Académique Documents

Professionnel Documents

Culture Documents

Thermobreak Brochure (New) PDF

Transféré par

Franz CanonizadoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Thermobreak Brochure (New) PDF

Transféré par

Franz CanonizadoDroits d'auteur :

Formats disponibles

Thermal Insulation

Closed Cell Physically crosslinked

polyolefin foam PHYSICALLY

insulation

C R O S S L I N K E D

SEKISUI TECHNOLOGY

PHYSICALLY

C R O S S L I N K E D

SEKISUI TECHNOLOGY

SPC011_Thermobreak 8pp_concept_FA.indd 1 28/04/14 3:24 PM

Setting the Standard

Thermobreak® is the leading and most innovative polyolefin foam thermal insulation available to the HVAC and Building industry

worldwide. Thermobreak’s performance is unsurpassed.

Thermobreak® thermal insulation is an all-in-one closed cell physically crosslinked polyolefin foam that is manufactured in

compliance to ASTM C1427 Standard.

Thermobreak® was developed in Australia and has sold worldwide for over 20 years. The revolutionary insulation product has a

factory applied reinforced foil facing and adhesive backing. Thermobreak® enables much faster installation and eliminates many

errors and limitations encountered when using older insulation technology.

Thermobreak® is manufactured using our proprietary physically crosslinked polyolefin foam technology, invented and

commercialised by the Sekisui Chemical group in Japan. The technology allows crosslinking of the polyolefin without the use of

chemical agents. Instead the Sekisui process utilises clean and precise crosslinking through irradiation (physical) means.

Sekisui has been manufacturing crosslinked polyolefin foams since 1967. Today Sekisui Foam division is the largest and leading

crosslinked polyolefin foam manufacturer in the world operating 10 foam factories located in Europe, USA, Thailand, Japan, Korea,

and Australia. PHYSICALLY

C R O S S L I N K E D

SEKISUI TECHNOLOGY

Our commitment to quality and the protection of the environment is embodied by our operations all being certified to both the ISO

9001 Quality Assurance and ISO 14001 Environmental standards.

PHYSICALLY

C R O S S L I N K E D

SEKISUI TECHNOLOGY

SPC011_Thermobreak 8pp_concept_FA.indd 2 28/04/14 3:24 PM

Sidra Hospital Doha, Qatar

M&E Consultant KEO International

Marriott Hotel Abu Dhabi, UAE Sama Beirut, Lebanon

M&E Consultant Herberger Engineers M&E Consultant ERGA Group

SPC011_Thermobreak 8pp_concept_FA.indd 3 28/04/14 3:24 PM

Technically Superior

Our unique physically crosslinked technology results in a smaller and more evenly distributed cell structure. Cell structure

directly affects thermal conductivity and vapour permeability. Both are key factors in insulation performance.

AREA Thermal Conductivity: 0.032 W/mK (230C) is the lowest

(m 2) THICKNESS

(m)

of any flexible insulation material. On equivalent thickness

THERMAL

CONDUCTIVITY

RATE

basis, Thermobreak® provides up to 18% better insulation

THERMAL ENERGY

than elastomeric and chemically crosslinked foams.

(W-K-m)

(W)

TEMPERATURE1 TEMPERATURE2

(K) (K)

TEMPERATURE DIFFERENCE

△T=T1-T2

(K)

Vapour Permeability of almost zero ensures our thermal

conductivity remains relatively constant for a period of 10

years thus significantly contributing to building sustainability

and energy cost reduction.

Third Party Certification & Testing

Thermobreak® is third party certified ensuring that our stated technical specifications and test results are third party verified

through factory inspection, audit and sample preparation. All our product testing is performed with ISO 1725 Certified

laboratories ensuring testing integrity and verification.

Energy Efficiency & Building Sustainability

Building Sustainability, Energy Efficiency, Indoor Air Quality and Health & Safety, are all key

elements embodied in the Green Building concept.

Green buildings are designed to reduce the overall impact of the built environment on human

health and the natural environment through energy efficiency, protecting occupant health,

improving employee productivity, and reducing waste, pollution and environmental degradation.

Central to the green building concept is thermal insulation. Thermobreak® insulation is

manufactured to support and comply with such initiatives and enables credit point accumulation

through various building accreditation systems such as LEED and Estidama.

