Académique Documents

Professionnel Documents

Culture Documents

330C L Excavator - 9 Engine PDF

Transféré par

RICHARDTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

330C L Excavator - 9 Engine PDF

Transféré par

RICHARDDroits d'auteur :

Formats disponibles

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Shutdown SIS

Previous Screen

Product: EXCAVATOR

Model: 330C L EXCAVATOR CYA

Configuration: 330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-

9 Engine

Disassembly and Assembly

330C Excavator Machine Systems

Media Number -RENR5438-14 Publication Date -01/04/2010 Date Updated -13/04/2010

i03605962

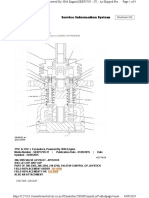

Main Hydraulic Pump - Disassemble - Series II

SMCS - 5070-015

Disassembly Procedure

Table 1

Required Tools

Tool Part Number Part Description Qty

A 1P-2420 Transmission Repair Stand 1

B 138-7575 Link Bracket 2

C 138-7573 Link Bracket 2

D 1U-8758 Pliers 1

E 1P-0520 Driver Group 1

126-7175 Push-Puller 1

5P-4808 Cap 2

6B-6684 Nut 2

126-7176 Forcing Screw 1

F 126-7177 Puller Leg 2

126-7181 Sliding plate 4

126-7182 Nut for the Forcing screw 1

126-7183 Crossblock 1

4C-5648 Threaded Adapter Gp 1

G 1P-1859 Retaining Ring Pliers 1

H 5F-7343 Puller Group 1

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Start By:

A. Remove the main hydraulic pump and the pump drive coupling. Refer to Disassembly and Assembly, "Main

Hydraulic Pump and Pump Drive Coupling- Remove".

NOTICE

Care must be taken to ensure that fluids are contained during

performance of inspection, maintenance, testing, adjusting and repair

of the product. Be prepared to collect the fluid with suitable containers

before opening any compartment or disassembling any component

containing fluids.

Refer to Special Publication, NENG2500, "Caterpillar Dealer Service

Tool Catalog" for tools and supplies suitable to collect and contain

fluids on Caterpillar products.

Dispose of all fluids according to local regulations and mandates.

NOTICE

Failure to properly assemble parts or failure to follow established

procedures can lead to damage to the parts and assembly.

To avoid damage to parts, always identify and mark the parts so that

they can be installed into the same location. Never force parts during

assembly. Keep parts clean and lubricated.

NOTICE

Keep all parts clean from contaminants.

Contamination of the hydraulic system with foreign material will

reduce the service life of the hydraulic system components.

To prevent contaminants from entering the hydraulic system, always

plug or cap the lines, fittings, or hoses as they are disconnected. Cover

any disassembled components and clean them properly before

assembly.

Clean the hydraulic system properly after any major component

exchange or especially after a component failure, to remove any

contamination.

Note: If a failure occurs, an accurate diagnosis of the cause can prevent a recurrence. Information is available to

analyze failures for piston pumps and motors. Refer to Special Publication, SEBD0641, "Analyzing Axial Piston

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Pump and Motor Failures".

Note: Inspect all parts. If any parts are worn or damaged use new parts for replacement. The installation of used

parts during reconditioning is acceptable. Reuse and salvage information is available on piston pumps. Refer to

Guideline for Reusable Parts and Salvage Operations, SEBF8032, "Piston Pumps and Motors". During

reconditioning, correct any conditions that might have caused the original failure.

1. Thoroughly clean the outside of the main hydraulic pump prior to disassembly.

Illustration 1 g00633959

2. Fasten the main hydraulic pump to Tooling (A) , as shown.

3. Remove drain plug (1) , and drain the oil from the main hydraulic pump into a suitable container for disposal.

4. Remove the socket head bolts that hold plate (2) in position.

5. Remove the plate and the O-ring seal from the main pump housing.

Illustration 2 g00633590

6. Remove socket head bolts (3) that hold pump control (4) in position.

7. Fasten Tooling (B) and a suitable lifting device to pump control (4) , as shown.

8. Remove pump control (4) from the main hydraulic pump. The weight of pump control (4) is approximately 48

kg (106 lb).

