Académique Documents

Professionnel Documents

Culture Documents

Aditya High Vacuum PVT LTD: POSITIONS (QW-405) GAS (QW-408)

Transféré par

Anand MakasanaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Aditya High Vacuum PVT LTD: POSITIONS (QW-405) GAS (QW-408)

Transféré par

Anand MakasanaDroits d'auteur :

Formats disponibles

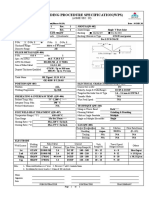

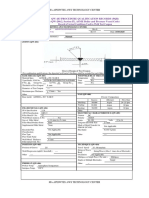

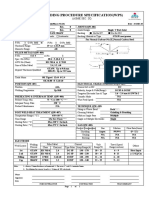

WPS No. WPS/PPIPL/GTAW/ASTMA240/0I Rev.

0

POSITIONS (QW-405) GAS (QW-408)

Position(s) of groove I All % Composition (Mixture)

Welding Progression j Vertical Up for 3G Gas(cs) [Flow Rate (Ipm)

Position(s) of Fillet I All Shielding Argon 99.995 | 5 - 1 2

PREHEAT (QW-406) Trailing Nil N. A. | N. A.

Preheat Temp.,min N.A

Interpass Temp.,max Nil Backing Argon 99.995 1 0 - 1 5 .

POSTWELD HEAT IRE AIM ENI (QW-407) ELECTRICAL CHARACTERISTICS (QW-409)

Current AC or DC DC Polarity : EN

Temp. Range Nil Amps (Range) As Below Volts (Range) As Below

Soaking Time Nil Tungsten Electrode Type & Size SFA 5 12 EWTh-2; tb2.4mm

Mode of Metal Transfer for GM AW N. A.

Electrode Wire Feed Speed & Range N. A.

TECHNIQUE (QW-410)

Siring or Weave Bead String & or Weave Multiple or Single Pass (per Single Multiple

Orifice/Gas Cup Size 10mm side)

Initial Cleaning Degreasing Multiple or Single Single

Interpass Cleaning Wire brushing & Grinding Electrodes

N. A. Travel Speed (Range) As below

Method of Back Gouging Pccning Nil

Contact Tube to Work N. A. Oscillation Nil

Distance Other -

Weld Filler Metal Current

Polarity Volt Range, V Travel Speed, Remarks

Layer(s) Process Class Diameter Amp, A mm/min.

1 GTAW ER308L 1.6mm DCEN 60-120

REST AS REQUIRED

We. the undersigned, certify that the WPS has been prepared, taking guidance from the requirements of section IX of the ASME Code- 2007,

Base Material used being ASTM A 240 TP 304L, the P No. has been taken on the basis of equivalence to SA 240 TP 304L for testing purposes

only.

Aditya High Vacuum Pvt Ltd

Anand Makasana

DATE: 01.03.2019

Vous aimerez peut-être aussi

- Method Statement For Lifting WorksDocument12 pagesMethod Statement For Lifting WorksRachel Flores85% (26)

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- WPS 6G CS Pipe CorrectDocument4 pagesWPS 6G CS Pipe CorrectAla ReguiiPas encore d'évaluation

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniPas encore d'évaluation

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajPas encore d'évaluation

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedPas encore d'évaluation

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- WPS and PQRDocument4 pagesWPS and PQRdandiar1Pas encore d'évaluation

- WPS-ASME-009-1 Rev1Document1 pageWPS-ASME-009-1 Rev1Ahmed LepdaPas encore d'évaluation

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinPas encore d'évaluation

- Smaw PQR FinalDocument3 pagesSmaw PQR Finalsheikmoin100% (1)

- WPS1Document10 pagesWPS1bhavin178Pas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Textbook of Dental Anatomy, Physiology and Occlusion, 1E (2014) (PDF) (UnitedVRG)Document382 pagesTextbook of Dental Anatomy, Physiology and Occlusion, 1E (2014) (PDF) (UnitedVRG)Konstantinos Ster90% (20)