> Green Star Compliant (VOC) > Relatively constant thermal conductivity over a 10 year period

> No CFCs or HCFCs > Zero PVC, Zero Formaldehyde

> Zero Ozone Depletion Potential > Compliance to RoHS Directive

(Montreal Protocol) > Compliance to REACH Directive

> Low GWP > Resistance to Mould Growth

> Superior thermal insulation > Non-Allergenic Properties

SPC011_Thermobreak 8pp_concept_FA.indd 4 28/04/14 3:24 PM

Burj Residences Dubai, UAE

M&E Consultant Holfrord Associates

Palm Twin Towers Doha, QATAR Zuellig Building Manila, Philippines Lim Tower HCMC, Vietnam

M&E Consultant MZ & Partners First LEED Platinum building in the Philippines M&E Consultant CASA (HK)

M&E Consultant Meinhardt Philippines

SPC011_Thermobreak 8pp_concept_FA.indd 5 28/04/14 3:24 PM

Dubai Marriott Hotel Al Jaddaf, Dubai, UAE Royal Adelaide Hospital Adelaide, South Australia Movenpick Hotel Bangalore, India

M&E Consultant CKR Consulting Engineers M&E Consultant Lehr Consultants Intl. M&E Consultant Sankalpa Tech

Qatar Petroleum (QP) Plaza Doha, Qatar

M&E Consultant KEO International

SPC011_Thermobreak 8pp_concept_FA.indd 6 28/04/14 3:24 PM

Compliance to International Fire & Smoke Standards

Thermobreak® has been tested and complies to International Fire and Smoke Standards including

> BRITISH (BS)

> ASTM

> AUSTRALIAN (AS)

> ISO

Our testing regime includes various thicknesses in the range to ensure safety across all thickness used in projects. It is the only

polyolefin foam based sheet insulation to achieve FM Approval to FM4924, a demanding large scale room corner fire test.

Quality Materials Engineered to Last

Thermobreak® is supplied with factory applied reinforced aluminium foil facing and

repositionable acrylic tissue adhesive system. Our materials are of the highest quality.

Our aluminium foil facing is reinforced providing additional physical protection to

the insulation and at the same time reducing heat flow.

Thermobreak® is the only material that uses tissue interlayer based adhesive

system. Unlike conventional direct coated adhesives, our system ensures that the

adhesive provides 100% coverage on the duct surface and on the foam insulation.

This feature also provides the additional benefit of repositionability, an essential

requirement during installation. The insulation can be lifted off the duct numerous

times during alignment without tearing the insulation.

In keeping with current green building trends and demands such as indoor air quality,

our adhesive system is low VOC (Green Star) compliant and offers credit points for

building ratings systems such as LEED and Estidama.

Proven Reliability for Over 20 Years

With Thermobreak® installed in over 600 projects worldwide, our experience and results speak for themselves.

Tested and proven and in a variety of climatic conditions Thermobreak® has established an enviable reputation as a quality,

reliable, closed cell insulation performing flawlessly and delivering significant energy savings to building owners and operators.

Technical Support & Distribution Network

Backed by the technical expertise of Sekisui, a global multinational, our commitment and technical support to our customers

is unrivalled. Our office locations throughout Asia Pacific, India and the Middle East provide technical support to our customers

and distributors.

This includes our ThermaCalc® thickness selection software, heat flow and temperature profile analysis software, a series of

Technical Information Bulletins for M&E professionals, detailed Installation Instructions and full set of third party certificates.

Our extensive distribution network throughout ensures that materials are locally available at all times.

Complete Range for your HVAC Insulation Needs

Thermobreak® is available in a complete range to cover typical HVAC requirements:

> Thermobreak® Sheet (duct and large pipes, underslab)

> Thermobreak® Tube® (preformed tube up to 10’ IPS (273mm ID) and 50mm wall thickness

> Thermobreak® NO CLAD® - Sheet and pipe insulation for external applications and heavy duty traffic areas

> Thermobreak® Acoustic® - Fibre free acoustic liner with factory applied acrylic adhesive

SPC011_Thermobreak 8pp_concept_FA.indd 7 28/04/14 3:24 PM

Technical Specifications

Physical Properties FIRE AND SMOKE BEHAVIOUR

Material: Physically (irradiation) crosslinked closed BS476 Parts 6 & 7: CLASS 0

cell polyolefin foam with factory applied

reinforced aluminium foil and acrylic AS1530 Part 3 Ignitability Index: 0

adhesive backing Spread of Flame Index: 0

Heat Evolved Index: 0

Density: 25 kg/m3 (foam core only)

Smoke Developed Index: 0-1

Thermal Conductivity: 0.032 W/m/°K (@ 23°C mean temp.)

