Académique Documents

Professionnel Documents

Culture Documents

Elektrisola Datasheet Al

Transféré par

Carlos CaraballoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Elektrisola Datasheet Al

Transféré par

Carlos CaraballoDroits d'auteur :

Formats disponibles

Al99.

5 Aluminum Wire

Al99.5

Aluminum Wire

General Description Features

ELEKTRISOLA enameled aluminum wire is mainly Low density allows coil weight reduction

used as an electrical conductor wherever coils are Rapid heat dissipation

in motion. Because of the low density of aluminum,

the coil weight can be reduced to one third of a

similar copper coil. This weight advantage allows Applications

for easier and more efficient acceleration of the

moving part, resulting in performance increases

VCM coils for HDD actuator

such as: reduced access times of hard disk drives Voice coils (e.g. headphones)

and improved sound quality & sensitivity for High-Fidelity speakers

speakers and voice coils. For these applications, Induction heaters

self-bonding aluminum wire are mainly used. Others

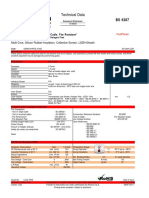

Electrical Characteristics (Note 1)

Min Typ Max

Symbol Parameter (Note 3) (Note 2) (Note 3) Units

Conductivity 36.0 S*m/mm²

Resistivity 0.0278 Ω*mm²/m

Thermal coefficient of resistance 3800 4000 4200 10E-6/K

Mechanical Characteristics (Note 1)

Min Typ Max

Symbol Parameter (Note 3) (Note 2) (Note 3) Units

T Tensile strength 120 130 150 N/mm²

Y 1% Yield strength at 1% 80 90 100 N/mm²

Elongation 5 20 35 %

BPP Bending proof performance (Note 4) 20 %

Physical Characteristics (Note 1)

Min Typ Max

Symbol Parameter (Note 3) (Note 2) (Note 3) Units

Density 2.7 kg/dm³

October 2009 1 www.elektrisola.com

Note 1: Unless otherwise specified, all limits are guaranteed for annealed and enameled wire at T A = 20°C and measured

according international standard IEC 851 as far as applicable.

AL99.5 Aluminum Wire

Note 2: Typical Values represent the most likely parametric norm.

Note 3: All limits are guaranteed by testing or statistical analysis.

Note 4: BPP tests are conducted with a 0.100mm hard drawn bare wire according ELEKTRISOLA internal specification.

The value specifies the Time To Fracture (TTF) compared to copper (100%) under these test conditions.

Typical Performance Characteristics

Tensile strength vs. elongation

(Diameter: 0.100mm)

160

Tensile strength [N/mm²]

140

120

100

80

60

40

20

0

0 5 10 15 20 25 30

Elongation [%]

BANNED SUBSTANCES COMPLIANCE

ELEKTRISOLA FEINDRAHT AG certifies that the products and packing materials meet the provision from the European

Union for the Restriction of certain Hazardous Substances (RoHS) and the directive for Waste from Electrical and

Electronic Equipment (WEEE).

ELEKTRISOLA FEINDRAHT AG Telephone +41 (0)41 487 77 00 Sister Companies: ELEKTRISOLA Dr. Gerd Schildbach, Germany

Hauptstrasse 35, PO Box 177 Fax +41 (0)41 487 78 00 ELEKTRISOLA GmbH, Italy

CH - 6182 Escholzmatt E-Mail info@elektrisola.ch ELEKTRISOLA Inc., USA

Switzerland Internet www.elektrisola.ch ELEKTRISOLA Sdn. Bhd., Malaysia

ELEKTRISOLA SA, México

ELEKTRISOLA Hangzhou, China

October 2009 2 www.elektrisola.com

Annex A

AL99.5 Aluminum Wire

Electrical Resistance

The limits of electrical resistance are calculated according to IEC standard 317-0-3 Annex C.1 “Method for the

calculation of linear resistance” for aluminum wire and for smaller diameters they are derived from IEC

standard 317-0-1 Annex C.1 for copper wire and are restricted by a factor of 2.