- WPS-ASME-007-1 Rev0Document1 pageWPS-ASME-007-1 Rev0Ahmed LepdaPas encore d'évaluation

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamPas encore d'évaluation

- Wps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationDocument5 pagesWps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationAmit ChapagainPas encore d'évaluation

- Qw-483 Suggested Format For Welding Procedure Qualification Records (PQR)Document4 pagesQw-483 Suggested Format For Welding Procedure Qualification Records (PQR)aliPas encore d'évaluation

- Tips Wps FormatDocument5 pagesTips Wps FormatWaqas WaqasPas encore d'évaluation

- WPS GTAW-SMAW h2Document1 pageWPS GTAW-SMAW h2Jesus Gabrielw Blanco GhostbustersIzPas encore d'évaluation

- WPS CuNiDocument4 pagesWPS CuNiSripathyPas encore d'évaluation

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaPas encore d'évaluation

- PQRDocument2 pagesPQRafqzfiePas encore d'évaluation

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaPas encore d'évaluation

- WPS-ASME SEC IX-for PSODocument3 pagesWPS-ASME SEC IX-for PSOSultan ZebPas encore d'évaluation

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoPas encore d'évaluation

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyPas encore d'évaluation

- WPS-CS-113 Rev.1Document2 pagesWPS-CS-113 Rev.1Muhammad BilalPas encore d'évaluation

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberPas encore d'évaluation

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranPas encore d'évaluation

- WPS Gtaw+smawDocument2 pagesWPS Gtaw+smawAnand GPas encore d'évaluation

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Emmanuel Loayza100% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriPas encore d'évaluation

- WPS BhelDocument2 pagesWPS BhelpradhankruhsnaPas encore d'évaluation

- Pre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectDocument2 pagesPre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectBagandi ManurungPas encore d'évaluation

- Qw-482 Welding Procedure Specification (WPS)Document3 pagesQw-482 Welding Procedure Specification (WPS)Sagar GourPas encore d'évaluation

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- WPS 03 2014Document2 pagesWPS 03 2014vinuPas encore d'évaluation

- Wps PQR Welder Qualification Certification ConsultancyDocument2 pagesWps PQR Welder Qualification Certification ConsultancyEmam SayedPas encore d'évaluation

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- Welding Procedure Specification (W.P.S) : Alstom India LimitedDocument2 pagesWelding Procedure Specification (W.P.S) : Alstom India LimitedAhmed saberPas encore d'évaluation

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelPas encore d'évaluation

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191Pas encore d'évaluation

- Arl-Al - WPS-001 PDFDocument2 pagesArl-Al - WPS-001 PDFrajuajiPas encore d'évaluation

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148Pas encore d'évaluation

- WPS PDFDocument5 pagesWPS PDFHakanPas encore d'évaluation

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesPas encore d'évaluation

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertPas encore d'évaluation

- PWPS 001Document2 pagesPWPS 001Mehrdad RezaeiPas encore d'évaluation

- WC9Document5 pagesWC9Suresh KrishnanPas encore d'évaluation

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYPas encore d'évaluation

- Transducer Handbook: User's Directory of Electrical TransducersD'EverandTransducer Handbook: User's Directory of Electrical TransducersPas encore d'évaluation

- Instrumentation and Test Gear Circuits ManualD'EverandInstrumentation and Test Gear Circuits ManualÉvaluation : 5 sur 5 étoiles5/5 (1)

- Cataloge ICARDocument66 pagesCataloge ICARAgoess Oetomo100% (1)

- Shoulder Joint Position Sense Improves With ElevationDocument10 pagesShoulder Joint Position Sense Improves With ElevationpredragbozicPas encore d'évaluation

- Bi RadsDocument10 pagesBi RadsFeiky Herfandi100% (1)