(ASTM C518) 0.036 W/m/°K (@ 36°C mean temp.) ASTM E84: COMPLIES (NFPA 90A & B)

Flame Spread Index: <25

Water Vapour Permeability: 8.19 x 10-15 kg/Pa.s.m Smoke Developed Index: <50

(ASTM E96) (0.029 mg.m/N.h)

ASTM C411: COMPLIES (NFPA 90A & B)

Water Vapour Permeance: 3.3 x 10-4 g/MN.s

FM 4924 Thermobreak Sheet APPROVED

Water absorption by volume: <0.1% v/v

Up to 25mm thickness

(JIS K6767) (0.00038 g/cm2)

AS 3837 BCA Group Number: 1

Permeability Resistance Factor: μ > 20,000

Smoke Index: ≤250

Resistance to fungi: Zero Growth

(ASTM G21) BS 6853 Annex B Smoke Toxicity COMPLIES (R < 1.0)

Ozone Resistance: Excellent IMO MSC 61(67) Part 2 Smoke Toxicity COMPLIES

UV Resistance: Excellent ISO 5659 Part 2 Smoke Density COMPLIES (IMO MSC 61(67) Part 2)

Dm < 200

Noise Reduction Coefficient: 0.20 (12mm foam thickness)

Satisfies max allowable

(ISO 354) 0.30 (25mm foam thickness)

concentrations for the

following combustion gases:

Operating Temperature Range: -80 °C ~ +100 °C (no adhesive)

CO, HCl, HBr, HF, HCN, NOx, SO2

GreenStar Rating: Low VOC Emitting

UL 94 Horizontal Burn APPROVED (HF-1)

(ASTM D5116)

Physical Property Requirements: COMPLIES (Type II - Sheet)

(ASTM C1427) Size Availability

REACH Directives: COMPLIES 8-mm 50m X 1200 mm rolls

(1907/2006/EC)

10-mm 20m X 1200 mm rolls

Product Certification may be plant specific. Please consult with your local representative.

12-mm 20m X 1200 mm rolls

Distributed by

© Sekisui Pilon April 2014

15-mm 20m X 1200 mm rolls

20-mm 20m X 1200 mm rolls

25~50-mm 2300mm X 1200mm sheets

Other sizes available on request.

Australian Plant Thailand Plant

1-5 Parraweena Rd, PO BOX 2898, 700/329 Moo 6, Amata Nakorn Industrial Estate,

Taren Point NSW 2229 Australia Tumbol Donhua-Ioh, Amphur Muang Chonburi 20000

Tel: +61 2 9525 9880 Tel: +66 38 213219-26

Email: info@sekisuifoam.com.au Email: info@thaisekisui.co.th

Web: www.sekisuifoam.com.au Web: www.thaisekisui.co.th

SPC011_Thermobreak 8pp_concept_FA.indd 8 28/04/14 3:24 PM

Vous aimerez peut-être aussi

- J.M. Hurst Cyclic AnalysisDocument45 pagesJ.M. Hurst Cyclic AnalysisChristian Robinson80% (10)

- Valve Body PDFDocument9 pagesValve Body PDFTimur TOT100% (2)

- CoreJava Ratan CompleteMarerial PDFDocument398 pagesCoreJava Ratan CompleteMarerial PDFSivaShankar100% (7)

- Closed Cell Physically Crosslinked Polyolefin Foam InsulationDocument8 pagesClosed Cell Physically Crosslinked Polyolefin Foam Insulationzackii90Pas encore d'évaluation

- Thermobreak Solarblock Brochure - Email - 18012021Document4 pagesThermobreak Solarblock Brochure - Email - 18012021Trương Tấn KhoaPas encore d'évaluation

- Sekisui Thermobreak LS - Brochure 090516 INTL LOW RESDocument4 pagesSekisui Thermobreak LS - Brochure 090516 INTL LOW RESTuyen NguyenPas encore d'évaluation

- Thermobreak SolarblockDocument4 pagesThermobreak SolarblockChristian Dominic Dela CruzPas encore d'évaluation

- Armaflex C1Brochure en 20190604Document6 pagesArmaflex C1Brochure en 20190604Adil AminPas encore d'évaluation