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

9. Perform the following steps in order to disassemble pump control (4) .

Note: Inspect all parts. If any parts are worn or damaged use new parts for replacement. The installation of

used parts during reconditioning is acceptable. Reuse and salvage information is available on piston pumps.

Refer to Guideline for Reusable Parts and Salvage Operations, SEBF8032, "Piston Pumps and Motors".

During reconditioning, correct any conditions that might have caused the original failure.

Note: The following procedure is written for the 345B excavator. The following procedure will work for the

320B through the 345B excavators. This procedure will not cover electrohydraulic machines.

Illustration 3 g01931340

a. Remove six socket head bolts (5) in order to remove pump control group (6) from pump control (4) .

Illustration 4 g01931435

b. Remove two bushings (10) that are for power shift pressure.

c. Remove both torque control pistons (11) from the two bushings (6) .

d. Remove two adjustment screws (7) .

e. Remove O-ring seal (12) from each adjustment screw (7) .

f. Remove four seats (13) , two springs (8) , and two negative flow control spools (9) .

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Illustration 5 g01932137

g. Remove two O-ring seals (14) , two O-ring seals (15) and two dowels (16) from pump control group

(17) .

Illustration 6 g01932156

h. Remove two pins (21) and two horsepower control spools (20) .

i. Remove two springs (19) and two seats (18) .

Illustration 7 g01932195

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Illustration 8 g01932196

Personal injury can result from parts and/or covers under spring

pressure.

Spring force will be released when covers are removed.

Be prepared to hold spring loaded covers as the bolts are loosened.

j. Remove plug (24) from the pump control group (17) .

k. Remove sensor (25) (Not Shown).

l. Remove the O-ring seal from plug (24) .

m. Remove seat (26) and ball (27) .

n. Use a tap in order to thread bushing (28) .

o. Screw an M6 bolt into bushing (28) in order to remove bushing (28) .

Note: The horsepower adjustment screw is under cap (22) .

p. Remove cap (22) in order to replace the screw and the nut that is under the cap.

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

ReferenceRefer to the Testing and Adjusting, "Pump Control (Output Flow) - Adjust" for the proper

adjustment.

q. While you retain pump control group (17) , loosen six socket head bolts (23) evenly in order to release

the spring force. Do not remove all of the socket head bolts at one time. Longer bolts will be needed to

retain pump control group (17) when you release spring force.

r. Remove pump control group (17) .

Illustration 9 g01933414

Assembled View

(17) Pump control group

(29) Pump head

Illustration 10 g01933415

Exploded View

s. Remove two seats (33) .

t. Remove two springs (30) .

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

u. Remove two springs (34) .

v. Remove two seats (31) .

w. Remove two springs (35) .

x. Remove two spring spacers (32) .

Illustration 11 g01934815

y. Remove eight socket head bolts (36) and two covers (37) from pump head (29) .

Note: The maximum displacement adjustment screw is under cap (38) . Remove cap (38) in order to

replace the screw and the nut that is underneath the cap.

Note: Refer to Testing and Adjusting, "Pump Control (Output Flow) - Adjust" for the proper

adjustment.

Illustration 12 g01934894

z. Remove plug (39) from each cover (40) . Replace the O-ring seal on each plug (39) .

aa. Remove O-ring seals (42) from each cover (40) . Replace all the O-ring seals (42) .

ab. Remove bolts (41) from the large piston.

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Illustration 13 g01935037

ac. Remove two pistons (43) from the pump head (29) .

ad. Remove two rings (44) from each piston.

ae.

Illustration 14 g01935039

af. Remove two alignment pins (45) .

ag. Mark the positions of trunnions (46) prior to removing trunnions (46) from the large pistons in pump

head (29) . The rods must be installed in the same orientation.

Illustration 15 g01935206

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Illustration 16 g01935207

ah. Raise the temperature of each trunnion (47) in order to loosen the adhesive. Raise the temperature of

each trunnion (47) to 120 °C (248 °F).

ai. Use an allen wrench in order to loosen socket head screw (48) in each large piston. It is not necessary to

completely remove the socket head screws.

aj. Remove trunnion (47) from the large pistons. This will permit removal of the large pistons from the

pump head.