- S108T02 Series S208T02 Series: I (RMS) 8A, Zero Cross Type Low Profile SIP 4pin Triac Output SSRDocument13 pagesS108T02 Series S208T02 Series: I (RMS) 8A, Zero Cross Type Low Profile SIP 4pin Triac Output SSRnetiksPas encore d'évaluation

- Ethics, Privacy, and Security: Lesson 14Document16 pagesEthics, Privacy, and Security: Lesson 14Jennifer Ledesma-Pido100% (1)

- Ancamine Teta UsDocument2 pagesAncamine Teta UssimphiwePas encore d'évaluation

- Injection Analyzer Electronic Unit enDocument67 pagesInjection Analyzer Electronic Unit enmayralizbethbustosPas encore d'évaluation

- Sithpat006ccc019 A - 2021.1Document34 pagesSithpat006ccc019 A - 2021.1Mark Andrew Clarete100% (2)

- Chemrite SP 200Document3 pagesChemrite SP 200ghazanfarPas encore d'évaluation

- EBANX Beyond Borders 2020Document71 pagesEBANX Beyond Borders 2020Fernanda MelloPas encore d'évaluation

- AACO 7th Aviation Fuel Forum: AttendanceDocument3 pagesAACO 7th Aviation Fuel Forum: AttendanceJigisha Vasa0% (1)

- InotroposDocument4 pagesInotroposjuan camiloPas encore d'évaluation

- Intraocular Pressure and Aqueous Humor DynamicsDocument36 pagesIntraocular Pressure and Aqueous Humor DynamicsIntan EkarulitaPas encore d'évaluation

- Celitron ISS 25L - Product Spec Sheet V 2.1 enDocument9 pagesCelitron ISS 25L - Product Spec Sheet V 2.1 enyogadwiprasetyo8_161Pas encore d'évaluation

- 1.8 SAK Conservations of Biodiversity EX-SITU in SITUDocument7 pages1.8 SAK Conservations of Biodiversity EX-SITU in SITUSandipPas encore d'évaluation

- 1979 The Cult Phenomenon in The United States - DR John Gordon ClarkDocument8 pages1979 The Cult Phenomenon in The United States - DR John Gordon ClarkFrederick BismarkPas encore d'évaluation

- 2 - Pizeo Electric SensorDocument33 pages2 - Pizeo Electric SensorNesamaniPas encore d'évaluation

- Osh e MeerDocument3 pagesOsh e MeerfatduckPas encore d'évaluation

- OM Mannual FOsDocument38 pagesOM Mannual FOsAbdulmuqtadetr AhmadiPas encore d'évaluation

- 15 UrinalysisDocument9 pages15 UrinalysisJaney Ceniza تPas encore d'évaluation

- Soft Tissue SarcomaDocument19 pagesSoft Tissue SarcomaEkvanDanangPas encore d'évaluation

- Uppercut MagazineDocument12 pagesUppercut MagazineChris Finn100% (1)

- Course Weekly Schedule Health Science TheoryDocument6 pagesCourse Weekly Schedule Health Science Theoryapi-466810096Pas encore d'évaluation

- GeoSS Event Seminar 12 July 2012 - SlidesDocument15 pagesGeoSS Event Seminar 12 July 2012 - SlidesNurmanda RamadhaniPas encore d'évaluation

- 224 Chinese Healing ExercisesDocument4 pages224 Chinese Healing ExercisesKiné Therapeut-manuelle Masseur GabiPas encore d'évaluation

- Upper Limb OrthosesDocument29 pagesUpper Limb OrthosesMaryam KhalidPas encore d'évaluation

- Low Voltage Fixed and Automatic Power Factor Correction SystemsDocument6 pagesLow Voltage Fixed and Automatic Power Factor Correction Systemszabiruddin786Pas encore d'évaluation

- Dif Stan 3-11-3Document31 pagesDif Stan 3-11-3Tariq RamzanPas encore d'évaluation