point Guidelines for the Design and Installation of Pump Piping

in time when the maximum operating or design temperature is Systems, Welding Research Council, Inc., New York, USA.

reached. The calculation of the combined piping loads on a [11] Baniotopoulos, C. C., 1996, "Saddle-Supported Pipelines:

nozzle would be better to include the effects of the coefficient of Influence of Unilateral Support and Thickness on the Stress

friction that exists immediately prior to reaching the maximum State,” International Journal of Pressure Vessels and Piping, 67,

temperature and that which is coincident with the maximum Elsevier Science Ltd., London, pp. 55-64.

temperature in the thermal cycle, which is considered to be µk. [12] Baniotopoulos, C. C., Panagiotopoulos, P. D., 1997,

Additionally, empirical testing clearly shows that the coefficient "Stress Distribution Along Above-Ground Pipelines on a

of kinetic (or sliding) friction is only 60% - 67% of that for the Frictional Supporting System,” Computers and Structures, 64,

coefficient of static friction. Elsevier Science Ltd., London, pp. 783-789.

Finally, in the design of certain supports and restraints, to [13] Intergraph, Corp., 2011, CAESAR II, Release 5.30

accommodate the forces caused by friction in addition to the Technical Reference Manual, Houston, TX.

loads imposed by bearing, what is definitely implied is that there [14] Sobieszczanski J., 1972, "Inclusion of a Support Friction

exists an associated bearing area over which the frictional forces into a Computerized Solution of a Self-compensating Pipeline,"

may act. In the case of pipe strap-to-pipe interfaces, this line J Engng Ind (Trans ASME), pp. 797-802.

contact can be considered an infinitesimal area that approaches [15] Reddy, G. R., Suzuki, K., Watanabe, T., and Mahajan, S.

zero. Ultimately, this infinitesimally small contact area implies C., 1999, "Linearization Techniques for Seismic Analysis of

that the shear stress created by any piping movement that is Piping System on Friction Support," J. Pressure Vessel

retarded by friction increases without bound, which cannot be Technology”, 121, ASME, New York, pp. 103-108.

physically correct. Therefore, supports and restraints where [16] ANSYS, Inc., 2007, Release 11.0 Documentation for

friction must be considered by the Code [19] should or must ANSYS, Canonsburg, PA.

have some clearly definable contact or bearing area. [17] Kannappan, S., 1986, Introduction to Pipe Stress Analysis,

Wiley-Inter-science, New York, USA, Chap. 1-3.

REFERENCES [18] Tube Turns Division, 1979, Piping Engineering, Tube

Turns Division of Allegheny Ludlum Industries, Louisville, KY.

[1] Peng, L., 1989, "Treatment of Support Friction in Pipe

[19] ASME, 2015 ASME Boiler and Pressure Vessel Code,

Stress Analysis," Design and Analysis of Piping and

Section III, Rules for Construction of Nuclear Facility

Components, PVP Vol. 169, ASME, New York, pp. 143-148.

Components, Division 1, Subsection NF, Supports, American

[2] Bakre, S. V., Jangid, R. S., and Reddy, G. R., 2007,

Society of Mechanical Engineers, New York.

"Response of Piping System on Friction Support to Bi-

[20] Antaal, B. S., Williams, D. K., and Hari, Y., 2012,

Directional Excitation," Nuclear Engineering and Design, 237,

"Considerations of the Restraint Introduced by Piping Support

Elsevier Science Ltd., London, pp. 124-136.

Friction in a Comprehensive ASME B31.3 Analysis,” PVP2012-

[3] Suzuki, K., Watanabe, T., Mitsumori, T., Shimizu, N.,

78658, ASME Pressure Vessels & Piping Conference, Toronto,

Kobayashi, H., and Ogawa, N., 1995, "Experimental Studies on

ON, July 15-19, 2012, ASME, New York.

Seismic Response Systems with Friction – Part 1: Large-Scale

[21] Halliday, D. and Resnick, R., 1978, Physics, Parts I and II

Shaking Table Vibration Test," J. Pressure Vessel Technology”,

Combined, Third Edition, John Wiley & Sons, New York, USA,

117, ASME, New York, pp. 245-249.

p. 101.

[4] Kolonits, F., 2000, "The Crawling Cat - Ratcheting of

Supports in Piping Systems,” International Journal of Pressure

10 Copyright © 2017 ASME

View publication stats

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- MRR Status Storekeeper QA/QC Inspector M.R.R. Issued Date M.R.R. NoDocument24 pagesMRR Status Storekeeper QA/QC Inspector M.R.R. Issued Date M.R.R. NoChiranjeevi AnilPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Full-Faced Expansion Joints: InstallationDocument3 pagesFull-Faced Expansion Joints: InstallationChiranjeevi AnilPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Minfm66916 Astm A352 Grade LCC PDFDocument2 pagesMinfm66916 Astm A352 Grade LCC PDFChiranjeevi AnilPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Pump Off at End of Time RecordDocument2 pagesPump Off at End of Time RecordChiranjeevi AnilPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- EJ Alignment PDFDocument1 pageEJ Alignment PDFChiranjeevi AnilPas encore d'évaluation

- Minfm66916 Astm A352 Grade LCCDocument2 pagesMinfm66916 Astm A352 Grade LCCChiranjeevi AnilPas encore d'évaluation