Illustration 17 g01935275

Typical example

ak. Remove large pistons (49) from the pump head.

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Illustration 18 g01935295

10. Remove dowels (50) from the main pump housing.

11. Remove port plate (51) from each pump rotating group.

Note: Port plates (51) are lapped to the barrel. Keep port plates (51) with each rotating group.

NOTICE

In order to ensure that each piston assembly is installed into its

original bore, identify and mark each piston assembly, retaining plate

and the barrel before removing the piston assembly.

To avoid damage to the barrel assembly parts, do not allow the parts to

separate from the assembly during removal or installation.

Illustration 19 g01935338

12. Remove cylinder barrel (52) from each rotating group.

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Illustration 20 g01935340

13. Remove spacer (53) , and bevel spring washers (54) from the center bore of each cylinder barrel (52) .

Illustration 21 g01936157

14. Remove gasket (55) .

15. Remove socket head screws (56) from each retaining plate (57) .

Illustration 22 g01936159

16. Remove centering pin (58) and retaining plate (57) for each rotating group.

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Illustration 23 g01936173

17. Remove pistons (59) for each rotating group.

Illustration 24 g01936233

18. Remove O-ring seals (60) from each piston (59) .

19. Make sure that pistons (59) have no pits. Pistons (59) must not have any scratches on the surface.

Illustration 25 g01936413

20. Install a M16 X 2.00 THD bolt (61) in the end of lower pump rotating group (62) .

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

21. Drive the lower pump rotating group upward until the lower pump rotating group rests loosely in the pump

housing.

Illustration 26 g01936577

22. Attach Tooling (C) and a suitable lifting device to the top of lower pump rotating group (62) in order to

completely remove the lower pump rotating group from the pump housing.

Illustration 27 g01936594

23. Remove plug (63) from the main pump housing.

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Illustration 28 g01936634

24. Install a M10 X 1THD bolt (64) into the threaded hole.

25. Tighten bolt (64) in order to remove the upper pump rotating group from the main pump housing.

26. Remove the main pump housing from Tooling (A) and turn over the main pump housing.

27. Refasten the main pump housing to Tooling (A) .

Illustration 29 g01936673

28. Use Tooling (D) in order to remove retaining ring (65) .

Illustration 30 g01936693

29. Remove shim (66) from the pump housing.

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Illustration 31 g00640797

Illustration 32 g01936695

Cross section of main pump

30. Use Tooling (E) and a suitable hammer in order to remove the lip seal (67) .

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Illustration 33 g01938994

31. Remove bolts (69) .

32. Remove pilot pump (68) from the main pump housing.

Illustration 34 g01998148

33. Remove O-ring seals (70) from the pilot pump.

Illustration 35 g01998433

34. Fasten Tooling (F) to shaft (72) .

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

35. Remove shaft (72) and bearing (71) from the pump housing.

Illustration 36 g01998453

36. Use a suitable press in order to remove bearing (71) from shaft (72) .

Illustration 37 g01998456

37. Use a 4 mm (0.2 inch) socket head capscrew in order to remove key (73) from shaft (72) .

Illustration 38 g01998459

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

38. Remove gear (74) from the main pump housing. Slide the gear to the center of the housing and remove the

gear from the top of the housing.

Note: The gear is not symmetrical. Make sure that you mark the gear orientation.

Illustration 39 g01998460

39. Use a pry bar in order to remove bearing (75) .

Disassembly Procedure for the Lower Pump Rotating Group

Illustration 40 g01998474

Cross section view of the lower pump rotating group.

(A) Dimension that is determined by shim (80) during the assembly

(76) Retaining ring

(77) Bearing assembly

(78) Bearing assembly

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

(79) Plate

(80) Shim

Illustration 41 g01998517

Cross section view of bearing assembly (78) .