- Armaflex Product BrochureDocument6 pagesArmaflex Product Brochureraameesh100% (1)

- PeekDocument23 pagesPeekwamikshahidrizviPas encore d'évaluation

- DuPont EPD Styrofoam XPSDocument16 pagesDuPont EPD Styrofoam XPSmrigssPas encore d'évaluation

- Catalogo DOF EN14Document28 pagesCatalogo DOF EN14krilinX0Pas encore d'évaluation

- AIC Tech Praval PDFDocument21 pagesAIC Tech Praval PDFgetashishvaidPas encore d'évaluation

- GS Brochure GS TPO Roofing MembranesDocument10 pagesGS Brochure GS TPO Roofing MembranesRana MahatoPas encore d'évaluation

- Brochure Thermal Insulating CoatingDocument2 pagesBrochure Thermal Insulating CoatingVictor De AlvaPas encore d'évaluation

- UK - EU Fire Test Case Studies PAGES LRDocument32 pagesUK - EU Fire Test Case Studies PAGES LRsundarPas encore d'évaluation

- Tectyl 502CDocument2 pagesTectyl 502Cmoinu85Pas encore d'évaluation

- Closed Cell Foam Insulation in HVAC Products: White PaperDocument3 pagesClosed Cell Foam Insulation in HVAC Products: White Paperhessam_seifiPas encore d'évaluation

- Quartzene®: Recon Chemicals/Svenska AerogelDocument18 pagesQuartzene®: Recon Chemicals/Svenska AerogelrasasiPas encore d'évaluation

- GS BrochureDocument8 pagesGS BrochureVikram DhabalePas encore d'évaluation

- NBR Vs EPDM 0616Document4 pagesNBR Vs EPDM 0616ammarashraf91Pas encore d'évaluation

- Armaflex Class 0: For Safety, Efficiency & Better Indoor Air QualityDocument6 pagesArmaflex Class 0: For Safety, Efficiency & Better Indoor Air QualitySalamet TeguhPas encore d'évaluation

- 01-Mi-Dti Cut Sheet 0715Document2 pages01-Mi-Dti Cut Sheet 0715Marvin EstradaPas encore d'évaluation

- Laboratory Testing of Hydrocarbon Fire Protection Coatings and Effect of Wet EnvironmentsDocument16 pagesLaboratory Testing of Hydrocarbon Fire Protection Coatings and Effect of Wet EnvironmentsDinh Quoc HungPas encore d'évaluation

- Aquashield Cool Roof - TDSDocument2 pagesAquashield Cool Roof - TDSAnoop ShankarPas encore d'évaluation

- TK Micro Microchannel Cores - ThermoKey - 09.22 - LRDocument14 pagesTK Micro Microchannel Cores - ThermoKey - 09.22 - LRJaskaran SinghPas encore d'évaluation

- Building Insulation BulletinDocument4 pagesBuilding Insulation BulletinSarath ChukkapalliPas encore d'évaluation

- Your Guide To Coatings For Extreme ConditionsDocument17 pagesYour Guide To Coatings For Extreme Conditionsحسن عبدالهادي الصلويPas encore d'évaluation

- SilcoTek Coating Overview Brochure WebDocument6 pagesSilcoTek Coating Overview Brochure WebIker MelladoPas encore d'évaluation

- Durkgel ASC - CR (INT) - 2Document3 pagesDurkgel ASC - CR (INT) - 2Mukiara LuffyPas encore d'évaluation

- Xtratherm High Performance Instulation BoardsDocument36 pagesXtratherm High Performance Instulation BoardsCal MoranPas encore d'évaluation

- THERMOTEC AUST Thermal Pipe 4 Zero A4 4pp PDFDocument4 pagesTHERMOTEC AUST Thermal Pipe 4 Zero A4 4pp PDFGeorge_Wabag_2014Pas encore d'évaluation

- Technical Data Sheet Circuitworks Heat Sink Grease: ChemtronicsDocument3 pagesTechnical Data Sheet Circuitworks Heat Sink Grease: ChemtronicsANDRES Q APas encore d'évaluation

- Physically Crosslinked Closed Cell Polyolefin Foam Insulation For DuctsDocument8 pagesPhysically Crosslinked Closed Cell Polyolefin Foam Insulation For DuctsĐặng Văn SiêuPas encore d'évaluation

- Leaflet Ekoprodurpm2233j enDocument12 pagesLeaflet Ekoprodurpm2233j enThao NguyenPas encore d'évaluation