- Minfm66915 Astm A352 Grade LCBDocument3 pagesMinfm66915 Astm A352 Grade LCBChiranjeevi AnilPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- KINFLEX Installation PDFDocument5 pagesKINFLEX Installation PDFChiranjeevi AnilPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Stand On SpecsDocument6 pagesStand On SpecsChiranjeevi AnilPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Minfm66916 Astm A352 Grade LCCDocument2 pagesMinfm66916 Astm A352 Grade LCCChiranjeevi AnilPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

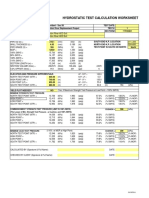

- Hydrostatic Test Calculation Worksheet: Minimum 'Strength Test' PressureDocument4 pagesHydrostatic Test Calculation Worksheet: Minimum 'Strength Test' PressureChiranjeevi AnilPas encore d'évaluation

- 389 LoadCasesDocument1 page389 LoadCasesChiranjeevi AnilPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Cooling Tower SolutionDocument38 pagesCooling Tower SolutionThabangPas encore d'évaluation

- PHD Thesis - Anthony Lo - 9 Dec 2014Document264 pagesPHD Thesis - Anthony Lo - 9 Dec 2014Hiei ArshavinPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Hoja Técnica Roto Xtend Duty Fluid PDFDocument2 pagesHoja Técnica Roto Xtend Duty Fluid PDFFederico Liaudat100% (2)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- "JD" Series Pulling Tool: 4Jdc Operation ManualDocument4 pages"JD" Series Pulling Tool: 4Jdc Operation Manualsong Li100% (1)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Catalogo de Partes Blue BirdDocument112 pagesCatalogo de Partes Blue Birdjhongua7Pas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Simpson Fence Base and BracketDocument3 pagesSimpson Fence Base and BracketAloPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Deformation ProcessDocument25 pagesDeformation Processutpal singhaPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Foundation EngineeringDocument90 pagesFoundation EngineeringAnonymous 2R2pCtCDPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- DPR TemplateDocument5 pagesDPR TemplateSantoshkumar GurmePas encore d'évaluation

- 29 V3800dit 26Document2 pages29 V3800dit 26Hector Dongo ArrayanPas encore d'évaluation

- Ipc 9521Document4 pagesIpc 9521ashu0470Pas encore d'évaluation

- Igcse/O Level Add Maths Vectors (Constant Velocity) Past PapersDocument13 pagesIgcse/O Level Add Maths Vectors (Constant Velocity) Past PapersKiefer Ansel OBBOHPas encore d'évaluation

- PrimeRoyal HPD LE IOMDocument82 pagesPrimeRoyal HPD LE IOMTadeo FajardoPas encore d'évaluation

- V Clic Workshop ManualDocument44 pagesV Clic Workshop ManualWG-Friend IvybridgePas encore d'évaluation

- Ncode Designlife BrochureDocument4 pagesNcode Designlife BrochuredelaneylukePas encore d'évaluation

- Depth of Water: A. Soil and Water Conservation EngineeringDocument36 pagesDepth of Water: A. Soil and Water Conservation EngineeringJayvee Laureta100% (1)

- Item Code Item Name Item Class Brand Model Code Warehouse Group Warehouse Code Location Code Sales Price Available QtyDocument8 pagesItem Code Item Name Item Class Brand Model Code Warehouse Group Warehouse Code Location Code Sales Price Available Qtyrahmat agungPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Slab Analysis of Ring Rolling AssumingConstantShearFrictionDocument7 pagesSlab Analysis of Ring Rolling AssumingConstantShearFrictionMatteo Dalla Vecchia100% (1)

- C 20 MC 3 4 SemDocument53 pagesC 20 MC 3 4 SemK Kartik KartikPas encore d'évaluation

- A.C Lecture 2Document5 pagesA.C Lecture 2mamnd tahaPas encore d'évaluation

- Tablas Medidas Tubos de Acero API5L - ASTM A53 - A106Document6 pagesTablas Medidas Tubos de Acero API5L - ASTM A53 - A106Reinaldo AndaraPas encore d'évaluation

- Clutch Actuator & TCM AssemblyDocument13 pagesClutch Actuator & TCM AssemblyVinh XuânPas encore d'évaluation

- BTech 1st Sem: Mechanical Science: Stress & StrainDocument10 pagesBTech 1st Sem: Mechanical Science: Stress & StrainTechno India Group100% (1)

- Fuji Electric VFZ501A 7W DatasheetDocument2 pagesFuji Electric VFZ501A 7W Datasheetghmp123Pas encore d'évaluation

- Transducer: TypesDocument39 pagesTransducer: Typestujuh belasPas encore d'évaluation

- PC2 - Practice Exam WorkedDocument12 pagesPC2 - Practice Exam WorkednomsyPas encore d'évaluation

- Carrier Supra 644 Refrigeration Unit For TrucksDocument2 pagesCarrier Supra 644 Refrigeration Unit For TrucksgoogleheadPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Building Utilities Reviewer ComprehensiveDocument3 pagesBuilding Utilities Reviewer ComprehensiveReynald HarrisPas encore d'évaluation

- Intergraph Caesar Course ContentDocument2 pagesIntergraph Caesar Course ContentValesh MonisPas encore d'évaluation

- Training ReportDocument60 pagesTraining Reportarjun100% (1)