(78a) Bearing cone

(78b) Spacer

(78c) Bearing cup

(78d) Bearing spacer

(78e) Bearing cone

(78f) Bearing cup

1. Disassemble the lower pump rotating group, as follows.

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Illustration 42 g01998553

2. Use Tooling (G) in order to remove retaining ring (76) from the lower pump rotating group.

Illustration 43 g01998638

3. Remove plate (79) .

Illustration 44 g01998654

4. Use Tooling (H) and a suitable press in order to remove bearing assembly (77) , shim (80) , and bearing

assembly (78) from the shaft.

5. Place Tooling (H) on the outer edge of the bearing cup (78`c) .

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Note: Do not push on the bearing cage.

Illustration 45 g01998675

6. Remove spacer (78b) .

Illustration 46 g02003056

7. Use Tooling (H) and a suitable press in order to remove bearing cone (78a) from the shaft.

Disassembly Procedure for the Upper Pump Rotating Group

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Illustration 47 g02003060

Cross section view of the upper pump rotating group.

(A) Dimension that is determined by shim (41) during the assembly

(80) Retaining ring

(81) Bearing assembly

(82) Bearing assembly

(83) Plate

(84) Shim

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Illustration 48 g02003065

Cross section view of bearing assembly (82) .

(82a) Bearing cone

(82b) Spacer

(82c) Bearing cup

(82d) Bearing spacer

(82e) Bearing cone

(82f) Bearing cup

1. Disassemble the upper pump rotating group, as follows.

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Illustration 49 g02003097

2. Use Tooling (G) in order to remove retaining (80) from the shaft.

Illustration 50 g02003116

3. Remove plate (83) from the shaft.

Illustration 51 g02003121

4. Use Tooling (H) and a suitable press in order to remove bearing assembly (81) , shim (84) , and bearing

assembly (82) from the shaft.

5. Place Tooling (H) on the outer edge of bearing cup (82c) , as shown.

Note: Do not push on the bearing cage.

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

330C L Excavator CYA00001-UP (MACHINE) POWERED BY C-9 Engine(SEBP3397 - 42) - Documentation

Illustration 52 g02003142

6. Remove spacer (82b) .

Illustration 53 g02003213

7. Use Tooling (H) and a suitable press in order to remove bearing cone (82a) from the shaft.

Copyright 1993 - 2017 Caterpillar Inc. Thu Jun 22 06:33:09 EST 2017

All Rights Reserved.

Private Network For SIS Licensees.

https://127.0.0.1/...web/sisweb/mediasearch/mediaheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[22/06/2017 06:34:06 a.m.]

Vous aimerez peut-être aussi

- Caterpillar Cat 329E LN Excavator (Prefix RLD) Service Repair Manual (RLD00001 and Up)Document27 pagesCaterpillar Cat 329E LN Excavator (Prefix RLD) Service Repair Manual (RLD00001 and Up)kfm8seuuduPas encore d'évaluation

- 325C Excavators Stick Lowering Control Valve Hydraulic System - AttachmentDocument2 pages325C Excavators Stick Lowering Control Valve Hydraulic System - AttachmentAndrei BleojuPas encore d'évaluation

- Techdoc Print Page TEST TRANSMISSIONDocument11 pagesTechdoc Print Page TEST TRANSMISSIONtyok sajaPas encore d'évaluation

- 232D/236D/242D/ 246D/262D: Skid Steer LoadersDocument20 pages232D/236D/242D/ 246D/262D: Skid Steer LoadersCapacitaciones RutasPas encore d'évaluation

- Parts Guide Sharp MX-M 202-232D PDFDocument86 pagesParts Guide Sharp MX-M 202-232D PDFCristian Bobaru100% (2)

- 330l Elect 1Document2 pages330l Elect 1Nath JeffPas encore d'évaluation

- Diagrama Electrico PDFDocument9 pagesDiagrama Electrico PDFhenotharenas100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document31 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Richard Haison Chuima Ayvar100% (1)

- Lubrication System: Systems OperationDocument4 pagesLubrication System: Systems OperationHasby Potter100% (1)

- 330D Sist Control ElectrDocument3 pages330D Sist Control ElectrMiguel Angel Garrido CardenasPas encore d'évaluation