Nom. AWG Min Nominal Max Nom. AWG Min Nominal Max

Diameter Diameter

[mm] [Ω/m] [Ω/m] [Ω/m] [mm] [Ω/m] [Ω/m] [Ω/m]

0.0098 58 332.8 369.8 406.8 0.0420 18.18 20.13 22.09

0.0101 313.3 348.2 383.0 0.0430 17.34 19.21 21.07

0.0109 57 269.0 298.9 328.8 0.0437 16.79 18.60 20.40

0.0113 250.3 278.1 306.0 0.0440 45 16.57 18.34 20.12

0.0120 222.0 246.6 271.3 0.0450 15.84 17.54 19.24

0.0125 56 204.6 227.3 250.0 0.0460 15.16 16.78 18.41

0.0130 55.5 189.1 210.2 231.2 0.0470 44.5 14.63 16.08 17.52

0.0135 55 175.4 194.9 214.4 0.0480 14.03 15.41 16.80

0.0140 163.1 181.2 199.3 0.0490 13.46 14.79 16.12

0.0145 54.5 152.0 168.9 185.8 0.0500 44 12.93 14.21 15.48

0.0155 54 133.0 147.8 162.6 0.0520 43.5 11.95 13.13 14.32

0.0160 124.9 138.7 152.6 0.0530 11.51 12.64 13.78

0.0165 53.5 117.4 130.5 143.5 0.0550 43 10.68 11.74 12.80

0.0170 110.6 122.9 135.2 0.0560 10.31 11.33 12.34

0.0175 53 104.4 116.0 127.6 0.0580 9.607 10.56 11.51

0.0180 98.65 109.6 120.6 0.0600 42.5 9.076 9.865 10.65

0.0185 52.5 93.39 103.8 114.1 0.0620 8.500 9.239 9.978

0.0190 88.54 98.38 108.2 0.0630 42 8.232 8.948 9.664

0.0195 52 84.06 93.40 102.7 0.0650 41.5 7.606 8.406 9.330

0.0200 79.91 88.79 97.67 0.0670 7.178 7.912 8.756

0.0210 51.5 72.48 80.53 88.59 0.0680 6.977 7.681 8.489

0.0215 69.15 76.83 84.52 0.0700 41 6.600 7.248 7.990

0.0220 51 66.04 73.38 80.72 0.0710 6.423 7.045 7.756

0.0230 50.5 60.42 67.14 73.85 0.0740 5.932 6.486 7.115

0.0240 55.49 61.66 67.83 0.0750 40.5 5.781 6.314 6.919

0.0245 50 53.25 59.17 65.09 0.0780 40 5.361 5.838 6.376

0.0250 51.14 56.83 62.51 0.0800 5.106 5.549 6.049

0.0260 49.5 47.28 52.54 57.79 0.0830 39.5 4.756 5.155 5.604

0.0270 43.85 48.72 53.59 0.0850 4.542 4.916 5.334

0.0275 49 42.27 46.96 51.66 0.0880 39 4.247 4.586 4.964

0.0280 40.77 45.30 49.83 0.0900 4.067 4.385 4.739

0.0290 48.5 38.01 42.23 46.45 0.0930 38.5 3.816 4.106 4.428

0.0300 35.52 39.46 43.41 0.0950 3.662 3.935 4.237

0.0310 48 33.26 36.96 40.65 0.100 3.315 3.552 3.812

0.0320 31.22 34.68 38.15 0.101 38.0 3.252 3.482 3.734

0.0330 47.5 29.45 32.61 35.78 0.106 37.5 2.960 3.161 3.381

0.0340 27.74 30.72 33.70 0.110 2.755 2.935 3.133

0.0350 47 26.18 28.99 31.80 0.112 2.660 2.831 3.019

0.0360 24.75 27.40 30.06 0.113 37 2.614 2.781 2.964

0.0370 46.5 23.43 25.94 28.46 0.115 2.526 2.686 2.859

0.0380 22.21 24.60 26.98 0.118 36.5 2.402 2.551 2.712

0.0381 46.1 22.09 24.47 26.84 0.120 2.325 2.466 2.620

