Académique Documents

Professionnel Documents

Culture Documents

EXP No 01

Transféré par

Engr Latif Ahmad0 évaluation0% ont trouvé ce document utile (0 vote)

12 vues2 pagesUnconfined Compressive Strength of Cohesive Soil Sample.

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentUnconfined Compressive Strength of Cohesive Soil Sample.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

12 vues2 pagesEXP No 01

Transféré par

Engr Latif AhmadUnconfined Compressive Strength of Cohesive Soil Sample.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

Sarhad University of Science & Technology, Peshawar.

Exp#02: Unconfined Compressive Strength of Cohesive Soil Sample.

AIM:

The unconfined compression test is used to find out unconsolidated untrained shear strength of

cohesive soils. The unconfined compressive strength is the maximum load attained per unit area

or the load at 15% axial strain, whichever occurs first on a cylindrical sample tested in

compression. Shear strength is taken as equal to 1/2 the unconfined compressive strength. In

practice the test specimens are usually obtained by extruding thin-wall tube samples.

The length to diameter ratio of the specimen should be between 2 and 2.5.

APPARATUS:

Compression testing machine with digital screen to obtain measured deformations & loads

Vernier caliper or scale for measuring lengths, mold, spatula, soil sample, and moisture can

PROCEDURE:

Extrude the soil sample from Shelby tube sampler. Cut a soil specimen so that the

ratio (L/d) is approximately between 2 and 2.5. Where L and d are the length and

diameter of soil specimen, respectively.

Measure the exact diameter of the top of the specimen at three locations 120o

apart, and then make the same measurements on the bottom of the specimen.

Average the measurements and record the average as the diameter on the data

sheet.

Measure the exact length of the specimen at three locations 120o apart, and then

average the measurements and record the average as the length on the data sheet.

Calculate the deformation (∆L) corresponding to 15% strain. Strain (e) =∆L/L0,

Where L0 = Original specimen length.

Carefully place the specimen in the compression device and center it on the

bottom plate. Adjust the device so that the upper plate just makes contact with the

specimen and set the load and deformation dials to zero.

Apply the load so that the device produces an axial strain at a rate of 0.5% to 2.0%

per minute, and then record the load and deformation readings on the data sheet.

Keep applying the load until (1) the load (load dial) decreases on the specimen

significantly, (2) the load holds constant for at least four deformation dial

readings, or (3) the deformation is significantly past the 15% strain.

Remove the sample from the compression device and obtain a sample for water

content determination. Determine the water content as per first experiment.

CALCULATIONS & REPORTS:

Calculate axial strain for each value of deformation, where Strain= ∆L/Lo

Unconfined compressive strength=qu=P/A(KPa), where P(KN) is applied max load and

A(m2) is x-sec area of specimen.

Shear strength=τ=qu/2.

Civil Engineering Department, SUIT. Email: engrhanif6@gmail.com

Sarhad University of Science & Technology, Peshawar.

S.No Deformation(mm) Load(KN) Lo Lf Strain Area(m2) qu

1

2

3

4

5

6

So on…

Plot above values using Microsoft office Excel.

Civil Engineering Department, SUIT. Email: engrhanif6@gmail.com

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Concrete Code Check Theory EnuDocument117 pagesConcrete Code Check Theory EnuNaida AdemovicPas encore d'évaluation

- Module 2 - Analysis of Reinforced Concrete SectionDocument20 pagesModule 2 - Analysis of Reinforced Concrete SectionWelfedPas encore d'évaluation

- @æ B È A @æ B È A @æ B È A @æ B È A: Ductile Materials PDocument30 pages@æ B È A @æ B È A @æ B È A @æ B È A: Ductile Materials Pabdarhman 40Pas encore d'évaluation

- Kanazawa, Miller, Brown - Cyclic Deformation of 1% Cr-Mo-V Steel Under Out-Of-Phase LoadsDocument12 pagesKanazawa, Miller, Brown - Cyclic Deformation of 1% Cr-Mo-V Steel Under Out-Of-Phase LoadsDavid C HouserPas encore d'évaluation