- Engine Performance - Test - Engine Speed: 320D and 323D Excavators Hydraulic SystemDocument3 pagesEngine Performance - Test - Engine Speed: 320D and 323D Excavators Hydraulic SystemEm sulistio100% (1)

- Schematic Electric System Cat D8T Vol1Document33 pagesSchematic Electric System Cat D8T Vol1Andaru Gunawan100% (1)

- Hydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorDocument18 pagesHydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorjuampacervantesPas encore d'évaluation

- Using Caterpillar Monitoring System To Determine Diagnostic CodesDocument4 pagesUsing Caterpillar Monitoring System To Determine Diagnostic CodesAbdul AzisPas encore d'évaluation

- 322C Excavator Electrical System: Electrical Schematic Symbols and DefinitionsDocument2 pages322C Excavator Electrical System: Electrical Schematic Symbols and DefinitionsNeftali FuentesPas encore d'évaluation

- Senr6777senr6777-02 SisDocument12 pagesSenr6777senr6777-02 SisAngel David Zuñiga SuarezPas encore d'évaluation

- 320 e Cat PDF FreeDocument6 pages320 e Cat PDF FreeMICHAEL DONKORPas encore d'évaluation

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document7 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Albert Gafarov100% (1)

- Engine Performance - Test - Engine Speed: Testing and AdjustingDocument2 pagesEngine Performance - Test - Engine Speed: Testing and AdjustingDANIEL VARGAS RODRIGUEZ100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document10 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768samir2012cat100% (1)

- Pistoes c7Document6 pagesPistoes c7Alaina SousaPas encore d'évaluation

- Configuration ModeDocument40 pagesConfiguration ModeDANIEL VARGAS RODRIGUEZPas encore d'évaluation

- Injection Actuation CircuitDocument9 pagesInjection Actuation Circuitsamsularief03Pas encore d'évaluation

- 311Document2 pages311Anonymous cS9UMvhBq100% (2)

- Transmission - Disassemble: Welcome: x350kxmDocument25 pagesTransmission - Disassemble: Welcome: x350kxmSIA Stats RENTPas encore d'évaluation

- GRPTS TurbochargersDocument65 pagesGRPTS TurbochargersFaur RahmanPas encore d'évaluation

- Cat 950gii HL PDFDocument96 pagesCat 950gii HL PDFJuniaman SinagaPas encore d'évaluation

- Vernier Throttle For CATDocument12 pagesVernier Throttle For CATJose RojasPas encore d'évaluation

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document11 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Said Abotalip100% (1)

- Ajustes de Transmision CaterpillarDocument23 pagesAjustes de Transmision CaterpillarPlstina RamsPas encore d'évaluation

- 740B EJ Tier 2 Maintenance Parts ListDocument3 pages740B EJ Tier 2 Maintenance Parts ListMónica Rada UrbinaPas encore d'évaluation

- Groupon Vale CatDocument4 pagesGroupon Vale CatLuis Carlos RamosPas encore d'évaluation

- Power Train Troubleshooting: Essai Et RéglageDocument15 pagesPower Train Troubleshooting: Essai Et RéglageAly AbdelhamedPas encore d'évaluation

- 345b Electrical System Schematic Used in Service Manual Senr1925 Aurora - Cat Machines Electrical SchematicDocument1 page345b Electrical System Schematic Used in Service Manual Senr1925 Aurora - Cat Machines Electrical SchematicAlexPas encore d'évaluation

- D7R Track Type Tractor Electrical System (Differential Steer)Document2 pagesD7R Track Type Tractor Electrical System (Differential Steer)JorgePas encore d'évaluation

- Gear Pump (Pilot) - Test: Testing and AdjustingDocument8 pagesGear Pump (Pilot) - Test: Testing and AdjustingSam SungPas encore d'évaluation

- Plant Type Model LanguageDocument3 pagesPlant Type Model LanguageAlexander LopezPas encore d'évaluation

- Engine Air Intake: Service When IndicatedDocument14 pagesEngine Air Intake: Service When IndicatedLeandro Sienra100% (1)

- CONTENTS Hyundai Excavator R55 9 Service 414pagesDocument14 pagesCONTENTS Hyundai Excavator R55 9 Service 414pagesJagmohan VydjaiPas encore d'évaluation