0.0390 46.0 21.09 23.35 25.62 0.125 2.147 2.273 2.410

0.0400 20.04 22.20 24.35 0.126 36 2.114 2.237 2.371

0.0410 45.5 19.08 21.13 23.18 0.130 1.988 2.102 2.224

October 2009 3 www.elektrisola.com

Annex A

AL99.5 Aluminum Wire

Electrical Resistance (Continued)

Nom. AWG Min Nominal Max Nom. AWG Min Nominal Max

Diameter Diameter

[mm] [Ω/m] [Ω/m] [Ω/m] [mm] [Ω/m] [Ω/m] [Ω/m]

0.132 1.930 2.038 2.155 0.268 29.5 0.4754 0.4945 0.5146

0.134 35.5 1.874 1.978 2.090 0.270 0.4685 0.4872 0.5069

0.138 1.769 1.865 1.968 0.280 0.4361 0.4530 0.4708

0.140 1.720 1.812 1.911 0.286 29 0.4182 0.4342 0.4510

0.141 35 1.696 1.786 1.883 0.290 0.4069 0.4223 0.4385

0.149 34.5 1.522 1.600 1.683 0.295 0.3934 0.4081 0.4235

0.150 1.503 1.578 1.660 0.300 0.3806 0.3946 0.4094

0.159 34.0 1.340 1.405 1.474 0.301 28.5 0.3781 0.3920 0.4066

0.160 1.324 1.387 1.455 0.315 0.3456 0.3579 0.3708

0.169 33.5 1.189 1.244 1.302 0.319 28 0.3371 0.3490 0.3615

0.170 1.175 1.229 1.286 0.335 0.3061 0.3165 0.3274

0.179 33 1.062 1.108 1.158 0.339 27.5 0.2990 0.3090 0.3196

0.180 1.050 1.096 1.145 0.345 0.2888 0.2984 0.3084

0.189 0.9541 0.9943 1.037 0.350 0.2807 0.2899 0.2996

0.190 32.5 0.9442 0.9838 1.026 0.355 0.2729 0.2818 0.2911

0.200 0.8535 0.8879 0.9242 0.360 27 0.2640 0.2740 0.2846

0.202 32 0.8369 0.8704 0.9057 0.375 0.2436 0.2526 0.2620

0.210 0.7753 0.8053 0.8370 0.380 26.5 0.2373 0.2460 0.2550

0.212 31.5 0.7609 0.7902 0.8211 0.383 0.2336 0.2421 0.2510

0.220 0.7073 0.7338 0.7617 0.390 0.2254 0.2335 0.2420

0.222 0.6948 0.7206 0.7478 0.400 0.2144 0.2220 0.2299

0.224 0.6826 0.7078 0.7343 0.402 26 0.2123 0.2198 0.2276

0.225 31 0.6707 0.7015 0.7343 0.420 0.1947 0.2013 0.2083

0.230 0.6423 0.6714 0.7022 0.425 0.1902 0.1966 0.2033

0.236 0.6106 0.6377 0.6664 0.427 25.5 0.1885 0.1948 0.2014

0.239 0.5956 0.6218 0.6495 0.450 0.1699 0.1754 0.1811

0.240 30.5 0.5908 0.6166 0.6440 0.453 25 0.1677 0.1731 0.1787

0.250 0.5452 0.5683 0.5927 0.475 0.1527 0.1574 0.1624

0.253 30 0.5325 0.5549 0.5785 0.481 24.5 0.1489 0.1535 0.1583

0.260 0.5047 0.5254 0.5473 0.500 0.1379 0.1421 0.1464

0.265 0.4861 0.5057 0.5265 0.508 24 0.1331 0.1376 0.1423

October 2009 4 www.elektrisola.com

Vous aimerez peut-être aussi

- Cusn6: Copper Tin Alloy General Description FeaturesDocument4 pagesCusn6: Copper Tin Alloy General Description FeaturesJesus CanelonPas encore d'évaluation