- Analysis of Automotive Safety Issues Related To Depowering of Airbags Using Finite Elements and Lumped Mass ModelsDocument155 pagesAnalysis of Automotive Safety Issues Related To Depowering of Airbags Using Finite Elements and Lumped Mass ModelsNing LettucePas encore d'évaluation

- Tutorials Piezo Basics PDFDocument19 pagesTutorials Piezo Basics PDFsiddharthPas encore d'évaluation

- Mohr Coulomb ModelDocument19 pagesMohr Coulomb ModelhsetiyajiPas encore d'évaluation

- Ebook t357 Block1 Part3-4 E2i1 n9780749252670 l1Document96 pagesEbook t357 Block1 Part3-4 E2i1 n9780749252670 l1Bobby extramoneyguyPas encore d'évaluation

- Fourbolts - End PlateDocument11 pagesFourbolts - End PlatevtalexPas encore d'évaluation

- 004 LEER Over Reinforced Concrete Beam DesignDocument8 pages004 LEER Over Reinforced Concrete Beam DesignJimmy Villca Sainz100% (1)

- Epoxy Adhesion GuideDocument48 pagesEpoxy Adhesion Guidenoel80042100% (2)

- 2014, Nowel K, Robust Estimation of Deformation From Observation Differences For Free Control NetworkDocument16 pages2014, Nowel K, Robust Estimation of Deformation From Observation Differences For Free Control NetworkK NPas encore d'évaluation

- Morphological Evolution of MartensiteDocument17 pagesMorphological Evolution of MartensiteadarshPas encore d'évaluation

- Finger Print RecognitionDocument56 pagesFinger Print RecognitionOmar MahmoodPas encore d'évaluation

- Design of Beams - PPT SONAMDocument111 pagesDesign of Beams - PPT SONAMLovely Mae Cruza GawinganPas encore d'évaluation

- Full Text 02Document125 pagesFull Text 02Didik JunaidiPas encore d'évaluation

- PVP2012-78020 Comparison of Strain Rate Calculation Methods For ENV FatigueDocument6 pagesPVP2012-78020 Comparison of Strain Rate Calculation Methods For ENV FatigueOtso CronvallPas encore d'évaluation

- Test Bending RebarDocument4 pagesTest Bending Rebaraminiskandar50% (2)

- ColumDocument2 pagesColumSherlock HolmesPas encore d'évaluation

- Role of Infill WallDocument16 pagesRole of Infill WallGaurav MallaPas encore d'évaluation

- Fundamentals of Fatigue and Fracture Mechanics: RVC EDocument69 pagesFundamentals of Fatigue and Fracture Mechanics: RVC ESaima naazPas encore d'évaluation

- PDFDocument276 pagesPDFRosemberg Reyes RamírezPas encore d'évaluation

- 1111-110010-Mech - of SolidsDocument4 pages1111-110010-Mech - of SolidsjaydeepPas encore d'évaluation

- Burger Thesis SFRCDocument133 pagesBurger Thesis SFRCMihai Gheorghiu100% (1)

- Plastic Analysis 1Document31 pagesPlastic Analysis 1Varun ShastryPas encore d'évaluation

- Offshore Pipe Riser PDFDocument8 pagesOffshore Pipe Riser PDFdndudcPas encore d'évaluation

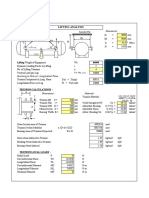

- Lifting Trunnion Calculations On Horizontal Vessel - 1Document1 pageLifting Trunnion Calculations On Horizontal Vessel - 1miteshpatel191Pas encore d'évaluation

- Thin-Walled Structures: Jovan Trajkovski, Jasenko Perenda, Robert Kunc TDocument7 pagesThin-Walled Structures: Jovan Trajkovski, Jasenko Perenda, Robert Kunc TMohamed AminePas encore d'évaluation

- Electrical Resistivity Variation in Uniaxial Rock CompressionDocument12 pagesElectrical Resistivity Variation in Uniaxial Rock CompressionTauseefPas encore d'évaluation

- Question Bank Strength of MaterialDocument19 pagesQuestion Bank Strength of MaterialSanjay TiwariPas encore d'évaluation