- 980F 3HK, 8CJ, 5XJ1-587Document2 pages980F 3HK, 8CJ, 5XJ1-587Rafa GarciaPas encore d'évaluation

- d6r Priority Valve TM TestadjustDocument5 pagesd6r Priority Valve TM TestadjustwawanPas encore d'évaluation

- 381Document8 pages381Nidya Wardah JuhanaPas encore d'évaluation

- CAT C9 Oil Pan InstslationDocument4 pagesCAT C9 Oil Pan InstslationEwgenyPas encore d'évaluation

- Renr4275renr4275-03 SisDocument2 pagesRenr4275renr4275-03 SisDaniel AlfonsoPas encore d'évaluation

- E200b Sistema HidraulicoDocument149 pagesE200b Sistema HidraulicoLuis Carlos RamosPas encore d'évaluation

- Cat Emcp 4.3Document9 pagesCat Emcp 4.3錯沒Pas encore d'évaluation

- 143H and 163H Motor Grader Hydraulic System Ripper AttachmentDocument2 pages143H and 163H Motor Grader Hydraulic System Ripper AttachmentMohamed Harb100% (1)

- Troubleshooting The Hydraulic Electronic Unit InjectionDocument7 pagesTroubleshooting The Hydraulic Electronic Unit InjectionWilson Suárez100% (1)

- Caterpillar 325 SENR6239Document2 pagesCaterpillar 325 SENR6239Jaime Villalba FlorPas encore d'évaluation

- Power Train: 6Y-2303 Clutch Gp-TransmissionDocument19 pagesPower Train: 6Y-2303 Clutch Gp-TransmissionDANIEL VARGAS RODRIGUEZPas encore d'évaluation

- 12 GDocument2 pages12 GMoises Carrera AnguloPas encore d'évaluation

- 330, 330 L and 330 LN Excavators 2el00001-Up (Machine) Powered by 3306 Engine (Sebp2198 - 01) - Systems & ComponentsDocument16 pages330, 330 L and 330 LN Excavators 2el00001-Up (Machine) Powered by 3306 Engine (Sebp2198 - 01) - Systems & ComponentsRZ Emi100% (1)

- Steering System Malfunction CAT 14MDocument14 pagesSteering System Malfunction CAT 14Miwan nawiPas encore d'évaluation

- Cat 527 BDW Track Skidder Electrical SchematicDocument8 pagesCat 527 BDW Track Skidder Electrical SchematicKeron TrotzPas encore d'évaluation

- Caterpillar Cat M318C WHEELED Excavator (Prefix H2F) Service Repair Manual (H2F00001 and Up) PDFDocument27 pagesCaterpillar Cat M318C WHEELED Excavator (Prefix H2F) Service Repair Manual (H2F00001 and Up) PDFfkdmmaPas encore d'évaluation

- Crankshaft removeSMCS - 1202 - 011Document3 pagesCrankshaft removeSMCS - 1202 - 011Ama AttaPas encore d'évaluation

- Caterpillar Cat 320d2 Excavator Prefix Zcs Service Repair Manual Zcs00001 and Up 1588418836Document23 pagesCaterpillar Cat 320d2 Excavator Prefix Zcs Service Repair Manual Zcs00001 and Up 1588418836rayendra100% (2)

- 300-5617 Cooler DisassemblyDocument6 pages300-5617 Cooler Disassemblyharikrishnanpd3327Pas encore d'évaluation

- Caterpillar Cat 320D Excavator (Prefix DHK) Service Repair Manual (DHK00001 and Up)Document22 pagesCaterpillar Cat 320D Excavator (Prefix DHK) Service Repair Manual (DHK00001 and Up)kfmuseddk100% (1)

- Piston & Rod RemovalDocument5 pagesPiston & Rod RemovalsxturboPas encore d'évaluation

- TA2 English - Motor GraderDocument21 pagesTA2 English - Motor GraderRICHARDPas encore d'évaluation

- Truck Diagnostics Comparision Mack Rev PDFDocument5 pagesTruck Diagnostics Comparision Mack Rev PDFRICHARDPas encore d'évaluation