- Calcium Silicate Insulation BrochureDocument52 pagesCalcium Silicate Insulation BrochuremukeshsinghtomarPas encore d'évaluation

- EcoTherm Structural Insulation Quick Guide Aug 2015Document40 pagesEcoTherm Structural Insulation Quick Guide Aug 2015harshstoryPas encore d'évaluation

- Energies 14 03310 v2Document17 pagesEnergies 14 03310 v2RE ACPas encore d'évaluation

- TEC-042226 - MET-DoR-001c-Corrotech Corroprufe DPC PDFDocument2 pagesTEC-042226 - MET-DoR-001c-Corrotech Corroprufe DPC PDFvelmurug_balaPas encore d'évaluation

- Protecting Plant Piping From CUI With Water RepellencyDocument2 pagesProtecting Plant Piping From CUI With Water RepellencySergey KichenkoPas encore d'évaluation

- Brochure of Koster TpoDocument16 pagesBrochure of Koster TpoChoey ShadowWalkerPas encore d'évaluation

- Industrial Fire ProofingDocument20 pagesIndustrial Fire Proofingkenoly123100% (3)

- Company Profile FMCGDocument13 pagesCompany Profile FMCGManish SharmaPas encore d'évaluation

- Temperature Resistant Coatings BrochureDocument5 pagesTemperature Resistant Coatings Brochureanon_68738065Pas encore d'évaluation

- Renewable and Sustainable Energy ReviewsDocument22 pagesRenewable and Sustainable Energy ReviewsALAKOUKOPas encore d'évaluation

- Coxwell Vs TraditionalDocument2 pagesCoxwell Vs TraditionalHarsh SharmaPas encore d'évaluation

- Thermochromic Smart Window Technologies For Building Application: A ReviewDocument21 pagesThermochromic Smart Window Technologies For Building Application: A ReviewWilliam MelloPas encore d'évaluation

- CFS Purenit BrochureDocument7 pagesCFS Purenit BrochuredrajkumarcePas encore d'évaluation

- BLDG Insl and EticsDocument124 pagesBLDG Insl and Eticssathish.kPas encore d'évaluation

- DOWSIL™ 340 Heat Sink Compound: Features & Benefits ApplicationsDocument2 pagesDOWSIL™ 340 Heat Sink Compound: Features & Benefits ApplicationsMauricio Fernandez GuevaraPas encore d'évaluation

- Urban Transformers Safety and Environmental ChallengesDocument8 pagesUrban Transformers Safety and Environmental ChallengesNicodemus Ervino MandalaPas encore d'évaluation

- Elcat Thermal GBDocument20 pagesElcat Thermal GBAlexandrePas encore d'évaluation

- Foam Book: All About Spray Polyurethane FoamDocument36 pagesFoam Book: All About Spray Polyurethane FoamKieran MuelanerPas encore d'évaluation

- Armaflex Class 1: Engineered To Prevent CondensationDocument6 pagesArmaflex Class 1: Engineered To Prevent CondensationTeoxPas encore d'évaluation

- Dow Corning Electronics FT Sc102Document2 pagesDow Corning Electronics FT Sc102Bijyendra KumarPas encore d'évaluation

- Thermal Aging Tests On XLPE and PVC Cable Insulation Materials of Saudi ArabiaDocument6 pagesThermal Aging Tests On XLPE and PVC Cable Insulation Materials of Saudi ArabiaWil LyPas encore d'évaluation

- Introduction To Fr-Acp (Fire Retardant Aluminum Composite Panels)Document12 pagesIntroduction To Fr-Acp (Fire Retardant Aluminum Composite Panels)Syed RaziuddinPas encore d'évaluation

- Kooltherm K5 External Wall BoardDocument6 pagesKooltherm K5 External Wall BoardShanePas encore d'évaluation

- Aircrete Blocks Technical ManualDocument95 pagesAircrete Blocks Technical Manualpseudosil100% (3)

- Ecoply Barrier - Spec Install Guide - WebsiteCurrentDocument36 pagesEcoply Barrier - Spec Install Guide - WebsiteCurrent郭骥Pas encore d'évaluation

- A Complete Range of Pipework and Ductwork Insulation 1301Document16 pagesA Complete Range of Pipework and Ductwork Insulation 1301umerPas encore d'évaluation

- Ternary Eutectic Chloride BaseDocument2 pagesTernary Eutectic Chloride BaseB.r. SharmaPas encore d'évaluation