- Spec - AAAC CAIRO DARIEN OPGWDocument4 pagesSpec - AAAC CAIRO DARIEN OPGWErnesto Antonio Astorga FloresPas encore d'évaluation

- Electronics – From Theory Into Practice: Applied Electricity and Electronics DivisionD'EverandElectronics – From Theory Into Practice: Applied Electricity and Electronics DivisionÉvaluation : 5 sur 5 étoiles5/5 (1)

- Cable Video Surveillance HR6Document1 pageCable Video Surveillance HR6elbac08Pas encore d'évaluation

- 1-V23834 L6 E1etc6 011001Document9 pages1-V23834 L6 E1etc6 011001brunobrambilla90Pas encore d'évaluation

- Singleturn Potentiometers PD200/210 20.0mm 100,000 Cycles WirewoundDocument6 pagesSingleturn Potentiometers PD200/210 20.0mm 100,000 Cycles WirewoundRafael CocãoPas encore d'évaluation

- Annex A - Abc Cable SpecificationsDocument4 pagesAnnex A - Abc Cable SpecificationschimiwangmoPas encore d'évaluation

- B 910 - B 910M - 02 Qjkxmc9cotewts1sruqDocument5 pagesB 910 - B 910M - 02 Qjkxmc9cotewts1sruqJuan Sebastián Londoño MartínezPas encore d'évaluation

- Specs ZTT OPGW 24 Fibers PDFDocument9 pagesSpecs ZTT OPGW 24 Fibers PDFVictor DoyoganPas encore d'évaluation

- Phoenix Contact 3044076 enDocument6 pagesPhoenix Contact 3044076 enDGPas encore d'évaluation

- Mgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedDocument2 pagesMgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedJason Secret100% (1)

- 3-Low Voltage Aerial Bundle Cables (6001000V)Document11 pages3-Low Voltage Aerial Bundle Cables (6001000V)apranaguptaPas encore d'évaluation

- Sc. Cl. - 001 - SAR0214HFESL-F3 (IE) CDocument1 pageSc. Cl. - 001 - SAR0214HFESL-F3 (IE) CSudarshika SumathipalaPas encore d'évaluation

- Phoenix Contact 3209549 enDocument74 pagesPhoenix Contact 3209549 enEngChengLengPas encore d'évaluation

- Industrial Ethernet Switch - SCX 2POE 2LX - 1108543: Product DescriptionDocument15 pagesIndustrial Ethernet Switch - SCX 2POE 2LX - 1108543: Product DescriptionOsama BakryPas encore d'évaluation

- Networking Cables Gigaflex 2400 Cable Series Cat 6 U/Utp LSNHDocument3 pagesNetworking Cables Gigaflex 2400 Cable Series Cat 6 U/Utp LSNHZeinab Ashraf ElgammalPas encore d'évaluation

- Phoenix Contact 3209549 enDocument6 pagesPhoenix Contact 3209549 enDGPas encore d'évaluation

- Power and Control Cable IEC 60502-1: Flame Retardant, Sunlight Resistant 90 °C / U /U 0,6/1 KVDocument2 pagesPower and Control Cable IEC 60502-1: Flame Retardant, Sunlight Resistant 90 °C / U /U 0,6/1 KVShashank SaxenaPas encore d'évaluation

- Specs ZTT TACSR AW 410 PDFDocument5 pagesSpecs ZTT TACSR AW 410 PDFVictor DoyoganPas encore d'évaluation

- Type 2 Surge Protection Device - F-MS-EE-T2-40 - 2910578: Key Commercial DataDocument5 pagesType 2 Surge Protection Device - F-MS-EE-T2-40 - 2910578: Key Commercial Datavardaan industriesPas encore d'évaluation