- Truck Diagnostics Comparision Mack Rev PDFDocument5 pagesTruck Diagnostics Comparision Mack Rev PDFRICHARDPas encore d'évaluation

- 330C Plano Electrico PDFDocument2 pages330C Plano Electrico PDFRICHARDPas encore d'évaluation

- Torque SpecificationDocument20 pagesTorque SpecificationSyed Mohammad Naveed100% (1)

- 216 and 226 Hydraulic System Skid Steer LoadersDocument2 pages216 and 226 Hydraulic System Skid Steer LoadersRICHARDPas encore d'évaluation

- 330D 336 PDFDocument2 pages330D 336 PDFRICHARDPas encore d'évaluation

- D5G XL & LGP TRACK TYPE TRACTORS FDH00001-UP (MACHINE) POWERED BY 3046 Engine (SEBP3363 - 41) - Documentaciónh PDFDocument3 pagesD5G XL & LGP TRACK TYPE TRACTORS FDH00001-UP (MACHINE) POWERED BY 3046 Engine (SEBP3363 - 41) - Documentaciónh PDFRICHARDPas encore d'évaluation

- Training Hydraulic Circuits PDFDocument5 pagesTraining Hydraulic Circuits PDFRICHARDPas encore d'évaluation

- 24 H Hidraulico PDFDocument2 pages24 H Hidraulico PDFRICHARDPas encore d'évaluation

- 216 Minicargador Electrico PDFDocument2 pages216 Minicargador Electrico PDFRICHARDPas encore d'évaluation

- D5G XL & LGP TRACK TYPE TRACTORS FDH00001-UP (MACHINE) POWERED BY 3046 Engine (SEBP3363 - 41) - Documentación PDFDocument3 pagesD5G XL & LGP TRACK TYPE TRACTORS FDH00001-UP (MACHINE) POWERED BY 3046 Engine (SEBP3363 - 41) - Documentación PDFRICHARDPas encore d'évaluation

- 303.5E2 CR EXCAVADORA Diagrama Hidraulico PDFDocument2 pages303.5E2 CR EXCAVADORA Diagrama Hidraulico PDFRICHARD100% (1)

- 914G Manual Del Estudiante PDFDocument89 pages914G Manual Del Estudiante PDFRICHARD67% (3)

- Luz de Valvula Motor C4.4 PDFDocument5 pagesLuz de Valvula Motor C4.4 PDFRICHARDPas encore d'évaluation

- 320 Wiht Motor 3066 PDFDocument68 pages320 Wiht Motor 3066 PDFRICHARD100% (3)

- TMO 271829752 Paccar Low Side Fuel System Pressure Testing 1 PDFDocument9 pagesTMO 271829752 Paccar Low Side Fuel System Pressure Testing 1 PDFRICHARD91% (11)

- Diagrama Electrico M312 Y M315 Interativo 3 PDFDocument10 pagesDiagrama Electrico M312 Y M315 Interativo 3 PDFRICHARD100% (1)

- 303.5E2 CR EXCAVADORA Diagrama Electrico PDFDocument2 pages303.5E2 CR EXCAVADORA Diagrama Electrico PDFRICHARD100% (2)

- 422F2 Diagrama Hidraulico PDFDocument12 pages422F2 Diagrama Hidraulico PDFRICHARDPas encore d'évaluation

- 3HAC050940 OM IRC5 Integrators Guide-En PDFDocument264 pages3HAC050940 OM IRC5 Integrators Guide-En PDFelmacuarro5Pas encore d'évaluation

- Machine Design Ball Screw Vol 1 e BookDocument22 pagesMachine Design Ball Screw Vol 1 e Bookविशाल पुडासैनीPas encore d'évaluation

- 4320 Tractor IntroductionDocument9 pages4320 Tractor Introductionodali batista0% (1)

- Theory of Machines Multiple Choice QuestionsDocument25 pagesTheory of Machines Multiple Choice QuestionsVidnyan SalunkePas encore d'évaluation