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965D'EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Pas encore d'évaluation

- Waqas Riaz: Total Years of Experience: 2 Years ObjectiveDocument2 pagesWaqas Riaz: Total Years of Experience: 2 Years ObjectiveIrfanPas encore d'évaluation

- Steel Top Hats Battens Capacitytables Product Technical ManualDocument16 pagesSteel Top Hats Battens Capacitytables Product Technical ManualbhukthaPas encore d'évaluation

- Esquema Elétrico NGD 9.3Document2 pagesEsquema Elétrico NGD 9.3LuisCarlosKovalchuk100% (1)

- SF6 Novec 4710Document4 pagesSF6 Novec 4710Fidya Eka PrahestiPas encore d'évaluation

- Shifting Meterials: Ground Floor ReceptionDocument3 pagesShifting Meterials: Ground Floor Receptionvishwas pandithPas encore d'évaluation

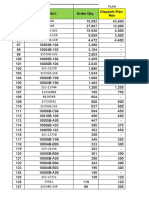

- Order Qty Vs Dispatch Plan - 04 11 20Document13 pagesOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPPas encore d'évaluation

- ITP InstrumentationDocument9 pagesITP InstrumentationzhangyiliPas encore d'évaluation

- Braun KF40 - CDocument17 pagesBraun KF40 - CAgung UtoyoPas encore d'évaluation

- Product Management Self-Learning ManualDocument261 pagesProduct Management Self-Learning ManualAbhishek Arekar100% (1)

- Restoration and Adaptive Re-Use of Queen Mary's High School: Phase-1Document4 pagesRestoration and Adaptive Re-Use of Queen Mary's High School: Phase-1Sonali GurungPas encore d'évaluation

- Material Safety Data Sheet: Roduct Ompany DentificationDocument6 pagesMaterial Safety Data Sheet: Roduct Ompany DentificationArgade GVPas encore d'évaluation

- ITIL Quick ReferenceDocument3 pagesITIL Quick ReferenceKalyaan KrushnaPas encore d'évaluation

- Calibration. of Storage Tanks Class # 2070 Srini Sivaraman SK JapanDocument4 pagesCalibration. of Storage Tanks Class # 2070 Srini Sivaraman SK JapanJose Rafael Mora CasalPas encore d'évaluation

- Woodworking Plans - Wheelbarrow PlanterDocument3 pagesWoodworking Plans - Wheelbarrow PlanterMirel HotescuPas encore d'évaluation

- 007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCDocument43 pages007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCpietoePas encore d'évaluation

- D6489 PDFDocument3 pagesD6489 PDFKalindaMadusankaDasanayakaPas encore d'évaluation

- Report On Automatic Phase Changer: Submitted ByDocument32 pagesReport On Automatic Phase Changer: Submitted ByAndrea JohnsonPas encore d'évaluation

- Makita 2708Document29 pagesMakita 2708Reuel JacintoPas encore d'évaluation

- Siemens Engineering Manual V7Document338 pagesSiemens Engineering Manual V7Jeremy Branch100% (2)

- CH 4 Data CommDocument4 pagesCH 4 Data CommHenna ShainaPas encore d'évaluation

- Concept of Circulation in A Free Vortex FlowDocument55 pagesConcept of Circulation in A Free Vortex FlowAnil KumarPas encore d'évaluation

- Car DeerDocument2 pagesCar DeerNEGameandParksPas encore d'évaluation

- EM230 BR BM3 Fitting InstructionsDocument2 pagesEM230 BR BM3 Fitting InstructionsRoman BabaevPas encore d'évaluation

- ElectronicsDocument3 pagesElectronicsashishkumar218Pas encore d'évaluation

- 1.1 General: "Processes and Environmental Management" at SUEZ LTD, BWSSB, TK HalliDocument29 pages1.1 General: "Processes and Environmental Management" at SUEZ LTD, BWSSB, TK HalliYogeesh B EPas encore d'évaluation

- Topic 6 ESD & EMI Considerations Electrostatic Sensitive Devices (M4.2, 5.12 &5.14) - 1Document49 pagesTopic 6 ESD & EMI Considerations Electrostatic Sensitive Devices (M4.2, 5.12 &5.14) - 1BeaglelalahahaPas encore d'évaluation

- Cosben e Brochure PDFDocument28 pagesCosben e Brochure PDFsmw maintancePas encore d'évaluation