- MV Power CablesDocument2 pagesMV Power CablesQC ĐNPas encore d'évaluation

- Instrumentation Cable: ApplicationDocument2 pagesInstrumentation Cable: Applicationbakien-canPas encore d'évaluation

- Surge Protection Device - TT-2-PE/S1-M-24DC - 2920638: Key Commercial DataDocument7 pagesSurge Protection Device - TT-2-PE/S1-M-24DC - 2920638: Key Commercial DataKurnia PratamaPas encore d'évaluation

- Loose Tube, Outdoor Aerial (Fig8) FO Cable 4-12-24 SM Tech Spec MLT Dry Core Dry Core SJDocument5 pagesLoose Tube, Outdoor Aerial (Fig8) FO Cable 4-12-24 SM Tech Spec MLT Dry Core Dry Core SJPetyo GeorgievPas encore d'évaluation

- Central Loose Tube Armoured External Cable: ComplianceDocument2 pagesCentral Loose Tube Armoured External Cable: CompliancenajiruddinshaikPas encore d'évaluation

- ZTT OPGW 18-96689-56 Hilos Con 2 Capas - Ver.CDocument9 pagesZTT OPGW 18-96689-56 Hilos Con 2 Capas - Ver.CGiancarlos OliveraPas encore d'évaluation

- ZTT Et Expressway Tacsr'Aw TW Conductor 22 - Xj10296Document5 pagesZTT Et Expressway Tacsr'Aw TW Conductor 22 - Xj10296Benjamin SalinasPas encore d'évaluation

- Copper Wire SpecificationDocument2 pagesCopper Wire SpecificationShakti SinghPas encore d'évaluation

- Nexans - EAXT ABC Cables With Messenge...Document3 pagesNexans - EAXT ABC Cables With Messenge...mazen zaloudPas encore d'évaluation

- LT Xlpe Cable: Design Code: Lvis09Cxswyl002C1.5Sa004S Document ID:TE/QMS/F/02Document2 pagesLT Xlpe Cable: Design Code: Lvis09Cxswyl002C1.5Sa004S Document ID:TE/QMS/F/02y8jkfz98m9Pas encore d'évaluation

- UTP Cat 5E Belden F CatDocument3 pagesUTP Cat 5E Belden F CatDumi NeluPas encore d'évaluation

- AL Spec. IGEN POWERTECHDocument13 pagesAL Spec. IGEN POWERTECHJatupol PongsirisartPas encore d'évaluation

- Opgw-12b1-48 (62.7 12.7)Document9 pagesOpgw-12b1-48 (62.7 12.7)Palle YulianPas encore d'évaluation

- Elbac Cable Datasheet 345901-00-GDocument1 pageElbac Cable Datasheet 345901-00-GKouakou CyrillePas encore d'évaluation

- RRU AISG Cable Assembly SpecificationDocument9 pagesRRU AISG Cable Assembly SpecificationBayu AndriantoPas encore d'évaluation

- Nexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHDocument2 pagesNexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHRijo RajanPas encore d'évaluation

- Accessory Cable GuideDocument9 pagesAccessory Cable GuideCarmelo BayonPas encore d'évaluation

- 0.9. OPGW - Technical Description of Optical FibresDocument7 pages0.9. OPGW - Technical Description of Optical Fibresgiorgis072Pas encore d'évaluation

- Printed-Circuit Board Connector - MC 1,5/ 3-ST-3,81 - 1803581Document15 pagesPrinted-Circuit Board Connector - MC 1,5/ 3-ST-3,81 - 1803581Evandro PavesiPas encore d'évaluation

- A2XS (FL) 2Y 1x 500RM - 50 110kV IEC 60840Document3 pagesA2XS (FL) 2Y 1x 500RM - 50 110kV IEC 60840Anonymous LNdiNQPas encore d'évaluation

- Fisa Tehnica Pentur Cablu Anti Incendiu JHSTH-2x2x0.8x500MDocument2 pagesFisa Tehnica Pentur Cablu Anti Incendiu JHSTH-2x2x0.8x500MSava SergiuPas encore d'évaluation