- TM-1104 AVEVA Plant (12.1) Equipment Modelling Rev 2.0 PDFDocument128 pagesTM-1104 AVEVA Plant (12.1) Equipment Modelling Rev 2.0 PDFTran Dinh VuongPas encore d'évaluation

- Coating Supply Machine PDFDocument26 pagesCoating Supply Machine PDFDeniMestiWidianto100% (1)

- Syllabus Vjti Structural EnggDocument276 pagesSyllabus Vjti Structural EnggPravin AwalkondePas encore d'évaluation

- BX-74 / BX-78: Sliding Gate Operator BX SeriesDocument24 pagesBX-74 / BX-78: Sliding Gate Operator BX SeriesStefce PetrovPas encore d'évaluation

- B - Mechanical EngineeringDocument4 pagesB - Mechanical EngineeringAnonymous dYDY4EhaPas encore d'évaluation

- BA Rainstar E11-E51 EnglDocument75 pagesBA Rainstar E11-E51 EnglBöhm úr100% (1)

- Local Inquiry Committee 2010-11 Siddhant College of Engineering, PuneDocument40 pagesLocal Inquiry Committee 2010-11 Siddhant College of Engineering, PuneChandrashekhar PatilPas encore d'évaluation

- Iti & MCVC CoursesDocument5 pagesIti & MCVC CoursesDIPAK VINAYAK SHIRBHATEPas encore d'évaluation

- Getting Started Using Adams Car MDR3Document138 pagesGetting Started Using Adams Car MDR3paulkastlePas encore d'évaluation

- Steam TurbineDocument22 pagesSteam Turbinetokwadi100% (1)

- B.Tech Final Year Project On AUTONOMOUS PARALLEL PARKING RC CARDocument11 pagesB.Tech Final Year Project On AUTONOMOUS PARALLEL PARKING RC CARMohammad Tarique Mumtaz100% (1)

- Mechanical Mechatronics Projects List PDFDocument33 pagesMechanical Mechatronics Projects List PDFDann EraPas encore d'évaluation

- Gamma 333Document3 pagesGamma 333हिमांशु बिष्टPas encore d'évaluation

- AUTOMOTIVE MECHATRONICsDocument9 pagesAUTOMOTIVE MECHATRONICsshubham golePas encore d'évaluation

- Saes B 053Document4 pagesSaes B 053malika_00Pas encore d'évaluation

- EAI Handbook of Analog Computation 1967Document396 pagesEAI Handbook of Analog Computation 1967elgauchoandresPas encore d'évaluation

- Mechatronics System Design (Lab 1)Document16 pagesMechatronics System Design (Lab 1)Ching KhangPas encore d'évaluation

- A Case Study On Various Defects Found in A Gear SystemDocument5 pagesA Case Study On Various Defects Found in A Gear SystemMouli SrikanthPas encore d'évaluation

- Bahir Dar Institute of Technology (BIT) Introduction To Robotics and AutomationDocument24 pagesBahir Dar Institute of Technology (BIT) Introduction To Robotics and AutomationBelayneh BirhanPas encore d'évaluation

- NB Series: The Machining Solution For Blisks Model Version 2018 / 2019Document24 pagesNB Series: The Machining Solution For Blisks Model Version 2018 / 2019reynabmgPas encore d'évaluation

- Elevating ScrewDocument14 pagesElevating ScrewLuhar HitenPas encore d'évaluation

- Vims 785 CDocument4 pagesVims 785 CHariWIHARSAPas encore d'évaluation

- Analyzing Taper Fits For ManufacturingDocument7 pagesAnalyzing Taper Fits For Manufacturingsalgado_24Pas encore d'évaluation

- 3054 Finding Top Center Position For No. 1 PistonDocument15 pages3054 Finding Top Center Position For No. 1 Pistonhenry lavieraPas encore d'évaluation

- Design and Fabrication of Pedal Operated Washing MachineDocument1 pageDesign and Fabrication of Pedal Operated Washing MachinesharukPas encore d'évaluation

- Anti Theft System Using I2C Inertial MEMS Sensor and ZigBee Using ControllerDocument1 pageAnti Theft System Using I2C Inertial MEMS Sensor and ZigBee Using ControllerSomu VenkatPas encore d'évaluation