- ZTT ACS Strand 7x3.21-1Document4 pagesZTT ACS Strand 7x3.21-1tees220510Pas encore d'évaluation

- Losses in T&D PDFDocument8 pagesLosses in T&D PDF1382acePas encore d'évaluation

- RG-6 CCS Coaxial CableDocument2 pagesRG-6 CCS Coaxial CableShashank SaxenaPas encore d'évaluation

- Type 2 Surge Arrester - VAL-MS 800/30 VF/FM - 2805402: Key Commercial DataDocument10 pagesType 2 Surge Arrester - VAL-MS 800/30 VF/FM - 2805402: Key Commercial Datapriyanka236Pas encore d'évaluation

- Type CAAI 3x25+1x16+NA25 mm2Document2 pagesType CAAI 3x25+1x16+NA25 mm2Ventas Deb's ImportPas encore d'évaluation

- Phoenix Contact 3010136 enDocument7 pagesPhoenix Contact 3010136 enDGPas encore d'évaluation

- MS202 (Specifications)Document1 pageMS202 (Specifications)hanryPas encore d'évaluation

- Jumper Cable Spec 14-16 PDFDocument3 pagesJumper Cable Spec 14-16 PDFRAMESH KUMARPas encore d'évaluation

- NFC Aaac Al4 - 34.4&54.6 Ees CableDocument5 pagesNFC Aaac Al4 - 34.4&54.6 Ees CableazzouzimedPas encore d'évaluation

- Flame Retardant Instrumentation Data CablesDocument60 pagesFlame Retardant Instrumentation Data CablesSongkunhua SongPas encore d'évaluation

- Cable RS232-RJ45 Hoja de DatosDocument1 pageCable RS232-RJ45 Hoja de DatosssecaesPas encore d'évaluation

- Product Information: Data Cable, U/UTP, Category 6, AWG23Document4 pagesProduct Information: Data Cable, U/UTP, Category 6, AWG23Numan AminPas encore d'évaluation

- Abc Cable Specification: 1. DesignDocument13 pagesAbc Cable Specification: 1. Designabdulkawi alasharyPas encore d'évaluation

- PBT Opgw CableDocument7 pagesPBT Opgw CableChristian CastroPas encore d'évaluation

- ZTT Et Expressway AAAC Conductor 21-Xj00486Document4 pagesZTT Et Expressway AAAC Conductor 21-Xj00486HarisPas encore d'évaluation

- Phoenix Contact 3009163 enDocument4 pagesPhoenix Contact 3009163 enDGPas encore d'évaluation

- Specification: Easy Electric Supply LimitedDocument7 pagesSpecification: Easy Electric Supply LimitedDavid Mamani HuacaniPas encore d'évaluation

- AQA A2 Physics A Chapter 8 Textbook AnswersDocument7 pagesAQA A2 Physics A Chapter 8 Textbook Answerscathylister100% (3)

- Magnetic Field & Electromagneitc InductionDocument149 pagesMagnetic Field & Electromagneitc InductionJazib AltPas encore d'évaluation

- Design and Precise Modeling of A Novel Digital Active EMI FilterDocument6 pagesDesign and Precise Modeling of A Novel Digital Active EMI FilterPaulo UchihaPas encore d'évaluation

- 9702 s19 QP 42 PDFDocument28 pages9702 s19 QP 42 PDFSabeha KhanPas encore d'évaluation

- Don Smith Missing PostsDocument3 pagesDon Smith Missing Postsjohn b smithPas encore d'évaluation

- 66 KV and Upwards: Capacitive Voltage Transformers (CVT) For HV MeasurementsDocument3 pages66 KV and Upwards: Capacitive Voltage Transformers (CVT) For HV MeasurementsAnonymous EZZErgaM1Pas encore d'évaluation

- Technical Data: Slim Concealed Ceiling Unit Fxdq-PbveDocument18 pagesTechnical Data: Slim Concealed Ceiling Unit Fxdq-Pbvevvukmirovic_2Pas encore d'évaluation

- Catalogo Valvulas YukenDocument124 pagesCatalogo Valvulas YukenLuis Alberto RamosPas encore d'évaluation

- Signal Reverser For Railway SignalingDocument23 pagesSignal Reverser For Railway SignalingVikas Srivastav100% (1)

- Gps Project ReportDocument82 pagesGps Project Reportgsrawat123Pas encore d'évaluation

- Electrical Machine Assignment 1Document2 pagesElectrical Machine Assignment 1Proma GurPas encore d'évaluation

- Modification Sheet Yaesu FT-847: So This and All of My Modification Sheet Are For Education Purposes Only !Document28 pagesModification Sheet Yaesu FT-847: So This and All of My Modification Sheet Are For Education Purposes Only !Yudi WisenoPas encore d'évaluation

- CMOS 1.8GHz VCODocument4 pagesCMOS 1.8GHz VCOsanjeevsoni64Pas encore d'évaluation

- Smart Crop Protection System From Animals: M. Jaya Prabha, R. Ramprabha, V. Vasu Brindha, C. Asha BeaulaDocument4 pagesSmart Crop Protection System From Animals: M. Jaya Prabha, R. Ramprabha, V. Vasu Brindha, C. Asha BeaulaYash ChPas encore d'évaluation

- Physics Cet 2013Document5 pagesPhysics Cet 2013Manoj. SPas encore d'évaluation

- Surge Test WhitepaperDocument13 pagesSurge Test WhitepaperMohamedHussein MohamedHusseinPas encore d'évaluation

- User Manual EN-Varplus Can-EASYCANDocument1 pageUser Manual EN-Varplus Can-EASYCANDenny PanjaitanPas encore d'évaluation

- Theme 2: Electric and Electromagnet Learning Area: 4.0 ElectromagnetismDocument23 pagesTheme 2: Electric and Electromagnet Learning Area: 4.0 ElectromagnetismNurul FadhilahPas encore d'évaluation

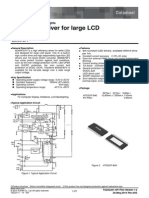

- Bd9397efv e PDFDocument30 pagesBd9397efv e PDFshafiuddin7326Pas encore d'évaluation

- IIT Physics - Magnatism Formula SheetDocument9 pagesIIT Physics - Magnatism Formula SheetParas Thakur100% (1)

- Analysis of Reactive Power Compensation by Using Capacitor BankDocument5 pagesAnalysis of Reactive Power Compensation by Using Capacitor BankThet TinPas encore d'évaluation

- Guitar Pickup TheoryDocument10 pagesGuitar Pickup Theoryhamzi_tarmizi4262100% (1)

- BetDocument16 pagesBetShivendra SangwanPas encore d'évaluation

- Lab Manual I Sem Basic ElectricalDocument48 pagesLab Manual I Sem Basic ElectricalGoutami T SunthankarPas encore d'évaluation

- TG Science 10 q2Document167 pagesTG Science 10 q2Phoebe Sudweste QuitanegPas encore d'évaluation

- CW-DSC-005 - Offshore Installation InstructionDocument32 pagesCW-DSC-005 - Offshore Installation InstructionMichel NgiangiPas encore d'évaluation

- Unit V - Blocking Oscillators and Time Base GeneratorsDocument29 pagesUnit V - Blocking Oscillators and Time Base GeneratorsNhan DinhPas encore d'évaluation

- 4 Point Starter - Working Principle and Construction of Four Point StarterDocument3 pages4 Point Starter - Working Principle and Construction of Four Point StarterMohd Rashid SiddiquiPas encore d'évaluation

- RLC CircuitsDocument15 pagesRLC CircuitsSasindran SPas encore d'évaluation

- ACJ1112Document6 pagesACJ1112Holly SmithPas encore d'évaluation